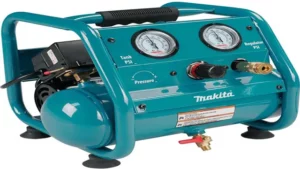

If you’re in the market for an air compressor, you might have come across the term “oil-free” and wondered what it means. Simply put, an oil-free air compressor is one that doesn’t rely on oil lubrication to operate. Instead, it uses alternative materials and systems to keep the components moving smoothly.

Why does this matter? For starters, an oil-free air compressor requires less maintenance. You don’t need to change the oil or filters regularly, which can save you time and money. Additionally, oil-free compressors are often more environmentally friendly, as they don’t release harmful oil vapors into the air.

Another benefit of oil-free compressors is that they’re typically quieter than their oil-lubricated counterparts. Without the need for oil to keep the parts moving, there’s less friction and noise during operation. Of course, there are some downsides to oil-free compressors as well.

They may not last as long as oil-lubricated models, as the lack of lubrication can cause more wear and tear on the components over time. Additionally, oil-free compressors may not be as powerful or efficient as those that use oil lubrication. Overall, an oil-free air compressor can be a great choice for those who prioritize ease of use and environmental friendliness.

However, it’s important to understand the trade-offs before making a purchase.

Definition and Functioning

An oil free air compressor is a type of air compressor that operates without the need for lubricating oil during the compression process. Unlike traditional compressors that use oil for lubrication, these compressors use specialized materials and techniques to reduce friction and wear, allowing them to operate without the risk of contaminating the compressed air with oil. They are commonly used in applications where clean air is essential, such as in medical, food and beverage, and electronics manufacturing industries.

Oil-free compressors are also known for being more environmentally friendly, as they do not emit oil mist into the air. They typically require less maintenance and are more energy-efficient, making them a popular choice for a wide range of industrial and commercial applications. Overall, oil-free air compressors serve as a reliable and efficient solution for ensuring high-quality, contaminant-free compressed air.

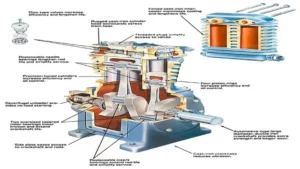

Explanation of an Air Compressor

An air compressor is a machine that converts mechanical energy into compressed air power. It is an essential tool in many industrial and mechanical processes where air pressure is needed for powering machines or for cleaning purposes. The compressor works by drawing in air from the surroundings and compressing it to a higher pressure inside a tank.

The compressed air can then be used for a variety of purposes such as inflating tires, operating pneumatic tools, or powering machinery. The compressors can be categorized into two types, namely positive displacement compressors and dynamic compressors. Positive displacement compressors use a mechanism of trapping and compressing air, while dynamic compressors use high-speed rotating impellers or vanes to compress the air.

When choosing an air compressor, it is important to consider factors such as the type of compressor, the required pressure, the flow rate, and the power source. With the right air compressor, you can achieve increased efficiency, productivity, and performance in your industrial or mechanical processes.

Oil Free Compressor Mechanism

An oil-free compressor mechanism is a type of compressor that uses air instead of oil to lubricate its moving parts. This type of compressor is commonly used in applications where oil contamination is a concern, such as in the food and pharmaceutical industries. The function of the oil-free compressor mechanism is to compress air or gas, which is then used to power various equipment or machines.

The mechanism works by drawing in air or gas through an inlet valve, compressing it using a rotor, and then discharging it through an outlet valve. The absence of oil means that the compressor is less messy, produces cleaner air, and requires less maintenance. Additionally, the oil-free design provides greater reliability and longevity, making it an ideal choice for applications that require continuous operation.

So, if you are in the market for a compressor and want to ensure that there is no oil contamination, an oil-free compressor mechanism is the way to go.

Benefits of an Oil-Free Air Compressor

An oil-free air compressor is a type of air compressor that does not require oil to operate. This makes it a favorable choice for industries that require clean air for their applications. The benefits of an oil-free air compressor include reduced maintenance costs, improved quality of air output, and increased energy efficiency.

Since an oil-free air compressor does not have oil in its system, it eliminates the risk of oil contamination in the air output, making it safe for use in sensitive industries such as food processing and pharmaceuticals. Additionally, since there is no need for oil changes, the maintenance costs associated with an oil-free air compressor are significantly lower than those of traditional air compressors. Finally, oil-free air compressors are more energy-efficient as they do not require the same amount of power to run a motor that traditional compressors do.

This can translate to significant savings in energy bills over the long term. Overall, an oil-free air compressor is a reliable and economical choice for industries that require clean and efficient air.

Eco-Friendly

Oil-free air compressors are a great solution for eco-conscious individuals and businesses. One of the major benefits of using an oil-free compressor is its environmental friendliness. Traditional lubricated compressors release oil into the air during operation, which can harm the environment and potentially cause health issues.

Oil-free compressors, on the other hand, produce clean air that is safe for humans and the environment. By investing in an oil-free compressor, you’re also reducing your carbon footprint and contributing to a healthier world. Plus, these compressors require less maintenance and have a longer lifespan, making them a cost-effective and sustainable option.

Switching to an oil-free compressor is a small but impactful step towards a greener future.

Low Maintenance Costs

Choosing an oil-free air compressor offers many benefits, one of which is low maintenance costs. Unlike traditional air compressors that require oil changes and regular filter replacements, oil-free compressors are much simpler to maintain. Without oil, there is no need to worry about oil leaks or contamination, reducing the number of potential maintenance issues.

Additionally, these compressors require less cleaning due to the lack of oil buildup. This not only saves time and money spent on maintenance but also ensures that your compressor is running at peak efficiency for longer periods. So, if you’re looking for an air compressor that requires minimal maintenance and can save you money in the long run, an oil-free compressor is definitely worth considering.

Suitable for Food and Beverage Industries

Food and Beverage Industries Oil-free air compressors are becoming increasingly popular in the food and beverage industry, and for good reason. Not only do they provide a cleaner and safer working environment, but they also offer numerous benefits over traditional oil-lubricated compressors. For instance, oil-free compressors do not contaminate the compressed air with lubricant, which can be a serious concern in industries where cleanliness and hygiene are crucial.

This results in pure and clean compressed air that is safe for food production and packaging. Furthermore, oil-free compressors require less maintenance and repair compared to their oil-lubricated counterparts, thereby reducing downtime and increasing productivity. They are also more energy-efficient, which means less power usage and lower energy bills.

Overall, oil-free air compressors are a smart investment for food and beverage industries that prioritize quality, safety, and efficiency.

Applications of an Oil-Free Air Compressor

When it comes to air compression systems, a term that we often hear is “oil-free air compressor.” So, what exactly is an oil-free air compressor, and how is it different from traditional compressors? Well, an oil-free air compressor is a type of compressor that does not use oil in its mechanisms. Instead, it uses alternative materials like Teflon or other synthetic lubricants to reduce friction and wear on its components.

The absence of oil in these compressors offers many benefits, especially in applications where air quality is critical, such as in the food and beverage industry, medical facilities, and electronics manufacturing. Oil-free compressors are also easier to maintain and operate compared to oil-lubricated ones, and they require less frequent oil changes. Overall, an oil-free air compressor is a reliable and efficient option for industries that require clean and dry compressed air for their operations.

Dental and Medical Industries

An oil-free air compressor has numerous applications in the dental and medical industries. In dental practices, air compressors are used to power dental handpieces, which require a constant flow of compressed air in order to operate with precision and efficiency. An oil-free air compressor is essential in this setting because it ensures that there is no risk of oil contamination, which could be harmful to patients.

Additionally, oil-free compressors are quieter and easier to maintain compared to their oil-lubricated counterparts. In the medical sector, oil-free air compressors are used in a variety of clinical applications such as respiratory therapy, anesthesia, and surgical tools. These compressors are utilized to power medical air compressors and vacuum systems, which play a fundamental role in maintaining a hygienic environment.

A compressor with oil can affect the quality of compressed air that is produced, and this can pose a significant risk to patients in a hospital setting. Overall, the use of an oil-free air compressor is of utmost importance in the dental and medical industries. The risk of contamination is greatly reduced, leading to a safer environment for patients.

Furthermore, as oil-free compressors require less maintenance, they can lead to cost savings for healthcare providers. As a result, it is imperative to ensure that these compressors are readily available and used whenever necessary.

Painting and Surface Coating

If you’re a professional painter or someone who enjoys DIY projects, you already know that a smooth and flawless finish is essential. Achieving this level of excellence requires precision equipment, and one of the best tools that can help you achieve it is an oil-free air compressor. Oil-free air compressors are ideal for painting and surface coating because they eliminate the risk of oil contamination, ensuring that your finish is blemish-free and lasts longer.

Oil-free compressors also provide a constant, uninterrupted flow of air, which makes it easier to control the spray pattern and achieve a consistent coverage. Additionally, oil-free compressors are more eco-friendly and cost-effective because they don’t require oil changes, filter replacements, or frequent maintenance. Whether you’re repainting a car, refinishing furniture, or coating a metal surface, an oil-free air compressor is an essential tool that can help you get the job done right the first time.

Conclusion

In conclusion, an oil-free air compressor is like the vegan of the compressor world – it operates without any animal products, or in this case, oil. This type of compressor eliminates the hassle and mess of oil changes, while still providing high-quality compressed air for all your needs. So, whether you’re looking to massage your tires, inflate your air mattress, or power your painting projects, an oil-free air compressor is the way to go.

Say goodbye to oily residues and hello to a clean, green compressor!

FAQs

What is an oil free air compressor?

An oil free air compressor operates without oil lubrication, making it cleaner for certain applications and easier to maintain.

What are the advantages of using an oil free air compressor?

The main advantages include low maintenance, reduced risk of oil contamination, and better air quality for sensitive applications.

How does an oil free air compressor work?

An oil free air compressor works by using special coatings and materials that eliminate the need for oil lubrication, such as Teflon or other polymers.

What are some common applications for oil free air compressors?

Oil free compressors are commonly used in the food and beverage industry, medical and dental facilities, and electronics manufacturing.

What are the limitations of an oil free air compressor?

Oil free compressors may have lower volumetric efficiency and a shorter lifespan compared to oil-lubricated compressors, especially in high-demand applications.

How do you maintain an oil free air compressor?

Maintenance typically involves regular cleaning and inspection of components, as well as monitoring for signs of wear and tear.

How do you choose the right oil free air compressor for your application?

Factors to consider include the required flow rate, pressure level, and duty cycle, as well as any specific requirements for air quality or contamination control.