Are you tired of struggling with a manual stapler, trying to staple thick stacks of paper or fabrics without success? It’s time to upgrade to a staple gun! These easy-to-use tools can make your stapling tasks a breeze, whether you’re a DIY enthusiast or a professional. However, before you can get started, you need to know how to assemble your new staple gun. In this blog post, we’ll walk you through the steps to assembling a staple gun so that you can start stapling like a pro in no time.

Think of it as putting together a puzzle where the end result is a powerful and efficient tool that will make your projects more manageable. So let’s dive in and learn how to put together your staple gun step by step.

Step 1: Gather Materials

Assembling a staple gun can seem daunting at first, but with the right materials and some patience, it’s a manageable task. The first step is to gather the necessary materials. You’ll need the staple gun itself, the corresponding staples, and any additional parts that may have come with the gun.

Some staple guns require the use of a separate tool for loading the staples, so make sure to have that handy as well. It’s also important to have a clear workspace with good lighting so that you can see what you’re doing. Take your time to familiarize yourself with the parts and how they fit together before beginning the assembly process.

With these materials and a bit of patience, you’ll be ready to put together your staple gun in no time!

What You’ll Need

When taking on any DIY project, the first step is always to gather all necessary materials. For this particular project that we’re about to undertake, you’ll need a few items to get started. Firstly, you’ll need a good quality canvas in the size of your choice, as well as a range of paintbrushes in different sizes.

Depending on the type of paint you’re using, you may also need a pallet knife and some paint mixing trays. Of course, you’ll need paint too – make sure you pick up enough paint in all the colors you need, as well as some white paint and black paint for tinting and shading. Lastly, you’ll need a cup for cleaning your brushes as you work and a drop cloth to protect your work surface.

With these materials in hand, you’re ready to get started on your DIY canvas painting masterpiece.

Checking for Missing Parts

Before you start assembling any product, it’s important to check if all the parts are present. This step can save you a lot of time and headaches later on. To begin, gather all the materials that come with the product.

This includes the instructions, the packaging, and all the individual components. Spread them out on a flat surface and take an inventory. Use the instruction manual to identify each part and cross-reference it with what you have.

Don’t assume that everything is there just because the box looks full. It’s common for small parts to get lost or accidentally thrown away during transportation or unpacking. By taking inventory and identifying missing parts at the start, you can contact the manufacturer and request replacements or return the product if necessary.

So, for any DIY project or assembly, always start with a thorough check to ensure that everything is accounted for.

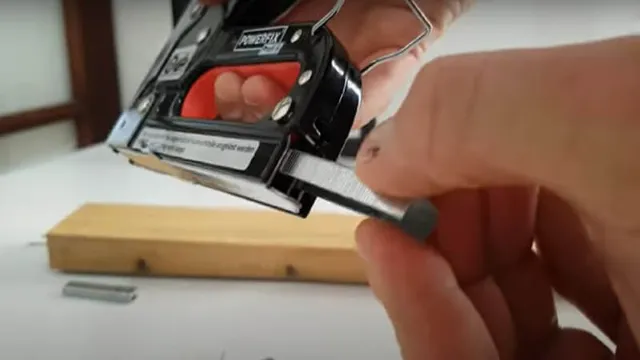

Step 2: Load the Staples

To load the staples, you must first locate the stapler’s chamber, which is typically on the underside of the gun. Once you’ve located the chamber, push the release button or slide the latch to open it up. Now you can place your staples into the chamber, with their legs facing down.

How many staples you can load will depend on the model and size of your staple gun, but you may be able to fit in several dozen at once. Be sure to check your specific stapler’s instructions for the correct size and type of staple to use, so you don’t run into any issues. Once you have loaded the chamber, you can release the button or latch to securely close it and prepare your stapler for use.

With your staples loaded and ready to go, you’re one step closer to completing your project!

Selecting the Right Staples

When it comes to stapling documents, selecting the right staples is crucial. After all, you don’t want your documents to fall apart or get damaged due to the wrong staples. Once you’ve identified the right type of staples for your stapler, it’s time to load them up.

Follow these easy steps for a hassle-free stapling experience. Firstly, check the stapler manual for instructions on the right way to load the staples. Usually, staples need to be loaded into a tray that slides out from the bottom of the stapler.

Secondly, make sure you’re loading the staples in the correct orientation and position as per your stapler’s guidelines. Incorrect loading can result in jamming and stapling errors. Lastly, ensure that you’re loading the correct amount of staples in the tray to avoid having to reload frequently.

By following these simple steps, stapling your documents will become a whole lot easier and efficient.

Opening the Loading Chamber

When it comes to using a stapler, loading the staples is a crucial step that requires care and attention. Opening the loading chamber is the first part of this process. Depending on the stapler’s type, the loading chamber might be located at the front or back of the device.

To open it, you’ll need to press the release button or tab that unlocks it. Once the loading chamber is open, you can begin to load the staples. Keep in mind that different types of staplers require different staple sizes, so be sure to check the instructions or packaging to ensure you’re using the correct ones.

Remember to align the staples correctly, inserting them in the direction that matches the stapler’s arrow. By following these steps, you’ll be able to successfully open the loading chamber and load the staples, enabling you to staple your papers and documents with ease.

Inserting the Staples

When it comes to loading staples in your stapler, it can be confusing at first. However, it is an essential step towards getting your work done efficiently. The second step is to insert the staples into the stapler.

Locate the staple tray and press the button or tab that releases the tray. Once you’ve opened the staple compartment, slide the staples into the tray with the sharp points facing downwards. Ensure that the staples are aligned correctly to avoid jamming.

Close the tray and push it back into the stapler until it clicks. You’re now ready to use your stapler! It’s that simple. Remember, the key to successful stapling is to load the right staples and align them correctly.

With practice, you’ll be a stapling pro in no time.

Step 3: Adjust the Tension

Adjusting the tension of a staple gun is crucial to achieving the perfect result. Once you’ve loaded the staples and taken care of the safety latch, the next step is to adjust the tension. Tension controls how tightly the staple is squeezed, which ultimately determines how deep it penetrates the material.

If you’re using a staple gun for the first time, start by adjusting the tension to the minimum setting. This will ensure that the staple doesn’t puncture the material too deeply. You can gradually increase the tension as needed until you find the right setting for your project.

If you’re unsure about how much tension to use, refer to the manufacturer’s instructions or consult an expert. By adjusting the tension, you’ll be able to achieve a neat and professional finish, whether you’re stapling upholstery, carpentry or crafts. Remember to always follow the safety instructions while using a staple gun to avoid injury or damage to yourself and the working surface.

Understanding Tension Settings

When adjusting the tension setting on your sewing machine, it’s important to understand how it works. The tension controls the tightness of the stitches, with higher tension creating tighter stitches and lower tension creating looser stitches. If your stitches are too loose or too tight, it’s likely a problem with the tension setting.

Start by pulling out a length of thread and holding it vertically. The thread should hang straight without sagging or pulling tight. If it’s sagging, your tension may be too loose, and if it’s pulling tight, your tension may be too tight.

Adjust the tension gradually and test again until you get the desired result. Remember to also check your bobbin tension as well, as it also plays a role in stitch tension. By understanding and adjusting your tension settings, you’ll be able to achieve professional-looking stitches with ease.

Locating the Tension Adjustment Dial

Once you have located the tension adjustment dial on your sewing machine, you can proceed to adjust the tension. The tension adjustment dial is typically located on the front or side of the machine and is easily recognizable by its numbered settings. It is essential to learn how to use this dial as it directly impacts the quality of your stitching.

If the tension is too loose, your stitches will be too wide and result in loose seams and loops. Conversely, if the tension is too tight, the thread will break or the fabric will pucker. To achieve the perfect tension for your project, start by testing your stitching on a scrap piece of fabric before you begin your actual sewing.

Slowly adjust the tension dial up or down as needed until your stitches are even and consistent. Remember to keep an eye on the tension throughout your sewing project and adjust as necessary for optimal results.

Adjusting the Tension

Adjusting the tension is a crucial step in achieving the perfect stitch for your sewing project. Once you have threaded your machine correctly and selected the appropriate stitch length and type, it’s time to adjust the tension. Tension refers to the tightness or looseness of the thread as it travels through the machine.

A correct tension ensures that the top and bottom threads are tightly interlocked, resulting in a smooth and even stitch. To adjust it, look for the tension dial on your machine and turn it gradually. Test the stitch on a scrap piece of fabric to see if the tension needs further adjustments.

If the stitch is too loose or too tight, readjust the tension accordingly. It may take a few tries to find the perfect tension, but the effort is worth it for a professional-looking finished product. Don’t be afraid to make adjustments until you get it right!

Step 4: Test and Use the Staple Gun

Once you have assembled your staple gun, it’s time to test it out and put it to use. Before you start stapling away, take a few moments to ensure that everything is properly secured and aligned. Double-check that the staple tray is securely attached and that the driver blade is in the correct position.

Once you’ve done this, load a few staples into the gun and test it out on a scrap piece of material. If everything is working properly, you should be able to press the trigger and hear a satisfying “click” as the staple is fired into the material. If not, check for any jams or misalignments and make the necessary adjustments.

With your staple gun now fully assembled and tested, you are ready to take on your next project with confidence!

Testing the Gun on Scrap Material

After properly loading the staple gun, it’s time to test it out on some scrap material before moving on to the actual project. It’s important to make sure that everything is in working order since a faulty gun can lead to frustration and wasted materials. Begin by lining up the gun with the material, pressing the nose firmly against it, and squeezing the trigger to release the staple.

Take note of the depth and firmness of the staple, as well as the ease of use. If everything checks out, it’s time to start your project with confidence. Don’t forget to keep the safety measures in mind while using the staple gun.

Remember to keep your hands and fingers away from the nose of the gun to avoid injuries. By taking these precautions and testing the gun on scrap material, you can ensure smooth sailing for your project and save yourself from any unnecessary stress.

Using the Staple Gun Properly

Once you’ve loaded the staples into your staple gun and adjusted the depth, it’s time to test it out before actually using it on your project. Testing the staple gun helps you ensure that the staples will penetrate your material deeply enough to be securely attached, but without going all the way through and causing damage. To test it out, hold the gun against a piece of scrap material, like a spare piece of wood or cardboard, and fire a single staple.

Check that it’s set correctly and not too loose or tight. Once you’re confident that everything is working properly, you can start using your staple gun on your project. Remember to always keep your fingers away from the trigger and the firing area while in operation, and take breaks as needed to avoid strain on your hand.

Happy stapling!

Conclusion

As you put the finishing touch on your staple gun assembly, you can’t help but feel a sense of accomplishment. Gone are the days of painstakingly hammering nails into place, now you have the power of the staple gun at your fingertips. With its sleek design and ease of use, it’s no wonder why staple guns have become a staple (pun intended) in the world of DIY projects.

Remember, always read the instructions carefully before starting any assembly, and in no time, you too can enjoy the satisfying feeling of a job well done…

with just the pull of a trigger.”

FAQs

What are the parts of a staple gun?

A staple gun typically has a body, magazine, trigger, spring, and driver blade.

How do you load staples into a staple gun?

Open the magazine, insert the strip of staples, and push the magazine back into place until it clips securely.

What size staples should I use with my staple gun?

The appropriate staple size will typically be listed in the manufacturer’s instructions or on the packaging of the staples.

How do I adjust the depth setting on my staple gun?

Refer to the manufacturer’s instructions for specific adjustment instructions, but typically there will be a dial or switch on the staple gun to adjust the depth.

What kind of projects are suitable for a staple gun?

Staple guns can be used for a variety of DIY and home improvement projects such as upholstery, woodworking, and crafting.

How do I maintain my staple gun?

Regularly clean the staple gun and lubricate moving parts according to the manufacturer’s instructions to ensure proper function.

Is it safe to use a staple gun?

As with any tool, proper precautions should be taken when using a staple gun, such as wearing safety goggles and using the tool only for its intended purpose.