How to Set Up a Torque Wrench for Accurate Measurements: A Step-by-Step Guide

Setting up a torque wrench may seem daunting at first, but it’s actually a straightforward process that anyone can do with a little bit of guidance. Torque wrenches are essential tools for accurately tightening bolts and nuts to specific torque values, which is crucial for ensuring safety and preventing damage to your equipment. In this blog post, we’ll walk you through the steps to set up your torque wrench and provide you with some useful tips to make the process easier and more efficient.

So whether you’re a professional mechanic or a DIY enthusiast, keep reading to learn how to set up a torque wrench like a pro!

What is a Torque Wrench?

If you’re working with mechanical equipment, you might have heard of a torque wrench, which helps measure the force used to tighten bolts and nuts accurately. Setting up a torque wrench can be intimidating if you’re new to it, but it’s essential to ensure your equipment is safe and working correctly. Firstly, you need to determine what torque setting is required for your specific application, which you can find in your equipment’s manual or online.

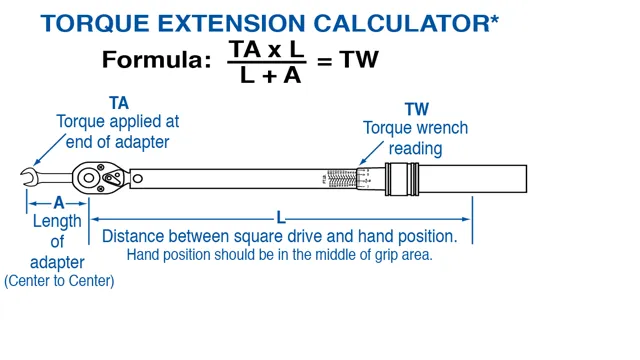

Once you have this information, set the torque wrench to the desired level by turning the handle or knob on the end of the wrench. Ensure that you’re holding the handle securely and that you’re turning it in the correct direction. Finally, attach the socket or the adapter to the torque wrench, and you’re ready to use it.

Remember to always read the instructions carefully and double-check the settings before starting any work. With a bit of practice, using a torque wrench can become second nature and help you work more efficiently and safely.

Definition and Function of Torque Wrench

A torque wrench is a tool that measures and applies a specific amount of force or torque to a fastener or bolt. It is commonly used in automotive and mechanical repairs to ensure that bolts and nuts are tightened to the correct specification. The purpose of using a torque wrench is to prevent under or over-tightening, which can cause damage to the equipment or even cause safety hazards.

The torque wrench provides a precise and accurate measurement of torque that can be set by the user, ensuring that the correct amount of force is applied to the fastener. Essentially, a torque wrench helps to ensure that the right amount of tension is applied, which extends the lifespan of equipment and makes it function effectively. In summary, a torque wrench is an essential tool for any mechanic or automotive enthusiast, and it is crucial to use it correctly to avoid any costly or dangerous errors.

Step-by-Step Guide on Setting Up Torque Wrench

If you’re unsure about how to set up a torque wrench, don’t worry! It might seem intimidating at first, but it’s actually a simple process that anyone can do with just a little bit of practice. First things first, make sure to choose the right torque setting based on the manufacturer’s specifications for the fastener you’re tightening. Once you’ve done this, attach the appropriate socket or bit to the wrench and make sure it’s securely fastened.

Then, set the desired torque level using the adjustment knob or scale on the handle. When you’re ready to use the wrench, place it onto the fastener and begin tightening until you feel the wrench “click” or reach its preset torque level. At this point, you can stop tightening and move on to the next fastener.

It’s important to note that torque wrenches should be regularly calibrated and maintained to ensure accuracy, so make sure to follow the manufacturer’s guidelines for proper care and use.

Step 1: Identify the Torque Specification

Setting up a torque wrench can seem like a daunting task, but it’s actually quite simple once you understand the necessary steps. The first step is to identify the torque specification for the specific application you will be working on. This information can usually be found in the vehicle’s service manual or in the manufacturer’s documentation.

It is essential to use the correct torque specification to ensure that the fastener is tightened to the correct level without over-tightening or under-tightening. Once you have identified the torque specification, it’s time to set up your torque wrench. By following the manufacturer’s instructions and properly calibrating your torque wrench, you can achieve accurate and consistent torque readings every time.

Remember that accuracy is crucial when using any type of wrench. By taking the time to set up your torque wrench correctly, you can avoid costly mistakes and ensure your work is done to a high standard.

Step 2: Set the Torque Wrench to Zero

Once you have chosen the right torque wrench for your project, it’s important to set it up properly to ensure accurate results. Step 2 in the process is to set the torque wrench to zero. This means that you zero out any tension or pressure that may be on the wrench before you begin using it.

To do this, simply adjust the wrench to the lowest setting and then turn it back to zero. This will relieve any residual pressure from the wrench and prepare it for use. When setting the wrench to zero, be sure to also check that the scale is calibrated correctly.

Even the slightest deviation can throw off your torque measurements, so it’s important to get it right from the start. By taking the time to set up your torque wrench correctly, you can ensure that you get the precision and accuracy you need to complete your project with confidence. So, don’t skip this important step and get started on your project today!

Step 3: Adjust the Torque Wrench to the Required Torque Value

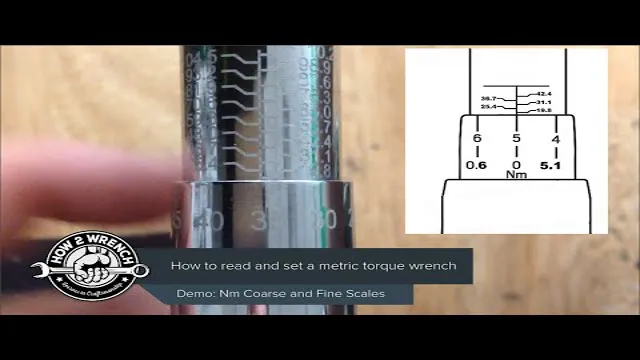

Once you have selected the right torque wrench for your job, the next step is to adjust it to the required torque value. This step is crucial in ensuring the accuracy of your work and preventing any damage or injury. Most torque wrenches come with an adjustable scale or digital display that allows you to set your desired torque value.

To do this, first, make sure the wrench is set to zero. Then, locate the adjustment knob or dial and turn it until the desired torque value is displayed. It’s important to note that different fasteners and materials may require different torque values, so always refer to the manufacturer’s specifications.

Once the proper torque has been set, you’re ready to start tightening. A torque wrench is a powerful tool, so always use it with caution and respect its capabilities. By taking the time to properly set up your torque wrench, you’ll ensure accurate and safe results every time.

Step 4: Use the Torque Wrench Correctly

When it comes to using a torque wrench, setting it up correctly is important to ensure accurate readings. Firstly, make sure to choose the correct torque setting for your specific task. Then, attach the appropriate socket size to the end of the torque wrench.

Next, adjust the torque wrench to the desired level by turning the handle until the desired measurement is shown on the gauge. Remember to use slow and steady force when tightening the bolt, keeping the wrench at a right angle to the bolt. Once the desired level of torque is reached, you’ll hear a distinct click letting you know it’s time to stop.

In short, use the torque wrench consistently and correctly to avoid any possible mistakes.

Tips for Maintaining Torque Wrenches

If you want to ensure the accuracy of your torque wrench, it’s essential to know how to set it up correctly. First, you should clean the tool regularly and store it appropriately to avoid excess wear and tear. When setting up the tool for use, consider the type of bolt you’re tightening and use the correct torque value according to the manufacturer’s specifications.

It’s crucial to use the right torque wrench for the job, as different wrenches are designed to handle different levels of force. Remember to adjust the wrench’s settings before each use, and avoid using it for applications that exceed its capacity. Finally, be sure to calibrate your torque wrench regularly to ensure consistent measurements and accuracy over time.

By following these tips, you can keep your torque wrench in good working order and get the most out of your investment.

Proper Storage Guidelines for Torque Wrenches

If you’re looking to extend the lifespan of your torque wrenches, proper storage is crucial. Here are some tips for maintaining torque wrenches so that they don’t lose their accuracy or performance over time. First, store your torque wrench in a clean, dry, and protected area.

This will prevent dust, moisture, and other harmful elements from corroding or contaminating the wrench. Additionally, always store your wrench in the same position as it was when last used. Torque wrenches can lose calibration when stored in a different position causing inaccuracies in future readings.

It’s also a good idea to loosen the setting on your wrench before storing it. This will relieve any tension that may have accumulated during use, which can lead to incorrect readings. Proper storage and maintenance of your torque wrenches will ensure that they last longer and provide accurate readings time after time.

Regular Calibration of Torque Wrenches

If you rely on torque wrenches in your work, you know how important it is to maintain and calibrate them regularly. In order to ensure their accuracy and reliability, there are some easy maintenance tips you can follow. First, always clean the wrench after each use to prevent buildup of dirt and debris.

Additionally, store your wrenches in a dry and cool place to prevent any rust or corrosion. It’s also a good idea to check the calibration of your wrenches regularly, especially if they are used frequently. If you find that a wrench is out of calibration, have it serviced by a professional to restore its accuracy.

By following these simple maintenance tips, you can ensure that your torque wrenches perform accurately and reliably every time you use them.

Conclusion

In conclusion, setting up a torque wrench is easier than you might think! All you need is your trusty torque wrench, a bit of muscle, and a few simple steps. Just remember to choose the correct torque setting, line up your wrench with the bolt, and make sure to tighten it at a slow and steady pace. And if you’re feeling really fancy, why not add a little extra torque for good measure? After all, we all know that a little extra power never hurt anyone.

So go forth and wrench with confidence, my friends!”

FAQs

What is a torque wrench?

A torque wrench is a tool used to tighten nuts and bolts to a specific level of torque.

Why is it important to use a torque wrench?

Using a torque wrench ensures that nuts and bolts are tightened properly, which can prevent damage to equipment and ensure safety.

How do I set the torque on a torque wrench?

To set the torque on a torque wrench, adjust the dial or scale to the desired torque level. Some torque wrenches also have a digital display that allows for precise torque settings.

Can a torque wrench be used for loosening bolts?

No, a torque wrench is designed for tightening bolts to a specific level of torque. It should not be used for loosening bolts.

How often should I calibrate my torque wrench?

Torque wrenches should be calibrated regularly, typically every 12 months or after a certain number of uses, to ensure accurate torque readings.

What are the different types of torque wrenches?

There are several types of torque wrenches, including beam, click, digital, and dial. Each works slightly differently but has the same goal of tightening bolts to a specific level of torque.

Do I need to use a different torque wrench for different sizes of bolts?

It is recommended to use a different torque wrench for different bolt sizes, as the required torque level may be different. It is important to check the manufacturer’s specifications for the correct torque level for each size of bolt.