Dry sprinkler systems are a critical part of any fire protection strategy and are commonly used in environments where temperatures can drop below freezing. But how do these unique systems work, and what sets them apart from traditional wet sprinkler systems?

In this blog post, we’ll take a closer look at how dry sprinkler systems operate, explain their key features, and explore why they are essential in specific environments. So, whether you’re a seasoned fire protection expert or are just curious about how these systems work, read on to learn more about one of the most critical components of modern fire safety.

Overview

A dry sprinkler system is a fire protection system commonly used in environments subject to freezing temperatures. Unlike wet pipe sprinkler systems that have water stored in the pipes, dry sprinkler systems keep compressed air in the pipes instead.

These systems work by using automatic control valves that allow water to flow into the pipelines when the air pressure drops below a set level, indicating the presence of a fire.

When this occurs, the air in the pipeline escapes through the sprinkler head, allowing water to flow out and extinguish the fire. The air pressure within the pipeline is continually monitored, and when it drops, a potential fire occurrence is detected, causing the release of water.

The unique design of dry sprinkler systems makes them ideal for use in buildings where the temperature frequently drops below freezing, preventing damaging pipe bursts. This system provides an efficient and reliable solution for fire protection in cold weather environments.

Definition of Dry Sprinkler Systems

Dry sprinkler systems are a type of fire protection system designed for use in areas with low temperatures that could potentially freeze traditional wet sprinkler systems.

These systems use pressurized air or nitrogen to fill the sprinkler piping and keep the system charged, and in the event of a fire, the sprinkler head opens and releases the air pressure, allowing water to flow into the piping and extinguish the fire.

Compared to wet sprinkler systems, dry sprinkler systems tend to have a slower response time due to the need to fill the piping with water, but they offer reliable protection in areas with freezing temperatures.

If you’re looking for fire protection for a facility that experiences low temperatures, a dry sprinkler system may be the right choice for you.

Benefits of Using Dry Sprinkler Systems

Dry sprinkler systems are an innovative solution for fire protection in areas that can experience freezing temperatures. Instead of using water in the pipes, these systems use compressed air or nitrogen to keep them dry until a fire is detected. This ensures that the pipes won’t freeze and fail when needed the most.

There are numerous benefits to using dry sprinkler systems, including reduced damage from leaks, lower maintenance requirements, and increased flexibility in installation locations.

In addition, they are perfect for use in areas that experience cold weather, such as refrigerated warehouses and unheated parking garages. Overall, dry sprinkler systems are a reliable and effective way to protect against fire damage, and their use can save lives and property.

Components of a Dry Sprinkler System

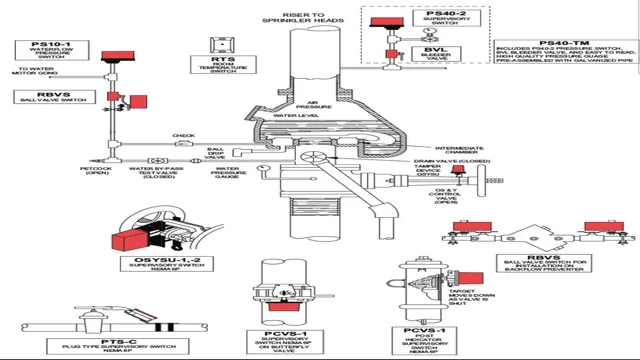

A dry sprinkler system is a type of fire protection system that utilizes air instead of water in its pipes, avoiding the risk of frozen and burst pipes in environments where water could freeze. The system is made up of several different components, including the dry pipe valve, a control valve, and a quick-opening device.

During a fire emergency, the dry pipe valve opens up and delivers compressed air into the piping network, which then opens up the sprinkler heads, releasing the pressurized air and allowing water to flow through.

This process leads to a slight delay in water being delivered to the affected area, but it ensures that the pipes remain free of water until an emergency occurs, eliminating the risk of freezing pipes during cold weather.

Overall, the dry sprinkler system is an effective way to protect commercial and industrial areas from fire damage, while also ensuring that the system is well-maintained and protected from the risks that come with using water in pipes.

Air Compressor

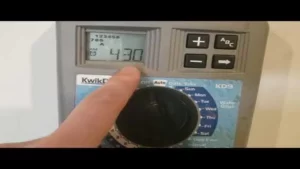

When it comes to dry sprinkler systems, there are several components that make up the system as a whole. One of the essential pieces to a dry sprinkler system is the air compressor. This device is responsible for supplying the system with compressed air that keeps the pipes dry and free of moisture.

The air compressor works by taking in air from the surrounding environment and compressing it to a high pressure, which is then stored in a tank until it’s needed by the sprinkler system.

The compressor is usually located near the main control unit of the system and needs to be maintained and inspected regularly to ensure it’s functioning properly. Without a functioning air compressor, the dry sprinkler system won’t work as it should, which can result in significant damage to the property in an emergency.

Regular maintenance and inspections can help prevent this from happening and keep the system ready to go at all times.

Control Valve

A control valve plays a crucial role in the operation of a dry sprinkler system. It is responsible for regulating the flow of water and air pressure throughout the system to ensure efficient performance. The valve consists of several components, including a valve body, actuator, seat, and plug.

The valve body is the main component that houses the other parts and controls the flow of water. The actuator, on the other hand, is responsible for activating the valve by translating the input signal into useful energy, such as pneumatic or hydraulic pressure. The seat and plug, on the other hand, work together to regulate the flow of water by controlling the opening and closing of the valve.

Overall, the control valve is a vital component of a dry sprinkler system that ensures the effective distribution of water in case of fire emergencies. Without it, the system may not function correctly, making it difficult to control fires and protect valuable assets.

Dry Pipe Valve

A dry pipe valve is a critical component of a dry sprinkler system. Essentially, this valve is what separates the pressurized air in the system from the water. When a fire is detected, the air pressure in the system drops, causing the valve to open and spray water through the sprinkler heads.

The dry pipe valve is made up of several parts, including the valve body, clapper valve, and the trim. The valve body, usually made of cast iron or ductile iron, houses the clapper valve and provides the necessary connections for the system. The clapper valve is a hinged mechanism that prevents water from entering the system until the air pressure drops.

The trim is made up of various components that ensure the system operates smoothly, including pressure gauges, alarms, and drains. Together, these components make up the dry pipe valve, a critical part of any dry sprinkler system.

Water Delivery System

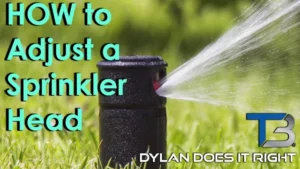

A dry sprinkler system is a fantastic option if you’re looking for a water delivery system that doesn’t require water to be constantly present in the pipes. Instead, these systems use compressed air to keep the pipes free of water until a fire activates the system and water is released. There are several components to these systems, including an air compressor, piping, and the sprinkler heads themselves.

The air compressor is responsible for keeping the pipes dry and the air pressure constant. Meanwhile, the piping is typically made of strong materials like steel or iron to withstand the pressure.

Finally, the sprinkler heads themselves are similar to those found in wet sprinkler systems, but they contain a valve that prevents water from entering the pipes until it is needed.

In short, a dry sprinkler system is an effective way to protect your property without the need for constant water presence.

How It Works

Curious to know how a dry sprinkler system works? Well, unlike wet systems that deliver water through pipes connected to a constant source of water, dry sprinkler systems use pressurized air or nitrogen instead of water.

The sprinkler heads are installed in the same way, however, the pipes in a dry sprinkler system are filled with air or nitrogen under pressure. This keeps the water out and prevents it from freezing in colder environments.

When a fire breaks out and the heat activates the sprinkler head, the air is released, causing the water to flow into the pipes and out of the sprinkler heads. It’s important to note that unlike a wet system, in a dry system, it takes longer for the water to reach the fire, which could result in more damage to your property.

Nevertheless, dry sprinkler systems are still highly effective for buildings where water could cause significant damage, such as cold storage facilities, parking garages, and museums.

So, now you know how a dry sprinkler system works!

Activation Process

The activation process for any service or product can be the most crucial step in achieving optimal results. At our company, the activation process is straightforward, streamlined, and user-friendly. Once you sign up for our service, you’ll receive an email with a link to activate your account.

Click on that link, and you’ll be directed to a page where you’ll be asked to complete a few easy steps to verify your email, choose a password, and personalize your account to your liking.

Once you’ve completed these steps, your account will be activated, and you’ll have access to all the features and benefits offered by our service. Our activation process ensures that you can get started quickly and efficiently, with minimal disruptions or delays.

So, if you’re ready to optimize your workflow and take your business to the next level, sign up today and activate your account with ease.

Water Delivery Process

Water delivery is a simple process that involves delivering clean and healthy water straight to your doorstep. The process starts with a customer placing an order for the desired amount of water, and the delivery team ensures that the order is dispatched promptly.

The delivery team typically uses a water tanker to transport the water and takes all the necessary precautions to ensure that the water is safe to consume.

Once the water is delivered, the team makes sure that the customer receives their order intact. The process is designed to be hassle-free and convenient for the customer. So, if you need quality water delivered to your doorstep, placing an order for water delivery is your best bet!

Pitfalls to Avoid

When it comes to any business venture, there are always pitfalls to avoid, and the same goes for using the “How It Works” approach. One of the biggest mistakes is assuming that this approach will work for all products or services without properly assessing its relevance to the market.

It’s essential to consider the product’s complexity and the audience’s familiarity with the industry to determine whether the “How It Works” approach will be beneficial.

Another common pitfall is using jargon and industry-specific terms that the average consumer may not understand, which can quickly lose their interest. Maintaining a conversational tone and using relatable analogies or metaphors can help simplify the process and keep the audience engaged.

In essence, the “How It Works” approach can be an incredibly effective marketing strategy, but it’s essential to avoid these common pitfalls to ensure its success.

Maintenance and Inspections

If you have a dry sprinkler system installed, you may be wondering how it works. Unlike wet systems, dry sprinkler systems use pressurized air instead of water in the pipelines. The air keeps the valves closed, preventing water from entering the pipes until a fire causes a drop in the air pressure.

Once the air pressure drops, the valves open, and water is released, extinguishing the fire. But how do you make sure this system is working properly? Regular maintenance and inspections are crucial. Dust, debris, and corrosion can build up over time, causing the system to malfunction.

Inspections should be done annually, at a minimum, and any issues should be addressed immediately. Regular testing and inspection of the air compressors, gauges, valves, and pipes are essential to ensure the system is working as intended. By taking these steps, you can rest assured that your dry sprinkler system is ready to protect you and your property in case of a fire emergency.

Regular Maintenance

Regular maintenance is essential to keeping your equipment and machinery in top condition. It’s a way to ensure that everything is running smoothly, and to prevent any unexpected breakdowns or failures.

Maintenance involves regular inspections and checks to identify any issues or potential problems and taking appropriate action to fix them before they become bigger issues.

As a business owner or operator, it’s crucial to have a comprehensive maintenance plan in place to ensure that your equipment is always performing at its optimal level. This includes everything from regular oil changes and filter replacements to a more detailed inspection of various components and systems.

By investing the time and resources needed for regular maintenance, you can extend the lifespan of your equipment, reduce downtime and repair costs, and increase the overall efficiency and productivity of your operation.

In other words, regular maintenance is essential for keeping your business running like a well-oiled machine. If you’re not sure where to begin with your maintenance plan, consider consulting with a professional who can provide you with guidance and recommendations on the best practices for your specific equipment.

Remember, prevention is always better than cure, and regular maintenance can help you avoid costly repairs and unexpected downtime.

Give your equipment the attention it needs and deserves, and it will repay you with years of reliable service.

Inspections and Testing

When it comes to ensuring the longevity of your equipment, regular maintenance and inspections are key. By implementing a maintenance schedule and conducting regular inspections, you can identify potential issues early on and prevent costly breakdowns.

These inspections can include checking for leaks, proper lubrication, adjusting belts and pulleys, and ensuring all safety features are functioning properly.

Additionally, testing can be conducted to assess equipment performance and identify any necessary repairs or upgrades. By taking a proactive approach to maintenance and inspections, you can extend the life of your equipment and avoid unexpected downtime. So don’t overlook the importance of regular upkeep – it can save you time and money in the long run.

Conclusion

In conclusion, a dry sprinkler system works by combining the power of compressed air and the precision of a sprinkler head. Like a trusty superhero duo, these two elements work together to detect and combat fires, helping to protect buildings and their occupants. With speed, efficiency, and a touch of aerodynamic ingenuity, dry sprinkler systems prove that sometimes, the best defense is a good offense.

FAQs on Dry Sprinkler System

What is a dry sprinkler system and how does it work?

A dry sprinkler system is a type of fire suppression system that uses pressurized air instead of water to put out fires. The system is pre-loaded with compressed air that holds a valve closed. When a fire is detected, the air pressure drops and the valve opens, releasing water into the sprinkler system pipes and extinguishing the fire.

How is a dry sprinkler system different from a wet system?

A wet sprinkler system is constantly filled with pressurized water, whereas a dry system is filled with pressurized air. In a wet system, the water is always present in the sprinkler piping and will discharge immediately upon activation, while in a dry system, the water must first be released from a valve.

What kind of buildings are dry sprinkler systems suited for?

Dry sprinkler systems are particularly useful in buildings where it may be difficult to keep the pipes from freezing in cold temperatures. This makes them ideal for use in unheated warehouses, garages, or storage facilities.

Are there any disadvantages to using a dry sprinkler system?

One potential disadvantage of a dry sprinkler system is that there is a delay between detection of the fire and activation of the sprinkler heads, since the valve must first release the water. Additionally, dry systems require more maintenance than wet systems to ensure that the valves are kept in good working order.

How do you maintain a dry sprinkler system?

Regular inspections of the dry sprinkler system should be performed to ensure that there are no blockages in the piping or leaks in the valve system. In addition, the air pressure in the system should be checked and recorded regularly to ensure that it is within a safe range.

Can a dry sprinkler system be used in conjunction with a wet system?

Yes, it is possible to combine a wet and dry sprinkler system in the same building. This is often done in larger buildings, with the wet system being used in areas where the potential for fire is higher and the dry system in less critical areas.

What kind of fire hazards is a dry sprinkler system best suited to handle?

The dry sprinkler system is particularly effective at suppressing fires caused by flammable liquids or gases, which can be difficult to extinguish with water alone. The release of water in these situations can actually cause the fire to spread, making the compressed air used by a dry system a better choice for such environments.