How to Rebuild Air Ratchet: A Step-by-Step Guide to Reviving Your Tool

Are you tired of spending money on new air ratchets every time your trusty tool starts to lose power? Don’t throw it away just yet! With a little know-how and some basic tools, you can easily rebuild your air ratchet to its former glory. In this step-by-step guide, we’ll walk you through the process of disassembling, cleaning, and reassembling your air ratchet. From replacing worn-out seals to lubricating moving parts, our guide covers all the essential steps you need to know to get your tool working like new again.

So grab your toolbox and let’s dive in!

Gather the Necessary Tools and Parts

When it comes to rebuilding your air ratchet, you’ll need a few essential tools and parts to get the job done right. Firstly, you’ll need a ratchet rebuild kit that includes essential components, such as bearings, seals, and gaskets. Additionally, you’ll need a socket set and wrenches, screwdrivers, pliers, and a clean cloth.

It’s crucial to ensure that you have the right size and type of tools to prevent any damage to the ratchet during the rebuild process. If you’re uncertain, consult the manufacturer’s guide or a professional mechanic. Overall, having the necessary tools and parts for the rebuild ensures that the job is done efficiently and cost-effectively, avoiding any extra expenses.

Examples: ratchet rebuild kit, lubricating oil, screwdriver, pliers

When it comes to fixing or maintaining your ratchet, having the right tools and parts is essential. One of the first steps you should take is to gather the necessary tools and parts that you’ll need for the job. If you’re rebuilding your ratchet, you’ll likely need a ratchet rebuild kit, which includes all the essential parts like pins, pins rings, and pawls that you’ll need to replace.

It’s also important to have lubricating oil on hand to make sure everything runs smoothly. A screwdriver and pliers are also essential tools that you’ll need to get the job done. Additionally, it’s important to make sure that you have the right size and type of screwdriver and pliers, as this can make all the difference in completing the job without damaging anything.

By gathering the right tools and parts before you start, you’ll be prepared to tackle your ratchet repair project with confidence and ease.

Disassemble the Ratchet

If you want to rebuild your air ratchet, you need to know how to disassemble it properly. Begin by disconnecting the air hose and draining any air left in the ratchet. You’ll need to remove the retaining ring, so use a pair of snap-ring pliers to do that.

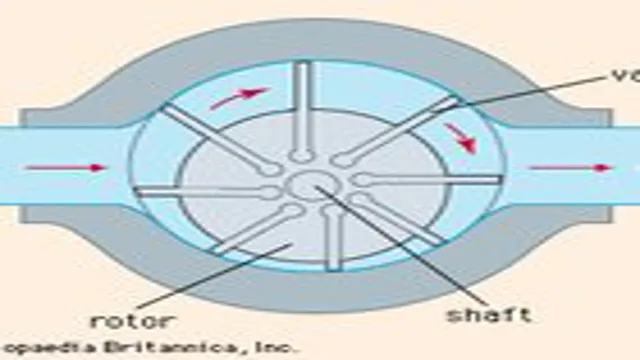

Once you’ve done that, carefully pull out the head assembly. Be sure to pay attention to how the pieces fit together so you can put them back in the correct order. Then, remove the rotor and vanes and inspect them for any signs of wear or damage.

You can also clean them with a solvent and a brush. After that, you can remove the rest of the pieces and inspect them. Look for any damage or wear and replace any parts that need it.

Once everything is clean and in good condition, you can begin reassembling your ratchet.

Examples: remove the drive head, clean and inspect each component

If you ever find yourself needing to disassemble a ratchet, it’s essential first to remove the drive head. Once you’ve done that, you can clean and inspect each component thoroughly. Disassembly can help you troubleshoot any problems with your ratchet and perform necessary maintenance.

You may need to use a few basic tools like a hammer, pliers, and a socket wrench to get the job done. It’s important to work slowly and carefully to avoid damaging the ratchet or any of its components. Before you attempt disassembly, be sure to consult the manufacturer’s manual to see if there are any specific instructions you should follow.

This method of disassembling the ratchet will ensure that you get a more in-depth look at each piece, ensuring it’s working correctly.

Replace Damaged or Worn Parts

If you want to rebuild your air ratchet, the first step is to replace any damaged or worn parts. This is essential for ensuring that the tool is functioning at its best. Take the time to carefully inspect all components, paying close attention to any signs of wear or tear.

Some common parts that may need to be replaced include the bearings, o-rings, and seals. These components play a critical role in ensuring that the ratchet operates smoothly and effectively. If you notice any wear or damage, it’s important to replace these parts as soon as possible.

This will help prolong the lifespan of your air ratchet and ensure that it remains a reliable tool in your workshop.

Examples: broken pawls, corroded springs, damaged gaskets

When it comes to maintaining your equipment, one of the most important things to keep in mind is replacing damaged or worn parts. This is particularly important when it comes to smaller components like pawls, springs, and gaskets, which may not seem like a big deal individually, but can cause major problems if left unreplaced. For example, a broken pawl can prevent your equipment from operating properly, while a corroded spring may cause it to fail unexpectedly.

Similarly, a damaged gasket can lead to leaks, reducing the efficiency of your equipment and potentially causing damage or safety issues. By regularly inspecting your equipment and replacing any damaged or worn parts, you can help ensure that it continues to operate properly and safely over the long term. So, whether you’re performing routine maintenance or responding to a specific issue, be sure to take the time to check your equipment for signs of wear and tear and replace any parts as needed.

Your equipment – and your bottom line – will thank you for it!

Clean and Lubricate Components

If you are trying to rebuild an air ratchet, cleaning and lubricating the components is essential for its optimal functioning. Disassemble the tool and use a cleaning solution to remove any dirt, grime, or rust from the parts. You can use a toothbrush or a wire brush to scrub some of the smaller components.

Make sure to dry the components thoroughly before applying the lubricant. A high-quality lubricant will protect the moving parts, reduce friction and prevent wear and tear. Don’t over-lubricate the air ratchet as it can attract dirt and debris, ultimately damaging the components.

By keeping your air ratchet clean and lubricated, you can ensure that it will last for a long time and operate smoothly.

Examples: use cleaning solution and lubricating oil for maximum performance

Clean and lubricate your components regularly to ensure maximum performance. One of the most important factors in keeping your machinery running smoothly is ensuring that all of the parts are clean and properly lubricated. Cleaning the components removes any dirt, debris, or built-up residue that may impede their performance, while lubricating them ensures optimal movement and reduces friction between the parts.

To accomplish this, use a high-quality cleaning solution to thoroughly clean the disassembled components, taking special care to remove any dirt or debris from hard-to-reach areas. Once clean, apply a lubricating oil to all the moving parts, including joints, bearings, and other friction points to ensure optimal performance. Properly cleaning and lubricating your components not only helps to extend their lifespan, but also ensures that your machinery operates smoothly and efficiently.

Remember, a little bit of maintenance and upkeep can go a long way in ensuring the longevity and functionality of your equipment.

Reassemble the Ratchet

If you’re looking to rebuild your air ratchet, reassembling it can seem like a daunting task. However, with a bit of patience and attention to detail, it’s a straightforward process. First, make sure you have all the necessary parts, including the ratchet head, rotor assembly, vanes, and drive shaft.

Start by placing the rotor assembly into the ratchet head, followed by the vanes. Then, carefully insert the drive shaft into the assembly, ensuring it’s seated properly. Finally, secure the drive shaft with the retaining ring, and test the ratchet to make sure it’s working correctly.

With these steps, you’ll have your air ratchet back in action in no time!

Examples: follow manufacturer’s instructions and torque specifications

When reassembling a ratchet, it’s important to follow the manufacturer’s instructions and torque specifications. Taking a wild guess and trying to tighten the parts without any guidance can lead to improper reassembly. This can further lead to issues such as the ratchet not working properly or even damage to the tool.

To start with, go over the manufacturer’s instructions thoroughly. Check for any specific instructions related to the ratchet you will be reassembling. Look for any particular torque specifications that are necessary to tighten the parts in place.

These torque specifications are essentially the amount of force that needs to be applied to the bolts or screws when tightening. It’s essential to use the correct torque specifications because over-tightening the bolts and screws can result in the bolt shearing or the threads becoming stripped. On the other hand, under-tightening can result in the parts coming loose.

Once you have all the necessary instructions and tools, begin reassembling the ratchet carefully. One of the most important steps is to use a torque wrench to tighten the bolts and screws to the torque specifications stated in the instructions. This helps you to ensure that the parts are tightened enough without damaging them.

In summary, always ensure to follow the manufacturer’s instructions and torque specifications when reassembling a ratchet. Doing so will not only prevent damage to the tool but also ensure that it works effectively.

Test the Ratchet

If you’re tired of your air ratchet wrench that isn’t working correctly, it’s time to take action and rebuild it. The air ratchet is a tool that enables you to perform fast and efficient work with ease. However, over time, wear and tear can affect the tool’s performance, leading to jams or reduced power.

Rebuilding the air ratchet can save you money and make sure your tool is working at optimal performance. To begin rebuilding the ratchet, you should first test it to pinpoint any issues. To do this, connect the air tool to an air compressor and check the ratchet’s trigger action, torque, and speed.

Now that you’ve identified the problem areas, you can disassemble and clean all the parts, replacing any damaged or worn-out components. Once you’ve reassembled the tool, conduct another test to ensure that the ratchet is working correctly. Rebuilding an air ratchet may seem daunting, but it’s worth the effort to know that your tool is in top shape and ready for any job.

Examples: ensure smooth operation and proper torque delivery

When it comes to ensuring smooth operation and proper torque delivery, testing the ratchet is crucial. A ratchet is a handy tool used for tightening or loosening bolts and nuts. However, a faulty ratchet can lead to frustrating errors and delays in work.

Testing the ratchet involves checking that all the moving parts are in good condition and working correctly. It’s essential to ensure that the pawl engages the teeth properly to prevent slipping. Also, make sure that the torque setting is accurate to avoid over or under-tightening bolts or nuts.

Additionally, the handle should be comfortable to grip, allowing for maximum torque delivery without causing strain or fatigue to the hand. Testing the ratchet tool is crucial before using it to ensure that all the components are functioning as they should. By testing the ratchet, you can avoid errors or mishaps that could lead to unnecessary expenditures and delays.

Overall, regularly checking and maintaining all tools, including ratchets, is vital to ensure optimal performance and avoid work delays.

Conclusion and Maintenance Tips

Congratulations! You’ve successfully rebuilt your air ratchet and brought it back to life! It’s like giving CPR to a tool – you’ve breathed new life into it. And just like that, you’ve saved yourself money and extended the life of your trusty air ratchet. Remember, a little patience, a little know-how, and a lot of determination can go a long way.

Don’t be afraid to get your hands dirty and tackle the next DIY project on your list. Who knows, with the skills you’ve acquired from rebuilding your air ratchet, you might just become a DIY master!”

Examples: keep tools clean and lubricated for longer lifespan

tools, clean, lubricated, lifespan, ratchet When it comes to increasing the lifespan of your tools, keeping them clean and lubricated is one of the best things you can do. The ratchet, in particular, is a tool that can benefit greatly from proper maintenance. A ratchet is a type of wrench that works by allowing you to turn a bolt or nut in one direction, then automatically resetting to turn it again in the opposite direction without having to remove the wrench.

To test the functionality of your ratchet, start by inspecting it and cleaning off any dirt or debris. Then, apply a small amount of lubricant to the moving parts. Hold the ratchet handle firmly and pull the socket end in one direction.

The ratchet should turn freely in one direction and then catch and hold tight when turned in the opposite direction. If the ratchet is not working properly, it may be time to replace it or take it apart for further inspection and repairs. By regularly cleaning and lubricating your tools, you can keep them working smoothly and extend their lifespan.

FAQs

What are the common signs that indicate the need for a rebuild for an air ratchet?

Common signs that indicate the need for a rebuild for an air ratchet are slippage, reduced power, air leaks, and increased vibration.

How often do I need to rebuild my air ratchet?

The frequency of air ratchet rebuilds depends on the frequency of use and the operating environment. Typically, it is recommended to rebuild an air ratchet every 500 hours of use.

What is involved in a typical air ratchet rebuild?

A typical air ratchet rebuild includes disassembly, cleaning, replacement of worn or damaged parts, reassembly, and testing.

Can I rebuild my own air ratchet?

Yes, with the proper tools, knowledge, and experience, it is possible to rebuild an air ratchet. However, it is recommended that only experienced individuals attempt this process.

What tools do I need for an air ratchet rebuild?

The tools needed for an air ratchet rebuild include screwdrivers, pliers, wrenches, a socket set, a torque wrench, and an air compressor.

Where can I find replacement parts for my air ratchet rebuild?

Replacement parts for air ratchet rebuilds can be found at hardware stores, auto parts stores, and online retailers.

How can I prevent the need for frequent air ratchet rebuilds?

To prevent the need for frequent air ratchet rebuilds, it is important to follow the manufacturer’s maintenance guidelines, use the proper lubricants, and avoid exposing the tool to harsh operating conditions.