Are you tired of your air compressor constantly shutting off or not reaching its full potential? One area that often gets overlooked is the unloader valve. This small but essential part of your compressor ensures that air is released from the compressor pump when it shuts off, preventing damage to the motor and the rest of your machine. However, over time, wear and tear can cause the valve to become misadjusted, resulting in frustrating performance issues.

But fear not! With a few simple steps, you can learn how to adjust the unloader valve on your air compressor and keep your machine running at its best. So, put on your DIY hat and let’s dive in!

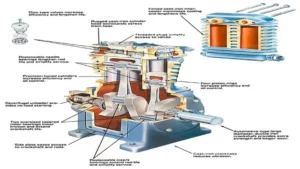

What is an Unloader Valve?

If you have an air compressor, you may have heard of an unloader valve. But what is it exactly? Well, the purpose of an unloader valve is to prevent the compressor from starting under load. This means that when you turn on your compressor, the unloader valve releases the pressure that has built up in the air compressor head, so it can start easily.

In other words, it takes the load off the motor, allowing it to turn over more easily. If you want to adjust the unloader valve on your air compressor, you will need to locate it first. It is typically found near the pressure switch and looks like a small brass nipple.

To adjust it, loosen the lock nut and turn the adjustment screw clockwise to increase the pressure setting or counterclockwise to decrease it. Just be sure to consult your air compressor manual before making any adjustments to ensure you don’t cause any damage.

Definition and Function

An unloader valve is a relief valve that is used in positive displacement pumps to regulate the flow of fluids and prevent the pump from stalling. It works by releasing the pressure generated by the pump when it is not in use or when the flow rate is low. This prevents the build-up of pressure that can damage the pump, and also reduces the energy consumption of the system.

In simple terms, an unloader valve is like a safety valve that prevents the pump from overworking and prolongs its lifespan. If you compare it to a traffic light, the unloader valve acts like the green light that regulates the flow of cars to prevent congestion and accidents. Overall, an unloader valve is an essential component of any positive displacement pump system, as it ensures smooth and efficient operation while protecting the pump from damage.

Why Adjust the Unloader Valve?

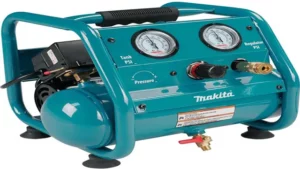

“How to Adjust the Unloader Valve on Your Air Compressor for Optimal Performance” If your air compressor suddenly shuts off or fails to maintain constant pressure, you may need to adjust the unloader valve to correct the problem. The unloader valve is designed to release any trapped air in the compressor’s cylinder and discharge tube when the unit is turned off, preventing damage to the equipment and regulating pressure. To adjust the unloader valve, start by turning off and unplugging the compressor and removing any valves or fittings that connect the air supply line.

Next, locate the unloader valve, which is typically located near the pressure switch or pressure gauge. Use a wrench to adjust the nut or bolt on the unloader valve to change the activation point and ensure that the valve opens and closes properly. Finally, test the unit by turning it on and monitoring its pressure levels to ensure optimal performance.

With proper maintenance and adjustments to the unloader valve, your air compressor can function efficiently and protect you from any safety hazards.

Signs that You Need to Adjust It

The unloader valve is a crucial component in the functioning of a pressure washer. It releases pressure when the trigger of the spray gun is released, preventing the motor from overloading. However, with time and use, the unloader valve may require adjustments.

Signs that indicate an adjustment is needed include irregular water flow, pressure drops, and a pulsating spray. If these issues are not addressed, they can cause damage to the pressure washer’s motor and affect the overall efficiency of the device. Adjusting the unloader valve is a simple and straightforward process that involves making small modifications to the internal valve settings.

Regular maintenance of the unloader valve will ensure that your pressure washer continues to operate smoothly and efficiently. By adjusting the unloader valve, you can extend the life of your pressure washer, save on repair costs, and maintain consistent pressure levels during use.

Benefits of Proper Adjustment

The unloader valve is an important component of a pressure washer that regulates the water pressure by diverting excess water back to the pump. Unfortunately, this valve can become unadjusted over time, leading to a range of negative consequences. Not only does a poorly adjusted unloader valve result in inconsistent pressure output and reduced cleaning efficiency, but it can also cause damage to other parts of the pressure washer.

That’s why it’s crucial to periodically adjust the unloader valve to ensure that it’s working correctly. By doing so, you’ll benefit from more consistent water pressure, longer equipment lifespan, and improved cleaning results. Plus, by maintaining your pressure washer properly, you’ll avoid costly repairs and replacements down the line.

So, don’t overlook the importance of a well-adjusted unloader valve and make sure your pressure washer is performing at its best.

Steps to Adjust the Unloader Valve

Adjusting the unloader valve on an air compressor can help prevent damage to the motor and increase the lifespan of your unit. The first step is to turn off the compressor and relieve all pressure by pulling the release valve. Then, locate the unloader valve on your compressor and take note of its current setting.

To adjust the valve, use a wrench or pliers to turn it in either direction until you hear a hissing sound. This means that air is being released from the system. Keep turning the valve until the hissing stops, indicating that the valve is now properly adjusted.

Remember to test your compressor to ensure that it starts and stops correctly, as well as to check the pressure it produces. With these simple steps, you can easily adjust your unloader valve and keep your air compressor operating at its best.

Step 1: Turn Off the Air Compressor

If you’re looking to adjust the unloader valve on your air compressor, it’s important to start by turning off the machine altogether. This will not only keep you safe from potential accidents, but it will also prevent any unintended changes to the air pressure settings. Once the air compressor is off, locate the unloader valve and release any pressure that may be still inside the system.

This can be done by pulling the release ring or toggle on the valve. From there, you can adjust the pressure settings on the unloader valve, which will allow the compressor to turn off and on at the desired pressure level. It’s important to make sure that the settings are appropriate for your specific needs and that you test the machine’s performance after making any changes to the valve.

By following these steps, you’ll be able to safely and effectively adjust the unloader valve on your air compressor.

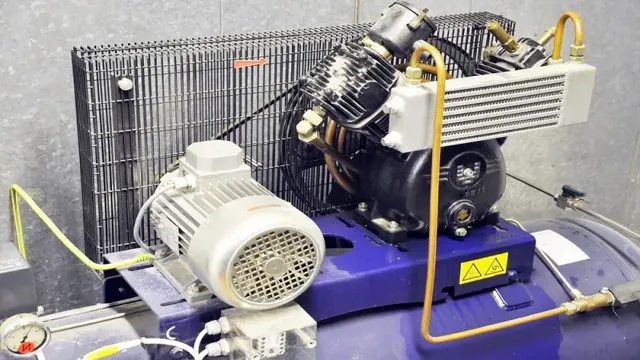

Step 2: Locate the Unloader Valve

Now that you’ve followed step one and turned off your pressure washer, it’s time to locate the unloader valve. This valve is typically located near the pressure regulator and is responsible for controlling the pressure output. Most pressure washers have a knob that you can turn to adjust the pressure output, and this knob is connected to the unloader valve.

To locate the valve, look for a small brass or steel tube that’s connected to the pressure hose. This tube is typically located near the pressure regulator, and you should be able to easily identify it by its size and shape. Once you’ve located the unloader valve, you can start adjusting it to get the desired pressure output.

Remember to be careful when adjusting the valve, as the pressure can build up quickly and cause damage if you’re not careful. With a little patience and practice, you should be able to adjust the unloader valve and get your pressure washer running smoothly again.

Step 3: Adjust the Unloader Valve

Adjusting the unloader valve is crucial for the smooth functioning of your pressure washer. Here are some simple steps to help you adjust the unloader valve effectively. Firstly, you need to locate the unloader valve, which is usually located near the pressure pump.

Once you have located it, turn off the pressure washer and remove the plug. Next, using a wrench, loosen the jam nut on the stem of the unloader valve by turning it counterclockwise. You can then adjust the pressure by turning the stem clockwise or counterclockwise.

If you want to increase the pressure, turn the stem clockwise, and if you want to decrease it, turn the stem counterclockwise. Once you have achieved the desired pressure, tighten the jam nut by turning it clockwise with the wrench. Now, replace the plug and turn on the pressure washer to make sure that the pressure is adjusted according to your requirements.

By following these simple steps, you can adjust the unloader valve effortlessly and ensure optimal performance of your pressure washer.

Step 4: Test the Unloader Valve

Adjusting the unloader valve is an essential step to ensure your pressure washer functions correctly. Testing the unloader valve during this process is vital to preventing system damage. To do this, you need to adjust the unloader valve to the pressure level recommended by the manufacturer.

First, you’ll need to tighten the unloader valve to the pressure washer’s maximum pressure. Start the pressure washer and note if the pressure drops significantly when the trigger is released. If it does, the unloader valve needs to be adjusted.

Take off the cap on the unloader valve and turn it clockwise to increase the pressure or counterclockwise to decrease it slowly. Continue adjusting until the pressure drop decreases and the pressure stays relatively constant when you release the trigger. That’s it! Your pressure washer is now correctly adjusted, and the unloader valve is in top condition.

Conclusion

Adjusting the unloader valve on your air compressor can be a daunting task, but with a few simple steps, it can be done quickly and easily. Just like a conductor fine-tuning the pitch of an orchestra, adjusting the unloader valve ensures that your compressor is functioning at its optimal level, producing the sweetest air sounds around. So go ahead, turn that unloader valve and listen to your compressor sing! Your ears and your air tools will thank you.

“

Summary of Key Points

If you own a pressure washer, it’s important to understand how to adjust the unloader valve. This critical piece of equipment is responsible for regulating water pressure, and an improperly adjusted valve can cause damage to both your machine and the surface you’re cleaning. Step one is to locate the unloader valve, which is typically found on the pump.

Next, turn off the pressure washer and relieve pressure by squeezing the trigger until water stops flowing. Adjust the pressure by turning the knob clockwise to increase pressure and counterclockwise to decrease pressure. Once you’ve achieved the desired pressure, turn the pressure washer back on and test it out.

Remember to make small adjustments until you achieve the proper pressure, and never force the valve beyond its intended pressure limit. By following these simple steps, you can ensure your pressure washer is working at its optimal capacity and ready to tackle any cleaning job.

Final Thoughts and Tips

Adjusting the unloader valve can often be a tricky task, but with the right steps, it can be done easily and effectively. First, start by locating the unloader valve, which can usually be found near the pressure switch. Once you’ve located it, turn off the pressure washer and release the pressure by pulling the trigger on the spray gun.

Next, remove the cap from the unloader valve and turn it clockwise to increase the pressure, or counterclockwise to decrease the pressure. It’s important to make sure you’re adjusting the pressure in small increments to avoid any damage to the pressure washer. Finally, test the pressure by turning the pressure washer back on and checking for any changes in the pressure.

If it’s still not at the desired level, repeat the process until you reach the desired pressure level. By following these simple steps, you can adjust the unloader valve on your pressure washer and ensure it’s working effectively for your next cleaning task.

FAQs

What is an unloader valve on an air compressor?

An unloader valve on an air compressor is a device that releases pressure in the discharge line of the compressor while the engine is idling or stopped.

Why do you need to adjust the unloader valve on an air compressor?

Adjusting the unloader valve on an air compressor can help prevent compressor damage and improve performance by controlling how much pressure is released during idling or stopping.

How do you know if the unloader valve on your air compressor needs adjusting?

Signs that the unloader valve on your air compressor needs adjusting can include excessive noise, pressure drops, and an inability to restart the compressor.

Can you adjust the unloader valve on any air compressor?

Most air compressors have adjustable unloader valves, but some models may not. Consult the owner’s manual or manufacturer for guidance.

How do you adjust the unloader valve on an air compressor?

To adjust the unloader valve, turn the adjustment screw while monitoring the compressor to achieve the desired pressure release levels. Consult the owner’s manual or manufacturer for detailed instructions.

Is it dangerous to adjust the unloader valve on an air compressor?

Adjusting the unloader valve on an air compressor can be dangerous if not done properly. Always follow safety guidelines and consult the owner’s manual or manufacturer for guidance.

What are some common problems that can occur if the unloader valve on an air compressor is not adjusted correctly?

Common problems that can occur if the unloader valve on an air compressor is not adjusted correctly include excessive pressure, compressor damage, and reduced overall performance.