Are you working on a DIY project or a professional mechanic, trying to fix a vehicle but wondering what a torque wrench is? Look no further! A torque wrench is a tool used to tighten bolts or nuts to a precise level of tightness. It’s a must-have tool in any mechanic toolbox. When tightening bolts or nuts, over-tightening can lead to damage, while under-tightening can result in loose or wobbly components.

A torque wrench applies a specific amount of force to the bolt, measured in foot-pounds or Newton-meters, to ensure it’s tightened to the manufacturer’s specification. Think of it as a kitchen scale for mechanics! A torque wrench saves time, money, and, most importantly, ensures safety on the road.

Definition and Function

A torque wrench is also known as a type of tool used for tightening bolts or nuts to a specific level of tightness, measured in torque. It is typically used in applications where precision is necessary, such as in automotive or aerospace industries. The wrench is designed to apply a specific amount of force or tension to the bolt or nut, ensuring that it is tightened to the exact specifications required.

The user sets the wrench to the desired torque level, and the wrench signals or “clicks” when the correct level of torque has been reached. A torque wrench is an essential tool for any mechanic or DIY enthusiast who requires precise torque settings for their project. By using a torque wrench, you can ensure that your nuts and bolts are tightened to the correct level, preventing under or over tightening, which can cause damage to your equipment.

So, if you want to make sure that you tighten your bolts and nuts with the utmost precision, you need a torque wrench, also known as a torque spanner.

What is a torque wrench?

A torque wrench is a tool used to tighten bolts and nuts with great precision. It measures the amount of rotational force, or torque, applied to the fastener, ensuring that it meets the required specification. Torque is measured in units of force multiplied by distance and is usually expressed in pound-feet or Newton-meters.

A torque wrench is essential in various fields like automotive, mechanics, carpentry, plumbing, and construction, among others. It helps to avoid applying too much torque, which can damage the equipment or pull threads out of the material. Similarly, not tightening enough can cause the material to fail, which can be catastrophic.

Therefore, a torque wrench is an essential tool for any project requiring precision torque specifications.

What is the function of a torque wrench?

A torque wrench is a tool that is used to tighten nuts, bolts, and other fasteners to a specific level of torque. This level of torque is critical to ensure that the fastener is not too loose or too tight, which can lead to safety issues, premature wear and tear, or even failure. The function of a torque wrench is to apply a specific amount of force to a fastener until it reaches the desired level of torque.

There are various types of torque wrenches available, including click-type, beam-type, digital, and even hydraulic torque wrenches. Each type of torque wrench has its own advantages and disadvantages, but they all serve the same basic purpose of tightening fasteners to a precise level of torque. If you work with machinery, automotive, bikes, or other mechanical equipment, it is essential to have a torque wrench in your tool kit to ensure that your fasteners are tightened correctly.

Trust me, you don’t want to risk safety or the performance by guessing how much torque is enough!

Types of Torque Wrenches

A torque wrench is also known as a precision tool used to tighten bolts and nuts accurately to a specific level of tension. There are different types of torque wrenches available on the market, each having its unique features and benefits. The beam wrench is the most basic and inexpensive torque wrench type, which uses a simple fulcrum and lever system to apply torque.

The click-type torque wrench is more advanced and commonly used, as it produces a clicking sound once the preset torque is reached. The electronic torque wrench is the most sophisticated and expensive type, which uses electronic signals to measure and display torque. It is suitable for working with sensitive equipment that requires accurate and consistent torque levels.

The dial torque wrench is another type of torque wrench that measures torque using a dial gauge. It is easy to read and has a wide range of applications, making it a versatile option for mechanics and engineers. Choosing the right torque wrench depends on the application, budget, and personal preference.

While all types of torque wrenches are designed to apply precise torque, the different types make them suitable for different applications and industries.

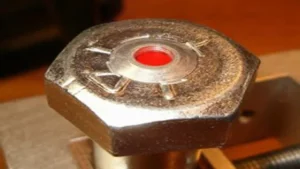

Click-style torque wrench

When it comes to torque wrenches, there are several types to choose from depending on your needs and preferences. One popular type is the click-style torque wrench, which is known for its accuracy and ease of use. This type of wrench is designed to ensure that you tighten bolts and nuts to the correct torque specification by providing an audible ‘click’ sound when you reach the desired level of tightness.

It is ideal for use in automotive, aerospace, and industrial applications where precise torque settings are required. Whether you are a professional mechanic or a DIY enthusiast, investing in a reliable and accurate click-style torque wrench can save you time, money, and headaches in the long run. So, if you want to avoid over-tightening or under-tightening your bolts and nuts, consider getting a click-style torque wrench and enjoy the peace of mind that comes with knowing you have the right tool for the job.

Beam-style torque wrench

A torque wrench is a tool used to tighten bolts and nuts to a specific level of tension. There are different types of torque wrenches, and one of them is the beam-style torque wrench. This particular type of torque wrench works by measuring the amount of force applied to a lever arm on the wrench itself.

The wrench has a long arm connected to a pivot point, and a shorter arm connected to a socket. When the user applies force to the long arm, the shorter arm turns the socket and tightens the nut or bolt. The beam-style torque wrench has a visible pointer on a graduated scale that shows the amount of force applied.

This type of torque wrench is simple and reliable, and it doesn’t require any calibration or maintenance. It’s ideal for simple tasks and DIY projects where precision isn’t critical. However, for more complex projects or professional applications, a digital or click-style torque wrench may be a better choice.

Dial-style torque wrench

When it comes to torque wrenches, there are several types to choose from depending on the needs of your project. One popular type is the dial-style torque wrench, which is known for its accuracy and ease of use. This tool features a dial that displays the torque reading as you tighten or loosen a bolt or nut.

Many professionals prefer this type of torque wrench because it eliminates the need for conversions or calculations, making it a faster and more efficient option. You can simply set the desired torque level on the wrench and adjust the pressure applied until the dial reaches the desired reading. With its simplicity and accuracy, the dial-style torque wrench is an asset to any toolkit and can save time and effort on any project.

Digital torque wrench

If you’re looking for an accurate and efficient tool to measure and control torque, then a torque wrench is the perfect solution for you. There are several types of torque wrenches available in the market, each designed for a specific purpose. For instance, the digital torque wrench is becoming increasingly popular among professionals and DIY enthusiasts alike.

This type of wrench comes with a digital display that not only shows the torque measurement but also ensures precision and consistency. Additionally, there are click-type torque wrenches that produce an audible click sound when the right torque is achieved. Similarly, beam-type torque wrenches use a simple mechanical system to measure torque accurately.

These wrenches are easy to use and maintain and are ideal for light-duty tasks. Lastly, hydraulic torque wrenches are expensive but highly accurate tools that are used in heavy-duty applications. They use hydraulic pressure to generate torque and can handle high levels of stress and tension.

In conclusion, choosing the right type of wrench for your specific needs can make a significant difference in the efficiency and accuracy of your torque-related tasks.

Different Names for a Torque Wrench

A torque wrench is a versatile tool that is useful in a wide range of applications. It is used to apply a specific amount of torque to a bolt, nut, or other fastener to ensure that it is tightened to the correct specification. However, not everyone is aware that a torque wrench is also known as a “click wrench,” “torque screwdriver,” or “torque spanner.

” These different names reflect the different shapes and styles of torque wrenches that are available. For example, a click wrench has a distinctive “click” sound that indicates when the correct torque has been applied, while a torque screwdriver is designed for use in tight spaces where a regular wrench may not fit. No matter what name you know it by, a torque wrench is an essential tool for any mechanic or DIY enthusiast who wants to ensure that their bolts are tightened to the correct specification.

What is a torque wrench also known as?

A torque wrench is a tool that is used to apply a specific amount of force to a nut or bolt. This force is measured in units of torque, which are typically expressed in Newton meters or foot-pounds. Although torque wrenches are primarily known by this name, they are also referred to by several other names, depending on the region or industry.

In the automotive industry, torque wrenches are sometimes called “clicker wrenches” because they emit a clicking sound when the desired torque is reached. In the aerospace industry, they may be known as “tension wrenches” or “twist-off wrenches.” In general, these alternative names all refer to the same tool and perform the same function, but they may have slight variations in design or specifications based on their intended use.

Whether you call it a torque wrench, a clicker wrench, or a tension wrench, this handy tool is a must-have for anyone who needs precision and accuracy when tightening nuts and bolts.

Common terms for a torque wrench

A torque wrench is a handy tool used to tighten bolts and nuts to a specific torque value. While it is commonly referred to as a torque wrench, this useful tool goes by different names across different regions and industries. For instance, some people refer to it as a torque driver, torque multiplier, or torque spanner.

In the aviation industry, it is often called a clicker or a torqueing device. On the other hand, in the automotive industry, it is commonly referred to as a breaker bar or torque adapter. This wide range of names can sometimes cause confusion, especially for DIY enthusiasts or first-time buyers.

However, regardless of its name, a torque wrench remains essential in achieving precise and accurate tightening of fasteners, whether in a professional or personal setting.

Conclusion

In summary, a torque wrench can be appropriately dubbed as the “precision contortionist” of the tool world. With its ability to achieve accurate torque settings and handle intricate fastening tasks, it’s no wonder this tool has earned a variety of nicknames like “click wrench” or “tension wrench.” So whether you’re a seasoned mechanic or a DIY enthusiast, remember to keep this versatile and essential tool handy for all your torque-related needs.

After all, in the world of fastening, there’s nothing quite like having the right wrench for the job.

FAQs

What is a torque wrench?

A torque wrench is a tool used to apply a specific amount of torque to a fastener.

How does a torque wrench work?

A torque wrench works by applying a preset amount of torque to a fastener. Once the desired torque is achieved, the wrench will either click or provide a visual indication.

What are the different types of torque wrenches?

The different types of torque wrenches include beam torque wrenches, click torque wrenches, digital torque wrenches, and dial torque wrenches.

What is the importance of using a torque wrench?

Using a torque wrench ensures that fasteners are tightened to the appropriate torque specification and prevents over-tightening, which can damage the fastener or surrounding components.

Can a torque wrench be used for both tightening and loosening fasteners?

Yes, a torque wrench can be used for both tightening and loosening fasteners, as long as it is set to the appropriate torque value for each task.

What is the difference between an analog and digital torque wrench?

An analog torque wrench uses a mechanical gauge to indicate the level of torque being applied, while a digital torque wrench uses an electronic display to show the torque value.

How often should a torque wrench be calibrated?

A torque wrench should be calibrated at least once a year or after 5,000 cycles, whichever comes first, to ensure accuracy.