How Much PSI for Air Ratchet? Tips for Finding the Right Pressure

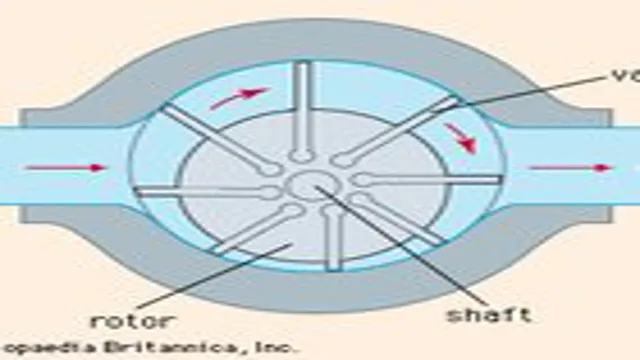

Do you often find yourself struggling to loosen or tighten bolts and nuts in tight spaces? Well, an air ratchet might just be the solution to your problem. An air ratchet is a type of power tool that operates using compressed air, enabling you to remove and tighten bolts quickly and efficiently. Its compact size and unique design allow you to access hard-to-reach areas easily, making it an essential tool in any mechanic’s arsenal.

In this blog post, we’ll discuss what an air ratchet is in detail and why it’s a must-have for anyone who works with mechanical equipment. So put on your safety gear and let’s dive in!

Understanding PSI

When it comes to using an air ratchet, it’s important to have the right amount of psi. The ideal psi for an air ratchet can vary, but typically it should be between 90 and 120 psi. However, it’s important to check the manufacturer’s recommendations for the specific air ratchet you are using.

Using too much or too little psi can affect the performance of the tool and lead to potential safety issues. It’s also important to remember that factors such as hose length and air flow can impact the psi delivered to the tool. In general, it’s best to start with the recommended psi and adjust as needed based on the task at hand.

This may take some trial and error, but finding the right psi can help ensure that your air ratchet operates at its best and that you can complete your tasks efficiently and safely.

What is PSI?

PSI stands for Pound per Square Inch, and it is a unit of pressure commonly used to measure gases and liquids’ pressure in various industries. Understanding PSI is essential in the automotive industry to ensure that tires have the correct pressure, which affects vehicle handling, fuel efficiency, and tire lifespan. Additionally, PSI plays a significant role in pneumatics, where it is used to determine the air pressure needed to operate various pneumatic devices.

In general, PSI is also used in scientific experiments to measure pressure, particularly in experiments that involve low-density gases. Therefore, understanding PSI is crucial in multiple industries and its applications affect daily life, making it worth learning more about.

Why is PSI important for air ratchets?

PSI If you’re looking for an air ratchet, you may have noticed that one of the key specifications you need to pay attention to is PSI. PSI stands for pounds per square inch, and in the case of air ratchets, it refers to the amount of air pressure required to power the tool. It’s an important consideration because the PSI rating of your air ratchet will determine its power and performance.

Simply put, the higher the PSI rating, the more powerful and efficient your air ratchet will be. However, it’s important to note that the PSI rating of your air ratchet should also be matched with the PSI rating of your air compressor to ensure compatibility and optimal performance. So when choosing an air ratchet, be sure to consider its PSI rating and make sure it’s a good match for your air compressor.

Recommended PSI for Air Ratchets

When it comes to using an air ratchet, knowing the right amount of pressure is essential. The recommended PSI for an air ratchet ranges from 90 to 120. However, to avoid causing damage to the ratchet or the workpiece, it’s important to start with a lower PSI and gradually increase it until you find the sweet spot.

Using too much pressure at once can cause the ratchet to overheat, leading to decreased efficiency, and potentially damaging its internal components. On the other hand, too little pressure can cause the ratchet to stall or not work at all. Keep in mind that the PSI requirements for an air ratchet may vary depending on the size and complexity of the job.

So, it’s important to follow the manufacturer’s instructions and recommendations every time you use your air ratchet. By doing so, you can ensure smooth and efficient performance, and extend the life of your tool.

Type of Air Ratchet

When it comes to air ratchets, the recommended PSI (pounds per square inch) can vary depending on the type and model of the ratchet. Generally speaking, most air ratchets require a PSI between 90 and 120, with some models requiring as little as 70 and others as much as 150. It’s important to check the manufacturer’s recommendations for your specific air ratchet to ensure you’re using it at the correct PSI.

Using the wrong PSI can lead to decreased performance, reduced lifespan of the tool, and even safety hazards. It’s also important to ensure you have the correct air compressor to provide the necessary PSI for your air ratchet. So, before using your air ratchet, make sure you’ve checked the manufacturer’s recommendations and have the right air compressor to provide the recommended PSI.

Size and Torque of Air Ratchet

When it comes to selecting the right air ratchet, understanding the recommended PSI is critical. PSI, or pounds per square inch, indicates the amount of air pressure that the tool requires to operate efficiently. Generally, most air ratchets require a PSI range between 90-120.

However, for larger applications, higher PSI levels may be required. It’s important to note that using a lower PSI than what’s recommended can result in inadequate torque and prolong the work time, while higher PSI levels can cause the tool to overheat and wear out faster. Therefore, check the manufacturer’s recommendations and make sure to match the PSI range with your air compressor’s output to ensure optimal performance.

In addition to PSI, the size and torque of an air ratchet should also be considered. Larger ratchets typically have a higher torque output, which means they can handle heavy-duty applications. However, they may also be heavier and bulkier, making them less portable.

Smaller ratchets offer greater portability and lighter weight, but they may not have the necessary torque for certain applications. Ultimately, selecting the right size and torque for your specific needs is crucial for efficient and effective work. So, consider the size and torque of an air ratchet along with the recommended PSI to make an informed decision and get the job done right.

Material being Worked On

Air ratchets are commonly used tools for repairing and maintaining vehicles and machinery. When it comes to using air ratchets, it is important to consider the recommended PSI for the specific task at hand. The PSI, or pounds per square inch, is a measurement of the air pressure that is needed to operate the tool properly.

To achieve maximum performance and prevent damage to the air ratchet, it is crucial to use the recommended PSI. Generally, most air ratchets have a recommended PSI range of 90-120, depending on the model and application. It is also important to note that the PSI can vary based on the thickness and material being worked on.

For example, thicker and tougher materials may require a higher PSI to ensure proper torque and speed. By following the recommended PSI guidelines, you can protect your tool, ensure optimal performance, and prevent any potential safety issues.

Factors to Consider When Choosing the Right PSI for Your Air Ratchet

When it comes to choosing the right PSI for your air ratchet, there are a few factors to consider. The first is the manufacturer’s recommendation. This information can usually be found in the owner’s manual or on the tool itself.

Following the manufacturer’s recommendation ensures that your air ratchet operates at its optimal capacity and doesn’t void any warranties. Another factor to consider is the type of work you’ll be doing. Higher PSI levels are typically needed for heavy-duty jobs, whereas lower PSI levels work fine for lighter tasks.

However, it’s essential to strike a balance between what your air ratchet can handle and the amount of pressure needed to get the job done. Additionally, long air hoses need higher PSI to maintain the same level of performance as short air hoses. To get the best results from your air ratchet, it’s crucial to carefully consider how much PSI you need.

Type of Task

When it comes to choosing the right PSI for your air ratchet, there are several factors to consider. One of the most important considerations is the type of task you will be performing. Different types of tasks require different levels of power and torque, which in turn require different levels of PSI.

For example, heavier-duty tasks such as loosening stubborn bolts may require a higher PSI and airflow rate, while lighter tasks such as assembling furniture may not require as much power. It’s important to choose an air ratchet with the appropriate PSI for the task at hand to ensure efficient and effective performance. Don’t underestimate the importance of paying attention to the type of task you will be using your air ratchet for when making your decision.

By considering this factor, you’ll be able to select the right PSI for your air ratchet and get the job done quickly and accurately.

Horsepower of Compressor

When choosing the right PSI for your air ratchet, there are a few factors to consider. The horsepower of your compressor is one of the most important factors to take into account. The more horsepower your compressor has, the easier it will be for your air tool to produce the correct amount of pressure needed to complete your task.

If your compressor lacks enough horsepower, it may take longer to get the job done or even fail to complete it at all. This is because a lower horsepower compressor doesn’t have enough power to maintain consistent pressure, leading to a lack of energy and potential damage to your air ratchet. So, it’s important to choose a compressor with plenty of horsepower to ensure your air ratchet can work effectively and efficiently.

Volume of Air Compressor

When it comes to choosing the right PSI for your air ratchet, there are several factors to consider. One of the most important is the volume of air compressor. If you have a small compressor, you might not have enough air pressure to properly operate your air ratchet.

On the other hand, if you have a large compressor, you could end up wasting energy and money unnecessarily. The key is to find the right balance between air pressure and volume that matches your specific needs. As a general rule of thumb, a compressor that can deliver at least 4 cubic feet per minute (CFM) at 90 PSI should be sufficient for most air ratchets.

Remember, having the right air pressure is crucial for achieving efficient and effective torque. So, don’t overlook the importance of selecting the right PSI and volume of air compressor for your air ratchet.

Conclusion

In conclusion, finding the right amount of psi for your air ratchet can be a tricky task. Too little pressure and your ratchet might not have enough power to get the job done, too much pressure and you risk damaging your tool or even worse, your project. So, what’s the perfect pressure? Well, the answer is simple: use the manufacturer’s recommendation as a starting point and adjust accordingly based on the task at hand and your personal experience.

Remember, just like a good joke, the right amount of psi for your air ratchet is all about finding the perfect balance. “

FAQs

1. What is the recommended air pressure for an air ratchet? A: The recommended air pressure for an air ratchet is typically between 90 and 120 psi. 2. Can I adjust the air pressure for my air ratchet? A: Yes, most air ratchets have an adjustable air pressure regulator that allows you to control the air pressure. 3. What happens if I use too much air pressure with my air ratchet? A: Using too much air pressure can damage or break the air ratchet and potentially cause injury or harm. 4. How do I determine the correct air pressure for my specific air ratchet model? A: The recommended air pressure can usually be found in the user manual or specifications for your specific air ratchet model. 5. Can I use a different type of air compressor for my air ratchet? A: It is recommended to use an air compressor with a minimum capacity of 3 gallons and an output pressure of at least 90 psi to properly operate an air ratchet. 6. Should I wear any protective gear when using an air ratchet? A: Eye protection is recommended to prevent any debris or particles from getting into your eyes while using an air ratchet. 7. Is it necessary to lubricate my air ratchet before each use? A: It is recommended to lubricate the air ratchet before each use to ensure proper function and longevity of the tool.