Air compressors are an essential tool in various industries, from automotive to construction. Compressors are used to increase the pressure of the air, making it ideal for powering pneumatic tools. However, to ensure the right amount of air pressure is delivered, a regulator is required.

But what exactly is an air compressor regulator, and how does it work? In this blog, we’ll explore the ins and outs of the air compressor regulator, discussing its function, components, and how to use it. Whether you’re a DIY enthusiast or a professional, understanding the air compressor regulator is essential to ensure you get the best results from your pneumatic tools and keep yourself safe while working. So, let’s dive in and learn all about the air compressor regulator.

What is an Air Compressor Regulator?

An air compressor regulator is a device that controls the pressure of air released from an air compressor. It works by reducing the pressure of the compressed air within the system to a level that is safe and appropriate for the intended use. When the air compressor is turned on, air begins to flow into the regulator, which features an adjustable valve that restricts or allows air to pass through depending on the desired level of pressure.

As the air passes through the regulator, it is filtered and measured, ensuring consistent pressure is released. By adjusting the valve within the regulator, users can customize the air pressure to meet their specific needs for everything from painting projects to powering tools. Overall, an air compressor regulator is an essential component in ensuring the safe and efficient use of compressed air in a variety of applications.

Definition

An air compressor regulator is a device used to control the air pressure that is released from an air compressor. It is an important component in any air compressor system because it allows the user to set the desired pressure level for their specific task. The regulator works by monitoring the pressure inside the air compressor tank and adjusting the airflow to maintain the desired pressure level.

This is accomplished by using a spring loaded valve to control the amount of air that is released. The regulator is typically located near the outlet of the air compressor and can be adjusted by turning a knob or adjusting a lever. By controlling the air pressure, the air compressor regulator ensures that all pneumatic tools and equipment operate at their optimal level, while also preventing damage to the equipment due to excessive pressure.

Whether you’re a mechanic in need of reliable tools, a carpenter, or a DIY enthusiast, an air compressor regulator is an essential component for your project.

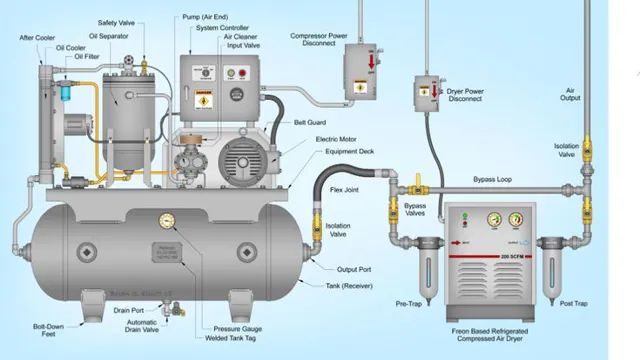

Components of an Air Compressor Regulator

If you’re wondering how an air compressor regulator works, it’s essential to understand its components. A regulator is an important part of your air compressor, and it controls the airflow, pressure, and temperature of the compressed air. The regulator consists of a pressure gauge, a pressure relief valve, a knob, and a diaphragm.

When the compressed air enters the regulator, it flows through the gauge, which displays the pressure. The diaphragm inside the regulator adjusts the pressure, depending on the knob position controlled by you, and the regulated air is ultimately released through the valve. The pressure relief valve functions as a safety measure and releases air if the pressure surpasses the limit.

In summary, the air compressor regulator works by regulating the pressure of the compressed air supply, ensuring consistent performance and safety.

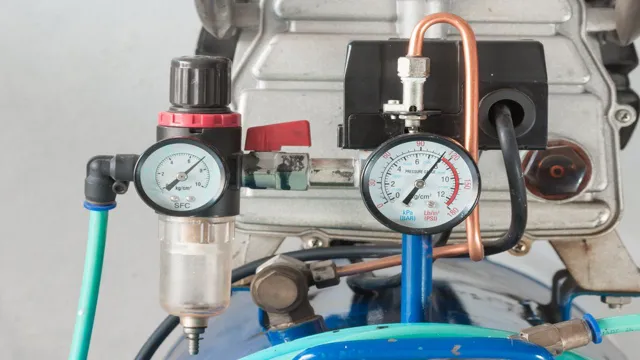

Pressure Gauge

As an essential component of any air compressor, the regulator serves as the key tool responsible for maintaining constant air pressure to ensure optimal performance. However, its functions can be even more effective with the addition of a pressure gauge. The pressure gauge is a critical component, which provides vital information to the user regarding the pressure levels produced by their air compressor.

This allows them to monitor the pressure constantly and adjust it accordingly using the regulator. With a pressure gauge, the user can make adjustments to the regulator to ensure a consistent and reliable supply of compressed air. As a result, the performance and longevity of the air compressor can be significantly improved.

So, if you want your air compressor to work efficiently and effectively, it’s essential to invest in a quality pressure gauge.

Control Knob

Air Compressor Regulator One of the most important components of an air compressor is the regulator. A regulator helps in regulating or controlling the airflow and pressure output of an air compressor. It is a vital component that ensures the compressed air output stays at a stable, consistent level.

A regulator consists of different parts, including the control knob, gauge, and diaphragm. The control knob is used to adjust the output pressure of the compressed air. It is situated on top of the regulator and is turned clockwise or counterclockwise to adjust the pressure.

The gauge provides a visual display of the output pressure and helps monitor the pressure while the compressor is in use. The diaphragm is a flexible, thin film that separates the high-pressure inlet and low-pressure outlet chambers of the regulator. It deflects inward or outward depending on the air pressure, allowing the air pressure to remain stable.

With a properly functioning regulator, you can ensure that your air compressor is working optimally and delivering the desired output pressure for your needs.

Diaphragm

The diaphragm is a small but crucial component of an air compressor regulator. It functions as a type of membrane that separates two halves of the regulator and helps regulate the amount of air that flows through it. As air enters the regulator, it first passes through the diaphragm, which responds to changes in pressure by expanding or contracting.

This movement then triggers a series of mechanisms that adjust the pressure levels and flow rate of the air being delivered. One way to think of the diaphragm is as a sort of gatekeeper, allowing the right amount of air to pass through depending on the demands of the situation. If there is too much pressure, the diaphragm expands to reduce the flow, while if there is too little, it contracts to allow more air to pass.

This continuous adjustment ensures that the air compressor provides a steady and reliable source of compressed air, making it an essential tool for countless industrial and commercial applications. Overall, while the diaphragm may seem like a small and insignificant part of an air compressor regulator, it plays a vital role in maintaining optimal performance and efficiency. Without it, the regulator would not be able to operate as intended, and the compressor would not be able to deliver the constant and reliable airflow necessary for many industrial processes.

Valve

Valve An air compressor regulator is an essential component that controls the air pressure flowing through the system. It’s highly advisable to know the parts of the regulator to diagnose and fix common issues like pressure drops, leaks, and malfunctions. A typical air compressor regulator consists of a valve, an air gauge, a diaphragm, a knob, and a manifold.

The valve is responsible for controlling the airflow by opening or closing the passageway to maintain consistent airflow and pressure flow rates. The air gauge measures the pressure inside the system to guide the valve’s operation and assess the compressor’s performance. The diaphragm acts as a controller by sensing the air pressure and changing the valve position to maintain the required pressure efficiently.

The knob adjusts the regulator’s pressure setting, allowing you to fine-tune the system’s output. Lastly, the manifold acts as a junction point for connecting the inflow and outflow pipes to the regulator. The regulator’s components are vital for ensuring stable and efficient air output while preventing any damage to the compressor, making air compressor regulators a necessary component in every air compressor system.

How Does an Air Compressor Regulator Work?

If you’ve ever used an air compressor, you may have noticed a device attached to it called an air compressor regulator. But have you ever wondered how it works? Essentially, an air compressor regulator controls the amount of air pressure that’s released through the air hose, which ensures that you’re not overloading any equipment or tools you’re using. It does this by using a spring-loaded valve that opens and closes depending on the amount of air pressure flowing through it.

As the valve closes, it restricts the flow of air and increases the pressure; as it opens, more air is released and the pressure decreases. This means you can adjust the regulator to achieve the perfect pressure for your specific needs, whether that’s inflating a tire or powering a pneumatic tool. The regulator also has a gauge that displays the current pressure, so you can monitor it throughout your use of the compressor.

All in all, an air compressor regulator is a crucial component that ensures the safety and efficiency of your air-powered tools and equipment.

Step by Step Explanation

An air compressor regulator is a vital component of any compressed air system, as it is responsible for maintaining a constant pressure of air in the system. Essentially, the regulator is a device that controls the output pressure of the compressor by regulating the amount of air that is released from the compressor tank. It achieves this by using a diaphragm and a spring inside the regulator, which works together to adjust the air flow.

When the pressure in the tank exceeds the set level, the diaphragm pushes the spring, which reduces the size of the valve opening, allowing less air to escape from the tank. The opposite happens when the pressure inside the tank is below the set level: the diaphragm moves the spring, which allows more air to flow out of the tank. This process continues until the pressure in the tank reaches the desired level.

In short, an air compressor regulator works by regulating the flow of air from the tank, ensuring a constant and consistent amount of pressure is maintained throughout the system.

Advantages of Using an Air Compressor Regulator

Understanding how air compressor regulator works can provide you with numerous benefits. One of such is the ability to control the pressure of the air flowing through your air tools. By ensuring that the air pressure is regulated, you can prevent damage to your equipment and avoid accidents.

Another advantage of using an air compressor regulator is that it provides consistency. Regulating the air pressure allows for constant and uniform air flow, which translates to improved performance and quality of work. Furthermore, an air compressor regulator can save you money by reducing the amount of compressed air that you use.

By adjusting the pressure to match your tools’ requirements, you can reduce energy consumption and extend the life of your equipment. Overall, understanding how an air compressor regulator works can help you achieve better results in your work, prevent accidents and equipment damage, and save you money in the long run.

Increase Efficiency

Without an air compressor regulator, managing the pressure of an air compressor can be a tedious and challenging task. An air compressor regulator helps increase efficiency by regulating the pressure of the compressed air used in various applications, such as filling up tires and powering air tools. The benefits of using an air compressor regulator are numerous, and they include improved precision, enhanced control over the compressed air supply, and reduced wear and tear on the compressor.

With an air compressor regulator installed, you can effortlessly adjust the air pressure according to your specific needs, ensuring consistent and accurate results every time. So, whether you’re a DIY enthusiast or a professional mechanic, investing in an air compressor regulator is a surefire way to increase efficiency and make your work easier.

Reduce Wear and Tear

An air compressor regulator can be an excellent tool to reduce wear and tear on your equipment. By controlling the pressure released by your compressor, you can reduce the stress placed on your tools and machinery, leading to a longer lifespan and less frequent maintenance needs. Additionally, a regulator can help improve the performance of your equipment by ensuring a consistent pressure output.

This can lead to smoother operation, more efficient energy usage, and higher quality results. Whether you’re a professional mechanic or a DIY enthusiast, an air compressor regulator is an investment that can pay off in the long run. So why not take advantage of this simple yet effective tool and keep your equipment running at peak performance?

Conclusion

In conclusion, an air compressor regulator is like the conductor of an orchestra. It sets the tone and controls the flow of air, ensuring that each instrument (tool) gets the right amount of pressure and operates at maximum efficiency. Without a regulator, the air compressor would be like a wild, free-flowing river, causing chaos instead of creating harmony.

So, think of the regulator as the maestro of your compressor and enjoy the sweet sound of perfectly controlled air flow.”

FAQs

What is an air compressor regulator and how does it work?

An air compressor regulator is a device that controls the amount of pressure that is released through the air hose. It works by adjusting the air pressure to the desired level.

Can I use any air compressor regulator with my compressor?

No, you need to make sure that you choose a regulator that is compatible with your compressor. Check the manufacturer’s specifications before purchasing a regulator.

How do I adjust the pressure on my air compressor regulator?

First, make sure that your compressor is turned off. Then, adjust the knob on the regulator to increase or decrease the pressure. Turn on the compressor to check the pressure and make further adjustments if necessary.

Does a higher pressure setting on my air compressor regulator mean more power?

No, a higher pressure setting does not equate to more power. It simply means that more air will be released through the hose at a higher pressure.

What happens if I set the pressure too high on my air compressor regulator?

Setting the pressure too high can damage the tools or equipment you are using, or even cause an unsafe working environment. It’s important to use the manufacturer’s recommended pressure settings.

Can I use an air compressor regulator for other tools besides an air compressor?

Yes, an air compressor regulator can be used for any tool that requires compressed air.

What should I do if my air compressor regulator is not working properly?

First, check the connections and make sure everything is properly tightened. If that doesn’t work, you may need to replace the regulator. Contact the manufacturer or a professional for assistance.