Welcome to the world of DIY enthusiasts and mechanics where having a reliable air compressor is an essential tool. Central Pneumatic’s air compressor is one of the most popular brands in the market today, favored by individuals and professionals alike. Whether you’re a beginner or a seasoned compressor user, operating your Central Pneumatic air compressor can be a tricky business.

That’s why we’re here to guide you through the process of how to use Central Pneumatic air compressor. The first thing to keep in mind when operating a Central Pneumatic air compressor is safety. Check your compressor regularly and examine the hose connections, power cords, and pressure gauges to ensure that they are securely in place.

Using protective gear like goggles and gloves is also imperative. Once safety is firmly in place, it’s time to turn your attention to the air compressor. Familiarize yourself with the different components, such as the air tank, regulator valve, and pressure switch.

Understand how the compressor’s cycle works, where it will fill the air tank, and then cut off once it has reached its maximum pressure capacity. Also, note that using the air compressor for long hours can lead to overheating, so ensure that the compressor isn’t operating for extended periods without rest. Maintaining the compressor is also an essential aspect of using it.

Change the oil, drain moisture regularly, and replace its air filter to keep it in good condition. With these basic instructions, you can efficiently operate your Central Pneumatic air compressor, ensuring that your DIY projects and professional assignments are done with precision. So why not give it a try and enjoy the efficiency, ease, and reliability of your compressor in your next project?

Introduction to Central Pneumatic Air Compressor

Using a Central Pneumatic air compressor is simple once you know the basics. The first step is to carefully read the user manual that comes with your unit. It will give detailed instructions on how to set up, operate, and maintain your compressor.

Next, make sure you have all the necessary accessories such as hoses, fittings, and tool attachments. Before you start it up, ensure that the compressor is in a well-ventilated area, away from any flammable materials, and is placed on a stable surface. To start it up, plug in the unit and turn on the power switch and the regulator.

Adjust the pressure regulator to your desired level, and then attach the pneumatic tool or accessory to the hose. When you’re finished using the compressor, turn off the power switch and then bleed the pressure from the tank using the relief valve. Regular maintenance of your Central Pneumatic air compressor will ensure its longevity and efficient operation.

By following these simple steps, you can safely and effectively use your Central Pneumatic air compressor for years to come.

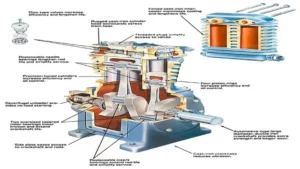

Understanding the Components of Central Pneumatic Air Compressor

Central Pneumatic Air Compressor If you’re in the market for an air compressor, you may have come across the Central Pneumatic brand. Central Pneumatic Air Compressors are popular among DIY enthusiasts and professionals alike for their reliability, affordability, and ease of use. But what makes up this reliable and efficient machine? A Central Pneumatic Air Compressor typically consists of a tank, motor, pump, and regulator.

The tank stores the compressed air, while the motor powers the machine and keeps the compressor pumping. The pump draws in air and compresses it, eventually delivering it to the tank. The regulator adjusts the pressure of the compressed air and controls the flow.

With all these components working harmoniously, it’s no wonder why Central Pneumatic Air Compressors are a preferred choice for many.

Preparing Your Air Compressor for Use

If you’re looking for an affordable and reliable air compressor, the Central Pneumatic air compressor is a great option. Before using it, it’s important to properly prepare the machine to ensure it works efficiently and safely. Start by checking the oil level and adding oil if needed, then connect the air hose securely to the compressor.

Make sure to adjust the regulator to the correct pressure for your project. It’s also a good idea to wear safety gear such as eye and ear protection to avoid injury. Always follow the manufacturer’s instructions for use and maintenance to keep your Central Pneumatic air compressor running smoothly for years to come.

By taking these simple steps, you can be confident that your compressor will be ready for any project you have in mind.

Operating Your Central Pneumatic Air Compressor

If you are using a Central Pneumatic air compressor for the first time, it’s important to follow a few key steps to ensure you get the most out of your machine. First, make sure you have a safe and secure location to operate your compressor. Next, check the oil level and add more if needed, making sure to only fill to the appropriate level indicated on the dipstick.

Connect your compressor to a power source and turn it on, allowing it to build pressure before you begin using it. When operating your Central Pneumatic air compressor, always wear appropriate safety equipment such as goggles and ear protection. It’s important to know the maximum pressure rating of your tools and to never exceed that pressure.

Remember to regularly maintain and clean your compressor to ensure it operates at peak performance. By following these simple steps, you can use your Central Pneumatic air compressor with confidence and efficiency.

How to Start and Stop Your Air Compressor

Starting and stopping your central pneumatic air compressor can seem daunting, but it’s actually quite simple. To start the compressor, plug it in, turn the pressure regulator knob counterclockwise to its lowest setting, close the tank drain valve, and turn the on/off switch to “on.” You will hear the compressor start running and building pressure in the tank.

Once the pressure reaches the desired level, use the regulator knob to adjust it accordingly. When you’re finished using the compressor, turn the pressure regulator knob counterclockwise to its lowest setting, open the tank drain valve, and turn the on/off switch to “off.” The compressor will shut off, and any remaining air will be released from the tank.

Always remember to properly maintain your compressor, including regularly checking the oil level and filter for any wear and tear. By following these steps, you can safely operate your central pneumatic air compressor and complete your DIY projects with ease.

Adjusting the Pressure and Flow Rate of Your Air Compressor

Operating a Central Pneumatic air compressor is a straightforward process, but there are a few factors to consider to ensure the machine is running correctly. One of the most important factors is adjusting the pressure and flow rate of the compressor. The pressure and flow rate determine the amount of air that the compressor can produce, so getting these correct is essential to ensure the machine is running at full capacity.

To adjust the pressure, you can use the regulator knob, which is typically located near the tank. Turning the knob clockwise will increase the pressure, and counterclockwise will decrease it. Adjusting the flow rate is similar, and it can be done using a flow control valve.

This valve restricts or allows air to flow into the compressor, affecting the rate of output. With the right pressure and flow rate, your Central Pneumatic air compressor will run smoothly and efficiently, providing an endless supply of compressed air for all your needs.

Using Your Air Compressor with Different Tools

Using an air compressor with different tools can seem overwhelming, but it doesn’t have to be. The most important thing is to first understand how to operate your central pneumatic air compressor. This involves checking the oil level, connecting the air hose, and adjusting the pressure regulator.

Once you have that down, you can easily switch between tools like a nail gun, impact wrench, or paint sprayer by adjusting the pressure and attaching the appropriate accessory. Keep in mind that not all tools require the same amount of pressure, so it’s important to refer to the tool’s manual for the manufacturer’s recommended settings. With a little bit of practice and patience, you’ll be able to confidently use your air compressor with any tool that comes your way.

Maintaining Your Central Pneumatic Air Compressor

If you want to keep your Central Pneumatic air compressor in top shape, it’s essential to follow some basic maintenance tips. Firstly, you’ll need to check the oil levels regularly and replace it every 500-1000 hours of use. It’s also important to drain the tank after each use to prevent moisture buildup, which can lead to rust and corrosion.

Make sure to clean or replace the air filter every three months to ensure that the compressor runs efficiently. Additionally, lubricate the compressor periodically, using a high-quality lubricating oil, and inspect the belts for wear and tear. By following these simple steps, you’ll extend the life of your Central Pneumatic air compressor and ensure its optimal performance.

So, if you’re wondering how to use a Central Pneumatic air compressor, be sure to keep these maintenance tips in mind and enjoy a powerful and reliable tool for years to come.

Regular Maintenance Tasks to Keep Your Air Compressor in Good Working Condition

Maintaining a central pneumatic air compressor is essential to ensure it runs efficiently and lasts longer. One of the regular maintenance tasks is to check the oil level and replace it as necessary. The oil helps lubricate the moving parts and prevents rust and corrosion.

Similarly, cleaning the air filter will help increase airflow and maintain peak performance. It’s also important to regularly drain any accumulated moisture from the tank to prevent rust and maintain the integrity of the compressor. Finally, inspect the hoses and connections for any signs of wear and tear, and replace them immediately to prevent leaks.

By taking these simple steps, you can keep your central pneumatic air compressor in good working condition, extend its lifespan, and save yourself from expensive repairs. Remember, prevention is always better than cure.

Troubleshooting Common Issues with Your Air Compressor

Maintaining Your Central Pneumatic Air Compressor Your central pneumatic air compressor is an essential tool that runs on compressed air to power various machines. It is essential to keep it well-maintained to get optimum performance, extend its lifespan, and avoid costly repairs. One of the most important things you can do is to change the oil regularly – about every 500 hours of use.

You should also check the air filters regularly and replace them when they’re dirty. Another common issue with air compressors is leakage. Leaks can occur in the hoses and fittings, causing a drop in air pressure and putting a strain on the compressor.

Be sure to inspect hoses and fittings frequently and replace damaged ones. Additionally, remember to drain the moisture from the compressor regularly to prevent rust and corrosion. By maintaining your central pneumatic air compressor, you can ensure its longevity and get the most out of your investment.

Conclusion and Final Thoughts

In conclusion, using a central pneumatic air compressor can be compared to playing a musical instrument. Just like a musician needs to know the right notes and techniques to create beautiful music, a user must know how to operate and maintain their compressor to produce a smooth and effective flow of air. With the right knowledge, tools, and attention to detail, you can obtain excellent results, impressing your friends, and not to mention making all your DIY projects a breeze.

So, let’s rock and roll and get started on those compressor projects!”

FAQs

What is a Central Pneumatic Air Compressor?

A Central Pneumatic Air Compressor is a type of air compressor that is commonly used for various tasks, from inflating car tires to powering pneumatic tools.

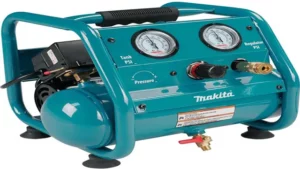

What are the different types of Central Pneumatic Air Compressors?

The different types of Central Pneumatic Air Compressors include portable compressors, ultra-quiet compressors, twin-tank compressors, and pancake compressors.

How do I set up a Central Pneumatic Air Compressor?

To set up a Central Pneumatic Air Compressor, start by reading the instruction manual that came with your specific model. Ensure that it is placed on a firm and level surface and that all the necessary connections are made.

What are the safety precautions I should take while using a Central Pneumatic Air Compressor?

Always wear safety goggles and ear protection when using a Central Pneumatic Air Compressor. Make sure to follow the manufacturer’s recommended operating pressure and avoid overloading the compressor.

How often should I perform maintenance on my Central Pneumatic Air Compressor?

The maintenance schedule for a Central Pneumatic Air Compressor will vary depending on the model and frequency of use. It is recommended to check for oil leaks, clean the air filter, and change the oil as needed.

How can I increase the lifespan of my Central Pneumatic Air Compressor?

To increase the lifespan of your Central Pneumatic Air Compressor, ensure that it is properly maintained, operated at the correct pressure, and stored in a clean and dry environment when not in use.

What are some common issues with Central Pneumatic Air Compressors and how can I troubleshoot them?

Common issues with Central Pneumatic Air Compressors include low pressure, leaks, and overheating. Troubleshoot these issues by checking for blockages, tightening connections, and ensuring that the compressor is not overloaded. If these steps do not resolve the issue, consult the instruction manual or contact customer support.