How Does a Digital Caliper Work to Accurately Measure Dimensions?

Have you ever wondered how digital calipers work? These handheld devices are essential tools for taking accurate measurements in a variety of industries, from manufacturing to engineering. But how do they actually get the job done? At their core, digital calipers use a combination of mechanical and electronic components to provide precise measurements of length, width, diameter, and depth. The jaws of the caliper are designed to move smoothly and lock into place, ensuring that the device stays in position while taking measurements.

But it’s the electronics that make digital calipers truly remarkable. These devices use a tiny computer chip to capture and process data from a range of sensors, including a linear encoding system and a dial mechanism for precision measurements. The results are displayed on an LCD screen, allowing users to read measurements in inches or millimeters with ease.

Whether you’re a professional in the engineering field or a hobbyist who loves getting hands-on with DIY projects, digital calipers are an essential tool that can help you get the job done right. By understanding how they work, you can gain even more appreciation for these incredible devices and the ways they simplify our lives every day.

What is a Digital Caliper?

A digital caliper is a handy tool used for measuring the distance between two points with high precision. It works by utilizing a linear encoder that converts the linear motion of the caliper into an electrical signal that is then displayed on a digital screen in metric or imperial units. The jaws of the caliper are used to measure the external or internal dimensions of an object and can also be used to measure the depth or step of an object.

The digital readout provides an accurate measurement and eliminates the need for manual reading and mathematical calculations, making the process quicker and more efficient. Additionally, some digital calipers have a hold function that retains the measurement on the display for ease of recording, and some have a zero setting that can be used to measure the difference between two measurements. In summary, a digital caliper is an essential tool for precision measurements in industries such as engineering, woodworking, metalworking, and more.

Definition and Uses

A digital caliper is a measuring tool used to obtain precise and accurate measurements of objects with high precision. It is an advanced version of the traditional Vernier caliper instrument that has been in use for centuries. The digital caliper is designed with a digital display screen that allows for accurate and precise measurements to be read and recorded.

The caliper is commonly used in the manufacturing industry, metalworking workshops, and engineering laboratories, among other fields that require high precision measurements. The digital caliper is an essential tool in such fields as it helps to ensure that products and parts are manufactured, measured, and assembled to a high degree of accuracy. With its various sizes, it can measure objects of different dimensions and shapes, making it a versatile measuring instrument.

In summary, a digital caliper is a valuable tool for anyone who requires precise and accurate measurements in their line of work, helping to ensure that their products meet the required standards.

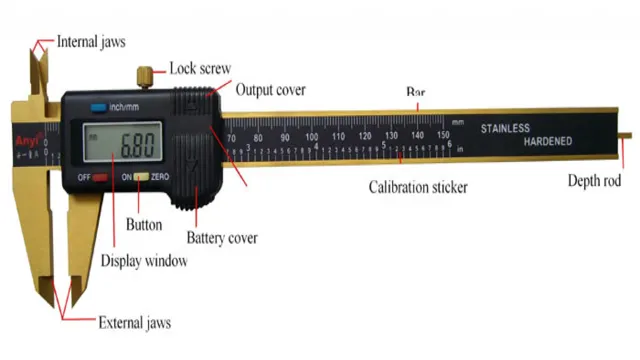

Components of a Digital Caliper

A digital caliper is a precision tool that is commonly used in mechanical workshops and laboratories to measure dimensions of objects quickly and accurately. The caliper consists of several components, including the caliper body, measuring jaws, depth probe, LCD display, and battery compartment. The caliper body is made of high-quality materials such as stainless steel or carbon fiber.

The measuring jaws are used to grip the object being measured, while the depth probe is used to measure the depth of holes and slots. The LCD display is used to display the measurements in digital form, while the battery compartment powers the digital display. The components of a digital caliper work together to provide accurate and reliable measurements, making it an essential tool in the sciences and engineering.

Are you looking for a precise and reliable tool to measure the dimensions of your objects? Consider getting a digital caliper!

How Do Digital Calipers Work?

Digital calipers are measuring devices that are used to take accurate and precise measurements of objects. But how does a digital caliper work? The device consists of two jaws, one of which moves along a beam towards the other. The jaws are connected to a digital display that indicates the distance between them.

The movement of the jaws is controlled by a linear encoder, which converts the physical distance between the jaws into an electrical signal that can be interpreted by the display. The digital display also allows for the reading to be taken quickly and accurately, making it a popular choice in many industries. With the added ability to switch between various units of measurement, including metric and imperial, digital calipers are an essential tool for anyone who needs to measure objects with precision and accuracy.

Overall, digital calipers work by converting physical distance into an electrical signal that can be interpreted by the display, making them ideal for hands-free measurement-taking and data collection.

Measurement Modes

Digital calipers are commonly used in various fields such as engineering and machining, to obtain precise measurements of objects with high accuracy. These calipers feature a digital display which provides instantaneous readings in either imperial or metric units. But how do digital calipers work? Inside the caliper, there is a small electronic circuit that comprises several components.

The circuitry is connected to the measuring jaws which make contact with the object being measured. When the jaws are closed, the circuit measures the distance between the jaws and displays it on the digital screen. Some digital calipers offer different measurement modes like depth measurement, step measurement, and others.

These modes help in measuring different parts of an object with high precision. All in all, digital calipers offer a faster and more accurate way of taking measurements than traditional mechanical calipers.

The Role of the Vernier Scale

Digital calipers are the measuring instruments that are commonly used in different fields for precise measurements. These calipers work based on the scale readings that are displayed on the digital display. The vernier scale plays an essential role in the functioning of digital calipers.

It’s a small secondary scale located on the main scale and used to read highly accurate measurements. Without the vernier scale, digital calipers would not be able to provide measurements that are as accurate as they currently do. The vernier scale’s role is to provide an additional measurement that complements the main scale’s measurement.

They work in tandem to deliver precise measurements that are essential for different industries. In conclusion, the vernier scale plays a crucial role in the functioning of digital calipers. It ensures that professionals receive the most accurate measurements possible enabling them to make informed decisions in their areas of work.

The Digital Display

Digital calipers are an essential tool for any machinist or engineer, measuring precise distances and dimensions down to the thousandth of an inch. But how do they work? At their core, digital calipers use a linear encoder, a long strip of metal coded with a series of notches and markings. As the caliper is opened or closed, a sensor reads the patterns on the encoder and sends that data to a microprocessor that calculates the measurement.

The results are then displayed on the digital screen of the caliper. This advanced technology allows for highly accurate readings and easy-to-read displays, making it a popular choice for both professionals and hobbyists alike. So if you’re in the market for a new caliper, consider going digital for a faster, more precise measuring experience.

Benefits of Using Digital Calipers

Digital calipers are highly efficient tools that work by converting linear movements into electronic readings that can be easily transferred to a computer system. Unlike traditional calipers that require manual reading and interpretation, digital calipers display measurements on a digital screen, making it easy to read even the smallest measurements. The benefits of using digital calipers are numerous.

They provide high accuracy, up to a thousandth of an inch, and can measure various shapes and thicknesses accurately. Additionally, digital calipers can convert between multiple units of measurement, making them incredibly versatile. They are also portable, handheld, and easy to use, making them great for both professionals and DIY enthusiasts.

Overall, digital calipers provide a fast, accurate, and efficient way of accurately measuring different objects.

Accuracy and Precision

Accuracy and Precision If you work with measurements, especially in a field where precision is paramount, you’ll understand the benefits of using digital calipers. These tools are designed to provide incredibly accurate measurements to within a few decimal places. They usually have a large, easy-to-read display screen that allows you to quickly see the results of your measurements.

Unlike traditional calipers, which can be difficult to read and interpret, digital calipers give you clear, precise results every time. The benefit of this accuracy and precision is that you can be confident in the measurements you’re taking, making it easier to produce high-quality products or achieve accurate results in experiments. If you’re looking for a reliable and efficient way to take measurements, digital calipers are an excellent choice.

Ease of Use and Efficiency

Digital calipers have revolutionized the measuring industry by providing a more efficient and user-friendly option over traditional measuring tools. The benefits of using digital calipers are immense, starting with their ease of use. A digital caliper is designed with a digital display that shows precision measurement readings, making it easy for users to obtain accurate measurements without the guesswork involved in reading analog scales.

Efficiency is also a key benefit of digital calipers as they speed up the measuring process; with just a few clicks, users are able to obtain precise measurements while minimizing the risk of human error. In addition to reducing the risk of errors, digital calipers also offer the advantage of being able to store measurement data, making it easier to analyze and compare measurements taken over time. Overall, digital calipers are an incredible tool that make measuring tasks a breeze, saving users time and improving the accuracy of their results.

Conclusion

In conclusion, a digital caliper might seem like a simple device, but it’s actually a powerful tool that accurately measures the tiniest of details. By using a combination of electronic sensors, microprocessors, and clever programming, a digital caliper takes precise measurements with ease, allowing for increased efficiency and accuracy in a range of industries. Whether you’re a machinist, jeweler, or DIY enthusiast, a digital caliper is a must-have tool that will revolutionize the way you measure and create.

So, the next time you need to measure the thickness of a human hair (or something equally small), just remember that it’s all thanks to the clever workings of a digital caliper!”

FAQs

What is a digital caliper and how does it work?

A digital caliper is a measuring tool used to get precise measurements of objects. It works by using a reference point and a sensor to calculate the distance from the reference point to the object being measured.

How accurate are digital calipers?

Digital calipers are very accurate, with most models having a precision of up to 0.01mm. However, the accuracy may vary depending on the brand and model.

Can a digital caliper measure both internal and external dimensions?

Yes, a digital caliper can measure both internal and external dimensions. Some models also have a depth gauge for measuring the depth of holes and slots.

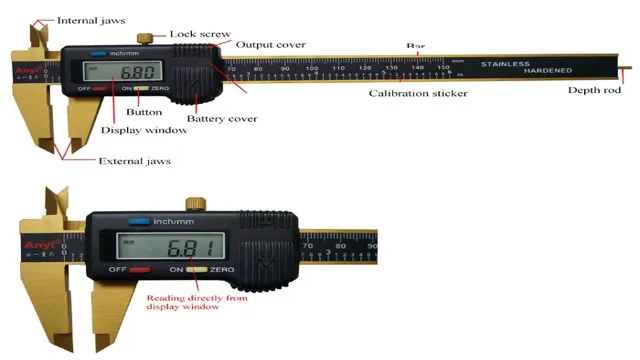

How do you read the measurements on a digital caliper?

To read the measurements on a digital caliper, you need to look at the digital display screen. The measurement will be displayed in either metric or imperial units, depending on what you have selected.

Can a digital caliper be zeroed or calibrated?

Yes, most digital calipers have a zero button that allows you to reset the reference point, and some models also have a calibration feature for accuracy.

Is it possible to connect a digital caliper to a computer or device?

Yes, some digital calipers have a USB port or Bluetooth connectivity that allows you to transfer the measured data to a computer or device.

Do digital calipers require any special maintenance?

Digital calipers require regular cleaning and protection from dust and moisture. Some models also require battery replacement or rechargeable batteries.