If there’s one tool that every woodworker and DIY enthusiast should have in their toolbox, it’s a high-quality grit grinding wheel. A grit grinding wheel is a crucial tool for sharpening chisels, as well as other cutting tools. However, with so many options available, it can be difficult to know which one to choose.

Thankfully, we’ve done the research for you and have found the best grit grinding wheel for sharpening chisels. This wheel is made from high-quality materials and has excellent durability. It’s also designed to provide the perfect amount of grit for sharpening chisels, ensuring that they stay sharp for longer.

Whether you’re a professional woodworker or simply enjoy DIY projects at home, a grit grinding wheel is a must-have tool. With the right wheel, you can sharpen your chisels and other cutting tools quickly and easily, ensuring that you always have a sharp edge when you need it most. So why wait? Invest in the best grit grinding wheel for sharpening chisels today, and take your woodworking and DIY projects to the next level!

Understanding Grit

Sharpening chisels requires the right grit grinding wheel to achieve the desired level of sharpness. The grit rating refers to the coarseness of the wheel and can range from coarse to fine. Generally, for sharpening chisels, experts suggest using a 3000 to 4000 grit wheel.

Coarser wheels can remove too much material and damage the chisel whereas finer wheels may not be able to reshape the edge. It’s essential to select the right grit for the job as it impacts the quality of the sharpened edge and the amount of time it takes to achieve it. A higher grit wheel results in a smoother and sharper edge, but it requires more patience and skill for the sharpening process.

Ultimately, it comes down to the level of precision required from the chisel and the tools and skillset available to the person sharpening it.

What is Grit?

Grit is a term used to describe the resilience and perseverance that individuals exhibit in the face of adversity. It’s the ability to keep going despite obstacles, setbacks, and failures. The concept of grit has gained popularity in recent years as psychologists and educators have recognized its importance in achieving success.

Some people are born with grit, while others can develop it through practice and experience. Developing grit requires a mindset shift towards embracing challenges and seeing failures as learning opportunities. It also involves developing a sense of purpose and passion, as well as a strong work ethic.

Grit can be applied in various contexts, from academics to sports to business. It’s a valuable trait to have, as it allows individuals to push through difficult times and come out stronger on the other side.

Different Grit Sizes and Their Uses

Grit is a term used to refer to the coarseness of sandpaper or other abrasive materials. It is the measure of how many abrasive particles are in a specific area of the material. The grit size determines how the material will perform when working on a surface.

The larger the grit size, the more abrasive it will be. A smaller grit size, on the other hand, will produce a smoother finish but take longer to work on the surface. The general rule of thumb is to start with a coarse grit size and progress to a finer one as the work progresses.

For instance, if you are sanding a rough surface, you should start with 40 to 60 grit sandpaper and move to a finer grit size, say 100 or 120 grit, as you go along, until you achieve the desired smoothness. So, understanding the grit size is crucial to ensure you use the right sandpaper for the job and get the desired results.

Choosing the Right Grit Size for Chisel Sharpening

When it comes to sharpening chisels, choosing the right grit size for your grinding wheel can make all the difference. So what grit grinding wheel should you use? Well, it all depends on the condition of your chisel and the level of sharpening you’re looking to achieve. If your chisel is in good condition and just needs a touch-up, a coarse grit wheel (such as a 60 grit) will be sufficient.

However, if your chisel is in rough shape and requires heavy regrinding, a finer grit wheel (such as a 220 grit) will work better. It’s important to note that a finer grit wheel will take longer to remove material, but it will also leave a smoother, more polished edge. Ultimately, the key is to find the right balance between speed and accuracy, depending on the condition of your chisel and the intended use.

So when deciding on a grit size for chisel sharpening, consider the level of sharpening required, and choose a grit size that will help you achieve the desired outcome.

Grit Size for Coarse Sharpening

When it comes to chisel sharpening, it’s important to choose the right grit size for the job. For coarse sharpening, a lower grit size such as 100 or 200 grit is recommended. This will quickly remove any nicks or chips on the chisel’s edge and create a rough surface to work with.

While a coarse grit size may sound harsh, it’s necessary to properly shape and repair the chisel’s edge before moving on to finer grits. Think of it like sanding a rough piece of wood before smoothing it out with finer grits. It may seem counterintuitive, but starting with a rough grit size actually makes the process more efficient in the long run.

So, if you’re tackling a dull or damaged chisel, be sure to choose a coarse grit size to get the job done.

Grit Size for Medium Sharpening

When it comes to chisel sharpening, choosing the right grit size can make a big difference in achieving sharp and precise cuts. For medium sharpening, a grit size of around 1000 to 2000 is generally recommended. This grit size is great for removing any nicks or chips in the blade while still maintaining a fine edge.

However, it’s important to note that the grit size alone isn’t the only factor in achieving a sharp chisel. Proper technique and pressure while sharpening are also crucial for optimal results. Think of it like sharpening a pencil – the right grit size is important, but if you don’t sharpen it evenly and with the correct pressure, you won’t get the desired point.

So, when sharpening chisels, take your time and focus on both the grit size and your technique for the best outcome.

Grit Size for Fine Sharpening

When it comes to sharpening your chisels, selecting the correct grit size can make a world of difference. Fine sharpening generally requires a grit size of at least 1000. This grit size is ideal for maintaining the edge of the chisel and removing any nicks or burrs.

A 1000 grit stone will remove enough material to make the edge sharp but will not remove too much material that it becomes a different shape. Going finer than 1000 grit will give you a polished edge, however, it may also round off the edge thereby reducing its keenness. Therefore, it’s ideal to stick to a 1000 grit or higher for maintenance and only raise the grit if you are striving for a polished finish.

By selecting the appropriate grit size, you can ensure that your chisels are sharp and ready for any woodworking task.

Types of Grinding Wheels for Chisel Sharpening

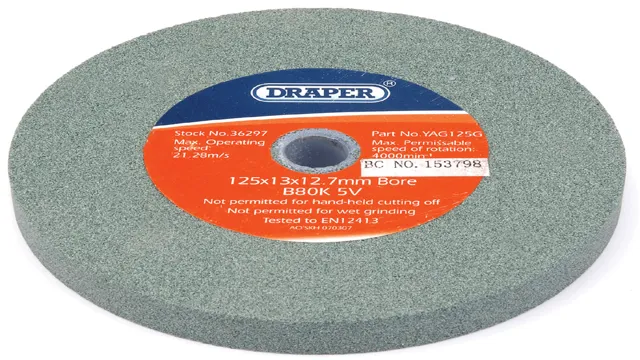

When it comes to sharpening chisels, choosing the right grinding wheel can make all the difference. There are various types of grinding wheels available, but the most commonly used ones for chisel sharpening are the white aluminum oxide and the green silicon carbide. White aluminum oxide wheels have a grit range between 60-120 and are perfect for general-purpose grinding, while green silicon carbide wheels have grit ranging from 80-120 and are ideal for sharpening harder materials like carbide tools.

When selecting the grinding wheel’s grit for chisel sharpening, it’s important to look at the chisel’s hardness and the degree of sharpness required. For instance, if you want to shape or sharpen the bevel of a chisel, a lower grit wheel may be appropriate. On the other hand, for honing or polishing the cutting edge, a higher grit wheel between 100-120 will do the job.

Sharpening chisels may seem like a daunting task, but with the right grinding wheel, it can be done quickly and efficiently. So, the next time you’re looking to sharpen your chisel, consider the angle, the chisel’s hardness, and the grit of the grinding wheel to achieve the perfect edge.

Aluminum Oxide Grinding Wheels

When it comes to chisel sharpening, using the right grinding wheel can make all the difference in getting the perfect edge. One type of grinding wheel that is commonly used for chisel sharpening is the aluminum oxide wheel. This type of wheel is great for general purpose grinding and works especially well for sharpening high-speed tool steels.

An aluminum oxide wheel is typically composed of aluminum oxide particles bonded together with a vitrified or ceramic bond. These wheels come in various grades and grits, each designed for specific tasks. For chisel sharpening, a medium grit wheel is generally preferred as it removes material quickly while leaving a smooth finish.

It’s important to note that aluminum oxide wheels are not ideal for grinding harder materials like carbide, so be sure to choose the appropriate wheel for the job. Overall, an aluminum oxide grinding wheel is an excellent choice for chisel sharpening due to its versatility and effectiveness.

Silicon Carbide Grinding Wheels

When it comes to chisel sharpening, choosing the right type of grinding wheel is essential to achieve optimal results. One of the most popular choices for chisel sharpening is a silicon carbide grinding wheel. These types of wheels offer a high level of hardness and durability, making them ideal for sharpening tools that require a close level of precision.

Silicon carbide grinding wheels come in a range of grit sizes, from very coarse to extremely fine. The coarser grits are ideal for quickly removing material and rough sharpening, while finer grits are better for honing and finishing. It’s important to select the appropriate grit size based on the level of sharpening you need to achieve for your chisels.

When shopping for silicon carbide grinding wheels, it’s also important to consider the grade of the wheel. The grade refers to the hardness of the abrasive material used to create the wheel. Higher graded wheels will have a harder abrasive that can handle tougher materials and higher levels of force.

Lower grade wheels are better suited for softer materials and less force. In conclusion, selecting the right type of grinding wheel can make all the difference when it comes to achieving optimal chisel sharpening results. Silicon carbide grinding wheels are a popular choice for their hardness, durability, and range of grit sizes and grades.

Take the time to select the appropriate wheel for your unique sharpening needs, and you’ll be on your way to sharper chisels in no time.

Conclusion

In the world of sharpening chisels, the grit grinding wheel is as essential as the chisel itself. It’s the dependable partner that takes your dull tool and turns it into a sharp masterpiece. But which grit to choose? Well, it all depends on your needs.

Are you looking to reshape an old chisel or simply touch up a sharp one? Is time of the essence or are you willing to take it slow? With so many options, it can be overwhelming. However, one thing is for sure – a well-chosen grit grinding wheel is the key to unlocking the full potential of your chisels. So, choose wisely and happy sharpening!”

FAQs

What is the recommended grit for sharpening chisels with a grinding wheel?

The recommended grit for sharpening chisels with a grinding wheel is between 120 to 1000 grit.

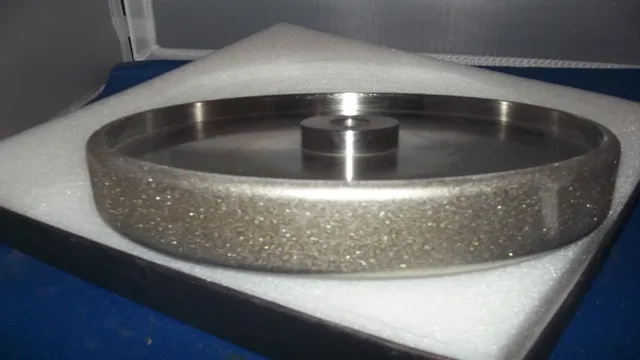

Can you use a diamond grinding wheel for sharpening chisels?

Yes, a diamond grinding wheel can be used for sharpening chisels.

Is it better to use a wet or dry grinding wheel for sharpening chisels?

It is better to use a wet grinding wheel for sharpening chisels as it prevents the tool from overheating and maintains its temper.

How often should you sharpen your chisels with a grinding wheel?

You should sharpen your chisels with a grinding wheel whenever they become dull or damaged.

Should you use a coarse or fine grit grinding wheel for heavy duty chisels?

It is recommended to use a coarse grit grinding wheel for heavy-duty chisels and a finer grit for finishing.

Can you use a bench grinder for sharpening chisels or do you need a specialized machine?

You can use a bench grinder for sharpening chisels, but it is recommended to use a specialized machine for better precision and control.

How do you properly maintain a grinding wheel for chisel sharpening?

To maintain a grinding wheel for chisel sharpening, you should dress it regularly with a dressing tool and clean it with a wire brush or dresser after each use.