How to Calibrate Harbor Freight Torque Wrench: Step-by-Step Guide for Accurate Results

If you’re a DIY enthusiast or a professional mechanic, having a torque wrench in your toolkit is a must. It’s a tool that helps you tighten bolts and nuts accurately, preventing damages to the parts and ensuring safety. Harbor Freight is one of the most popular brands on the market, and many people rely on their torque wrenches to get the job done.

However, it’s essential to keep your tools well-maintained and calibrated to ensure their accuracy and efficiency. If you’re wondering how to calibrate a Harbor Freight torque wrench, you’re in the right place. In this blog, we’ll guide you through the step-by-step process of calibrating your torque wrench, so you can continue your work with confidence and precision.

What is a Torque Wrench?

Have you ever wondered what a torque wrench is and how it works? Simply put, a torque wrench is a tool that helps to tighten bolts or screws to a specific level of torque. This is important because over-tightening can cause damage to the bolt or equipment, while under-tightening can pose a safety risk. One of the most popular brands of torque wrenches is Harbor Freight, but like any piece of equipment, it needs to be calibrated periodically to ensure accuracy.

So, how do you calibrate a Harbor Freight torque wrench? One method is to use a torque calibration tool to test the accuracy of the wrench at different torque settings. By making any necessary adjustments to the wrench, you can ensure that it will continue to provide reliable and accurate readings. Regular calibration can help extend the lifespan of your torque wrench and protect your equipment and safety on the job.

Explanation of a Torque Wrench and Why Calibration is Important

A torque wrench is a tool used to tighten bolts, screws, or nuts to a specific level of torque or rotational force. It helps prevent over-tightening or under-tightening, which can cause damage to equipment, components, or even cause injury. Torque wrenches come in different types such as click-type, beam-type, and digital.

Click-type wrenches emit an audible click when the desired torque level is reached. A beam-type wrench uses a calibrated spring and lever to determine torque, while digital wrenches have an electronic display that shows the torque level. It is essential to calibrate torque wrenches regularly to ensure accurate readings.

Calibration involves adjusting the wrench to match a known torque value using a calibration tool, and this helps to maintain the tool’s accuracy and reliability. Failing to calibrate a torque wrench can lead to inconsistent or incorrect torque values, which can result in equipment failure, safety hazards, or costly repairs. Overall, a torque wrench is a vital tool in any mechanic’s toolkit, and calibrating it is crucial for ensuring precision and reliability in mechanical work.

Steps to Calibrate a Harbor Freight Torque Wrench

If you own a Harbor Freight torque wrench, you know it’s an affordable and reliable tool for tightening bolts to the exact specification. However, like any other tool, it’s essential to calibrate it from time to time to ensure that it’s accurate. Calibration is easy to do and can be done at home with the right tools.

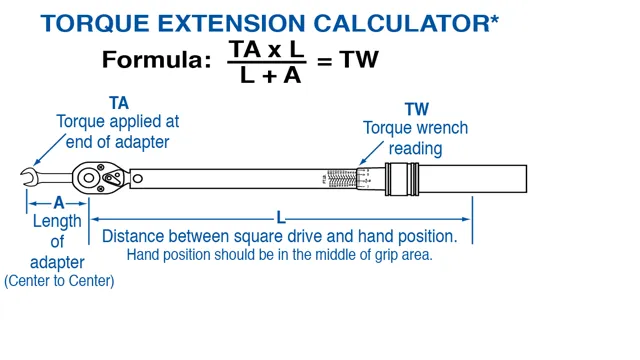

Here’s how to calibrate your Harbor Freight torque wrench: First, you’ll need a trusted calibration tool, which is typically a torque tester. This tool is used to measure the applied torque force, which helps you determine its accuracy.

Next, locate the torque adjustment knob on your torque wrench. It’s usually on the handle or near the head of the wrench.

Adjust the torque knob to your desired torque setting, then place the torque wrench into the torque tester.

Apply force to the torque wrench until it clicks. The torque tester will show you if the force you applied is within the acceptable range. If it’s not, you’ll need to adjust the wrench until it’s accurate.

Repeat this process for several torque settings to ensure that the wrench is reading accurately.

Step-by-Step Instructions on Calibrating Harbor Freight Torque Wrench

Calibrating Harbor Freight Torque Wrench If you’re looking for a way to ensure that your Harbor Freight torque wrench is accurately measuring torque, calibrating it is essential. The process can seem a bit daunting at first, but with a bit of guidance, it’s actually quite straightforward. Here are the steps you can follow to calibrate your Harbor Freight torque wrench.

First, you’ll need to find a torque testing device or torque wrench calibration tool that’s capable of measuring the torque range of your wrench. You can find these devices at specialty tool stores or online retailers. Once you have your torque testing device, set it to the desired torque measurement for your wrench.

Next, insert your Harbor Freight torque wrench into the torque testing device and apply pressure until the wrench clicks, indicating that the preset torque has been reached. Check the reading on the torque testing device to see if it matches the preset torque. If the reading doesn’t match the preset torque, you’ll need to adjust the calibration of your Harbor Freight torque wrench.

The process for doing this varies depending on the model of your wrench, so be sure to consult the instruction manual that came with your wrench for guidance. Once you’ve adjusted the calibration, repeat the torque testing process to ensure that the reading on both devices matches. If they do, your Harbor Freight torque wrench is now accurately calibrated and ready to use.

Calibrating your Harbor Freight torque wrench is crucial for accurate torque measurements, especially when working on delicate or precise projects. With these simple steps, you can easily calibrate your wrench and ensure that it’s providing reliable measurements every time you use it.

Tools Needed for Calibration

Calibrating a Harbor Freight torque wrench may seem like a daunting task, but with the right tools and steps, it can be done easily. To start, you’ll need a torque wrench calibration tool, which is specifically designed to check the accuracy of torque wrenches. Additionally, you’ll need a set of wrenches or socket adapters, torque stick or breaker bar, and a calibrated torque wrench to use as a reference.

Once you gather your tools, you can move on to the actual calibration process. Begin by adjusting the torque wrench to zero, then attach the torque wrench calibration tool to the torque wrench and follow the manufacturer’s instructions. Take note of the readings on the tool and compare them with the calibrated wrench.

If your torque wrench is not accurate, you can adjust it using the wrenches and socket adapters. Once you’ve made the necessary adjustments, retest the torque wrench and ensure that it meets the manufacturer’s specifications. With these simple steps and the right tools, you can easily calibrate your Harbor Freight torque wrench for accurate and reliable use.

Calibration Procedure

Calibration Procedure Calibrating your Harbor Freight torque wrench is an important maintenance procedure that should be done regularly to ensure accuracy. Here are the steps you need to follow to calibrate your Harbor Freight torque wrench: Step 1: Gather the necessary tools and equipment, including a torque tester and a certified weight. Step 2: Begin by setting your torque wrench to a low value, such as 10 lb-ft.

Step 3: Attach the torque tester to the end of the torque wrench, making sure it’s properly secured. Step 4: Apply a certified weight to the torque tester, and ensure that the torque wrench clicks at the specified torque value. Step 5: Repeat steps 2-4 at various torque settings, making sure your torque wrench is accurate at each setting.

Step 6: Once you’ve completed the calibration process, record the calibration values for future reference. Remember, accurate torque is critical for many mechanical applications, and regular calibration is necessary to maintain the integrity of your Harbor Freight torque wrench. By following these steps, you can ensure that your torque wrench is operating at peak performance and providing reliable results every time.

How Often to Calibrate a Harbor Freight Torque Wrench?

“How often to calibrate a Harbor Freight torque wrench?” is a common question among those who use torque wrenches frequently. Although Harbor Freight torque wrenches are designed to be durable and reliable, they still require calibration from time to time to ensure accuracy. The frequency of calibration depends on several factors, including how often the torque wrench is used, how it’s used, and the conditions under which it’s used.

Generally, it’s recommended to calibrate a torque wrench at least once a year, or more frequently if it’s used heavily or subjected to harsh conditions. Calibration should also be done if the torque wrench has been dropped or otherwise damaged, as this can affect its accuracy. It’s essential to follow the manufacturer’s instructions when calibrating a torque wrench to ensure that it’s done correctly and that the wrench remains accurate and reliable.

By calibrating your Harbor Freight torque wrench regularly, you’ll not only prevent errors and ensure accuracy but also prolong its lifespan.

Frequency of Calibration and Why it’s Important

When it comes to torque wrenches, it’s essential to ensure accuracy and consistency in every use. And that’s why calibration is crucial. The frequency of calibration depends on how frequently you use the torque wrench.

A good rule of thumb is to calibrate your Harbor Freight torque wrench every 5000 cycles or every six months, whichever comes first. By doing so, you ensure that your wrench is always delivering the same amount of force consistently. It’s also important to note that calibration is not only about accuracy; it’s about safety too.

An inaccurate torque wrench can result in improperly assembled parts, which can lead to accidents or breakage. In other words, if you want your Harbor Freight torque wrench to maintain its accuracy and safety, it’s necessary to calibrate it at a regular interval.

Conclusion

In conclusion, calibrating a Harbor Freight torque wrench is a simple process that can save you a lot of headache down the road. By using a torque calibration tool and following the manufacturer’s instructions, you’ll ensure that your wrench is accurate and reliable. And who knows, maybe one day you’ll even be able to confidently proclaim, “I torque like a pro!” So go forth and calibrate, my fellow DIYers!”

Final Thoughts on Calibrating Harbor Freight Torque Wrench

When it comes to calibrating your Harbor Freight torque wrench, it’s important to consider how often this should be done. While the manufacturer recommends calibrating the tool every 12 months or every 5,000 cycles, this may not always be necessary. If you’re using the wrench frequently or in rough conditions, it’s a good idea to calibrate it more often to ensure accurate readings.

On the other hand, if you only use the tool occasionally, you may be able to extend the calibration period. Ultimately, the best way to determine how often to calibrate your Harbor Freight torque wrench is to keep an eye on the accuracy of its readings. If you notice that the tool is consistently providing inaccurate readings, it’s time to recalibrate it.

By keeping your torque wrench calibrated, you can ensure that your projects are completed accurately and safely.

FAQs

What is a torque wrench?

A torque wrench is a tool used to tighten bolts or nuts to a specific level of tightness.

How do I know if my harbor freight torque wrench needs calibration?

If your harbor freight torque wrench is consistently giving inaccurate readings or if it has not been calibrated in a long time, it may need calibration.

How often should I calibrate my harbor freight torque wrench?

It is recommended to calibrate your harbor freight torque wrench every 12 months or after 5,000 uses, whichever comes first.

Can I calibrate my harbor freight torque wrench myself?

Yes, you can purchase a calibration tool and follow the instructions provided to calibrate your harbor freight torque wrench yourself.

How accurate are harbor freight torque wrenches?

Harbor freight torque wrenches can be accurate within +/- 4% of the reading when calibrated properly.

What should I do if my harbor freight torque wrench is not accurate after calibration?

If your harbor freight torque wrench is still not accurate after calibration, you may need to have it professionally calibrated or serviced.

Can I use my harbor freight torque wrench for both tightening and loosening bolts?

No, you should only use your harbor freight torque wrench for tightening bolts. Using it to loosen bolts can damage the tool and cause inaccuracies in readings.