How to Repair Air Ratchet: A Comprehensive Guide for DIY Enthusiasts

If you’re a mechanic or DIY enthusiast, then you probably understand the importance of having a reliable air ratchet in your arsenal of tools. But what happens when your go-to air ratchet breaks down, leaving you high and dry in the middle of a project? Don’t panic! In this blog post, we’ll show you how to repair an air ratchet so you can get back to work in no time. Whether it’s a simple fix or a more complicated repair, we’ve got you covered.

So grab your tools and let’s get to work!

Gather Necessary Tools and Equipment

When it comes to repairing an air ratchet, the first step is to gather all the necessary tools and equipment. This will ensure that you have everything you need to complete the job efficiently and effectively. Some of the essential tools you will need include a set of wrenches, a socket set, a screwdriver, and pliers.

Additionally, you will need a torque wrench to ensure that the ratchet is tightened to the correct level. It is also a good idea to have some lubricant on hand to clean and lubricate the ratchet parts. Overall, having all the necessary tools and equipment will make the repair process much easier and help to ensure that the ratchet is functioning properly.

So, before you begin repairing your air ratchet, take the time to gather everything you need and have it all at the ready, so you can tackle the job without any delays or complications.

Air ratchet repair kit

When it comes to repairing an air ratchet, having the right tools and equipment is crucial. To start with, you’ll need a repair kit specifically designed for your air ratchet model. It’s important to check the manual or do some research online to ensure you’re getting the right kit.

Along with the repair kit, you’ll need some basic tools like pliers, screwdrivers, and wrenches. Additionally, you’ll want to have a can of compressed air and some lubricant on hand. Keeping these tools and equipment on hand will not only help you repair your air ratchet quickly but also increase its lifespan.

So, before starting any repair work, make sure you have gathered the necessary tools and equipment to get the job done right.

Compressor

To start working with your compressor, you’ll need to gather the necessary tools and equipment. First and foremost, make sure you have safety gear such as eye protection, hearing protection, and gloves. You’ll also need an air hose to connect to your compressor, as well as any necessary adapters to ensure it fits properly.

Before using your compressor, you should always check the oil level and make sure it’s at its appropriate level. Additionally, tools such as air tools and pressure regulators may be needed depending on your specific project. By taking the time to gather all of the necessary tools and equipment, you can ensure a safe and successful use of your compressor.

Safety goggles

When it comes to using tools and equipment, safety should always be a top priority. This is especially true when handling power tools and volatile chemicals. That’s why wearing safety goggles should always be a must.

Safety goggles protect your eyes from flying debris, chemicals, and other hazards that could potentially cause blindness or other severe injuries. Before starting any project or task that requires the use of such tools and equipment, make sure to gather all the necessary items, including safety goggles. Keep them easily accessible and always put them on before starting any work.

It’s a small but critical step towards ensuring your safety and preventing accidents. Remember, your eyes are crucial to almost everything you do, so make sure to protect them with the right safety gear.

Rubber gloves

When it comes to using rubber gloves, it’s important to have the right tools and equipment on hand. First and foremost, you’ll need a good pair of gloves that fit you well and offer ample protection. Look for gloves made from high-quality latex or nitrile for the best results.

In addition to gloves, you may also want to consider using other tools to help you with your task. For example, if you’re cleaning a particularly tough mess, you might want to have a scrub brush or sponge on hand. Similarly, if you’re carrying heavy or bulky items, you might want to use a pair of tongs or other grippers to make the job easier.

With the right tools and equipment, using rubber gloves can be a breeze, no matter what your task may be.

Identify the Problem

If you’re having trouble with your air ratchet, the first step to repairing it is identifying the problem. A common issue with air ratchets is a lack of power or torque. This can be caused by a variety of factors, including a clogged air filter, worn gears, or a malfunctioning valve.

To diagnose the issue, start by checking the air filter for debris or dirt buildup. If the filter is clean, test the ratchet on a lower torque setting to see if it’s struggling. If it is, it may be necessary to replace the gears.

In some cases, the valve may need to be replaced as well. Once you’ve identified the problem, you can take the necessary steps to repair your air ratchet and keep it working effectively. With a little bit of know-how and some basic troubleshooting, you can have your air ratchet running like new in no time.

Check for air leaks

Identifying air leaks in your home is crucial in improving your energy efficiency and reducing monthly bills. The first step is to identify the problem areas. It could be as simple as feeling a draft around windows or doors, or noticing cracks and gaps in the walls.

It may even require a more in-depth inspection, such as checking for leaks in ductwork or around electrical outlets. Once you have located the issue, it is crucial to take action immediately, as even small leaks can result in significant energy loss over time. An easy and cost-effective solution is to use weatherstripping or caulk to seal the gaps and cracks.

Additionally, adding insulation to your home can also help to improve efficiency and reduce energy loss. With these simple steps, you can identify and correct air leaks in your home, ultimately saving you money and reducing your environmental impact.

Inspect the ratchet head

Inspecting the ratchet head is an essential step in identifying any problems with your tool. One common issue that can occur is when the teeth on the ratchet head become worn or damaged. This can cause the ratchet to slip or not engage properly, making it difficult to use and potentially dangerous.

To check for this issue, inspect the teeth on the ratchet head and look for any signs of wear or damage. If you notice any issues, it’s important to replace the ratchet head as soon as possible to prevent further damage and ensure your tool is working safely and effectively. By regularly inspecting the ratchet head, you can catch any problems early and keep your tool in top shape.

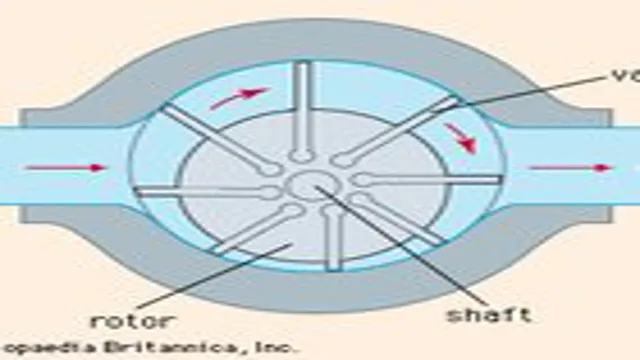

Examine the ratchet mechanism

The ratchet mechanism is an essential component of many tools and machines, including wrenches, jacks, and winches. However, this simple yet effective design can be prone to wear and tear over time. The problem often arises when the teeth of the ratchet become worn or damaged, preventing the mechanism from engaging and causing the tool or machine to malfunction.

Additionally, the ratchet may become jammed or stuck, leading to frustrating and potentially hazardous situations. To identify these issues, it’s important to thoroughly inspect the ratchet mechanism and its components for signs of damage or wear. Regular maintenance and lubrication can help prevent these problems from occurring in the first place.

By taking care of your tools and machines, you can ensure that they perform reliably and safely for years to come.

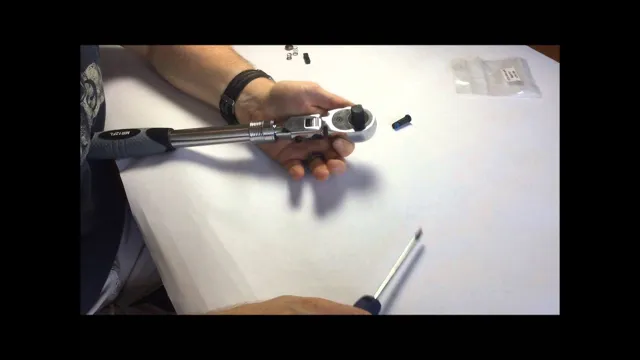

Disassemble the Ratchet

If you’re looking to repair an air ratchet, you’ve come to the right place! Disassembling the ratchet is the first step to diagnosing and fixing any issues. Start by finding the screws on the top and bottom of the ratchet and unscrewing them. Then, carefully remove the housing to expose the inner gears.

Pay attention to how everything is positioned and take pictures if needed. If there are any dirt or debris present, clean the parts thoroughly. If any gears are damaged or worn, you may need to replace them.

Don’t forget to lubricate the gears before reassembling everything. With a little patience and attention to detail, your air ratchet will be up and running in no time.

Unscrew the retaining ring

To disassemble the ratchet, the first step is to unscrew the retaining ring. This can be done by using a pair of pliers or a wrench to grip the ring firmly and turn it in a counterclockwise direction. Once the retaining ring is loose, it can be removed completely from the ratchet.

This will expose the internal components of the tool, including the pawl and the gear. From here, the ratchet can be taken apart further to clean or replace any damaged parts. It is important to pay close attention to the order in which the pieces are removed, so that they can be reassembled correctly later on.

With a little care and patience, anyone can disassemble a ratchet and make any necessary repairs or upgrades. So why not give it a try and see what you can accomplish with a bit of DIY spirit?

Remove the ratchet head

If you’re looking to disassemble a ratchet, the first step is to remove the ratchet head. This may seem daunting, but with a few simple steps, it can be accomplished in no time. First, locate the release switch on the ratchet head.

This is typically a small lever or button on the side of the head. Once you’ve identified the release switch, activate it by pressing or sliding it. This will disengage the ratchet mechanism and allow you to remove the ratchet head from the handle.

With the ratchet head removed, you can access and inspect the inner workings of the tool, or replace or repair any damaged components. Remember to be careful when handling any sharp or moving parts. By following these simple steps, you can easily disassemble your ratchet and keep it in good working condition.

Separate the socket retainer

To disassemble a ratchet, one of the first steps is to separate the socket retainer from the ratchet body. The socket retainer is the piece that grips onto the socket and holds it securely in place while in use. To begin, locate the small pin or button that is usually located somewhere near the socket retainer.

Depress or remove this pin to release the retainer from the ratchet body. Once the retainer is free, simply slide it off the ratchet and set it aside. Be sure to keep track of all the pieces and parts as you continue to disassemble the ratchet.

This is an essential step in taking apart the ratchet as it allows for easy access to the internal components of the tool. By separating the socket retainer, you can easily remove the socket and begin to investigate any issues or problems with the ratchet’s functionality.

Clean and Replace Parts

If you’re wondering how to repair your air ratchet, the first step is to clean and replace any worn-out parts. Over time, dirt and debris can build up in your ratchet, causing it to malfunction or wear down quicker than normal. To clean it, simply take apart the ratchet and use a soft cloth to wipe away any debris or grime.

If any of the parts look worn or damaged, it may be time to replace them. Check with the manufacturer for replacement parts or take it to a professional repair shop. By keeping your air ratchet clean and replacing any damaged parts, you’ll extend its lifespan and ensure it works properly when you need it most.

Clean the ratchet head and mechanism

When it comes to keeping your ratchet wrench functioning smoothly, it’s essential to keep the ratchet head and mechanism clean. Over time, dirt, debris, and rust can build up, causing your wrench to wear down faster or get stuck when you need it most. Fortunately, cleaning your ratchet wrench is a simple process that can help you keep it functioning correctly for years to come.

First, make sure you remove any visible debris or rust from the ratchet head using a wire brush or stiff bristle brush. Next, you’ll want to use a degreaser or solvent cleaners to dissolve any stubborn build-up. Once clean, inspect the ratchet mechanism and replace any broken or worn-out components.

Make sure to use compatible replacement parts to ensure your ratchet wrench functions as intended. By following these simple steps, you can help ensure your ratchet wrench is ready to tackle any job you throw at it!

Inspect and replace broken or worn parts

When it comes to the maintenance of your appliances, it’s important to inspect and replace broken or worn parts to ensure that they remain in good working order. Cleaning and replacing parts may sound like a daunting task, but it can be quite simple and straightforward. For example, if you have a refrigerator, you can clean the coils to ensure that they’re not clogged, and replace the water filter regularly so that the water you’re drinking is clean and safe.

Additionally, if one of your appliances is making strange noises or not functioning properly, it’s likely that a part needs to be replaced. It’s important to address these issues promptly to avoid causing further damage to the appliance, and to ensure that it continues to operate efficiently. By taking good care of your appliances and addressing any issues as soon as they arise, you can extend their lifespan and save yourself the expense of having to replace them prematurely.

So go ahead and inspect, clean, and replace any broken or worn parts to keep your appliances working like new!

Lubricate the new parts

When it comes to cleaning and replacing parts, don’t forget to lubricate the new parts. This helps to reduce friction and wear, allowing the parts to work smoothly and prolonging their lifespan. Lubricants come in various forms, such as oil, grease, and spray, and it’s important to choose the right one depending on the type of part and its intended use.

Apply the lubricant evenly and sparingly, using a clean cloth or brush to prevent any excess from building up and potentially causing problems down the line. By taking the time to lubricate your new parts properly, you’ll be helping to ensure optimal performance and preventing unnecessary wear and tear, ultimately saving you time and money.

Reassemble the Ratchet

After successfully disassembling your air ratchet, it’s time to reassemble it. Start by placing the pawl back into the ratchet head and ensuring it’s secure. Next, attach the ratchet gear by sliding it onto the square drive shaft until it clicks into place.

Make sure to line up the grooves on the ratchet gear with the grooves on the shaft. Then, insert the spring back into the ratchet head and position the anvil over it. Secure the anvil with the retaining ring by pressing it down firmly onto the anvil until it clicks into place.

Double-check all the parts to make sure they’re correctly aligned and seated before testing your reassembled air ratchet. Give it a test run to ensure it’s working correctly before use. With these steps, your air ratchet will be back in action in no time.

Reattach the socket retainer

Once you have successfully cleaned and lubricated the components of your ratchet, it’s time to reassemble it. One crucial step is to reattach the socket retainer. This part holds the socket in place, ensuring a secure grip on the nut or bolt.

Start by placing the retainer on the square drive of the ratchet and push it in place. Make sure it fits securely and is aligned correctly with the drive. Then use a small screwdriver or similar tool to press down the locking ball inside the retainer.

This will help keep the socket from slipping off while in use. With the retainer in place, you can now reattach the other components of the ratchet, such as the pawl and spring. Once everything is securely in place, give the ratchet a test spin to ensure it is working correctly.

Don’t forget to store it in a dry, cool place to protect it from rust and damage.

Replace the ratchet head

If you find that your ratchet head is worn out or damaged, don’t worry! It’s a straightforward process to replace it. First, you’ll need to disassemble the ratchet by removing the retaining pin with pliers. Once the pin is out, you can remove the old ratchet head and replace it with a new one.

Make sure that the new head fits securely onto the square drive and that you’ve tightened the retaining pin back into place. A good analogy for this process is changing a light bulb – it might seem intimidating at first, but once you know the steps, it’s a quick and easy task. By replacing the ratchet head, you’ll be able to get back to your DIY projects with ease and precision.

So go ahead and tackle that pesky ratchet problem like a pro!

Secure the retaining ring

Now that you’ve replaced the faulty part in your ratchet, it’s time to reassemble it. The next step is to secure the retaining ring in place. The retaining ring is responsible for keeping the components of the ratchet in place and maintaining the right amount of tension.

It’s important to make sure it’s installed correctly to prevent any accidents or malfunctions later on. To secure the retaining ring, slide it over the components and into the designated slot until you hear a clicking sound. This means that it’s locked in place and will not move around during use.

Make sure to test it out and ensure that everything is working smoothly and securely. Once you’re satisfied, you can move on to the next step in the process. Remember, taking your time during this process is key to ensuring a properly functioning ratchet.

Test the Repaired Air Ratchet

After repairing an air ratchet, it’s crucial to test it before putting it back to use. You don’t want to risk any accidents or injury, so this step is non-negotiable. First, connect the ratchet to the air supply, ensuring that the inlet is clean and clear of any debris.

Next, engage the trigger and listen for any unusual noises that may signal improper repairs. Make sure the ratchet’s speed and torque are in working order. You can do so by testing it out on a bolt or nut.

If it turns smoothly and without any problems, then your repairs were successful, and you’re good to go. Remember to take extra precautions when working with air ratchets and other power tools. Safety should always be a top priority.

Connect to the air compressor

Connecting to the air compressor is the next step in testing your repaired air ratchet. Make sure the air compressor is turned off before connecting it to the ratchet. Locate the air inlet on the ratchet and attach the air hose from the compressor to it securely.

Tighten any clamps or fittings to prevent air leaks. Turn on the air compressor and allow it to build up pressure. Once the desired pressure is reached, squeeze the trigger of the ratchet to ensure it is working properly.

If you hear any unusual noises or experience any issues, turn off the compressor and double-check your connections. With the air compressor connected, you can now thoroughly test your repaired ratchet before putting it back into use.

Turn on the compressor

To test your air ratchet after repair, the first step is to turn on the compressor. This ensures that your ratchet has enough supply of compressed air to function properly. Once the compressor is on, connect the air ratchet to the air hose, and tighten it properly.

Now, hold the ratchet and pull the trigger to start it. You should hear a smooth whirring sound indicating that the air ratchet is functioning correctly. If you notice any unusual sounds or feel any vibrations, it may indicate a problem with the repair.

You can try adjusting the air pressure or checking the connections but if the problem persists, it’s best to take it back to the repair shop. Testing your air ratchet after repair ensures its reliability and safety when you need it most.

Test the ratchet on a bolt

Let’s give that repaired air ratchet a real test! The best way to ensure a proper repair is to take it for a spin and see how it performs. One great way to do this is by testing it on a bolt. Make sure the bolt is tight, then attach the ratchet and give it a go.

With every turn, listen for smooth and consistent clicks from the ratchet. If there are any skips or slips in the mechanism, then there may still be an underlying issue that needs to be addressed. But if the ratchet works perfectly, you can rest assured that your repair job was a success! So, go ahead and give that ratchet a try – you might just be surprised by how well it performs.

Conclusion

In conclusion, repairing an air ratchet may seem daunting at first, but with a little know-how and elbow grease, anyone can get it back in working order. Just remember to take things apart carefully, keep track of all the little pieces, and don’t hesitate to consult online guides or forums for tricky repairs. With these tips, you’ll soon be a pro at fixing air ratchets and leaving your neighbors in awe of your mechanical prowess.

Just don’t be surprised if they start flocking to your doorstep with their own broken tools in need of repair!”

Tips to maintain your air ratchet

After repairing your air ratchet, it’s important to test it out before putting it back to work. This will help ensure that all of the repairs were successful and that the tool is functioning properly. To test your air ratchet, start by attaching it to an air compressor and testing the speed and torque on a scrap piece of material.

Make sure to listen for any unusual sounds or vibrations, as this could indicate that there’s still an issue with the tool. You should also check for any leaks in the air hose or connections, as this could affect the performance of the tool and potentially cause damage over time. By taking the time to test your repaired air ratchet, you can prevent any further damage or potential hazards while using the tool on future projects.

When to take your ratchet to a professional

When it comes to repairing your air ratchet, there are times you may want to consider taking it to a professional. One way to test if the repair job was successful is by checking the functionality of the tool after the repair. You can do this by using the ratchet on a test area, ensuring that it works properly and without hesitating.

If it seems like there are still issues, it may be best to take it to a professional who can provide a deeper diagnosis and ensure that the ratchet is in good working order. In conclusion, understanding when to take your ratchet to a professional can save you time and money in the long run, and testing the repaired tool can save you from future frustration.

FAQs

What are the common issues that can go wrong with an air ratchet?

Some common issues that can go wrong with an air ratchet include leaks, worn out parts, and lack of lubrication.

How do I know if my air ratchet needs repair?

You may notice decreased power, strange noises, or difficulty turning the ratchet. Additionally, if you notice any leaks or damage to the tool, it may need repair.

Can I repair my air ratchet myself?

It is possible to repair your air ratchet yourself if you have experience working with mechanical tools and the proper knowledge. However, it is often best to take your tool to a professional for repair to ensure it is fixed correctly.

What are some basic maintenance tips to keep my air ratchet in good condition?

Lubricate your tool regularly, clean it after each use, and store it in a dry, cool place. You should also inspect your tool for any signs of damage or wear.

How much does it typically cost to repair an air ratchet?

The cost of repairing an air ratchet can vary depending on the extent of the damage and the cost of replacement parts. It is best to get a quote from a professional to determine the cost of repair.

What should I look for when choosing a professional to repair my air ratchet?

Look for a reputable repair shop with experience repairing air ratchets. Additionally, check online reviews and ask for referrals from friends or colleagues.

Is it better to repair or replace my air ratchet?

It depends on the extent of the damage and the cost of repair. If the repair cost is significantly high, it may be more cost-effective to replace the tool altogether.