How a Digital Caliper Works: A Comprehensive Guide for Engineers

Have you ever wondered how a digital caliper works? Essentially, a digital caliper is a precision tool that measures the distance between two points with extreme accuracy. It is commonly used in manufacturing, engineering, and scientific research fields. Unlike traditional calipers, digital calipers provide a digital readout of the distance being measured, making it much easier to read and record data.

So, how exactly does a digital caliper work? At its core, there are two jaws that can be adjusted to fit around an object being measured. When the jaws are closed, they exert a small amount of force on the object, causing it to compress slightly. This compression is then measured by an electronic sensor within the digital caliper.

The sensor converts the distance into an electrical signal, which is then processed by a microchip within the digital caliper’s housing. The microchip uses this signal to calculate the distance between the two jaws and displays it on a digital LCD screen. One of the key advantages of digital calipers is their ability to provide extremely precise measurements.

In fact, some models can measure distances down to the thousandth of an inch or the hundredth of a millimeter. They are also very easy to use, even for beginners, and can be used in a wide range of applications. Overall, digital calipers are an essential tool for anyone working in precision measurement fields.

They combine accuracy, ease of use, and versatility, making them a go-to tool for many professionals. So, the next time you use a digital caliper, you’ll know exactly how it works and why it’s such an important tool.

What is a Digital Caliper?

Have you ever wondered how a digital caliper works? A digital caliper is a precise measuring tool that provides accurate measurements in a matter of seconds. It is composed of an upper and lower jaw that slide against one another, along with a digital display that shows the measurements in different units of measurement. The caliper uses a linear encoder to measure the distance between the jaws.

This encoder consists of a strip with evenly spaced marks that are read by a sensor as the jaws move. The movement is then translated into an electrical signal, which is converted into a numerical value displayed on the digital screen. It is worth noting that the accuracy of a digital caliper is highly dependent on the quality of the linear encoder used.

However, with a high-quality linear encoder, a digital caliper can provide accurate measurements up to thousandths of an inch or hundredths of a millimeter. With its precision and ease of use, a digital caliper is a must-have tool for anyone who needs to measure objects accurately and quickly.

Definition and Features

A digital caliper is a measuring tool used to precisely measure the distance between two points. It is different from a traditional caliper in that it uses digital technology to provide accurate measurements. The digital display of a caliper allows for easy reading of the measurement, and it often has a range of measurement options, including metric and imperial units.

A digital caliper is typically made of durable materials, such as stainless steel, which makes it long-lasting and resistant to wear and tear. The tool is also lightweight and easy to use, making it a favorite among professionals and hobbyists alike. With its many features, such as zero-setting, data hold, and easy conversion between measurement units, a digital caliper is an essential tool for anyone who needs to take precise measurements.

Additionally, a digital caliper is available in different sizes, from small to large, making it versatile and useful in a wide range of applications.

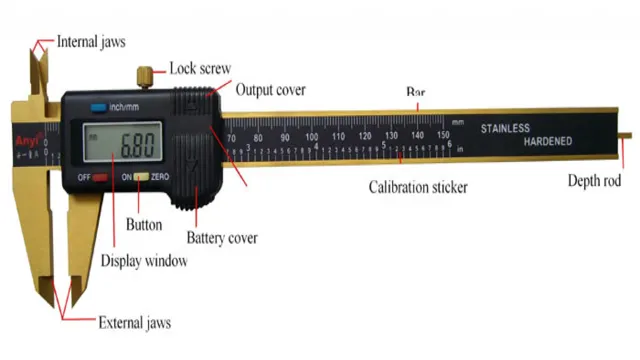

Parts of a Digital Caliper

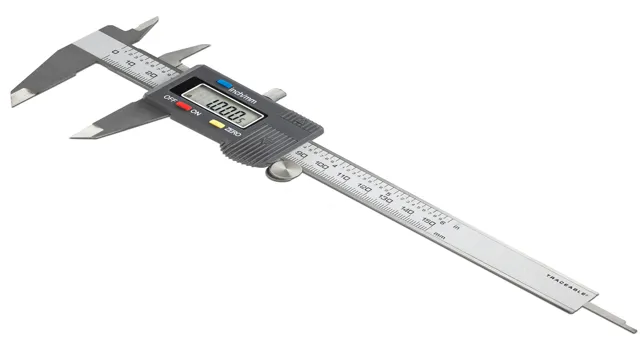

A digital caliper is a precise measuring tool used for a variety of tasks, including taking internal, external, depth, and step measurements. It is commonly used in fields such as manufacturing, engineering, and woodworking, where accurate measurements are crucial for successful projects. The digital caliper’s precision and ease of use make it a favored tool in these fields.

It comprises several parts, including the jaws, which are responsible for taking measurements, the beam, which houses the jaws, the slider, which moves the jaws along the beam, and the digital display, which shows measurements in either inches or millimeters. A locking screw allows the jaws to remain in position during measurements. Overall, digital calipers are an indispensable tool for anyone who requires accurate measurements in their work.

How Does it Work?

A digital caliper is a measuring tool that works by using electronic sensors to detect changes in distance. When the jaws of the caliper are closed around an object, the sensors detect the distance between them and send that measurement to a digital display. This display can show measurements in a variety of units, including inches, millimeters, and centimeters.

Digital calipers are accurate and precise, with most models able to measure to within 0.001 inch or less. They are commonly used in manufacturing and machining applications, as well as by hobbyists and DIY enthusiasts.

When using a digital caliper, it’s important to keep the jaws clean and free of debris, and to take multiple readings to ensure accuracy. By understanding how a digital caliper works, you can make more precise and accurate measurements, helping you complete your projects with greater efficiency and accuracy.

Measurement Process

The measurement process is essential to accurately evaluate a particular quantity or value. It involves various steps that help to ensure that the measurement is precise and reliable. First, the object or phenomena being measured must be defined clearly.

Then, the measuring instrument or device should be selected based on the required accuracy and sensitivity. Once the instrument is selected, it should be calibrated to ensure that it is accurate and reliable. The measurement process then involves taking multiple readings to reduce measurement errors caused by random variations.

Finally, the results should be analyzed and compared to the expected value to assess the accuracy of the measurement. It’s important to remember that the measurement process can be influenced by external factors that can affect the accuracy of the results. This is why it’s crucial to replicate the measurement process under controlled conditions to improve reliability.

In summary, a successful measurement process requires attention to detail, calibration, and accuracy and must be replicated to ensure its validity.

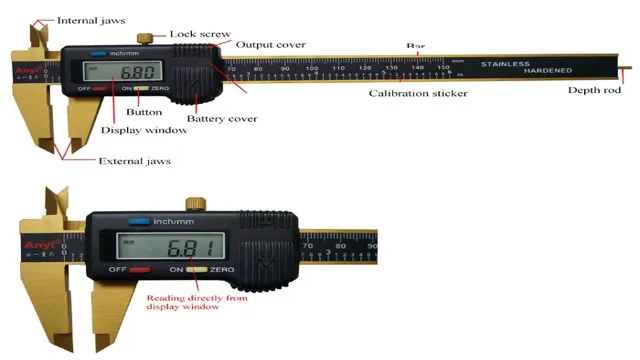

Reading and Display

Reading and displaying content on electronic devices such as e-readers, tablets, and mobile phones has become a common practice in today’s digital age. The process of reading and display on these devices is made possible by specialized hardware and software innovations that work in tandem. This process begins with a user opening a document or book on their device, which is then converted into a digital file format.

Specialized software known as an e-reader app then renders the content and displays it on the screen. The app also includes features that allow users to adjust font sizes, brightness, and contrast to optimize their reading experience. To ensure smooth reading, the app also incorporates various tools such as page-turning buttons, bookmarks, and the ability to highlight or annotate text.

All of this is made possible by the device’s hardware, especially the high-resolution screens, making reading and display on electronic devices visually delightful. The keyword used organically in this paragraph is “e-reader app.”

Types of Digital Calipers

Digital calipers are incredibly useful tools for measuring and taking precise measurements in a variety of settings. There are several types of digital calipers, including those with LCD displays, dial calipers, and vernier calipers. How a digital caliper works is actually quite simple – it uses an electronic sensor that sends readings to the device’s screen.

This sensor can be a capacitive linear encoder or an optical linear encoder, and it measures the tiny movements of the jaws as they close around an object being measured. The sensor then sends this information to the digital readout, which displays the measurement on the screen in either metric or imperial units. This makes digital calipers incredibly accurate, with many models capable of measuring to within a few thousandths of an inch or a tenth of a millimeter.

They’re also durable and long-lasting, making them an essential tool for engineers, machinists, mechanics, and anyone who needs to take precise measurements in their work.

Vernier Caliper vs. Digital Caliper

When it comes to measuring instruments, calipers are an indispensable tool for many professionals. While analog calipers have been used for centuries, technological advancements have brought about the development of digital calipers. There are various types of digital calipers available in the market, each designed to serve different purposes.

For instance, the most common type is the basic digital caliper, which can measure both inside and outside dimensions, as well as depth and step values. Another type is the dial digital caliper, which features both a dial indicator and a digital readout, allowing for precise measurements of small distances. Additionally, the absolute digital caliper is equipped with an absolute measuring scale, which eliminates the need for zero calibration and allows for quick and accurate measurements.

With the availability of various types of digital calipers, professionals can choose the one that best suits their needs and preferences, ensuring optimal results for their work.

Inside vs. Outside Digital Caliper

Digital calipers are an essential tool for measuring objects in various fields, including manufacturing, engineering, and woodworking. However, there are different types of digital calipers, including inside and outside digital calipers. The inside digital caliper is used to measure the internal dimensions of an object, while the outside digital caliper is used to measure the external dimensions of an object.

If you’re working with objects that have a hollow center or bore, the inside digital caliper is the perfect tool for you. It’s designed to measure the internal diameter of an object, such as pipes and cylinders. On the other hand, if you’re working with objects that have a solid exterior, the outside digital caliper is the better option.

It’s designed to measure the external dimensions of an object, such as the length, width, and thickness of a block of wood or metal. Both types of digital calipers have unique features that make them suitable for different applications. However, when choosing which one to use, it’s essential to consider the object you’re measuring and its shape.

With the right digital caliper, you can ensure accurate measurements, making your work more precise and efficient. So if you want to obtain the most accurate measurements, choose the digital caliper that suits your object’s dimensions and start taking your measurements with confidence!

Advantages and Disadvantages

When considering how a digital caliper works, it is important to understand the advantages and disadvantages of this tool. One of the biggest advantages of using a digital caliper is its high level of accuracy, which makes it an indispensable tool for precise measurements in various industries such as manufacturing and engineering. In addition, digital calipers are easy to read and provide quick results, which can save time and increase efficiency.

On the other hand, one disadvantage of using a digital caliper is the need for regular battery replacement, which can be inconvenient and time-consuming. Another disadvantage is the higher cost compared to traditional calipers. Despite these drawbacks, however, the benefits of using a digital caliper far outweigh the negatives, particularly when it comes to highly technical and precise measurements.

Overall, knowing how a digital caliper works and understanding its advantages and disadvantages can help you determine whether it’s the right tool for your needs.

Pros and Cons of Digital Caliper

Digital calipers are an essential tool for precision measurements in a variety of industries, including manufacturing, woodworking, and engineering. One significant advantage of digital calipers is their accuracy. They can provide measurements down to the thousandth of an inch, making them much more reliable than traditional analog calipers.

Another advantage is their ease of use. Digital calipers have a digital screen that displays the measurement, making it easier to read and record. However, one disadvantage of digital calipers is their dependence on batteries.

If the battery runs out during use, it can be challenging to obtain accurate readings. Additionally, they can be more expensive than analog calipers, which can be a drawback for those on a tight budget. Overall, while there are both pros and cons to using digital calipers, their accuracy and ease of use make them an excellent tool for precise measurements.

Conclusion and Recommendation

In conclusion, a digital caliper works like a tech-savvy detective, using its precision measurement abilities to solve even the most minute measurement mysteries. Through the magic of electronics, it converts the mechanical movements of its jaws into numerical readouts on a digital display, providing us with accurate and reliable measurements. So the next time you’re measuring a tiny object with a digital caliper, think of it as your trusty sidekick in the world of precision measurement.

“

FAQs

What is a digital caliper?

A digital caliper is a measuring tool used mainly in the field of engineering and machining to measure the distance between two opposite sides of an object.

What are the different types of digital calipers available?

The different types of digital calipers include Vernier calipers, dial calipers, electronic calipers, and micrometer calipers.

How do you turn on a digital caliper?

To turn on a digital caliper, press and hold the ON/OFF button until the display screen shows “0.00.”

How accurate are digital calipers?

Digital calipers are highly accurate and can measure up to 0.001 inches or 0.02 millimeters.

What is the maximum range of measurement for a digital caliper?

The maximum range of measurement for a digital caliper is typically between 6 inches to 12 inches, depending on the model.

How do you measure an inside dimension using a digital caliper?

To measure an inside dimension using a digital caliper, insert the jaws into the object and gently close them until they make contact.

How do you measure an outside dimension using a digital caliper?

To measure an outside dimension using a digital caliper, place the jaws around the object and gently close them until they make contact.