Got an air compressor lying around but don’t know what to do with it? How about creating a powerful vacuum pump with it? That’s right, with a few modifications and a bit of DIY ingenuity, you can turn your ordinary air compressor into a high-functioning vacuum pump that can tackle a variety of tasks, from extracting fluids and gases to powering machinery. In this blog post, we’ll guide you through the steps of building your own vacuum pump with an air compressor and discuss the materials and tools you’ll need to get started. Whether you’re a DIY enthusiast or a seasoned professional, creating a vacuum pump from an air compressor is a fun and rewarding project that will keep you engaged and productive.

So, put on your safety goggles, roll up your sleeves, and let’s get started!

Understanding the Basics

Have you ever wondered how to make a vacuum pump with an air compressor? Well, it’s actually quite simple! First off, you’ll need a few materials such as a check valve, hose clamps, and vacuum fittings to connect everything together. Next, disconnect the air compressor from its power source and from any hoses or tools it may be connected to. Then, attach the vacuum fittings and check valve to the compressor’s intake port.

Finally, attach the hose and hose clamps to the other end of the vacuum fittings and you’re almost ready to go! Just turn on the compressor and let it run until all of the air has been removed from the system. Congratulations, you’ve just made a vacuum pump with an air compressor! Remember to always exercise caution when working with air compressors and make sure to follow all safety guidelines.

How a Vacuum Pump Works

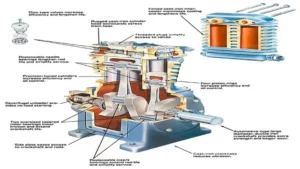

A vacuum pump is an essential piece of equipment across a wide range of industries. But how does it work? There are several types of vacuum pumps, but most work on the principle of creating a vacuum by removing air or other gases from a sealed chamber. This is achieved by using a rotor with vanes or blades that rotate, trapping and compressing the gas as it moves through the pump.

The compressed gas is then exhausted from the pump, creating a vacuum in the chamber. One particular type of vacuum pump, called a rotary vane pump, uses a series of sliding vanes that sweep air into and out of the pump through a series of rotating lobes. The lobes pull air in and compress it to create suction before it is released through an exhaust hole.

Understanding how a vacuum pump works can help you choose the right pump for your specific application, ensuring optimal performance. So, whether you need a vacuum pump for laboratory research, industrial manufacturing, or medical applications, knowing the basics can make all the difference in selecting the perfect pump for your needs.

How an Air Compressor Works

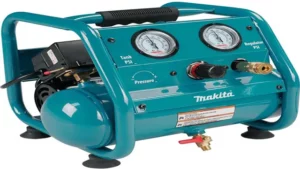

An air compressor is a versatile tool that uses air pressure to power a variety of tools and machines. It works by drawing in air and compressing it into a storage tank until it reaches a preset level of pressure. When you turn on a tool or machine that is connected to the compressor, the compressed air is released and used to power the device.

Understanding the basics of how an air compressor works is important if you want to choose the right type of compressor for your needs. The two most common types of air compressors are reciprocating and rotary screw compressors. Reciprocating compressors work by using pistons to compress air, while rotary screw compressors use rotating screws to compress air.

Regardless of the type of compressor you choose, it is important to make sure it has the right capacity to meet your needs. By knowing the basics of how an air compressor works, you can make an informed decision when choosing a compressor for your home or business.

Tools and Materials Needed

If you’re interested in making a vacuum pump with an air compressor, there are some tools and materials you’ll need to get started. First and foremost, you’ll need an air compressor that has a tank size of at least 10 gallons. You’ll also need a vacuum gauge to measure the level of vacuum, as well as a check valve to prevent air from flowing back into the system.

In addition, you’ll need a pressure relief valve to prevent pressure from building up too much, which can be dangerous. Other materials you’ll need include a vacuum pump oil, tubing, fittings, and a few other small items. Once you have all the necessary tools and materials, you can get started on building your vacuum pump with your air compressor.

Just make sure to follow the instructions carefully and take all necessary safety precautions to ensure that your pump works correctly and safely.

List of Required Tools

As you embark on a DIY project, it’s important to make sure you have all the necessary tools and materials. This ensures that you don’t hit any roadblocks down the line and that you’re able to complete the task at hand. Depending on the project, the tools and materials needed will vary.

However, some basic tools that you’ll need for most projects include a hammer, screwdriver set, pliers, measuring tape, level, and a utility knife. Additionally, you may need power tools such as a drill, saw, or sander for more advanced projects. It’s important to invest in high-quality tools that will last and get the job done efficiently.

Don’t forget to have safety equipment, such as gloves, safety goggles, and ear protection. By taking the time to gather all your necessary tools and materials, you’ll be setting yourself up for a successful and stress-free DIY project.

List of Required Materials

When it comes to starting a new DIY project, having the right tools and materials is essential. Depending on the project at hand, there may be specific tools and materials required to complete it successfully. For instance, if you are planning on installing new shelves, you will need a level, measuring tape, drill, screws, brackets, and the shelving material, such as wood or glass.

On the other hand, if you want to give your walls a fresh coat of paint, you will need paint, a paintbrush or roller, painter’s tape, a drop cloth, and a ladder. In summary, it is always wise to make a list of required materials before starting a DIY project. This way, you can ensure that you have everything you need before you begin, saving you time and frustration in the long run.

Step-by-Step Guide

Have you ever considered making your own vacuum pump with an air compressor? If you’re in need of a vacuum pump but don’t want to spend a lot of money, this might be the perfect solution. Here’s how to make a vacuum pump with an air compressor in just a few easy steps. First, you’ll need to gather the necessary materials including a check valve, a vacuum gauge, some tubing, and a vacuum chamber.

Next, you’ll need to attach the check valve to the compressor using some tubing. Then, attach the vacuum gauge to the check valve and connect the vacuum chamber to the gauge using more tubing. Finally, turn on the air compressor and let it run until the vacuum pressure reaches the desired level.

With just a little bit of effort and some basic materials, you can create your very own vacuum pump that will work just as well as any store-bought model. So why not give it a try?

Step 1: Preparing Your Air Compressor

Preparing your air compressor is the first step to ensuring that it runs smoothly and efficiently. To start, check the oil levels and add more if necessary. It’s also important to inspect any air filters present and clean or replace them as needed.

Then, make sure that all connections and hoses are secure and not damaged. Afterward, plug in your air compressor and let it run for a few minutes to warm up and allow the oil to circulate throughout the machine. This will help prevent damage to the compressor’s internal components when it’s in use.

By taking the time to properly prepare your air compressor, you’re setting yourself up for success later on. With these simple steps, you can make sure that your compressor will be running smoothly for years to come.

Step 2: Building the Vacuum Chamber

When it comes to building a vacuum chamber, one of the crucial steps is the construction of the chamber itself. To create an effective vacuum chamber, you’ll need a container that is airtight and able to withstand the pressure differences created by the vacuum. There are many different materials that can be used for the construction of a vacuum chamber, such as stainless steel, glass, or acrylic.

Once you’ve chosen your material, the next step is to cut it to size and shape it to fit your needs. After that, you’ll need to add the necessary ports, such as a vacuum port and a vent valve, as well as any additional features you require. Finally, seal off the chamber to make sure it is air-tight and ready to use.

By following these steps, you’ll be able to construct an effective and reliable vacuum chamber that can be used for a variety of different applications.

Step 3: Connecting the Vacuum Chamber to the Air Compressor

Once you’ve assembled your vacuum chamber, it’s time to connect it to your air compressor to begin the vacuum process. But where do you start? Don’t worry, we have you covered with this step-by-step guide! First things first, make sure that the air compressor is unplugged before you begin. Next, locate the air inlet on your vacuum chamber.

This is where you’ll connect the hose from your compressor. Attach the hose to the air inlet and tighten it securely. Once the hose is attached, turn on your air compressor and adjust the pressure to the recommended level for your vacuum chamber.

Your vacuum chamber manual should have this information. Now you’re ready to begin your vacuum process! It’s important to note that not all vacuum chambers will connect to an air compressor in the same way. Always refer to your specific vacuum chamber manual for instructions on how to properly connect your air compressor.

And remember to use caution and follow all safety guidelines when working with air compressors and vacuum chambers. Connecting your vacuum chamber to your air compressor is a crucial step in the vacuuming process. By following these simple steps, you can ensure a successful and efficient vacuum each time.

Happy vacuuming!

Step 4: Testing the Vacuum Pump

When it comes to testing your vacuum pump, it’s important to take it one step at a time. This step-by-step guide can help you make sure that your pump is working properly and efficiently. First, start by checking all of the hoses and connections to ensure that there are no leaks.

Next, turn on the pump and make sure that it is pulling a strong vacuum. You can test this by using a vacuum gauge or by placing your hand over the end of the hose and feeling for suction. Additionally, check the oil levels and make sure that they are filled to the recommended level.

This will help to ensure that your pump is running smoothly and won’t overheat. By taking the time to test your vacuum pump, you can ensure that it is working properly and effectively, which will ultimately help to extend its lifespan and save you money in the long run.

Safety Tips

If you’re looking for a quick and easy way to make a vacuum pump with an air compressor, there are a few things you need to keep in mind before you get started. Firstly, ensure that you have all the necessary components such as a vacuum gauge, a check valve, and a vacuum pump oil. Secondly, make sure that your air compressor is compatible with the vacuum pump as this will ensure that it can create enough pressure to generate a vacuum.

It’s also important to remember that the process of creating a vacuum can be dangerous and therefore it’s important to wear protective gear such as gloves and goggles. Lastly, ensure that you follow all safety instructions and keep the area well-ventilated to avoid any unwanted accidents. With these tips in mind, making your own vacuum pump with an air compressor should be a breeze!

Wearing Proper Gear

When it comes to motorcycle riding, wearing proper gear is a must. The right gear can mean the difference between life and death in the event of an accident. Firstly, helmets are essential for protecting your skull and brain from injury.

It’s important to choose a helmet that fits correctly, as a poorly fitting helmet could come off during an accident. Secondly, protective clothing like jackets, pants, and gloves provide protection for your skin. Leather is a popular material as it’s durable and resistant to abrasions.

Boots should also be worn to protect your feet and ankles. It’s important to make sure your gear is up to date and in good condition, as worn or outdated equipment may not provide adequate protection in the event of an accident. Remember, safety should always come first when riding a motorcycle.

Avoiding Electrocution

When it comes to avoiding electrocution, safety should always be your top priority. There are a few key tips to keep in mind that can help you stay safe around electricity. First and foremost, avoid touching any electrical equipment or outlets with wet hands.

Water can conduct electricity and increase your risk of electrocution. Additionally, make sure to unplug any appliances or tools before attempting to clean or repair them. It’s also important to keep electrical cords in good condition, avoiding any frayed or damaged wires.

Finally, if you’re not sure how to safely handle electrical equipment, don’t hesitate to contact a professional for help. By following these simple tips, you can minimize your risk of electrical accidents and stay safe around electricity.

Conclusion

In conclusion, making a vacuum pump with an air compressor is a cost-effective and practical solution for those who need to create a vacuum in their projects without breaking the bank. With a few simple steps and some basic tools, turning your air compressor into a vacuum pump is a breeze! So why spend a fortune on expensive equipment when you can DIY it with just a little bit of ingenuity and know-how? Trust us, with your newly created vacuum pump, you’ll be able to create a vacuum just as quickly as you can say “suction power!”

FAQs

What is a vacuum pump and how does it work with an air compressor?

A vacuum pump is a device that removes gas molecules from a sealed chamber to create a vacuum. When used with an air compressor, the compressor provides the necessary pressure to create the vacuum.

Can any air compressor be used to make a vacuum pump?

Yes, any air compressor that can reach a minimum pressure of 90 psi can be used to convert it into a vacuum pump.

What are the materials needed to make a vacuum pump with an air compressor?

The materials needed include an air compressor with a tank, a vacuum attachment or chamber, piping, valves, gauges, and fittings.

Is it possible to control the level of vacuum created with the air compressor?

Yes, the level of vacuum can be controlled with the use of a vacuum gauge and a valve to regulate the airflow.

How can the vacuum pump be used in different applications?

The vacuum pump can be used for a variety of applications such as fluid transfer, degassing, vacuum forming, and air conditioning systems.

Can the vacuum pump be used for medical or laboratory purposes?

Yes, vacuum pumps are commonly used in medical and laboratory applications for tasks such as suctioning fluids, filtering and drying samples, and vacuum distillation.

What are the advantages of making a vacuum pump with an air compressor?

The advantages of making a vacuum pump with an air compressor include cost-effectiveness, versatility, and the ability to easily adjust the level of vacuum created.