There’s nothing quite like the satisfaction of taking a dull chisel and bringing it back to life with a sharp edge. But when it comes to sharpening, there’s no one-size-fits-all solution. Choosing the right grit for sharpening chisels can be a confusing process, especially if you’re new to woodworking.

Do you go with a coarse grit to remove material quickly? Or a fine grit to get a razor-sharp edge? How do you know when it’s time to switch to a higher or lower grit? Choosing the right grit for sharpening chisels requires a bit of knowledge and experimentation. In this blog post, we’ll cover everything you need to know to make an informed decision. We’ll explain what grit is, how it affects your sharpening process, and provide tips for selecting the perfect grit for your chisels.

So grab your favorite chisel and let’s get sharpening!

Understanding Grit Sizes

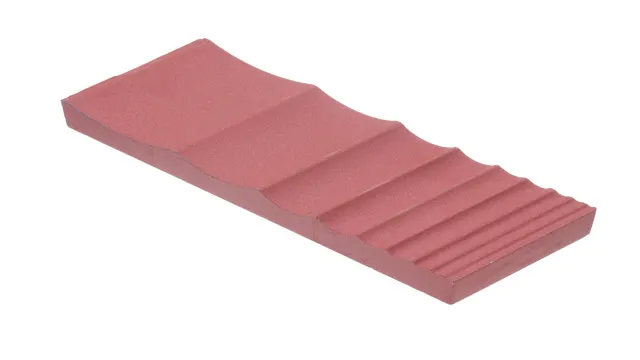

When it comes to sharpening chisels, the grit size of the sharpening stone is an essential factor to consider. Grit size refers to the coarseness level of the stone’s abrasive particles, which determines how much material it removes per stroke. Generally, chisels and other cutting tools require a coarser grit size for initial sharpening to remove any dullness and damage.

A grit size of 200 to 400 is ideal for this purpose. Medium grit sizes ranging from 800 to 1200 are suitable for honing and refining the edge, while finer grit sizes of 4000 and up are best for polishing and fine-tuning the edge for a razor-sharp finish. It’s essential to pay attention to the grit size of the sharpening stone to achieve the desired results and ensure the longevity of your cutting tools.

Remember, lower grits are coarser while higher grits are finer in terms of sharpening stones, and knowing which grit to use is crucial for sharpening your chisels properly.

What is grit size?

Grit size is a term used to describe the coarseness or fineness of abrasive materials used in grinding, cutting, or polishing. It is measured in microns and refers to the size of individual abrasive particles contained within the material. The smaller the grit size, the finer the abrasive particles, and the smoother the resulting surface.

Conversely, the larger the grit size, the coarser the abrasive particles, and the rougher the surface finish. The choice of grit size depends on the application and desired outcome. For example, a fine grit size would be appropriate for polishing delicate electronic components, while a coarse grit size would be suitable for removing thick layers of rust from a metal surface.

Overall, understanding grit size is essential for achieving the desired surface finish in various industrial and commercial applications.

How is grit size measured?

Grit size is an important aspect of abrasives used in the development of a variety of products, including knives, tools, and even automotive parts. It can be measured in various ways, but the most common method is through the use of a screen. This screen has a series of openings of a particular size, and the abrasive particles are passed through it.

The grit size is then determined by the size of the largest particle that is retained on the screen. This is represented by a number on the abrasive material, such as 60 or 120. The higher the number, the smaller the abrasive particle, and the finer the finish that can be achieved.

Understanding grit sizes is crucial to choosing the right abrasive for your project, as using a material with a grit size that is too coarse can result in a rough finish, while using a grit size that is too fine can take too long to achieve the desired result. So, when selecting an abrasive material, be sure to consider the grit size to ensure that you get the perfect finish for your project.

What do grit sizes mean?

If you’ve ever purchased sandpaper, you’ve likely noticed numbers on the packaging labeled as grit sizes. But what do these numbers really mean? In short, grit sizes refer to the coarseness or fineness of the abrasive particles on the sandpaper. The higher the grit number, the finer and less abrasive the sandpaper will be.

For instance, a 60-grit sandpaper would be rougher and more aggressive for removing material compared to a 220-grit sandpaper, which would leave a smoother surface finish. Grit sizes typically range from coarse (40-80) to medium (100-150) to fine (180-220) and extra-fine (240-400). It’s important to choose the correct grit size for your project to ensure the best results.

Determining the Right Grit for Chisels

When it comes to sharpening chisels, determining the right grit can be a bit confusing. The grit refers to the coarseness of the sharpening stone, with lower numbers indicating a coarser grit and higher numbers indicating a finer grit. For chisels, it’s generally recommended to start with a coarser grit, such as 250 or 400, for sharpening the initial edge.

From there, you can move up to a finer grit, such as 1000 or 2000, to achieve a polished and sharp edge. It’s important to keep in mind that using too fine of a grit too soon can actually cause your chisel to lose its sharpness rather than improve it. So, start with a coarser grit and work your way up to a finer grit for the best results.

What type of chisel do you have?

If you own a chisel, it is important to determine the right grit for it. The grit of the chisel refers to the coarseness of the abrasive material on the sharpening stone. Different grits are used for different levels of sharpening and honing.

For example, a chisel that is very dull will require a lower grit to remove the worn metal and reshape the edge, while a sharpened chisel may require a higher grit to hone and polish the edge. When choosing the right grit for your chisel, it is important to consider the type of work you will be doing with it. If you plan to use the chisel for heavy-duty work, such as carving or woodworking, you may want to go with a lower grit to ensure that the edge is strong and can withstand the pressure.

On the other hand, if you are using the chisel for fine detail work, like carving intricate designs or cutting fine joinery, you may want to choose a higher grit for a finer edge. It is also important to note that different types of chisels may require different grits. For instance, a bevel-edged chisel may require a higher grit to achieve a sharper edge than a paring chisel, which is generally used for lighter work.

Ultimately, the right grit for your chisel will depend on the specific task you need it for, and the type of chisel you own. Taking the time to determine the right grit will ensure that your chisel stays sharp and effective for longer.

What is the current state of the chisel?

Chisels are essential tools for any woodworker, and maintaining them is crucial for the quality of their work. When it comes to sharpening chisels, determining the right grit for the job can be confusing. The grit size determines how much material is removed, and using the wrong grit size can cause damage to the chisel.

For general maintenance, a 1000-grit waterstone is recommended. This grit size is perfect for honing the edge and removing any burrs. However, if the chisel is dull or damaged, a coarser grit, such as 400 or 600, should be used to remove the damaged metal.

On the other hand, if the chisel only needs a touch-up, a finer grit, such as 4000 or 6000, can be used for a smoother finish. It’s important to note that the proper grit size also depends on the type of wood being worked with. So, it’s always a good idea to test the chisel on a scrap piece of wood before working on the final project.

Overall, selecting the right grit size for chisels will not only improve the quality of the work but will also extend the life of the tool.

What is the intended use of the chisel?

When it comes to chisels, there are plenty of factors to consider to ensure that they perform optimally. One of the most critical aspects is determining the appropriate grit for your chisel. The intended use of the chisel plays a vital role in deciding the perfect grit.

For instance, if you are looking to remove material quickly, then a lower grit is the way to go. On the other hand, if you want a smoother finish, then a higher grit is imperative. Generally, grit levels for chisels ranging from 120 to 600 are adequate for most applications.

However, depending on the material you intend to work with, you may need to adjust your grit level. It is always best to start with a coarse grit and gradually work your way to a finer grit. That way, you get a smooth finish without compromising the quality of your project.

Ultimately, the right grit for your chisel is determined by how well it performs the task at hand, ensuring that the finished product meets all the desired criteria.

Recommended Grit Sizes for Chisels

If you’re wondering what grit to use when sharpening your chisels, there are a few things to consider. The grit size refers to the size of the abrasive particles on the sharpening stone: the smaller the grit number, the coarser the stone. For initial sharpening or repairing of chipped edges, a coarse grit between 100 and 400 is recommended.

Once you’ve established a new bevel with the coarse grit, you can move on to a finer grit for honing and polishing. A medium grit between 800 and 1000 is ideal for this step, followed by a fine grit between 3000 and 8000 for a razor-sharp edge. However, keep in mind that the grit size should also depend on the type of steel your chisel is made of.

Softer metals may need a coarser grit, while harder metals can be sharpened with finer grits. Ultimately, the choice of grit size will depend on your personal preference and the level of sharpness you want to achieve for your chisels.

Rough shaping and repairs: 80-120 grit

When it comes to chisels, rough shaping and repairs require a grit size of 80-120. This range is perfect for removing large amounts of material or for fixing any nicks or chips in the blade. However, it’s important to note that the grit size ultimately depends on the material of the chisel and the task at hand.

Using a higher grit size may not only take longer to shape the chisel, but it can also cause unnecessary wear and tear. On the other hand, using a lower grit size could be too abrasive and ruin the blade. So, it’s important to choose the right grit size for your specific needs.

Remember, a well-maintained and sharp chisel is essential for any woodworking project. With the right grit size for rough shaping and repairs, your chisel will be ready to tackle any project with ease.

Sharpening and honing: 400-1000 grit

When it comes to sharpening chisels, it’s important to use the right grit size to achieve the desired level of sharpness. For honing and sharpening, grit sizes of 400-1000 are recommended for chisels. The lower grit sizes are used to remove any nicks or dents on the blade while higher grit sizes are best for achieving a razor-sharp edge.

It’s important to remember that the grit size determines the level of abrasiveness, and using too low of a grit size can result in a rough edge that quickly dulls. On the other hand, using too high of a grit size can take a very long time and may not result in the desired level of sharpness. It’s recommended to start with a lower grit and work upwards to achieve optimal results.

By choosing the right grit size for your chisels, you can ensure that they perform at their best and are ready for any woodworking project that comes your way.

Polishing and final honing: 4000-8000 grit

When it comes to sharpening your chisels, polishing and final honing are crucial steps. The best grit sizes to use during these steps typically range from 4000-8000. This range ensures that your chisels are not only sharp but also smooth and polished.

Using grits that are too coarse can leave unsightly scratches on your chisel, while using grits that are too fine may not remove all the burrs and dull spots. Aiming for a grit size of around 6000 will give your chisel the best possible edge for most woodworking tasks. However, it’s always good to experiment with different grits to see what works best for you and your chisels.

As always, be sure to maintain consistent pressure and angle throughout the sharpening process to achieve the best results. By taking the time to polish and hone your chisels, you’ll be able to work more efficiently and produce higher quality woodworking projects.

Conclusion

In conclusion, when it comes to sharpening chisels, grit is the real deal. And not just any grit – the right grit. You don’t want to be left with a dull blade after all that hard work! So remember, the grittier the better (within reason, of course).

Choose a coarse grit to get rid of nicks and bumps, a medium grit for smoothing and refining the edge, and a fine grit for that razor sharp finish. And as always, keep your grit game strong and your chisels sharper than sharp!”

FAQs

What grit should I use for sharpening chisels?

It depends on the level of dullness or damage on the chisel. For general sharpening, a 1000 or 2000-grit stone should suffice. For more damaged edges, starting with a 400-grit stone and working your way up to a higher grit is recommended.

Can I use sandpaper for sharpening chisels?

Yes, you can use sandpaper to sharpen chisels. However, it is recommended to use higher-quality sandpaper or a dedicated sharpening stone for better results.

What angle should I sharpen my chisels at?

The optimal angle for chisel sharpening is between 25 to 30 degrees. This angle provides a balance between sharpness and durability.

How often should I sharpen my chisels?

This depends on how frequently you use your chisels. For heavy use, it may be necessary to sharpen your chisels after each use. For casual use, sharpening every few months may suffice.

Can I use a honing guide for sharpening chisels?

Yes, a honing guide can help maintain an accurate and consistent angle while sharpening chisels.

How do I know when my chisel is sharp enough?

A sharp chisel should be able to shave hairs off your arm or slice through paper with ease. You can also test the sharpness by gently running your finger along the edge and feeling for any burrs or rough areas.

Should I oil my chisels after sharpening?

It is recommended to oil your chisels after sharpening to prevent rust and corrosion. Simply wipe a thin layer of oil onto the blade before storing.