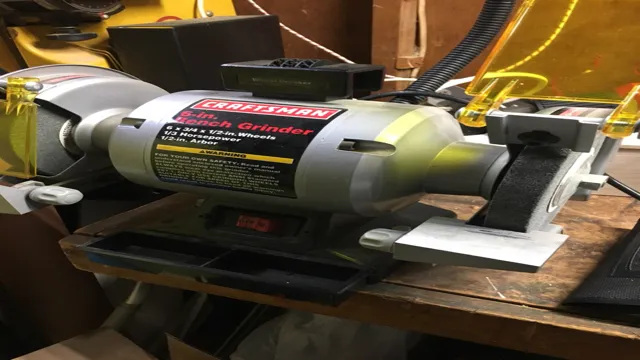

How to Build a Bench Grinder Stand: Step-by-Step Guide for DIY Enthusiasts

Are you looking for a way to make your bench grinder more stable and secure? Whether you’re a DIY enthusiast or a professional workshop owner, a bench grinder stand is a must-have accessory. Not only does it make grinding tasks easier and safer, but it also helps to keep the workspace organized and clutter-free. In this blog post, we’ll show you how to build a bench grinder stand from scratch using simple materials and basic tools.

With our step-by-step instructions and helpful tips, you’ll be able to create a sturdy, customized stand that fits your grinder perfectly. Let’s get started!

Materials Needed:

If you have a bench grinder that you use frequently, you may want to consider building a bench grinder stand to enhance its stability and safety. To build your bench grinder stand, you will need a few materials, including a piece of plywood, metal angle brackets, screws, and a dowel rod. Begin by cutting the plywood to the desired size, marking out the location for the grinder, and drilling a hole through the center for the dowel rod.

Next, attach the angle brackets to the plywood to form the base. Finally, insert the dowel rod through the hole and attach your bench grinder to the stand using screws. And voila! You now have a sturdy bench grinder stand that will keep your grinder secure and at the perfect height for smooth operation.

– Steel Angle Iron

If you’re looking to construct a sturdy and robust structure, you’ll certainly require the right materials. One crucial component for this type of project is steel angle iron. This versatile material is often used in construction to create the framework for a variety of structures, including buildings, bridges, and even vehicles.

Steel angle iron is known for its strength and durability, making it an ideal material for supporting heavy loads and withstanding high stress levels. It’s also resistant to rust and corrosion, which makes it an excellent choice for outdoor applications, where it’s frequently exposed to the elements. Additionally, steel angle iron is reasonably priced and readily available, making it a popular choice for construction professionals and do-it-yourself hobbyists alike.

Whether you’re building a new structure or repairing an existing one, steel angle iron is a vital material that can provide strength and structural integrity for years to come.

– Flat Steel

Flat steel is a popular material used for a variety of projects due to its durability and versatility. It is made by rolling steel through a series of steel rollers to flatten it into a consistent thickness. This type of steel is commonly used for building structures, as it is strong enough to support heavy weight loads.

It is also used for manufacturing equipment, machinery, and household items. To use flat steel for your project, you will need to ensure that you have the proper tools and equipment. This may include welding equipment, cutting tools, and protective gear.

In addition, you will need to ensure that the steel is properly cleaned and treated to prevent rust and corrosion. By using flat steel for your project, you can be confident in its strength and durability, making it a worthwhile investment for any construction or manufacturing project.

– Screws and Bolts

When it comes to screws and bolts, the material used can greatly affect the durability and strength of your project. The most common materials used are steel and stainless steel, but there are also options such as brass, aluminum, and titanium. Steel screws and bolts are great for heavy-duty applications as they are stronger than most other materials and are readily available.

On the other hand, stainless steel screws and bolts are more resistant to rust and corrosion and are perfect for outdoor projects. Brass screws and bolts have excellent conductivity and are commonly used in electrical applications. Aluminum screws and bolts are lightweight and great for applications where weight is a concern, such as in aerospace industries.

Lastly, titanium screws and bolts are incredibly strong and resistant to corrosion, making them perfect for projects that require both strength and durability. No matter what your project requires, choosing the right material can make all the difference in its success.

– Drill

When it comes to DIY projects, a drill is one of the most essential tools to have in your arsenal. This versatile tool can be used for everything from drilling holes to screwing in screws and even sanding and buffing surfaces. To get started with using a drill, there are a few materials you’ll need to have on hand.

First and foremost, you’ll need a drill itself. There are many types and sizes of drills available, but a standard cordless drill is the most common and versatile choice for most applications. You’ll also need a set of drill bits in various sizes to accommodate different projects.

A screwdriver bit set is also a useful addition, as it allows you to change between drilling and screwing in a snap. A set of sanding and buffing attachments can also come in handy for finishing projects. With these materials at your fingertips, you’ll be ready to take on any DIY project that comes your way.

– Saw

If you’re planning on starting a DIY woodworking project, a saw is undoubtedly one of the most essential tools you’ll need. However, choosing the right saw for your needs can be daunting, given the range of options available in the market. Some of the materials you’ll need to consider when selecting a saw include the blade’s type, length, and TPI (teeth per inch), as well as the handle’s material and grip.

For instance, a handsaw with a larger TPI is ideal for cutting smaller and more delicate materials, while a hacksaw with a smaller TPI is perfect for tougher materials like metal. Another crucial factor to consider is the saw’s tooth design – from rip teeth to crosscut teeth, each design has its application depending on the wood’s type and thickness. Therefore, understanding the key variables about saws’ materials and design is essential to choose the right tool for your DIY project, ensuring that you deliver high-quality results without compromising your safety or your woodworking style.

Steps for Building a Bench Grinder Stand:

If you’re looking to improve your workshop organization, building a bench grinder stand is a great place to start. Not only does it provide a secure and stable platform for your grinder, but it can also help reduce clutter and create more working space. To get started, you’ll need to gather the necessary tools and materials, including wood, screws, and a sturdy base.

Once you have everything you need, it’s time to get to work! Start by measuring and cutting the wood to the appropriate lengths and angles. Then, use screws to attach the pieces together in a sturdy, stable shape. Be sure to add cross-bracing for added support and stability.

Finally, attach your grinder securely to the top surface of the stand, and voila! You now have a sturdy, reliable platform for all your grinding needs. With this simple guide, learning how to build a bench grinder stand has never been easier.

1. Cut the steel angle iron according to the desired height and length of the stand

If you find yourself in need of a bench grinder stand, building one yourself is a cost-effective and customizable option. The first step is to cut your steel angle iron to the desired height and length. Make sure you measure accurately, as this will affect the stability of the stand.

Once you have your pieces cut, use a welding machine to fuse them together into a sturdy frame. If you don’t have access to a welding machine, you can also use bolts and nuts to secure the pieces together. Next, add some support braces and a shelf for your grinder to rest on.

This shelf should be made from a solid material, like plywood, and should be secured to the top of the stand. Finally, add some finishing touches, like paint or a rust-resistant coating, to protect your stand from wear and tear. By following these steps, you will have a functional and durable bench grinder stand that meets your specific needs.

2. Cut the flat steel for the top and base of the stand

When building a bench grinder stand, the second step involves cutting the flat steel required for both the top and base of the stand. This is an important step as it sets the foundation for the rest of the stand. Make sure to use a measuring tape to get the exact dimensions needed for the steel.

Once you have the measurements, use a metal cutting saw to cut the steel to the correct size. It’s important to ensure that you have a flat and level surface to work on when cutting the steel to avoid any errors in measurements. Remember, the top and base are crucial components of the stand and need to be sturdy enough to hold the weight of the grinder, so take your time and get the cuts right.

With the flat steel cut to size, you can now move onto the next step in building your bench grinder stand.

3. Drill holes in the base for stability and attach the legs using screws and bolts

If you’re looking to build a bench grinder stand, one of the crucial steps is to create a stable base. To do this, drill holes in the base that are large enough to accommodate bolts and screws that will be used to attach the legs. For maximum stability, it’s recommended to use a sturdy material such as metal or hardwood.

Once the holes are drilled, attach the legs to the base using the bolts and screws to ensure a secure fit. Keep in mind that the height of the stand will depend on your personal preference, as well as the type of work you’ll be doing. Consider the ergonomics of your workbench and choose a height that will help prevent potential discomfort or injury.

With a stable base and securely attached legs, your bench grinder stand will provide a sturdy platform for all your grinding needs.

4. Attach the top plate to the legs using screws and bolts

If you are looking to build a bench grinder stand, attaching the top plate to the legs using screws and bolts is the next key step. This stage of the process is crucial as it effectively connects the legs, allowing the stand to take its final shape. To begin, ensure that the top plate is measured and cut accurately to fit the desired dimensions.

It is essential to consider the weight of the bench grinder and how much the stand will need to support. Once the top plate is properly aligned, use screws and bolts to secure it to the legs firmly. It is essential to ensure that the screws are tightened appropriately to prevent any wobbling or instability in the completed stand.

By following these steps, you can ensure that your bench grinder stand is sturdy and stable, keeping you safe while using your equipment. Remember to use high-quality screws and bolts and double-check all measurements and alignments. With these precautions in place, you can complete your bench grinder stand, ready to take on your next project!

5. Add any final touches or adjustments to ensure stability and levelness

If you’re looking to build a bench grinder stand and want it to be sturdy and level, here are some steps to guide you. First, gather all the necessary tools and materials, such as a saw, drill, bolts, and wood. Cut the wood into the desired lengths and drill the holes where the bolts will go.

Next, assemble the base of the stand and secure it with the bolts. Then, attach the top platform where the grinder will be placed, using additional bolts to secure it in place. After that, make sure everything is level and stable by checking for any wobbling or shaking.

If needed, add shims or additional support beams to keep the stand stable. Lastly, make any final adjustments or touches to ensure the grinder stand is secure and ready for use. By following these simple steps, you can create a bench grinder stand that is both practical and durable.

Tips for Building a Bench Grinder Stand:

If you’re an avid DIYer, you know the importance of having the right tools in your workspace. A bench grinder is one such tool that is popular among metalworkers, woodworkers, and mechanics. However, using a bench grinder without a proper stand can be dangerous and could result in an accident.

That’s why building your own bench grinder stand is a great idea. The first step in building a bench grinder stand is to determine the appropriate size for your grinder. Once you have decided on the size, it’s time to choose the right materials, such as wood or metal.

Next, you’ll need to measure and cut the pieces for the stand and assemble them using screws or welding. Don’t forget to add rubber feet to the bottom of the stand to prevent it from slipping. Finally, test the stand for stability by placing the grinder on top and giving it a shake.

If it feels wobbly, make necessary adjustments until it’s secure. Building a bench grinder stand can be a fun DIY project that ensures safety in your workspace while giving you a sense of accomplishment.

– Use a level to ensure the stand is balanced and stable

If you’re looking to build a bench grinder stand, then there are several important tips you should keep in mind. First and foremost, you’ll want to ensure that you’re using the right materials for the job. This means selecting durable, sturdy materials that can withstand the weight of your grinder without buckling or tipping over.

Additionally, you should use a level to ensure that your stand is balanced and stable. This will help prevent accidents and injuries while you’re working. Finally, make sure to take care when assembling your stand, following the instructions carefully and double checking your work to ensure everything is secure.

By following these tips and taking the time to build a sturdy, reliable stand, you’ll be able to enjoy safe and efficient grinding for years to come.

– Consider adding rubber feet to prevent sliding or scratching floors

When building a bench grinder stand, it’s essential to consider adding rubber feet to prevent sliding or scratching floors. Rubber feet can easily be attached to the bottom of the stand, providing a stable base and reducing any vibration caused by the grinder. Not only will rubber feet help protect your floors, but they’ll also improve safety by preventing the stand from slipping or toppling over during use.

When selecting rubber feet, opt for high-quality, long-lasting products. Investing in durable rubber feet will help you avoid having to constantly replace them, ensuring that your stand remains sturdy and reliable for years to come. Overall, adding rubber feet is a simple yet effective way to improve the functionality and safety of your bench grinder stand.

– Follow all recommended safety precautions when using power tools

When it comes to building a bench grinder stand, following all recommended safety precautions is crucial. Not only do you need to consider the safety of yourself, but also anyone else who may be nearby. Before you begin, make sure you have all the necessary safety gear, including eye and ear protection, gloves, and a dust mask.

Don’t forget to unplug your grinder when you’re not using it and keep your work area clean and clutter-free. When building your stand, make sure it’s sturdy and can support the weight of your grinder. Use a level to ensure it’s stable and won’t tip over during use.

Remember, accidents can happen even to the most experienced DIYers, so always err on the side of caution. With these tips and a little common sense, you can safely build a bench grinder stand that will make your DIY projects a breeze.

Conclusion:

In conclusion, building a bench grinder stand is a valuable skill for any DIY enthusiast to have. With the right materials, tools, and a little bit of elbow grease, you can have a sleek and sturdy stand to support your grinder in no time. Not only does it make for a safer and more efficient work environment, but it also gives you a sense of accomplishment knowing that you did it yourself.

So get grinding, and build that stand like a boss!”

Building a bench grinder stand is a relatively simple process that requires a few basic materials and tools. By following these steps and tips, you can easily create a sturdy and stable stand for your grinder that will improve your work efficiency and safety.

If you’re looking for a simple and practical solution for your bench grinder, building a stand is definitely the way to go. Not only will it keep your equipment stable and secure, but it will also help improve your workflow by allowing you to work at a more comfortable height. To get started, all you need are a few basic materials such as wood, screws, and a drill.

First, measure your grinder and cut your wood pieces according to the size you need. Then, assemble the frame using screws, making sure to reinforce the joints for added stability. For the legs, consider using thicker wood or metal pipes for extra support.

Lastly, attach the grinder securely to the stand and double-check that everything is level. By following these tips and using quality materials, you can build a durable and reliable stand that will enhance your workspace and productivity.

FAQs

What materials do I need to build a bench grinder stand?

You will need plywood, screws, a drill, a saw, and possibly a metal mounting plate if your grinder is heavy.

Can I build a bench grinder stand without power tools?

It’s possible, but it will be difficult. You may need to use hand tools like a hand saw and a screwdriver, which will take longer and require more effort.

How tall should my bench grinder stand be?

It should be about waist height, so you can use it comfortably without straining your back.

Do I need to attach my bench grinder to the stand?

Yes, you should attach it securely to prevent it from falling over or moving while in use.

Can I use a bench grinder stand for other tools?

Yes, if the tool can fit securely on the stand and the stand is strong enough to support it.

Do I need to anchor the bench grinder stand to the ground?

It’s not necessary, but it may be a good idea if you plan to use heavy or large items on the stand.

Can I add drawers or shelves to my bench grinder stand?

Yes, but it will require additional woodworking skills and materials. It’s a good idea if you need extra storage space or organization for your tools.