Punches and chisels are common tools that you will find in almost any workshop or craft room. They are versatile tools that come in handy for various applications, such as cutting, carving, and shaping materials. These tools come in different sizes and shapes, and their effectiveness depends largely on the materials used in their construction.

In this blog, we will explore some of the most common materials used in making punches and chisels. As we delve into the specifics, you will gain valuable insights on what to look out for when purchasing these tools for your next project. So sit tight and let us drill down to the details!

Introduction

If you’re wondering what material is commonly used to make punches and chisels, then you’ve come to the right place. Usually, both tools are made of hardened carbon steel, as it provides the necessary strength and durability to withstand heavy use. Carbon steel has a higher carbon content than regular steel, which makes it more resistant to wear and tear and less likely to chip, bend, or break.

The blades of chisels and the tips of punches are heat-treated to enhance their hardness and toughness, enabling them to cut through tough materials like wood, metal, or stone with minimal effort. Additionally, carbon steel is relatively easy to sharpen and maintain, which ensures that your punches and chisels remain razor-sharp and ready for action whenever you need them.

Defining Punches and Chisels

Punches and chisels are essential tools that have been used for centuries to create shapes and designs on various materials such as wood, metal, and stone. A punch is a metal rod with a sharp point that is used for making holes in materials, while a chisel is a metal tool with a cutting edge used for carving or shaping materials. These tools have different designs and sizes depending on their intended use.

Punches and chisels are useful for DIY projects or on a more significant scale in construction work, such as in masonry or metalwork where precision and accuracy are paramount. Whichever use, these tools offer excellent precision and control, making them a go-to tool for artisans and craftspeople worldwide.

Importance of Material in Tool Selection

When it comes to selecting the right tool for a project, material plays a crucial role. The material used in a tool affects its durability, strength, and precision. Depending on the task at hand, certain materials may be more suitable than others.

For example, steel tools are known for their durability and long lifespan, but they may not be appropriate for delicate tasks that require a lighter touch. In contrast, carbon fiber tools offer increased precision while sacrificing some strength. Ultimately, the right material for a tool will depend on the specific needs and requirements of the project.

By carefully considering the material of a tool, one can ensure that they have the right tool for the job.

Materials Used for Punches and Chisels

When it comes to punches and chisels, a common material used is high-carbon steel. This material is known for its durability and strength, making it ideal for tools that require a lot of force and pressure. High-carbon steel is also resistant to wear and tear, meaning punches and chisels made from this material will last a long time before needing to be replaced.

Another material that is sometimes used is alloy steel, which offers similar durability and strength but may be less resistant to corrosion. Ultimately, the choice of material for punches and chisels will depend on the intended use and the user’s personal preferences. Whatever material is chosen, it’s important to keep the tools well-maintained and sharpened to ensure they remain effective and safe to use.

High-Carbon Steel

When it comes to punches and chisels, high-carbon steel is a frequent material of choice due to its durability and resistance to wear and tear. High-carbon steel is made by adding carbon to steel, resulting in a harder and stronger material that can withstand repeated use. This makes it perfect for tools that are used for heavy-duty work like punching through metal or carving stone.

However, it’s important to note that high-carbon steel can also be more brittle than other types of steel, so it’s essential to treat your punches and chisels with care to avoid any unnecessary damage. Nonetheless, high-carbon steel punches and chisels can provide invaluable assistance to anyone who needs them in their workshop.

Alloy Steel

Alloy Steel When it comes to punches and chisels, the material used is crucial to their performance. One popular material choice for these tools is alloy steel. Alloy steel is made by adding other elements to steel, which alters its properties, such as making it more durable, corrosion-resistant, and able to withstand high temperatures.

This makes it ideal for use in punches and chisels, as they are subject to wear and tear during use. One specific type of alloy steel commonly used in punch and chisel production is chrome-vanadium steel. This type of alloy steel has a high chromium content, which makes it resistant to corrosion and wear, and a moderate vanadium content, which provides additional strength and toughness.

By using alloy steel for punches and chisels, manufacturers can ensure that their tools are durable and can withstand the demands of their intended use.

Tungsten Carbide

Punches and chisels are essential tools in the construction and metalworking industries. These tools require durable materials to withstand the heavy usage and repetitive impacts. One such material used for punches and chisels is tungsten carbide.

It is a hard alloy that combines tungsten and carbon in equal parts and is known for its high strength and durability. Tungsten carbide punches and chisels are resistant to wear, corrosion, and extreme temperatures, making them an excellent choice for heavy-duty jobs. They also maintain their sharpness and precision for longer periods, reducing the need for frequent replacements.

Using tungsten carbide materials for punches and chisels ensures a longer tool lifespan, increased productivity, and reduced costs in the long run.

Ceramic

Ceramic punches and chisels are becoming increasingly popular in industries that require high precision and durability. Ceramic is a hard and durable material that can withstand high temperatures and corrosion. As compared to traditional materials, such as steel and carbide, ceramic has superior hardness and toughness, which makes it ideal for producing punches and chisels.

Additionally, ceramic is more resistant to wear and tear, which means that it lasts longer and requires less maintenance. However, ceramic punches and chisels are more expensive than their traditional counterparts, but they offer a range of benefits that make them a worthwhile investment in the long run. Ceramic punches and chisels are commonly used in industries such as aerospace, automotive, electronics, and medical equipment manufacturing.

In conclusion, ceramic is an excellent material for producing punches and chisels that offer superior performance and durability.

Choosing the Right Material

When it comes to making punches and chisels, the most commonly used material is high-carbon steel. This is because high-carbon steel is very strong and hard, making it ideal for handling tough materials like stone, metal, and wood. Additionally, high-carbon steel can be easily sharpened and maintains its edge for longer periods of time, which is essential for tools that see a lot of use.

It’s important to note that there are other materials used for punches and chisels, such as tempered steel, but high-carbon steel is the most popular choice due to its durability and effectiveness. So, if you’re in the market for punches and chisels, make sure you look for ones made from high-carbon steel.

Considerations for Specific Applications

When it comes to choosing the right material for specific applications, there are a few key factors to consider. One of the most important is the properties of the material itself. For example, if you are looking for a material that has high strength and durability, you may want to consider metals or composite materials.

On the other hand, if you are looking for a material that is lightweight and easy to work with, you may want to consider plastics or polymers. Another important consideration is the environment that the material will be used in. For example, if the material will be exposed to extreme temperatures or chemicals, you will need to choose a material that is resistant to these types of conditions.

Ultimately, the right material for your specific application will depend on a variety of factors, and it is important to carefully evaluate each option before making a decision.

Pros and Cons of Each Material

When it comes to building or renovating your home, choosing the right materials is crucial. There are various materials to choose from, and each one comes with its own set of pros and cons. For instance, if you want a classic and timeless look, hardwood flooring is an excellent choice.

It’s also durable and easy to maintain. However, it can be quite expensive, and it can be vulnerable to scratches and water damage. Laminate flooring, on the other hand, is affordable and highly resistant to scratches and water.

However, it may not provide the same warmth and authenticity that hardwood does. The same goes for countertops – granite is beautiful and durable, but it can stain and chip if not properly taken care of. Quartz, on the other hand, is virtually indestructible, but it doesn’t have the same natural look that granite does.

It’s important to weigh the pros and cons of each material to determine what would work best for your home and your budget.

Conclusion

After careful consideration and research, it can be deduced that the material commonly used to make punches and chisels is none other than good old-fashioned steel. And just like a great punch line, steel has proven to be durable, versatile, and essential in creating a masterpiece. So the next time you’re hard at work chiseling away or delivering some punches, take comfort in knowing that your trusty tool is made of the best material for the job.

“

FAQs

What is the typical material used to manufacture punches and chisels?

High-carbon steel is commonly used to make punches and chisels.

How does the material choice affect the performance of punches and chisels?

The choice of material determines the durability and the ability to hold a sharp edge, affecting the performance of punches and chisels.

Are there any alternatives to high-carbon steel for making punches and chisels?

Yes, there are other materials such as tungsten carbide, which offers excellent hardness and resistance to wear and tear.

Can punches and chisels be made of different materials for different applications?

Yes, the material used to manufacture punches and chisels can be varied, depending on the application and the level of precision required.

What should be the ideal Rockwell hardness for punches and chisels?

The ideal Rockwell hardness for punches and chisels is in the range of 55-60 HRC to offer the right balance between hardness and toughness.

How can we maintain the sharpness of punches and chisels?

Regular sharpening using a honing stone or diamond file can help to keep the sharpness of the punches and chisels.

What is the advantage of using a multi-purpose punch and chisel kit over individual tools?

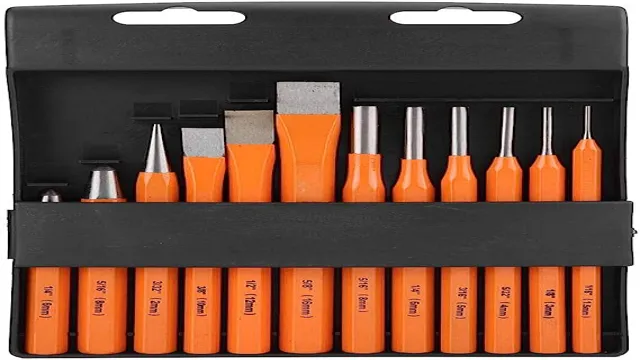

A multi-purpose punch and chisel kit offers versatility and flexibility, making them ideal for a wide range of applications.