How an Air Ratchet Works: A Comprehensive Guide to Understanding its Mechanism and Benefits

Are you curious about how an air ratchet works? Well, let’s imagine you’re working on a car engine and you need to remove a rusted bolt. A regular wrench won’t do the job, so you turn to an air ratchet. With this tool, you can effortlessly unscrew that bolt in seconds.

But have you ever wondered how an air ratchet actually works its magic? In this blog, we’ll dive into the mechanics behind this popular tool and explain how it uses compressed air to make tough jobs a breeze. So, let’s get started and uncover the secret power of the air ratchet!

Introduction

Air ratchets are incredibly useful tools that can make a mechanic’s job a lot easier. But how do air ratchets work? Well, the name itself gives us a clue – air is used to power the ratchet. The user simply attaches the ratchet to an air compressor, which will provide the necessary power to the tool.

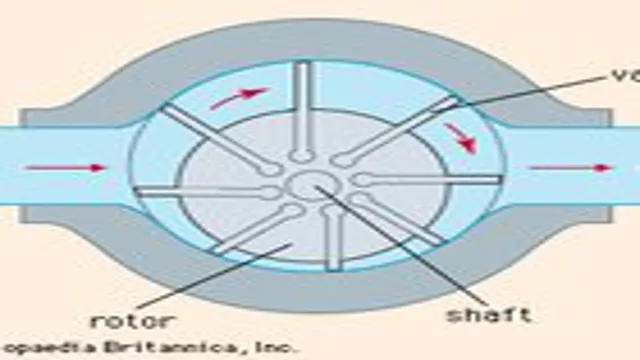

When the user pulls the trigger, the compressed air flows into the ratchet’s motor and turns the rotor. The rotor then drives the anvil to which the socket is attached, allowing it to turn. One of the main benefits of air ratchets is that they work quickly and efficiently, making them ideal for tasks that require a lot of torque.

Plus, their lightweight and compact size make them easy to maneuver, even in tight spaces. If you’re a mechanic or just someone who likes to DIY, an air ratchet is definitely a tool you should consider adding to your arsenal.

What is an Air Ratchet

An air ratchet is a type of power tool used primarily for auto repairs and maintenance. It is a handheld tool that uses compressed air to turn sockets and nuts, making it easier and faster to loosen and tighten bolts in tight spaces. These ratchets are commonly used in automotive repair shops and by mechanics because they allow them to work on engines and other car parts with ease.

The air ratchet is compact and lightweight, making it easy to maneuver in tight corners and spaces. Additionally, it is designed to provide a substantial amount of torque, which is the force required to turn a bolt or nut. Overall, an air ratchet is a highly versatile and essential tool for those who work in the auto repair industry.

Components of an Air Ratchet

An air ratchet is a versatile tool used in various applications, such as automotive repair and maintenance, machinery installation, and assembly. It operates similarly to a conventional ratchet, but instead of manual turning, compressed air or electricity powers it. A standard air ratchet comprises several essential components, including the drive head, the reversing switch, the trigger, the air inlet, and the exhaust port.

The drive head is the primary component of the air ratchet, responsible for turning the socket and tightening or loosening bolts and nuts. The reversing switch enables the user to switch the direction of the drive head, making it possible to work on threaded fasteners without needing to switch tools. The trigger is the entry point of the compressed air or electric current into the tool, allowing the user to regulate the speed and power of the air ratchet.

The air inlet is where the air hose or electrical cord is attached to the tool, providing the necessary power source to operate it. Lastly, the exhaust port releases the compressed air from the motor to the surrounding environment. Understanding the components of an air ratchet is crucial in using and maintaining the tool effectively.

Working Mechanism

If you are wondering how an air ratchet works, here is a brief explanation. Firstly, an air ratchet consists of a motor, ratcheting mechanism, and a trigger designed to provide torque in a single direction. The tool operates using compressed air that is introduced into the motor housing chamber through an air inlet.

The compressed air causes the motor to rotate, which is then transferred to the ratchet mechanism that moves the socket in a reciprocating motion. By pulling the trigger, compressed air is delivered to the motor, which then rotates the ratchet mechanism, providing the necessary torque to fasten or unfasten nuts and bolts. In simpler terms, an air ratchet is essentially a pneumatic-powered tool that uses compressed air to provide torque to the mechanism, allowing for easier and quicker manipulation of nuts and bolts.

Overall, air ratchets are a highly efficient tool present in most automotive workshops and industrial factories.

Pneumatic System

A pneumatic system works by using compressed air to transmit energy. The whole system is made up of three main parts: the compressor, the tool or machine, and the air treatment unit. The compressor is responsible for compressing air before sending it through the system.

The tool or machine uses the air to create the desired motion or energy, like turning a motor or operating a cylinder. The air treatment unit filters and regulates the compressed air, ensuring it is clean and suitable for use. The main advantage of using a pneumatic system is its reliability, as compressed air is not as susceptible to fluctuations in temperature or power outages.

Additionally, it is a safe option as it reduces the risk of fire or electrical shock. Overall, when properly designed and maintained, a pneumatic system can increase operational efficiency and productivity while minimizing safety risks.

Ratcheting Mechanism

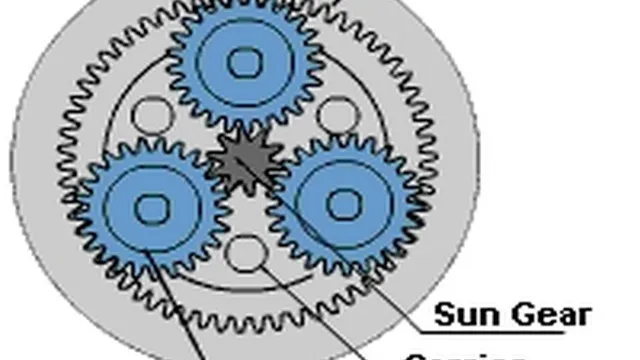

A ratcheting mechanism is an essential component in a variety of tools and machines. It works by allowing one-way motion, preventing backward or reverse movements. The mechanism is composed of a ratchet wheel, a pawl, and a pivot.

The ratchet wheel is a round gear with teeth that are sloped on one side and flat on the other. The pawl is a small lever that rests against the ratchet wheel’s teeth to allow one-way movement. The pivot is what holds the pawl in place and allows it to move up and down when pressure is applied.

When an initial force is applied to the ratchet wheel in the desired direction, the pawl lifts away from the flat side of the teeth and falls into the grooves on the sloped side, locking the wheel in place. This allows the wheel to continue turning in the same direction without snapping back. The ratcheting mechanism is often used in hand tools like wrenches and socket sets, as well as in machines like escalators and winches.

It is a crucial component that allows for efficient and safe operations.

Air Ratchet vs Manual Ratchet

When it comes to choosing between an air ratchet and manual ratchet, understanding the working mechanisms of both tools is crucial. Manual ratchets require manual effort to tighten or loosen nuts and bolts, basically using a gear system that only moves in one direction and locks in place when released. On the other hand, an air ratchet functions by attaching to an air compressor and using the power of compressed air to turn the socket.

This makes it faster and easier to use as it doesn’t require as much physical strength as a manual ratchet to get the job done. However, it’s important to note that an air ratchet can be louder and heavier than a manual ratchet, and may require extra maintenance. Ultimately, the choice of whether to use an air ratchet or manual ratchet depends on the job requirements, personal preference, and budget.

Benefits of Using an Air Ratchet

An air ratchet is a versatile tool used in automotive, mechanical, and construction industries. It is powered by compressed air and designed to fit into tight spaces where a regular ratchet cannot reach. The air ratchet is easy to use and efficient in tightening and loosening bolts, nuts, and screws with less effort than manual ratchets.

One major benefit of using an air ratchet is its speed and power, which makes work faster with its high torque capabilities. In addition, using an air ratchet reduces the risk of repetitive strain injuries associated with manual ratchets. It also offers precision and accuracy as it allows you to apply just the right amount of torque needed for each task, resulting in fewer mistakes and damage to equipment.

Ultimately, understanding how an air ratchet works is essential in maximizing its benefits and achieving professional results in various applications, saving time and energy while ensuring safety and efficiency.

Increased Efficiency and Speed

An air ratchet is a valuable tool for anyone who needs to work with nuts and bolts regularly. One of the biggest advantages of using an air ratchet is the increased efficiency and speed it provides. With an air ratchet, you can tighten or loosen bolts quickly and effortlessly, without having to exert as much physical effort.

This means you can get tasks done faster and move onto other projects more quickly. Additionally, air ratchets are built to be durable and long-lasting, which means you won’t have to replace them as often as other types of ratchets. Overall, using an air ratchet can help you work more efficiently and complete tasks faster, which is a huge benefit for anyone who values productivity.

So, if you’re looking for a reliable and efficient tool for your next project, consider using an air ratchet and see the benefits for yourself.

Reduced Operator Fatigue

Air ratchets serve as powerful and efficient tools that can make a daunting task seem much easier. The use of air ratchets reduces operator fatigue significantly, as the tool’s mechanism helps in applying torque effortlessly without overexerting the user’s wrist muscles. With its ergonomic design, an air ratchet gives a comfortable grip, enabling the user to work for prolonged periods.

Its lightweight design makes it easy to handle, and with its high-speed rotation, it ensures the job is completed quickly and efficiently. Using an air ratchet improves productivity and reduces the chance of injury while saving time and effort, making it an indispensable tool in any mechanic’s toolkit.

Conclusion

In conclusion, an air ratchet is like a tiny superhero that saves the day in tight spaces where human strength and wrenches can’t reach. Powered by compressed air, the ratchet’s internal mechanism uses a series of gears and pawls to convert the continuous rotary motion into intermittent one-directional torque. This allows you to loosen or tighten nuts and bolts quickly and smoothly, without causing extra hand fatigue.

Think of it like a speed demon that rushes to your rescue with precision and power. So next time you need a trusty sidekick for your DIY project or mechanic job, bring out the air ratchet and let it do the heavy lifting for you!”

FAQs

What is an air ratchet and how does it work?

An air ratchet is a type of power tool that is powered by compressed air. It works by using the compressed air to turn a rotor inside the tool, which then drives a socket and wrench in a back-and-forth motion to tighten or loosen bolts.

What are the advantages of using an air ratchet?

The advantages of using an air ratchet include its speed and efficiency, as well as its ability to work in tight spaces. It also reduces the amount of strain and fatigue on the user’s arm and wrist.

How does the torque output of an air ratchet compare to other types of power tools?

Air ratchets typically have a lower torque output than other power tools, such as impact wrenches. However, they are still capable of generating enough torque to loosen or tighten bolts in most applications.

Can an air ratchet be used on all types of bolts?

An air ratchet can be used on most types of bolts, including hex head, square head, and Torx head bolts. However, it may not be suitable for very large or heavily rusted bolts.

Is maintenance required for an air ratchet?

Yes, like all power tools, an air ratchet requires regular maintenance to keep it in good working condition. This includes lubricating the internal parts, cleaning the air filter, and checking for any signs of wear or damage.

What safety precautions should be taken when using an air ratchet?

Safety precautions when using an air ratchet include wearing eye and ear protection, avoiding loose clothing or jewelry, and making sure the tool is properly grounded. It is also important to use the correct size socket and to never use the tool to apply excessive force.

How long do air ratchets typically last?

The lifespan of an air ratchet depends on the quality of the tool and how well it is maintained. With proper care and maintenance, an air ratchet can last for many years of regular use.