Are you tired of manually watering your garden or lawn? Well, why not automate the process by installing a sprinkler system? It not only saves time but also ensures equal water distribution throughout the area. But, how do you connect the air compressor to the sprinkler system? It may sound daunting, but it’s relatively easy. In this blog post, we’ll guide you through the steps of connecting an air compressor to a sprinkler system.

So, sit back, relax, and let’s get your garden irrigated with minimal effort!

Gather Necessary Materials

Before connecting your air compressor to your sprinkler system, it’s important to gather all the necessary materials. Depending on the specific system you have, you may need a variety of fittings, hoses, and adapters to ensure a proper connection. Be sure to check the manufacturer’s instructions and recommendations to ensure you have all the correct parts.

You will also need an air compressor with enough power to effectively run your sprinkler system. Make sure to choose a compressor with the proper cubic feet per minute (CFM) rating and pressure to meet your system’s needs. In addition, it’s important to have safety equipment on hand in case of an accident, such as eye and ear protection.

By gathering all the necessary materials before starting the installation process, you can ensure a successful and safe connection between your air compressor and sprinkler system.

Air Compressor

When you first get your air compressor, there are a few things you need to gather before you can start using it. First, you’ll need an electrical source, such as an outlet or extension cord, to power your compressor. Make sure to check the voltage and amperage requirements of your specific compressor so you don’t overload the circuit.

Next, you’ll need a hose to connect your compressor to your tools. Air hoses come in a variety of lengths and diameters, so make sure to choose one that will allow you to work comfortably without restricting your movements. Finally, you’ll need some basic safety equipment, such as protective eyewear and earplugs.

Compressors can be quite loud, and they can also generate a lot of debris and dust, so protecting your eyes and ears is essential. With these materials in hand, you’ll be ready to start exploring all the different ways you can use your air compressor to make your projects faster, easier, and more efficient.

Sprinkler System

If you’re planning to install a sprinkler system in your yard, the first step is to gather all the necessary materials. You’ll need to purchase a variety of components, including sprinkler heads, valves, piping, and a controller. It’s important to choose high-quality products that are designed to withstand the wear and tear of outdoor use.

You may want to consider consulting with a professional landscaper or irrigation specialist to help you select the best materials for your needs. Don’t forget to factor in the size and layout of your yard when determining how many sprinkler heads and zones you’ll need. By taking the time to gather all the necessary materials upfront, you can ensure that your sprinkler system installation goes smoothly and that you end up with a system that provides the right amount of water to keep your plants healthy and thriving.

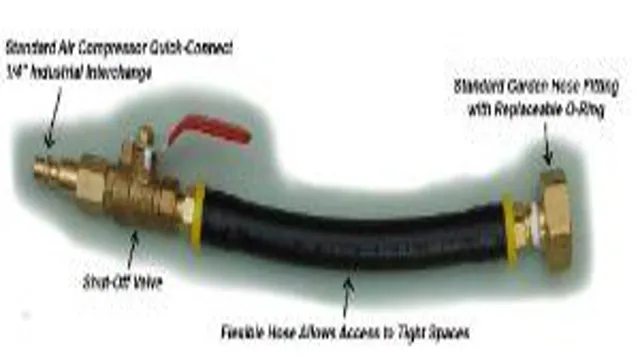

Air Hose

If you’ll be working with air tools or want to inflate some tires, you’ll need an air hose. Before you head to the hardware store, gather all of the necessary materials to make sure you get the right hose. First, figure out what diameter you need by looking at the fittings on your tools or the tire valve stem.

Then, measure the distance between your compressor and where you’ll be using the hose to make sure you get a long enough one. Don’t forget to consider the quality of the hose material itself – you’ll want something durable that can handle high pressures without leaking or breaking. With these considerations in mind, you’ll be prepared to shop for an air hose that meets your needs and will help you get the job done efficiently.

Prepare for Connection

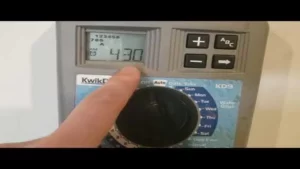

When it comes to connecting your air compressor to your sprinkler system, preparation is key. First, ensure that your sprinkler system is turned off and depressurized before attempting to connect the air compressor. Next, locate the compressed air inlet on your sprinkler system and attach the air compressor hose to the inlet, making sure to secure it tightly.

It’s important to note that the air compressor’s pressure should be set to match the maximum pressure rating of your sprinkler system to prevent damage. Once connected, slowly turn on the air compressor and increase the pressure until it matches the desired pressure for your sprinkler system. Keep a close eye on pressure levels and make necessary adjustments as needed.

By taking the proper steps and being mindful of pressure levels, you can successfully connect your air compressor to your sprinkler system and ensure efficient operation.

Turn Off Water and Disconnect Power

Before installing new appliances or making repairs, it’s important to prepare for the connection by turning off the water and disconnecting power. This not only ensures safety but also prevents potential damage to the appliances. Water can cause short circuits and electrical shocks while power can damage pipes and plumbing.

So, it’s crucial to take necessary precautions before starting any work. Turning off the water supply is simple and can usually be done via a shut-off valve. Make sure you also turn off the power to the appliance or area you’re working on, and double-check that it’s not live before starting any work.

This will not only protect you but also help prevent any damage that could occur to your home. Taking these simple steps before getting started will ensure the job is done safely and without any issues.

Attach Fittings to Air Compressor

When it comes to attaching fittings to your air compressor, preparation is key! It’s important to ensure you have everything you need before starting, such as the right fittings and any necessary adapters. Check the owner’s manual to determine the correct type and size of fitting to use. Once you have the fittings, you can begin the installation process by screwing them securely onto the compressor’s outlet port.

It’s essential to use Teflon tape and an adjustable wrench to prevent any leaks. Remember, every air compressor is different, so take the time to read the instructions and familiarize yourself with the setup. By taking the necessary steps to prepare for the connection, you’ll save yourself time and frustration in the long run while ensuring a reliable and safe connection.

Attach Fittings to Sprinkler System

Before connecting the fittings to your sprinkler system, it’s essential to prepare the setup for the installation process. Start by locating the main water source and turning off the valve to cut the water to the sprinkler system. Next, remove any dirt or debris from the pipes and fittings to ensure a clean and tight fit.

Once the area is prepped and ready, attach the fittings to the sprinkler system by using Teflon tape to seal the connections and prevent any leakage. It’s essential to ensure all fittings are tightly secured to prevent any water from escaping and potentially damaging the surrounding landscape. Once the fittings are in place, it’s time to connect the sprinkler heads, which will distribute water to the yard.

Remember to follow the manufacturer’s instructions carefully and avoid over-tightening the connections. With these steps completed, your sprinkler system is ready for use, and you can enjoy an efficient and healthy lawn that’s easy to maintain.

Test and Adjust

Connecting an air compressor to a sprinkler system requires a few steps to ensure everything operates smoothly. The first step is to install an air hose fitting onto the air compressor and connect it to the sprinkler system using a quick disconnect fitting. Next, turn on the air compressor and adjust the pressure to match the sprinkler system’s requirements.

It’s crucial to test the system and observe any issues, such as leaks or insufficient pressure. Once the system is running correctly, it’s time to make any necessary adjustments. These adjustments may involve tweaking the pressure or changing the orientation of the sprinkler heads to achieve optimal coverage.

With proper testing and adjustments, your sprinkler system will be efficiently connected to your air compressor, ensuring a lush and healthy lawn.

Test the Connection

When you’re setting up a network, it’s critical to test and adjust the connection to ensure it’s stable and reliable. Testing the connection involves checking for internet connection, speed, and overall connectivity. It’s essential to carefully examine each device and system that makes up the network to avoid any hiccups during connection.

You can use online tools to test the speed of the network and determine the overall quality of the connection. If the speed is slow, you may need to adjust the configuration settings to boost the speed and enhance the performance of the network. A slow connection can make web browsing and downloading large files tedious and time-consuming.

In short, testing and adjusting the connection is crucial in ensuring optimal performance for your network.

Adjust Pressure as Needed

When it comes to properly inflating your vehicle’s tires, testing and adjusting the pressure can make all the difference in the world. Even if you think your tires are at the recommended pressure, external factors such as temperature or driving conditions can cause the pressure to fluctuate. That’s why it’s important to regularly test your tire pressure with a reliable gauge and adjust it as needed.

Over or under-inflated tires can impact your vehicle’s performance and even lead to a blowout, so taking a few extra minutes to double check and adjust the pressure can not only improve your vehicle’s handling and fuel efficiency but also your overall safety on the road. Don’t let something as simple as tire pressure go overlooked – take the time to test and adjust as needed. Your vehicle (and your wallet) will thank you.

Conclusion

In conclusion, connecting an air compressor to your sprinkler system requires a bit of know-how and a lot of patience. It’s not rocket science, but it does require some careful planning, the right tools, and a willingness to get your hands dirty. Whether you’re a seasoned DIY enthusiast or a novice homeowner, with a little bit of effort and a lot of creativity, you’ll be able to connect your air compressor to your sprinkler system in no time.

So don’t be afraid to give it a try, and remember: the key to success is always in the details. Happy sprinkling!”

FAQs

What is an air compressor and how does it work in a sprinkler system?

An air compressor is a tool that supplies pressurized air to the sprinkler system’s pipes. When connected to the sprinkler system, the air compressor helps push the water through the pipes and out of the sprinkler heads, resulting in efficient irrigation.

What kind of air compressor should I use for my sprinkler system?

It is recommended to use a portable air compressor with a maximum pressure of 150 PSI for a sprinkler system. It should also have a tank size of at least 20-30 gallons, as it will need to store a large volume of air for continuous operation.

How do I connect the air compressor to my sprinkler system?

To connect the air compressor to your sprinkler system, you need to locate the main water supply valve and turn off the water flow. Then, attach the air compressor to the system’s mainline using an air compressor hose and a quick-connect fitting. Once connected, turn on the air compressor and allow it to generate enough pressure to pressurize the pipes.

How much pressure should the air compressor generate for my sprinkler system?

The recommended pressure for a sprinkler system is between 40 and 60 PSI. A portable air compressor with a maximum pressure of 150 PSI can easily achieve this level of pressure.

How often should I run the air compressor to maintain my sprinkler system?

You should run the air compressor before and after each irrigation cycle to ensure that the pipes are pressurized correctly. It is also recommended to run the compressor once a month to keep the system in peak working condition.

What should I do if I hear water running once I turn off the air compressor?

If you hear water running once you turn off the air compressor, there may be a leak in the system. You should turn off the main water supply valve immediately and check for leaks in the pipes, sprinkler heads, or valves. Repair any damaged components before running the system again to avoid further water waste.

Can I use an air compressor for other irrigation systems besides sprinklers?

Yes, an air compressor can also be used for drip irrigation or soaker hoses. However, you should ensure that the system can handle the pressure generated by the compressor to prevent damage to the hoses and emitters. It is also recommended to use a regulator to maintain the correct pressure for the irrigation system.