How Does an Air Ratchet Work? A Comprehensive Guide on Inner Mechanism

Have you ever wondered how mechanics are able to tighten bolts and nuts so quickly and effortlessly? The answer lies in the air ratchet – a powerful tool that has revolutionized the way automotive repairs are carried out. An air ratchet is a hand-held power tool that utilizes compressed air to turn sockets in tight spaces where using a regular wrench would be impossible. At first glance, an air ratchet may seem a lot like an electric drill, but the two differ in terms of their functioning.

While a drill rotates continuously, an air ratchet turns only when the trigger is pulled. This allows for precise control in tight areas where accuracy is paramount. The compressed air is what provides the power to turn the ratchet.

It enters the tool through an inlet and travels into the head of the ratchet. The air then acts on the turbines, which spin the ratchet mechanism. As the ratchet turns, the socket in the head of the tool rotates in small increments to tighten or loosen the bolt or nut.

Air ratchets are highly efficient tools that are widely used in automotive repairs, particularly in engine bays. They are lightweight, durable, and easy to use, making them a favorite among mechanics. Whether you’re an amateur mechanic or a professional, an air ratchet can be an invaluable addition to your toolkit.

In conclusion, the air ratchet is a powerful tool that has revolutionized the world of automotive repairs. It utilizes compressed air to deliver precise torque control in tight spaces, making the job of tightening and loosening bolts a breeze. So, if you’re looking to improve your DIY automotive skills, investing in an air ratchet is a great place to start!

Introduction

Are you curious about how an air ratchet works? Well, an air ratchet is a powerful tool that works by using compressed air to turn a socket. It’s not like a traditional ratchet that requires manual strength to turn. The compressed air creates a force that causes the ratchet to move in one direction.

When the ratchet reaches the end of its travel in one direction, it shifts and moves in the opposite direction. This allows the user to loosen or tighten bolts and nuts with ease. One of the best things about an air ratchet is that it is very fast and efficient compared to a manual ratchet.

In addition, it is more convenient and comfortable for the user since it requires less physical effort. So, if you need to work on your car or any other machinery, an air ratchet will surely be a great addition to your toolbox.

Understanding Air Ratchets

Air ratchets are powerful tools that are extensively used in different mechanical applications. These ratchets are designed to provide an efficient and quicker way of tightening or loosening bolts and nuts. They function by using compressed air to generate rotational power that is then transferred to the socket wrench, enabling it to apply torque with minimal physical effort.

They are versatile tools that are commonly used in automotive repair, construction, and manufacturing industries. With an air ratchet, you can handle tough and hard-to-reach areas and get the job done in less time. They come in different sizes, shapes, and speeds, making them ideal for various applications.

Whether you are looking for a tool to use at home or in a professional setting, an air ratchet can significantly improve your efficiency and productivity.

Components of an Air Ratchet

An air ratchet is a versatile and efficient tool that has become an essential part of a mechanic’s arsenal. It is used for tightening bolts and nuts in tight spaces where a regular wrench cannot fit. The air ratchet is composed of several essential components that work together to enable it to run smoothly and efficiently.

The most integral part of an air ratchet is the motor, which provides the power to drive the ratchet mechanism. The motor is usually an air-powered motor that is attached to the main body of the ratchet. Another crucial component of an air ratchet is the ratchet mechanism itself.

This mechanism allows the ratchet to turn in one direction only, making it ideal for tightening and loosening bolts and nuts in confined spaces. A sturdy handle provides the user with a comfortable grip, and a trigger allows them to control the tool’s speed and direction. All these components work together harmoniously to make an air ratchet a powerful and efficient tool that is essential in any mechanic’s toolbox.

How It Works

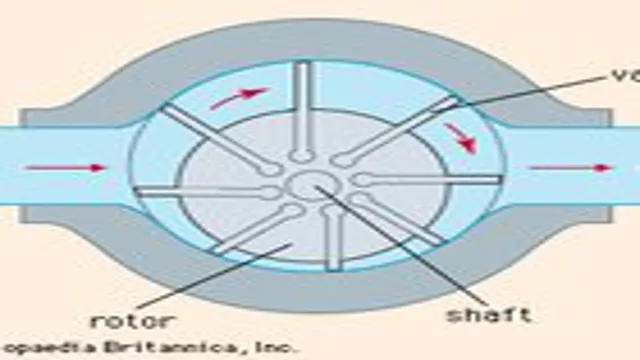

An air ratchet is a powerful tool that mechanics use to tighten or loosen nuts and bolts. It’s a specialized type of ratchet that uses compressed air to turn the socket at high speeds. The design of an air ratchet is comprised of several parts, including an air motor, a rotor, a trigger valve, and a reversing mechanism.

When the trigger valve is activated, compressed air enters the ratchet and causes the rotor to turn. The turning motion is then transferred to the socket, which turns the nut or bolt. The reversing mechanism allows the user to change the direction of the turning motion, making it possible to both tighten and loosen fasteners.

An air ratchet is a perfect tool for jobs in tight spaces where using a standard ratchet would be challenging. It’s a versatile and efficient tool that allows mechanics to work faster and more efficiently. So, that’s how an air ratchet works, and now you know why mechanics love it so much!

Trigger Mechanism

The trigger mechanism is an essential component of any firearm, and it works by releasing the hammer or striker, which then strikes the cartridge primer and initiates the firing process. The trigger itself is a lever that is pulled by the shooter’s finger, and it is usually connected to a sear or a catch. When the trigger is pulled, the sear or catch is released, allowing the spring-loaded hammer or striker to fly forward and hit the primer.

A good trigger should have a smooth and consistent pull, with a minimal amount of creep or overtravel, and it should be easy to reach and operate. An example of a well-designed trigger is the one found on the Smith & Wesson M&P Shield, which has a crisp and clean pull weight of around 6 lbs, and a short reset for rapid follow-up shots. Overall, the trigger mechanism is a critical part of any firearm, and it is essential to choose a gun with a high-quality trigger that fits your needs and preferences.

Air Supply System

An air supply system is an essential component of many machines, especially those that require the circulation of air for efficient performance. It works by drawing in fresh air from the surrounding environment and filtering it to remove any impurities. The purified air is then directed to the machine where it is needed.

The system is made up of several parts, including the air intake, filter, ducts, and fans. The air intake is usually located outside the machine and is designed to minimize the amount of dust and debris that enters the system. The filter traps any remaining impurities and prevents them from entering the machine.

The ducts ensure that the air flows smoothly to where it is needed, while the fan creates the necessary air pressure for efficient circulation. In summary, the air supply system is vital for the optimal functioning of many machines, and proper maintenance of each component is necessary for optimal performance.

The Ratchet Drive System

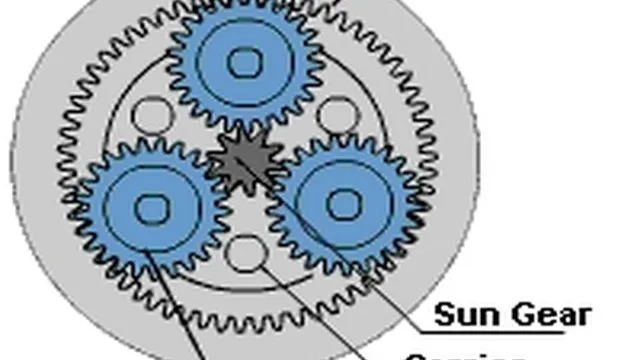

The ratchet drive system is a mechanical device that converts rotational motion into linear motion. It consists of a ratchet wheel and a pawl, which together transmit motion in only one direction. The pawl is a small, hinged component that engages with the teeth on the ratchet wheel, preventing the wheel from turning backwards.

When the ratchet wheel is turned in the forward direction, the pawl slides over the teeth and allows the wheel to rotate freely. However, when the wheel tries to rotate in the opposite direction, the pawl engages with the teeth and prevents any backward movement. This mechanism is commonly used in a variety of applications, from hand tools like wrenches to heavy machinery like cranes and elevators.

The ratchet system ensures smooth, controlled movement without the need for complex gearing or multiple components. Its compact design and high precision make it an ideal choice for applications requiring efficient and reliable motion control.

Impact System

The Impact System is a unique framework that helps businesses measure and improve their environmental, social, and economic impact. It works by analyzing the outcomes of a company’s actions and policies through a series of setup metrics. These metrics help identify how businesses can improve the impact of their actions and create a more sustainable future for all.

The Impact System works in a few simple steps. Firstly, companies need to define their purpose and mission. This helps create a clear understanding of what they stand for and the impact they want to have.

Next, they need to measure their current impact in each area, including their carbon footprint, social justice, and economic sustainability. This helps identify where efforts need to be focused and what changes need to be made. Once these metrics have been identified, companies can begin implementing changes through a combination of policy changes and stakeholder engagement.

This could include everything from reducing carbon emissions to promoting diversity and inclusion in the workplace. The process is iterative, with companies continually measuring their impact and making adjustments to their policies and processes as needed. The Impact System is an essential tool for businesses looking to make a positive impact on the environment and society.

By measuring their impact and making changes accordingly, they can create a more sustainable future for all. So, are you ready to join the movement and use the Impact System to improve your business’s impact?

Benefits of Using an Air Ratchet

If you’ve ever worked on a mechanical project or performed routine maintenance on your vehicle, you know how challenging it can be to reach those tight, hard-to-reach bolts and screws. That’s where an air ratchet comes in, helping you quickly and easily loosen or tighten nuts and bolts in a fraction of the time manual wrenching takes. But how does an air ratchet work? Well, compressed air from an air compressor is directed through the tool’s air motor, which converts the air pressure into rotational force to turn the ratchet.

The mechanism is similar to that of a traditional hand ratchet, but an air ratchet allows for faster and more efficient work, thanks to the compressed air that powers it. Not only does it save time and energy, but it also reduces the risk of injury resulting from manual labor. That’s why an air ratchet is a must-have tool for DIY enthusiasts and professional mechanics alike.

Fast and Efficient

If you are looking for a tool that can make your mechanical work faster and more efficient, then you can’t go wrong with an air ratchet. This handy tool is often used by mechanics and DIY enthusiasts alike because it makes loosening and tightening bolts a breeze. The main benefit of using an air ratchet is speed.

This tool can work much faster than a manual ratchet because it uses compressed air to turn the socket. This means that you can finish your work quickly without exerting as much physical effort. Additionally, air ratchets are designed to prevent wrist fatigue and strain, making them ideal for extended periods of use.

With its fast and efficient performance, an air ratchet is a tool you won’t want to be without. So why not make your work easier and invest in an air ratchet today?

Less Effort Needed

Using an air ratchet can save you a lot of effort when it comes to tightening or loosening bolts and nuts. The speed and power of an air ratchet allow you to handle tough jobs with ease, without having to put much effort into it. In fact, using an air ratchet can reduce the amount of time and energy spent on a task by up to 80%.

This is because the air ratchet’s powerful motor generates more torque than a manual wrench, making it easier to handle even the most stubborn bolts. Additionally, the ergonomic design of air ratchets reduces strain on the user’s hands and wrists, making it more comfortable to use for extended periods. Overall, using an air ratchet is a great way to reduce the amount of effort needed to get a job done quickly and efficiently.

Conclusion

In conclusion, an air ratchet is like a tiny superhero in your toolbox, using the power of compressed air to effortlessly turn nuts and bolts with lightning speed. It’s as if Thor himself has come down from Asgard to lend a hand to even the most stubborn of mechanical tasks. So next time you’re struggling with a particularly tight bolt, remember to call upon the air ratchet and let the power of air do the heavy lifting!”

FAQs

What is an air ratchet used for?

An air ratchet is commonly used for tightening and loosening bolts in tight spaces where a regular ratchet cannot reach.

How does an air ratchet work?

An air ratchet works by converting compressed air into rotational force, which is then used to turn the socket and tighten or loosen the bolt.

What are the advantages of using an air ratchet over a manual ratchet?

The main advantage of using an air ratchet over a manual ratchet is the speed. An air ratchet can loosen or tighten bolts much faster than a manual ratchet.

What are the safety precautions that should be taken when using an air ratchet?

Some safety precautions to take when using an air ratchet include wearing safety glasses and gloves, keeping loose clothing and hair away from the tool, and always disconnecting the air supply before changing sockets or making any adjustments.

Can an air ratchet be used for heavy-duty tasks?

Yes, an air ratchet can be used for heavy-duty tasks. However, it may not be as powerful as an impact wrench and may not be the best option for very large or stubborn bolts.

Do I need any special skills or training to use an air ratchet?

No, you do not need any special skills or training to use an air ratchet. However, it is important to read the user manual and follow all safety guidelines before using the tool.

How do I maintain my air ratchet?

To maintain your air ratchet, it is important to keep it clean and lubricated. You should also regularly check and replace the air filter and inspect the tool for any damage or wear.