When it comes to tightening bolts or nuts, there are various tools out there to get the job done. However, one tool that stands out from the rest is the pneumatic torque wrench. This specialized tool is designed to apply a specific amount of torque to a fastener, ensuring it is tightened to the exact specifications required.

But what exactly is a pneumatic torque wrench, and how does it work? In this blog post, we’ll dive into everything you need to know about this powerful and precise tool.

Definition

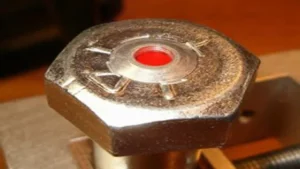

A pneumatic torque wrench is a type of power tool that is used to tighten nuts and bolts. Unlike manual torque wrenches that require physical effort to turn, pneumatic torque wrenches use compressed air to turn the tool’s head and apply torque to the fastener. This method of operation not only saves time and effort but also ensures consistent and accurate torquing.

These tools are commonly used in automotive and industrial settings, where precise torquing is required to prevent damage or failure of equipment. Pneumatic torque wrenches come in various sizes and designs, with adjustable torque settings that make them versatile and ideal for a wide range of applications. Their efficiency and ease of use make them a popular choice for professionals who need a reliable and fast tool to complete their work.

Explanation of the Technology

The technology we’re talking about here is Artificial Intelligence (AI). AI is an innovative technology that enables machines to learn, understand, and perform tasks that require human intelligence, like decision-making, problem-solving, and language translation. It uses extensive data to recognize and learn from patterns, creating predictions and recommendations based on that information.

This technology makes all that possible by utilizing various techniques such as machine learning, deep learning, natural language processing (NLP), and computer vision. These different methods enable machines to analyze and interpret large amounts of information to gain insights that can be used to improve efficiency, accuracy, and effectiveness across different industries. Additionally, AI’s versatility and scalability make it a valuable tool for businesses worldwide, offering endless possibilities for innovation and growth.

Types of Pneumatic Torque Wrenches

Pneumatic torque wrenches are a type of power tool used for tightening or loosening bolts and nuts in a variety of applications. These tools use compressed air to rotate the wrench, providing a high amount of torque with less effort from the user. There are several types of pneumatic torque wrenches available on the market, including impact wrenches, pulse wrenches, and fixed-cylinder wrenches.

Impact wrenches are the most common type and are often used in automotive and heavy equipment repairs. Pulse wrenches provide precise torque control and are ideal for repetitive assembly tasks. Fixed-cylinder wrenches are designed for use in tight spaces where a standard wrench cannot fit.

Each type of pneumatic torque wrench has its own unique benefits and can be tailored to specific tasks and applications. Whatever the job, a pneumatic torque wrench can make it easier, faster, and more efficient.

Advantages

Pneumatic torque wrenches are essential tools in various industries like construction, automotive, mining, and aerospace. These wrenches use compressed air to turn the nuts and bolts that require tightening. One advantage of using a pneumatic torque wrench is its efficiency and speed.

With just a quick blast of compressed air, you can tighten or loosen nuts and bolts in a fraction of the time compared to manual torque wrenches. In addition, pneumatic torque wrenches are more ergonomic than other types of torque wrenches. They are lightweight, easy to handle, and do not require much effort to use.

Pneumatic torque wrenches are also more accurate and reliable, ensuring that bolts or nuts are tightened with the correct amount of torque. They are durable and can handle tough working conditions and repetitive use. Overall, if you want a reliable, efficient, and fast way to tighten nuts and bolts, a pneumatic torque wrench is the way to go.

Accuracy and Consistency

Accuracy and consistency are critical components in any task. When we focus on delivering quality results, we not only win trust but also earn a good reputation. Accuracy ensures that our work is free of errors, while consistency makes sure that we maintain the same level of quality in all our tasks.

When we achieve accuracy and consistency in our work, we can deliver efficient results while also reducing the likelihood of errors. These factors can increase our credibility when working with others and providing services. From paperwork to project management, accuracy and consistency are essential elements in any field that can also benefit from productivity recovery issues.

In today’s digital era, businesses rely heavily on automation and software that require accuracy and consistency to function reliably. When workers accurately input data without errors and maintain consistency in specific, detailed work processes, they help maintain the smooth functionality of the system, ensuring that all data is error-free and valid. If there are errors, businesses could face significant financial loss, and operations may come to halt for an extended period of time, slowing down the workflow and possibly resulting in a poor outcome or end product.

Overall, accuracy and consistency are key advantages that can increase productivity, efficiency, and reliability in any field.

Cost-effective

One of the biggest advantages of cost-effective solutions is that they save you money. When businesses are able to increase efficiency and reduce operating costs, they can lower prices and become more competitive. This not only benefits the consumer, but it also helps businesses attract and retain customers.

Cost-effective solutions can be achieved through tactics such as outsourcing, automation, and process improvements. By identifying areas where savings can be realized and implementing changes, businesses can remain profitable while still providing quality goods and services. In fact, sometimes the most cost-effective solutions can result in higher quality products and better customer experiences.

By focusing on cost-effectiveness, businesses can increase their bottom line and stay ahead of the competition. So, if you want to keep your business running smoothly and remain profitable, it’s important to adopt cost-effective solutions.

Speed and Efficiency

When you prioritize speed and efficiency in your work or personal life, there are several advantages that come along with it. For starters, you can accomplish more tasks in a shorter amount of time, which can lead to increased productivity and a more fulfilling sense of accomplishment. Additionally, being able to work more quickly and efficiently can save you time and reduce stress levels.

You may also be able to complete work more accurately and with fewer errors when you’re not feeling rushed or overworked. On top of all of that, being able to move quickly and efficiently can show others that you’re reliable and capable, resulting in more opportunities and higher levels of success. Overall, prioritizing speed and efficiency can help you get ahead and succeed in both work and personal life.

Uses

A pneumatic torque wrench is a type of power tool that is used to tighten or loosen bolts and nuts in various mechanical applications. Instead of using manual force, a pneumatic torque wrench operates with compressed air, which allows for greater precision and control. This makes it an ideal choice for tasks that require a high level of accuracy and speed, such as automotive repair, construction, and assembly.

Pneumatic torque wrenches also come in various sizes and strengths, making them suitable for a wide range of applications. Whether you are a mechanic, engineer, or simply looking for a reliable tool to use at home, a pneumatic torque wrench can help you get the job done quickly and efficiently. With its ease of use, versatility, and power, it is no wonder that the pneumatic torque wrench is a popular choice among professionals and DIY enthusiasts alike.

In Vehicle Repair

Vehicle repair can be a costly and time-consuming experience, and in some cases, it may not even be feasible to take your car to a shop for repairs. That’s where in-vehicle repair comes in. Essentially, it means that a mechanic will come to you to assess and fix your car’s issues.

This service is particularly useful for those who have busy schedules, have trouble getting to a repair shop, or simply need their vehicle fixed promptly. With in-vehicle repair, you can be assured that the mechanic will take care of everything on site and promptly get you back on the road. Plus, you don’t have to worry about towing your vehicle to the shop or waiting for parts to be ordered.

Overall, in-vehicle repair can be a lifesaver for those who need their car fixed quickly and efficiently. So, next time you’re in a bind, consider this option as opposed to traditional repair shops.

In Manufacturing

In manufacturing, robots have become increasingly popular due to their efficiency, precision, and cost-effectiveness. They are used in various stages of the production process, including assembly line work, welding, painting, and quality control. These machines can complete tasks at a faster rate than their human counterparts, which allows for higher productivity levels and lower labor costs.

Additionally, robots can work in hazardous environments that may be dangerous for humans, which improves safety in the workplace. With advances in technology, robots are becoming more versatile and now have the ability to handle a wider variety of tasks. The manufacturing industry is constantly evolving, and the use of robots has quickly become essential in ensuring a competitive edge in the market.

Conclusion

In conclusion, a pneumatic torque wrench is not just your average wrench. With its use of compressed air, this tool allows for precise and efficient tightening of bolts and nuts. It’s no wonder why it’s become a staple in industries such as construction, automotive, and manufacturing.

With a pneumatic torque wrench on hand, you’ll be able to tighten bolts with ease and confidence. So, let’s give a round of applause to the little marvel that is the pneumatic torque wrench – the unsung hero of the toolbox!”

FAQs

What is a pneumatic torque wrench and how does it work?

A pneumatic torque wrench is a tool that uses compressed air to generate torque and tighten bolts or nuts. It works by using a motor to drive a rotating shaft, which then transfers the torque to the bolt or nut.

What are the advantages of using a pneumatic torque wrench over other types of torque wrenches?

One advantage is that pneumatic torque wrenches can provide higher torque output without requiring a larger wrench size. They are also generally faster and more efficient than other types of torque wrenches.

Can a pneumatic torque wrench be used on all types of bolts or nuts?

While pneumatic torque wrenches can be used on a wide variety of bolts and nuts, some types may require a specialized tool for optimal performance. It’s important to match the tool to the specific application to achieve the best results.

Are pneumatic torque wrenches safe to use?

Yes, pneumatic torque wrenches are generally safe to use when proper safety precautions are observed. It’s important to wear appropriate personal protective equipment and follow manufacturer guidelines for proper tool usage.

How do you maintain a pneumatic torque wrench?

Proper maintenance includes regular cleaning and lubrication of the tool, as well as periodic calibration to ensure accuracy. It’s important to follow manufacturer guidelines for maintenance to extend the life of the tool.

What is the accuracy of a pneumatic torque wrench?

The accuracy of a pneumatic torque wrench can vary depending on the model and manufacturer, but most are rated with an accuracy of +/-4% to +/-6% of the target torque value.

Can a pneumatic torque wrench be used in wet or humid conditions?

Yes, most pneumatic torque wrenches are designed to be used in a variety of weather conditions. However, it’s important to follow manufacturer guidelines and take proper precautions to ensure the tool remains in good working condition.