How to Calculate Torque Wrench Extension: A Complete Guide for Accurate Torque Measurements

If you are a DIY enthusiast or a professional mechanic, a torque wrench is a useful tool to have in your toolkit. It helps ensure that you tighten bolts and nuts at the appropriate level of tension to prevent damage. However, using a torque wrench involves more than just selecting the correct setting and tightening the bolt.

You also need to calculate the correct torque wrench extension to achieve the desired level of torque. It might seem complicated, but with a little bit of knowledge, you can master this skill in no time. In this blog post, we’ll explain in detail how to calculate torque wrench extension, so you can use your torque wrench like a pro.

Introduction

Calculating torque wrench extension can be a bit daunting, but it’s actually quite a simple process. First things first, you’ll need to determine the torque specification for the bolt or nut that you’re tightening. This information can usually be found in the manufacturer’s manual or online.

Once you have the torque specification, you’ll need to choose the appropriate torque wrench for the job and set it to the correct torque value. Next, you’ll need to determine the length of the wrench from the pivot point to the end of the handle. This is known as the “moment arm”.

Finally, you’ll need to calculate the required torque wrench extension by dividing the torque value by the moment arm. This will give you the amount of force you need to apply at the end of the wrench handle to achieve the desired torque. Remember to always use a torque wrench for accurate and consistent results, and to recheck torque values after a few cycles of use or if there’s any change in the fastener or joint.

By following these steps, you’ll be able to tighten bolts and nuts to the correct specification, ensuring the safety and reliability of your projects.

Explanation of Torque Wrench Extension

A torque wrench extension is an essential tool used in automotive and mechanical fields for tightening bolts and nuts with precision. It is an attachment designed to be used with a torque wrench to adjust its length to reach bolts in tight spaces. The extension tool ensures a longer reach without compromising the accuracy of the torque settings.

This tool is particularly useful for mechanics who work on cars or other vehicles because they need to work on hard-to-reach bolts frequently. The extension tool helps in applying the correct torque settings to critical components such as suspension or engine parts, which contributes to the longevity and safety of the vehicle. Using a torque wrench extension in conjunction with a torque wrench is a smart investment for anyone looking to maintain their vehicles themselves.

Factors that Affect Torque Wrench Extension

Calculating torque wrench extension may seem like a daunting task, but it’s actually quite simple once you understand the key factors that come into play. One of the most important factors is the length of the torque wrench. The longer the wrench, the greater the torque extension, which means you can achieve higher levels of torque.

However, it’s important to remember that using a very long wrench can also increase your chances of over-torquing, so it’s important to use the correct length for the specific task at hand. In addition to length, the type of torque wrench you are using and the calibration of the tool also play a role in determining the amount of torque extension. By taking these factors into account and using a torque wrench that is calibrated correctly, you can ensure that you are getting accurate and reliable results every time you use your tool.

Length of Wrench Handle

When it comes to torque wrenches, the length of the wrench handle can have a significant impact on the amount of torque being applied. The longer the handle, the more leverage you have, which means you can apply more force to the bolt you’re trying to tighten. However, this also means that you’ll need to use more force to turn the handle in order to achieve a given torque setting.

Another factor that can affect torque wrench extension is the type and size of the bolt you’re working with. Larger bolts will require more torque to tighten properly, while smaller bolts will require less. Additionally, the material of the bolt can have an impact on torque, as different materials have different levels of friction and require different amounts of force to turn.

It’s also worth noting that the accuracy of your torque wrench can be affected by the length of the handle. A longer handle can make it more difficult to gauge the amount of force being applied, which can lead to under- or over-tightening. To ensure you’re getting accurate torque readings, it’s essential to use a torque wrench that’s calibrated properly and to follow the manufacturer’s instructions carefully.

Ultimately, the best length for your torque wrench handle will depend on your specific needs and the type of work you’re doing. If you’re working with larger bolts or need to apply more force, a longer handle may be preferable. However, if you need to maintain precision and accuracy, a shorter handle may be the better choice.

By considering the factors that affect torque wrench extension, you can choose the right tool for the job and achieve reliable, consistent results.

Distance from Point of Rotation

When it comes to torque wrench extension, there are several factors that can affect its performance, including the distance from the point of rotation. The closer the distance from the point of rotation, the less torque is required to tighten a bolt or nut. This is because the closer the torque is applied to the point of rotation, the more leverage it has, which means less force is needed to achieve the desired torque setting.

On the other hand, the farther the distance from the point of rotation, the more torque is required to tighten a bolt or nut. This is because the farther away the torque is applied from the point of rotation, the less leverage it has, which means more force is needed to achieve the same torque setting. So, it’s important to consider the distance from the point of rotation when selecting a torque wrench for a specific task.

By understanding the factors that affect torque wrench extension, you can ensure that you select the right tool for the job and achieve the desired torque setting with ease and accuracy.

Torque Value

Torque wrenches are an essential tool in any mechanic’s arsenal, and their accuracy often depends on the torque value applied. However, several factors can affect the torque wrench extension, making it challenging to achieve the desired torque value. One crucial factor is the length of the torque wrench.

Typically, a longer tool will require more torque to achieve the same value as a shorter one. The type of material the fastener is made of also plays a significant role, with softer materials accommodating more torque before breaking. The thread type of the fastener should also be considered, as a fine thread requires less torque than a coarse thread to achieve the same force.

Finally, the condition of the torque wrench also affects accuracy, with a tool that has not been calibrated recently providing incorrect readings. By considering all these factors, you can ensure a higher level of accuracy when using a torque wrench.

Size of Socket

When using a torque wrench, the size of the socket can play a big role in how effective the tool is. The larger the socket, the more torque the wrench can apply. Conversely, a smaller socket will require less torque to achieve the same level of tightness.

Another factor that can affect torque wrench extension is the type of material being used. Softer materials, like aluminum, will require less torque than harder materials, like steel. Additionally, the length of the wrench itself can impact the amount of torque that can be applied.

A longer wrench will generally be able to apply more torque than a shorter one. It’s important to consider all of these factors when choosing a torque wrench and selecting the appropriate socket size for the job at hand. By doing so, you can ensure that your wrench is able to deliver the necessary level of torque to properly tighten bolts and fasteners.

Formula for Calculating Torque Wrench Extension

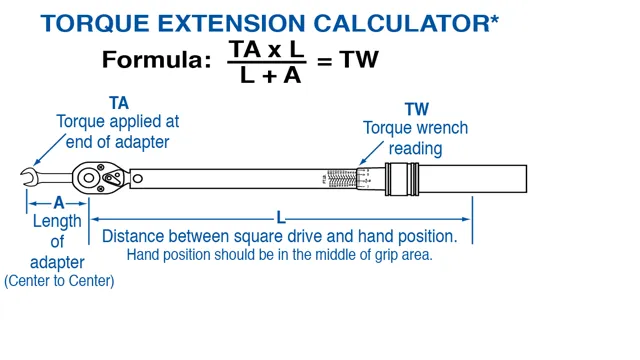

If you work in the automotive or mechanical field, you know just how important it is to use a torque wrench when tightening bolts. But, have you ever wondered how to calculate torque wrench extension? It may seem complex, but it’s actually a simple formula. To calculate the torque wrench extension, you need to know the torque value required, the length of the wrench, and the unit of measurement used.

Once you have these values, you can simply divide the required torque by the length of the wrench and convert the units to find the extension needed. It’s important to note that using the wrong extension can lead to over or under tightening, which can cause damage to the material being worked on. So, taking the time to calculate the correct torque wrench extension is crucial for ensuring a successful and safe project.

Step-by-Step Calculation Example

When it comes to tightening bolts, it’s essential to use the right level of torque to ensure everything stays secure. But how do you calculate the correct torque wrench extension? Here’s a step-by-step example to help guide you. First, you’ll need to know the torque specifications for your particular job.

Let’s say you’re tightening a bolt with a required torque of 50 foot-pounds. You’ll also need to know the length of your torque wrench and the distance from the point where the wrench is applied to the center of the bolt. Let’s assume your wrench is 12 inches long, and the distance from the point where it’s applied to the center of the bolt is 6 inches.

Next, use the formula T=CxL, where T is the required torque, C is the force constant of the wrench, and L is the length from the point where the wrench is applied to the center of the bolt. To calculate the force constant, divide the required torque (50 foot-pounds) by the length of the wrench (12 inches) to get 1667 foot-pounds per inch.

Finally, multiply the force constant (1667) by the distance from the point where the wrench is applied to the center of the bolt (6 inches) to get the required torque wrench extension – in this case, 25 foot-pounds. With this formula, you can ensure you’re using the right level of torque for any job.

Conclusion

Calculating torque wrench extension is like predicting the weather – it may seem complicated, but with the right tools and a little bit of math, anyone can do it. By considering factors such as bolt length, thread pitch, and desired torque setting, you can determine the correct extension for your torque wrench and ensure a tight and secure fit. So next time you’re embarking on a mechanical project, remember to calculate your torque wrench extension – and just like a well-prepared meteorologist, you’ll be ready for anything Mother Nature (or your engine) throws your way!”

FAQs

What is the formula to calculate torque wrench extension?

The formula to calculate torque wrench extension is: Extension (in) = Torque (ft-lb) / (20 x Diameter of Bolt (in)).

How do I choose the right torque wrench extension for my application?

You need to consider the bolt size, torque value needed, and the clearance available to determine the right torque wrench extension.

Can I use a torque wrench extension with any type of torque wrench?

Yes, torque wrench extensions can be used with any type of torque wrench as long as the extension is compatible with the wrench drive size.

What happens if I use the wrong torque wrench extension?

Using the wrong torque wrench extension can result in inaccurate torque readings, damaged bolts or fittings, and dangerous safety hazards.

How often should I calibrate my torque wrench extension?

It is recommended to calibrate your torque wrench extension annually or after every 5,000 cycles. However, it should be recalibrated if dropped or used beyond its capacity.

Can I adjust the torque value when using a torque wrench extension?

No, you cannot adjust the torque value when using a torque wrench extension. The extension only extends the reach of the torque wrench for hard-to-reach areas.

Are torque wrench extensions reusable?

Yes, torque wrench extensions are reusable as long as they are not damaged or worn out. It is important to inspect the extension before every use to ensure safety and accuracy.