Do You Really Need to Use a Torque Wrench for Accurate Tightening? Benefits Explained!

Are you unsure if you need a torque wrench or not? Depending on the task at hand, a torque wrench can make all the difference in achieving accurate and reliable results. A torque wrench is a precision tool designed to tighten nuts and bolts to a specific torque level, ensuring optimal performance and safety of your equipment. Think of it like a doctor using a stethoscope to check your heart rate – without the proper tool, you can’t get an accurate reading.

Whether you’re an experienced mechanic or a DIY enthusiast, having a torque wrench in your toolkit can save you time, money, and headaches down the road. In this article, we’ll explore what a torque wrench is, its benefits, and when you should use one. So, sit back, grab a cup of coffee, and let’s dive into the world of torque wrenches!

What is a Torque Wrench?

If you’re the kind of person who loves to tinker with cars or other machinery, you’ve probably heard of a torque wrench. But do you really need one? The short answer is yes. A torque wrench is an essential tool for anyone who wants to ensure that their bolts and fasteners are tightened to the correct specification.

Over-tightening can cause damage or even break the bolt or surrounding components, while under-tightening can lead to failure or looseness. Using a torque wrench takes the guesswork out of tightening bolts and helps ensure consistency across multiple fasteners. So, next time you’re working on your car or assembling furniture, don’t skimp on the torque wrench – your safety and the longevity of your equipment may depend on it.

Measuring Torque Accuracy

A torque wrench is a tool that is used to apply a specific amount of force or torque to a bolt or nut. It is important to use a torque wrench when working on machinery or vehicles, as over-torquing or under-torquing can cause serious problems. Torque wrenches work by measuring the amount of force being applied and alerting the user when it reaches the desired level.

Accuracy is essential when using a torque wrench, as even a small error can result in a significantly different outcome. Measuring the torque accuracy of a wrench involves testing it against a known standard, such as a calibration device, to ensure that it is working correctly. Reputable brands will include calibration certificates with their torque wrenches, so it is important to purchase from a trusted source.

By using a torque wrench with accurate measurements, the user can ensure the safety and longevity of their machinery or vehicle.

Benefits of Using a Torque Wrench

A torque wrench is a tool used in mechanical engineering and assembly to tighten nuts and bolts to a specific torque value, which is a measure of rotational force. The benefits of using a torque wrench are fairly straightforward – by tightening bolts to the correct torque value, they are less likely to become loose over time, reducing the risk of mechanical failure. This can be especially important in safety-critical applications such as automotive repair, aerospace engineering, and heavy machinery assembly.

Using a torque wrench can also help to ensure that bolts are tightened evenly and to the same torque value, reducing the risk of uneven loading or distortion. Ultimately, using a torque wrench is an essential part of any mechanical assembly or repair job, helping to ensure proper function and increased safety.

When Should You Use a Torque Wrench?

If you’re wondering if you really need to use a torque wrench, the answer is yes. A torque wrench ensures that bolts are tightened to a specific level of tightness, which is critical for the safety and performance of your equipment. Over-tightening or under-tightening bolts can cause damage or even failure.

It’s important to use a torque wrench when working on engines, transmissions, suspensions, and any other critical parts where precise torque is needed. Even if you’re an experienced mechanic and can “feel” the right amount of tightness, a torque wrench is still necessary to ensure accuracy and consistency. Plus, using a torque wrench can save you time and money by preventing mistakes and reducing the risk of needing costly repairs down the road.

So, always make sure you have a torque wrench of the proper size and type for the job before you start working.

Working with Critical Components

Torque wrench When it comes to working with critical components, knowing when to use a torque wrench can make all the difference. Torque wrenches are indispensable tools used to tighten bolts or nuts to specific levels of torque or tightness. These tools can prevent overtightening or uneven tightening, which can cause bolts to break or fail.

Torque wrenches are especially important when working with machinery or vehicles, where high levels of precision are crucial for safety and performance. For example, if you’re changing the tires on your car, using a torque wrench can help ensure that the lug nuts are tightened to the manufacturer’s recommended torque. By using a torque wrench, you can be confident that the wheels have been firmly secured, reducing the risk of accidents caused by loose wheels.

So, whenever you’re working with critical components that require precise, controlled tightening, be sure to use a torque wrench.

Working with New Parts

When you’re working with new parts, it’s essential to know when to use a torque wrench. A torque wrench is a tool that helps you tighten bolts to a specific level of tightness, which helps prevent over-tightening or under-tightening. This is particularly important when you’re working with parts that are critical to the function of your vehicle or machine, such as engine components or suspension parts.

By using a torque wrench, you can ensure that these parts are properly tightened to their recommended torque specifications, which can help prevent damage caused by improper installation. In short, if you want to make sure your machine or vehicle is in good working order, using a torque wrench is a wise choice.

Working with Old Parts

When it comes to working with old parts, especially those that have been in use for a long time, it’s important to use a torque wrench to ensure that all bolts and nuts are tightened to the correct specifications. This is because old parts can easily become warped or damaged, which can lead to the bolts and nuts becoming loose over time. Using a torque wrench ensures that each bolt or nut is tightened to the correct torque value, which helps to prevent stripping, cracking, or other damage that can result from over-tightening.

In addition, using a torque wrench can also help to prevent under-tightening, which can cause parts to vibrate or come loose during use. So if you’re working with old parts, it’s always a good idea to use a torque wrench to ensure that everything is tightened to the correct specifications.

How to Use a Torque Wrench

If you’re a DIY mechanic or just like working on cars, you may be asking yourself, “Do I really need to use a torque wrench?” The short answer is yes, you do. Torque wrenches are essential tools for ensuring the proper amount of pressure is applied when tightening bolts and nuts. Over-tightening or under-tightening can lead to damage or failure of critical components, which can be costly to fix.

By using a torque wrench, you can ensure that the bolts and nuts are tightened to the manufacturer’s specifications, which will help prolong the life of your vehicle. So, next time you’re working on a car, don’t neglect the torque wrench!

Selecting the Right Torque Wrench

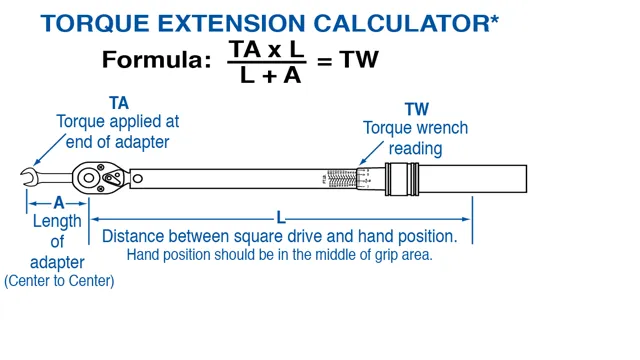

When it comes to performing tasks that involve the application of torque, selecting the right torque wrench is crucial. There are a variety of torque wrenches available, each with their specifications and limitations. Knowing the right wrench for the job can make all the difference in achieving accurate and consistent results.

Once you have the right wrench, using it correctly is equally important. Before starting any job, set the appropriate torque level as recommended by the manufacturer. Be sure to use the wrench perpendicular to the fastener and apply force steadily until the wrench clicks or signals that the desired torque has been achieved.

Avoid over-tightening, as this can cause damage, and under-tightening, which may result in a loosened joint. In conclusion, taking the time to select the right torque wrench and using it correctly will not only save you time but also ensure the safety and reliability of your work.

Setting the Torque Specification

Using a torque wrench is crucial when working on your car or any machinery that requires tight bolts. The torque specification determines the recommended torque value for a specific bolt or nut. The importance of following the torque specification cannot be overstated, as it ensures proper tension and prevents the bolt from breaking or coming loose.

To use a torque wrench, begin by selecting the correct torque setting for the bolt you are working on. The torque setting can be found in your car’s manual or online. Once you have the correct setting, attach the correct socket to your torque wrench.

Next, align the torque wrench with the bolt and start tightening it. As you approach the specified torque setting, the torque wrench will click or pop, indicating that you have achieved the correct tension. Remember, over-tightening can damage the bolt, while under-tightening can cause it to come loose.

By following the torque specification, you will ensure the bolt is properly tightened, preventing any potential damage or accidents. In summary, using a torque wrench is simple and essential when working on your car or any machinery. Ensure you follow the torque specification and keep your tools properly calibrated to maintain the accuracy of your torque wrench.

Conclusion

In the end, it all boils down to one simple question: do you want your nuts tightened properly or not? Sure, you could try to eyeball it or go by feel, but the truth is, nothing beats the precision and accuracy of a torque wrench. So the next time you’re tempted to skip this important tool, just remember that a little torque goes a long way in ensuring your safety and the longevity of your equipment. Don’t be a nut, use a torque wrench!”

FAQs

What is a torque wrench used for?

A torque wrench is a specialized tool used to precisely tighten bolts or nuts to a specific torque value.

Why is it important to use a torque wrench?

Using a torque wrench helps ensure that bolts or nuts are tightened to the correct torque specification, which is crucial for safety and preventing damage to threaded components.

Can I use a regular wrench instead of a torque wrench?

While it is possible to use a regular wrench to tighten bolts or nuts, a torque wrench offers more precise control and ensures uniformity in torque application.

Is it necessary to use a torque wrench for all types of bolts and nuts?

Not all bolts and nuts require a torque wrench, but it is recommended for critical applications such as automotive engines where precise torque values are necessary.

How do I choose the right torque wrench for my needs?

The right torque wrench depends on the specific application and torque range needed. It is important to choose a wrench that can accurately measure and apply the required torque.

Can a torque wrench be calibrated or adjusted?

Yes, most torque wrenches can be calibrated or adjusted to ensure accuracy and maintain consistent torque values.

Are digital torque wrenches better than manual ones?

Both types of torque wrenches have their own advantages and disadvantages. Digital torque wrenches offer easier readings and programmable torque values, while manual torque wrenches provide tactile feedback and do not require a power source.