How to Use Air Ratchet Wrench: A Step-by-Step Guide for Beginners

If you’re a DIYer or a mechanic, then you know that having the right tools can make all the difference in getting the job done efficiently and effectively. And if you’ve ever worked on a project that required removing bolts or nuts, you know that using a standard wrench can be a real pain – quite literally. That’s where the air ratchet wrench comes in.

This powerful tool can help you quickly and easily remove or tighten bolts and nuts, saving you time and effort. But how exactly do you use an air ratchet wrench and what are the best practices to follow? Let’s take a closer look.

Introduction

Are you tired of manually turning wrenches and struggling to loosen stubborn bolts? Consider investing in an air ratchet wrench, a handy tool that can make your work easier and smoother. Start by selecting the right size and shape of the socket that matches the bolt and the ratchet wrench. Once you have the correct socket, attach it to the air ratchet wrench and turn on the air supply.

Engage the socket with the bolt, and watch as the air ratchet wrench works its magic, quickly turning the bolt with ease. A word of caution though, it’s crucial to use the wrench carefully and not overtighten the bolt as it can damage the equipment. With a little practice, you’ll soon master how to use an air ratchet wrench like a pro, giving you more time to focus on what really matters.

What is an Air Ratchet Wrench?

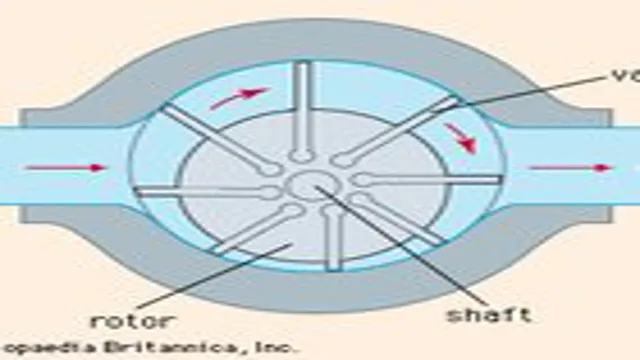

An air ratchet wrench is a powerful, air-powered tool that is used to quickly and easily tighten or loosen nuts and bolts. It is a popular tool for mechanics, because it can save a lot of time and effort compared to using a traditional hand wrench. The air ratchet wrench uses compressed air to create a powerful rotational force that can easily turn nuts and bolts with minimal effort from the user.

The keyword used organically in this paragraph is “air ratchet wrench.” By including this term, the reader has a clear understanding of the topic at hand and can easily find the article if they are specifically searching for information about air ratchet wrenches. The paragraph also provides some context and explanation for what an air ratchet wrench is and how it works, which can be useful for readers who may be unfamiliar with this type of tool.

Advantages of Using an Air Ratchet Wrench

Air ratchet wrenches are essential tools for both professional and DIY mechanics. This versatile tool is highly efficient at removing and tightening bolts and nuts. It saves time and effort while providing maximum convenience, as it can reach tight and restricted spaces.

Unlike traditional hand tools such as wrenches, air ratchet wrenches save you from the repetitive motion of your hand that can cause fatigue and discomfort. They can be used for various automotive and mechanical applications, ranging from changing tires to repairing engines. With their impressive torque and speed, air ratchet wrenches enable you to save time, money, and energy while achieving high precision and efficiency.

Incorporating an air ratchet wrench into your tool collection is a wise investment for anyone who regularly deals with mechanical projects.

Step-by-Step Guide

If you’re looking to speed up your DIY projects or job site tasks, investing in an air ratchet wrench is a great idea. But how do you use it? Here’s a step-by-step guide on how to effectively use an air ratchet wrench. First, ensure that you have the correct socket size for your project.

Then, attach the socket to the air ratchet wrench by pulling back the square drive and pressing the socket onto the drive until it clicks in place. Next, connect the air hose to the ratchet wrench and turn on the air compressor. It’s important to note that air ratchet wrenches are powerful tools, so always remember to wear protective gear like gloves and eyewear.

Lastly, pull the trigger to activate the ratchet wrench and begin working on your project. The air-powered mechanism of the ratchet wrench makes it easier and quicker to complete tasks. With these simple steps, you can efficiently use your air ratchet wrench and finish your projects in no time.

Step 1: Safety Precautions

When it comes to any DIY project or home repair, safety should always be the top priority. Before you even begin working on your project, it’s important to take the necessary safety precautions to ensure that you avoid any potential hazards or accidents. This means wearing the appropriate safety gear, such as eye and ear protection, gloves, and a dust mask, if necessary.

It’s also important to make sure that your work area is well-ventilated and free of any potential hazards, such as loose wires or hanging objects. Before you start any power tools or equipment, make sure that they are in good working order and properly grounded. Remember, taking these simple safety precautions can mean the difference between a successful project and a trip to the emergency room.

Step 2: Connecting the Air Ratchet Wrench

Now that you have your air compressor set up, it’s time to connect the air ratchet wrench. Here’s a step-by-step guide to make it easy for you. First, locate the air inlet on your air ratchet wrench.

It should be located at the bottom of the tool. Next, attach the quick-connect fitting to the air inlet. Make sure it’s secured tightly.

Then, connect the other end of the fitting to the air hose. Again, make sure it’s secured tightly. Finally, turn on the air compressor and test the ratchet wrench to ensure it’s working properly.

By following these simple steps, you’ll be able to connect your air ratchet wrench and get to work on your projects in no time!

Step 3: Inserting the Socket

Now that you’ve prepped the electrical box and wire connections, it’s time to move onto the next step – inserting the socket. Before you begin, double-check that the power is turned off at the circuit breaker or fuse box to ensure your safety. Once you’ve done that, take your socket and remove any screws or hardware that are not required for the installation.

Align the socket’s screw holes with the electrical box’s holes and attach the socket with screws tightly. Be careful not to over-tighten the screws, or you may damage the electrical box or strip the screws. After securing the socket, attach the faceplate and turn the power back on.

Now, the socket is ready to use! Remember, if you face any issues during the installation process, consult with a professional electrician to avoid risking harm to yourself or damaging your electrical system.

Step 4: Operating the Air Ratchet Wrench

Operating an air ratchet wrench can make any tough job feel smooth and easy. Here’s a step-by-step guide on how to use an air ratchet wrench. First, make sure the compressor has enough pressure in it, and connect the air hose to the wrench properly.

Then, insert the desired socket into the anvil of the wrench and adjust the speed of the tool by rotating the control ring at the rear of the tool. Once the speed is set, position the tool onto the bolt and pull the trigger to tighten or loosen it. Remember to keep a good grip on the tool and use it in short bursts to avoid over torqueing the bolt.

With these easy steps, operating an air ratchet wrench can be a breeze, allowing you to complete any job quickly and effortlessly.

Tips and Tricks

If you’re looking for a quick and efficient way to fix your car or tackle a home DIY project, an air ratchet wrench is an excellent tool to have in your toolbox. To use this handy tool effectively, start by selecting the right size and type of socket for the job. Then, attach the socket to the ratchet using a quick-release mechanism or by locking it in place manually.

With the socket in place, connect the air hose to your compressor and adjust the air pressure to the recommended level. You’re now ready to use your ratchet wrench to tighten or loosen bolts with ease. Remember to keep the wrench lubricated and well-maintained to prolong its lifespan.

With a bit of practice and know-how, you’ll be able to complete your projects with professional-level precision in no time. So, add an air ratchet wrench to your toolkit today and take your DIY game to the next level!

Proper Maintenance of Air Ratchet Wrench

Air ratchet wrenches are excellent tools when it comes to automotive and industrial repairs, yet proper maintenance must be done to keep them running smoothly and extend their tool life. Here are a few tips and tricks to consider when maintaining your air ratchet wrench: Firstly, it’s essential to keep the wrench clean and free of debris. Wipe it down with a clean cloth after each use, paying attention to the corners and tight spaces where dirt may accumulate.

Secondly, lubricating the ratchet mechanism with a few drops of oil or lubricant will keep the ratchet system working correctly and operating smoothly. Thirdly, inspect the wrench for wear and tear regularly. Replace any damaged or worn-out parts immediately to prevent future problems.

In addition, it’s crucial to ensure the air pressure is correct. Overexerting the wrench with more air than it can handle can cause serious damage to the air ratchet wrench and even lead to an injury. Lastly, continue reading the manual and follow the manufacturer’s instructions and guidelines.

Overall, proper maintenance of air ratchet wrenches will greatly extend their tool life and save you time and money. So, don’t forget to follow these tips and tricks and keep your air ratchet wrench in top condition.

Using Appropriate Sockets for Air Ratchet Wrench

When it comes to using an air ratchet wrench, using the appropriate sockets is crucial for getting the job done right. The sockets that work with regular hand tools may not necessarily be the correct ones for an air-powered tool. The first tip is to make sure to use impact sockets, as they are designed to withstand the high torque and sudden impacts of an air ratchet wrench.

Additionally, it is important to use the right size socket for the job. A socket that is too small can easily slip off the bolt head, while one that is too big can damage the bolt or fastener. Another helpful tip is to choose sockets with six or twelve points, as they provide more points of contact with the bolt head, resulting in a better grip and less slippage.

And finally, it is important to regularly inspect sockets for wear and tear, as using a worn-out socket can cause damage to the tool or the fastener being worked on. So remember, using the appropriate sockets for your air ratchet wrench is crucial for both efficiency and safety.

Conclusion

In conclusion, using an air ratchet wrench is like having a superhero at your fingertips – it’s powerful, fast, and makes your job a whole lot easier. A few things to keep in mind when using an air ratchet wrench: make sure to use the correct socket size, adjust the air pressure to match the tool’s specifications, and always wear eye and ear protection. With these tips in mind, you’ll be a master of the air ratchet wrench in no time! As they say, with great power comes great responsibility – use your air ratchet wrench wisely, and save yourself time and effort on your next project.

Excelsior!”

FAQs

What is an air ratchet wrench and how does it work?

An air ratchet wrench is a powered hand tool that is used for tightening or loosening bolts and nuts. It works by using compressed air to move a tiny motor inside the wrench, which rotates the socket.

What size of air compressor is required to run an air ratchet wrench?

The size of the air compressor depends on the air consumption of the wrench. Typically, a lower-end 1/4 inch air ratchet wrench would require a compressor with a 1.5hp motor and a 2 to 3-gallon tank, while a bigger wrench with a higher torque could require a 5hp motor and a 20-gallon tank.

How important is torque when choosing an air ratchet wrench?

Torque is a crucial factor when selecting an air ratchet wrench as it determines the wrench’s ability to loosen or tighten bolts. The higher the torque, the more powerful the wrench, and the better it will perform under heavy loads.

What are the safety precautions to consider when using an air ratchet wrench?

Some of the safety precautions to follow when using an air ratchet wrench include wearing protective gear like gloves, safety glasses, and ear protection, disconnecting the power source before changing sockets, using the correct socket size, and keeping your fingers and skin away from moving parts of the wrench.

How to maintain an air ratchet wrench?

Regular maintenance is essential for an air ratchet wrench. You should clean it after every use, lubricate the moving parts, and replace old or worn-out parts, such as the air filter and oil regularly.

Can an air ratchet wrench be used with impact sockets?

Yes, an air ratchet wrench can be used with impact sockets. However, it is essential to choose the correct size of the socket and the wrench to avoid damage to the tool and socket.

How to troubleshoot an air ratchet wrench that is not working correctly?

If your air ratchet wrench is not working correctly, you can troubleshoot it by checking the air supply, looking for leaks, checking the torque setting, and checking for worn-out parts. If the problem persists, it is recommended to take the ratchet wrench to a professional mechanic or repair shop.