What is a Digital Caliper and How Does It Work? A Comprehensive Guide.

Whether you’re a craftsperson, engineer, or simply someone who enjoys precision measuring, a digital caliper is an essential tool that can provide accurate and reliable results. But what exactly is a digital caliper, and how does it work? In general, a caliper is used to measure the distance between two opposite sides of an object, using two opposing jaws that can be adjusted to fit the object being measured. However, unlike a traditional caliper that requires manual reading of the measurement, a digital caliper has a digital display that gives you an exact readout of the measurement in real-time.

Digital calipers are typically made of stainless steel and can come in varying sizes and shapes depending on the application. They can measure both internal and external dimensions, as well as depth, step, and even thickness using the built-in depth gauge. Digital calipers have revolutionized the field of measuring, providing even more accurate results than their manual counterparts.

They are easy to use, more reliable, and durable, making them the go-to choice for professionals and hobbyists alike. In this blog post, we’ll take a deeper look into digital calipers, their parts, how they work, and tips for using them effectively. Join us as we explore the world of digital calipers and discover how they can improve your measuring game.

Introduction

Have you ever wondered what a digital caliper is and how it works? A digital caliper is a precision tool used to measure distances with high accuracy. It consists of two jaws, one fixed and one movable, that slide past each other to measure the length, width, or height of an object. The jaws are attached to a digital display that shows the measurement in either metric or imperial units.

This tool is commonly used in engineering, metalworking, woodworking, and other fields that require precise measurements. What makes digital calipers different from traditional ones is their ability to display the measurements on a digital screen. They are easy to use, highly accurate, and can save data for future reference.

Digital calipers are an essential tool for anyone who needs to take accurate measurements quickly and easily.

Define Digital Caliper

Digital caliper is a modern measuring instrument that is widely used in various fields of work, including engineering, woodworking, metal fabrication, and science labs. It is a highly accurate and precise instrument used to measure the distance between two points, the thickness or depth of an object up to 0.01 mm or 0.

0005 inches. Unlike traditional calipers, which require manual reading and interpretation, digital calipers have an electronic LCD screen that displays the measurement readings immediately. With the ability to switch between different measuring units, such as millimeters, inches, fractionals, and decimals, digital calipers are versatile enough to accommodate different measurement requirements.

The design and accuracy of digital calipers make them an essential tool for anyone who requires precise measurements in their work.

Brief history of Digital Caliper

Digital Caliper Introduction: A digital caliper is an essential tool for measuring the dimensions of an object precisely. It is an upgraded version of the traditional vernier caliper that was invented in 163 The digital caliper replaced the manual reading of the vernier caliper with a precise and easy-to-read electronic display.

It accurately measures the distance between two points with a resolution of 0.01mm, making it an essential tool for professionals in various fields. The digital caliper is a versatile tool used in engineering, carpentry, metalworking, and medicine, among other fields.

With the digital caliper, measurements can be obtained with accuracy to a fraction of a millimeter. Its ease of use and precision have made it a popular tool in workshops and factories.

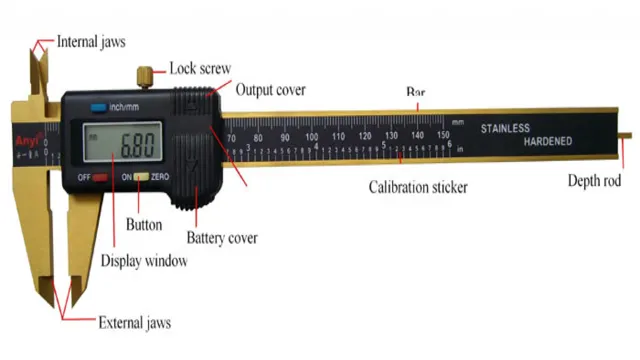

Components of a Digital Caliper

A digital caliper is a tool used to measure the length, width, and depth dimensions of objects with high precision. It is commonly used in industrial, automotive, and engineering settings. The components of a digital caliper include a slide, a jaws assembly, and an LCD display.

The slide is used to move the jaws assembly, which consists of two sets of jaws – an upper and lower jaw. The jaws are responsible for holding the object being measured in place securely. The LCD display is used to display the measurement reading, which is typically in decimal inches, millimeters, or fractions of an inch.

Digital calipers also have a zero button, which sets the display to zero when the jaws are closed, allowing for easy adjustment and calibration. Additionally, some models may have data output capabilities that allow for easy recording and transfer of measurements to computers or other devices. With its accuracy and advanced features, a digital caliper is a must-have tool for any precision measurement needs.

Jaws

Jaws, digital caliper, components A digital caliper is a precise instrument that uses jaws to measure the dimensions of an object. The jaws are the two long, flat, and parallel pieces that come together to form a measuring surface. They are usually made of hardened steel and have a serrated surface that helps grip the object being measured.

The jaws are attached to the body of the caliper at one end and splay out at the other end. The two jaws work in conjunction with the movable slider to take precise measurements. The slider moves along the calibrated scale and has a digital display that shows the measurement.

The jaws of a digital caliper can be used for inside, outside, and depth measurements. The inside jaws are used to measure diameters, the outside jaws are used to measure the width or thickness of an object, and the depth jaws are used to measure the depth of a hole or groove. When using a digital caliper, it is important to keep the jaws clean and in good condition to ensure accurate measurements.

Display

The display is an essential component of a digital caliper, providing an accurate reading of measurements taken. It is typically composed of an LCD screen with digits that display the measurements obtained, along with symbols to indicate the measurement units used. The display should be clear and easy to read, with a large enough font size to avoid strain on the user’s eyes.

Some advanced digital calipers come equipped with additional features, such as a backlight that makes the display visible in low-light conditions. The accuracy and functionality of the caliper are largely dependent on the quality of the display, making it a crucial consideration when selecting the right tool for the job.

Battery

The battery is one of the vital components of a digital caliper. It serves the purpose of supplying power to the device, enabling it to function correctly. Without the battery, the caliper cannot take accurate measurements or display accurate readings.

The battery used in a digital caliper is typically a small button cell, commonly known as a watch battery. It is easily replaceable, and the battery life of a digital caliper depends on its usage frequency. A digital caliper with an active battery should be able to give precise measurements over an extended period.

However, when the battery is low, the caliper may give incorrect readings, making it essential to replace the battery as soon as the device shows any signs of difficulty displaying accurate measurements. Choosing the right battery for a digital caliper is crucial to ensure it provides accurate measurement readings and continues functioning optimally.

Thumbscrew or Locking Screw

When it comes to the components of a digital caliper, one essential feature to consider is the thumbscrew or locking screw. The thumbscrew is responsible for tightening or loosening the jaws of the caliper, ensuring that accurate measurements are taken. Without this component, the caliper can become loose, affecting the accuracy of the readings.

On the other hand, the locking screw is designed to hold the jaws of the caliper in a fixed position, keeping them from moving during measurement. This feature is especially useful when users need to take multiple measurements of the same object without having to manually adjust the jaws each time. Overall, both the thumbscrew and locking screw are essential components of a digital caliper, ensuring precise and consistent measurements every time.

So, whether you need to take measurements for personal use or work purposes, it’s essential to pay attention to these critical features to ensure that you get the most accurate results possible.

Working Principle of a Digital Caliper

If you’ve ever worked in engineering or construction, you have probably heard of a digital caliper. A digital caliper is a measurement tool used to measure the distance between two points with extreme precision. It essentially works by using a digital display to show the reading instead of the analog scale on a conventional caliper.

The external and internal jaws of a digital caliper work in a similar way to the analog one, the difference is that the digital version is equipped with a micrometer-like gauge which reads the distance between the jaws in millimeters or inches. The digital caliper is designed with an LCD screen that displays the distance reading with accuracy in three decimal points regarding either metric or imperial units. Due to its high-precision readings that go above the basic measurement features of a traditional vernier caliper, the digital caliper is widely used in a wide range of applications, including engineering, metalworking, machining and carpentry.

Whether you are a professional in these fields or an amateur looking for accuracy with your project, a digital caliper will give you the necessary levels of precision that you need.

Types of measurement

A digital caliper is a tool used to measure the distance between two points with high precision. As its name suggests, it uses digital technology to provide accurate measurements in millimeters, inches, or fractional inches. Its working principle is simple: the user applies pressure on the jaws to close them around an object to be measured, and the result is shown on a digital display.

The digital caliper can also perform other types of measurements, such as depth and step measurements, making it a versatile tool for various industries. One of the advantages of using a digital caliper is its ability to store data and transfer it to a computer or printer for further analysis. This means that accurate measurements can be stored and shared easily, making it an important tool for quality control, manufacturing, and research applications.

Overall, a digital caliper is a reliable and efficient tool for measuring small distances with high accuracy, and it remains a vital component of many industrial and scientific fields.

Taking readings using digital caliper

Digital Caliper Digital calipers are a common piece of measuring equipment used in a variety of industries. The device is a more precise version of regular calipers that can measure distances and gaps with remarkable accuracy. The principle behind the digital caliper is relatively simple.

The caliper is composed of two main parts, a stationary arm, and a sliding arm that can move. The sliding arm has a digital display that shows the measurements that the user takes. The caliper can measure dimensions in both millimeters and inches.

The device measures the distance using a series of metal jaws that touch the surface being measured. The measurement is then displayed on the digital screen, and the user can easily see the value. The accuracy of the digital caliper makes it a useful tool for measuring small objects with precision.

The digital display and the caliper’s ease of use make it an efficient tool for shop workers, metalworkers, and anyone who needs to take precise measurements.

Advantages of a Digital Caliper

If you’re wondering what a digital caliper is, it is a tool used to measure the distance between two points with high accuracy. Compared to traditional calipers that require careful measurement interpretation, a digital caliper can give measurements in millimeters and inches down to fractions of a millimeter or thousandth of an inch. One of the main advantages of using a digital caliper is its accuracy.

With its digital display, you can avoid mistakes that come with interpreting analogue measurements. Plus, it is very easy to use. For example, it is ideal for artisans and DIY enthusiasts who need to measure pieces of materials, such as metal or wood, for precise fittings, cuts, and shapes.

Furthermore, compared to manual or vernier calipers that require reading and interpreting the pixel-thin markings, digital calipers will reduce human error and save time when used. Typically, they also come with additional functions like a zeroing mode, which allows you to take measurements faster and more conveniently. In conclusion, the digital caliper is a modern instrument with significant advantages over older types of calipers and other measurement tools, making it a go-to tool for those in need of measuring distances very accurately.

Accuracy and Precision

If you’re looking for an accurate and precise measurement tool for your DIY projects or mechanical works, a digital caliper is the perfect choice. Unlike traditional calipers, digital calipers offer more precise measurements with minimal errors. One of the main advantages of using a digital caliper is its ability to offer exact readings that can be easily seen on its digital display.

Unlike analog calipers, you don’t need to interpret readings from a scale, which can be challenging and may lead to inaccuracies. Digital calipers also offer a higher resolution, which means you can get measurements down to the smallest fraction of an inch or millimeter. Plus, digital calipers are easier to use, lighter, and smaller, making them a handy tool to carry around wherever you go.

With its accuracy and convenience, a digital caliper is an essential tool for any hobbyist, mechanic, or engineer.

Convenience

When it comes to using a caliper to measure objects accurately, a digital caliper can provide a few advantages that a traditional vernier caliper cannot match. One such advantage is convenience. While vernier calipers require the user to read and interpret small lines on a scale, digital calipers display measurements digitally, which can be more manageable and less prone to error.

Additionally, digital calipers often come with other features such as zeroing and the ability to switch between units of measurement, making them more versatile and user-friendly. The use of a digital caliper can save time, effort, and reduce errors, especially for those who need to measure a large number of objects quickly. Overall, investing in a digital caliper can be a convenient and intelligent decision for those in need of precise measurements for their projects or jobs.

Versatility

Digital calipers are versatile measuring tools that come with many advantages. They offer quick and precise readings of dimensions, making them ideal for various applications. With digital technology, measurements can be taken on surfaces of various shapes with ease.

Digital calipers provide accurate readings for measuring both internal and external dimensions, making them a versatile tool for any project. In addition, digital calipers can be calibrated for accuracy, ensuring that they perform reliably over time. This ability to calibrate and the versatility of digital calipers are just some of the many advantages that make them an essential tool for countless professions, from carpentry to engineering to metalworking.

Conclusion

In short, a digital caliper is like a high-tech tape measure – but instead of stretching out a tape, it uses advanced technology to precisely measure the distance between two points. As a staple tool in the worlds of engineering, manufacturing, and DIY projects alike, a digital caliper is a must-have for anyone who needs to take accurate measurements quickly and easily. So if you want to get your hands on the cutting-edge of measurement technology, a digital caliper might just be the tool for you!”

FAQs

What is a digital caliper used for?

A digital caliper is used for measuring the inner and outer dimensions of objects with high precision and accuracy.

How accurate is a digital caliper?

A digital caliper can be very accurate, with most models having a resolution of 0.01mm and a precision of 0.02mm.

Can a digital caliper measure depth?

Yes, a digital caliper can measure depth with its depth gauge feature, which is useful for measuring the depth of holes or slots.

How do you zero a digital caliper?

To zero a digital caliper, close the jaws and press the zero button to reset the display to 0.00mm.

How do you change the battery in a digital caliper?

To change the battery in a digital caliper, open the cover and remove the old battery. Insert the new battery with the correct polarity and snap the cover back in place.

What are the different types of digital calipers?

There are many different types of digital calipers, including general purpose calipers, depth calipers, and dial calipers.

Can a digital caliper measure angles?

Some digital calipers have a built-in protractor for measuring angles, while others require an additional attachment for this function.