How Does an Angle Finder Work: A Comprehensive Guide to Accurate Angle Measuring

How many times have you found yourself struggling with a project, unable to determine the correct angle? If you’re into woodworking, carpentry, or any other DIY projects that involve angles, then you know how important it is to measure and cut angles precisely. This is where an angle finder comes in handy. An angle finder is a small yet powerful tool that can easily determine the angles of an object or a corner.

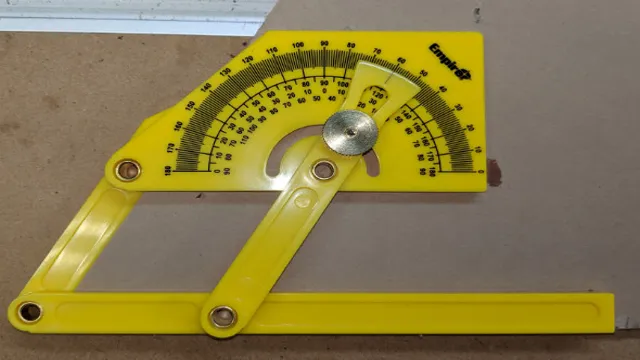

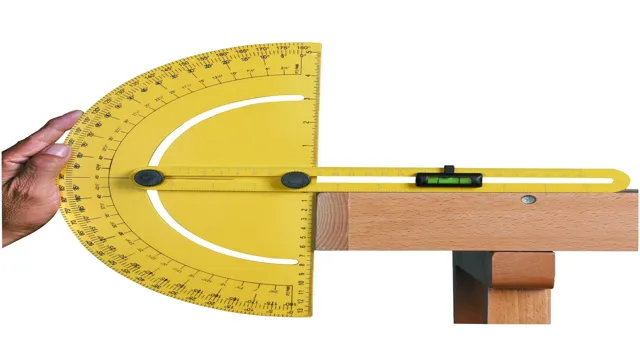

Whether you’re looking for a 90-degree angle or something more complex, an angle finder can do the job quickly and accurately. But how exactly does an angle finder work? At its core, an angle finder uses the principles of geometry and trigonometry to determine the angle of an object. It does this by using a set of arms that are hinged together, with an adjustable protractor on one end.

The user places the arms onto the object being measured, sets the protractor to the desired angle, and reads the measurement from a scale on the tool. Think of an angle finder as a digital protractor or compass, but with added features such as a level and a ruler. It’s a simple yet effective tool that can make a big difference in your DIY projects.

With an angle finder, you can measure angles with ease, accuracy, and speed. In conclusion, an angle finder is an essential tool for anyone who works with angles. Its ability to accurately measure angles can save you time and ensure that your projects come out perfectly.

Now that you know how an angle finder works, you can make better use of it in your next project.

Overview

Angle finders are tools that help you accurately measure angles, such as those found in woodworking, metalworking, and other construction projects. But how do they work? There are a few different types of angle finders, but most work on the same basic principle. Essentially, the tool has two arms that can be adjusted to fit around the angle you want to measure.

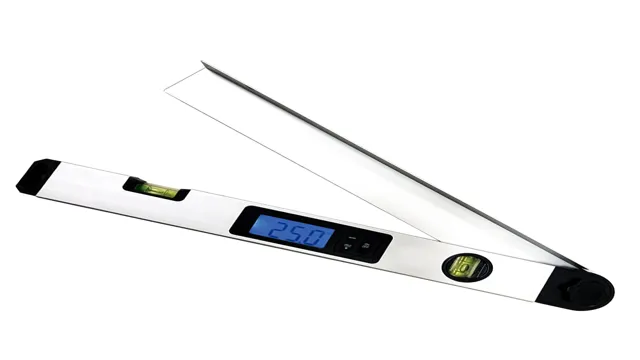

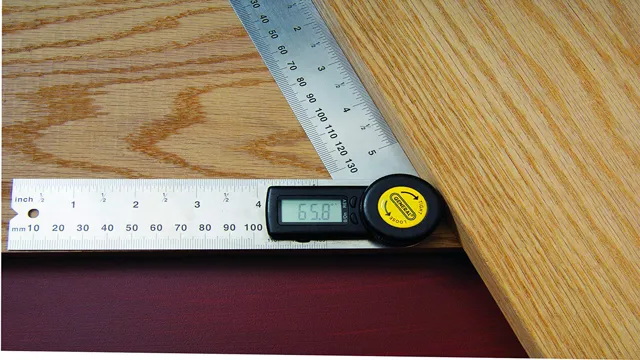

As you adjust the arms, the tool uses some type of sensor or gauge to calculate the angle between them. Some angle finders also come equipped with digital displays to provide a readout of the angle, making it even easier to get precise measurements. Overall, angle finders are handy tools that are essential for anyone who needs to measure angles in their work.

Definition and Function

A blog is an interactive and frequently updated online platform where writers express their thoughts, share their opinions, or discuss topics that interest a wide range of readers. The word blog is a shortened version of the term “weblog.” A blog can take various forms, from personal to organizational, and can cover a wide variety of topics such as technology, education, sports, politics, health, and lifestyle.

The primary function of a blog is to provide fresh and relevant content consistently to its audience. Blog articles can be short or long-form, depending on the writer’s preference, and can include images, videos, and infographics to engage readers. Blogging is an excellent medium for developing a community of like-minded individuals, and it is also an effective way for businesses and organizations to connect with their audience.

Overall, a blog acts as an avenue for individuals to express themselves and share their ideas while reaching out to a global audience.

Types of Angle Finders

Angle finders are a great tool for accurately measuring angles in various applications. They come in different types, each with its features and benefits that cater to different needs. The most common types of angle finders include digital, magnetic, protractor, and bevel gauges.

Digital angle finders feature an LCD display that shows angle measurements precisely and allow for easy reading. Magnetic angle finders utilize strong magnets to attach themselves to metal surfaces, making them ideal for carpentry projects. Protractor angle finders are ideal for measuring angles in school, drafting, or any application that requires precise angle measurements.

Bevel gauges, on the other hand, are helpful in woodworking applications, especially when creating angled cuts. Choosing the right angle finder depends on the type of project you are working on and the level of precision you require.

Mechanics of an Angle Finder

Have you ever wondered how an angle finder works? If you’re a tradesperson or woodworker, an angle finder is a vital tool for ensuring precise angles when cutting or joining materials. The mechanics of an angle finder are relatively simple. It consists of two arms that pivot around a hinge, forming a protractor.

The arms are held together by a spring that allows them to open and close. When placed against an object, the arms can be adjusted until they align with the surface’s angle, and a reading is taken from the scale on the protractor. The angle finder can measure angles from 0 to 180 degrees, making it a versatile tool for various projects.

Some angle finders come with digital displays that provide accurate readings, while others may have bubbling levels to ensure the tool is level. Overall, an angle finder is a must-have tool for anyone who requires precise angles in their work.

Measurement

An angle finder is a handy tool that helps measure angles accurately. The mechanics of an angle finder are based on a simple principle of triangular geometry. The tool has two arms joined by a pivot, with a scale marked along the length of each arm.

The user places one arm of the tool on the flat surface and the other arm on the surface whose angle needs to be measured. Once the tool is in position, the user reads the angle from the scale. The angle is measured in degrees, and the accuracy of the measurement depends on the precision of the tool and the skill of the user.

The key to getting an accurate reading is to ensure that the tool is placed on the surfaces correctly and that the arms are aligned precisely. In summary, an angle finder is a simple yet effective tool that can help measure angles with ease and precision.

Calibration

Calibration Mechanics of an Angle Finder When it comes to precision work in construction or woodworking, accuracy is key. One of the tools that can help you achieve precise angles is an angle finder. But have you ever wondered how it actually works? The mechanics of an angle finder are quite simple yet effective.

The tool consists of two arms that can be adjusted to match the angle you want to measure. Inside the tool, there is a small vial of liquid with a bubble in it. When the arms are adjusted to the desired angle, the bubble moves to the center of the vial, indicating that the angle is now calibrated.

It’s a simple yet effective way to ensure that your work is accurate. However, to get the most out of your angle finder, you need to make sure it’s calibrated correctly. Calibration is the process of making sure that the tool is accurate and is reading angles correctly.

The best way to calibrate your angle finder is to use a known reference angle, such as a square edge or an angle that has already been measured and confirmed to be accurate. Once you’ve used a reference angle to calibrate your tool, you can be confident that any other angles you measure with it will be precise. In conclusion, an angle finder is a surprisingly simple tool that can help you achieve accurate angles for your projects.

By using the mechanics of a liquid vial and bubble, you can calibrate the tool to ensure that your work is precise. Calibration is an essential step in using an angle finder, so make sure you take the time to do it properly. With a properly calibrated angle finder, you can create precise angles every time, leading to better quality work on all of your projects.

Display

When we think of an angle finder, we may imagine a simple tool that tells us the degree of an angle. However, the mechanics behind this device is more complex than we might think. The angle finder works by utilizing two arms that can pivot around a joint, allowing them to reach different angles.

One arm has a sensor that measures the angle, and this information is sent to a digital display. The two arms are connected by a gear that ensures that they move together and remain at a fixed distance from each other. This gear also allows the user to lock in an angle and ensure accuracy when measuring.

Overall, the mechanics of an angle finder may seem straightforward, but it is the precise coordination between the two arms and the gear that allows it to accurately measure angles.

Applications

An angle finder is a tool that measures the angle between two plane surfaces. How does an angle finder work? Well, there are various types of angle finders on the market today, but the most common one is the protractor. A protractor is an instrument that has a circular shape and lines marked from 0 to 180 degrees.

To use a protractor, you need to align the flat arm of the tool with one of the surfaces you want to measure the angle of. Then, you need to look where the other surface aligns on the protractor. The degree marking where the two surfaces meet gives you the measurement of the angle.

This tool is commonly used by carpenters, machinists, and mechanics for measuring angles in their work. The digital angle finder, on the other hand, uses a digital sensor to measure the angle and displays the result on a screen. It can measure angles with an accuracy of up to 0.

1 degrees. Regardless of the type of angle finder, it is an essential tool for anyone who needs to measure angles accurately.

Construction and Carpentry

When it comes to construction and carpentry, there are countless applications for these trades. From building homes and commercial buildings to crafting beautiful furniture pieces, there is no limit to what can be accomplished with the skills of a skilled construction and carpentry team. In the construction industry, some of the most common applications include framing and drywall installation, roofing, flooring, and even masonry work.

Each of these components is crucial to the overall structure and design of a building, and without skilled construction and carpentry professionals, these components would not be possible. Similarly, in the carpentry world, there are numerous applications for woodwork. Furniture making is perhaps the most well-known, but cabinetry, millwork, and even carving and sculpting are all popular applications for carpentry.

Whether you are looking for custom cabinetry for your home or business, or you want a handmade piece of furniture that will last for generations, skilled carpenters are a must-have. Ultimately, the applications for construction and carpentry are limited only by one’s imagination. From large-scale building projects to small-scale furniture or decor, these trades are essential to our physical world and enhance our quality of life in countless ways.

If you are considering a career in construction or carpentry, you will have the opportunity to make your mark on the world by creating structures and objects that will be enjoyed for years to come.

Metalwork and Machining

Metalwork and machining have countless applications in various industries. One of the most common applications of metalwork and machining is in the manufacturing of automobiles. Almost all components of a car, such as the engine, brakes, chassis, and suspension system, require metalwork and machining to be produced.

Metalwork and machining also play a crucial role in the manufacturing of aircraft and spacecraft components. These components have to be manufactured to precise specifications and require high levels of precision and accuracy in their fabrication. The construction industry also extensively relies on metalwork and machining to create various structural components such as beams, frames, and support structures.

Metalwork and machining have also made significant contributions in the medical field by producing essential components for medical equipment such as surgical tools, prosthetic devices, and medical implants. Overall, the applications of metalwork and machining are diverse, vital, and play a significant role in various industries.

Conclusion

In conclusion, an angle finder is a tool that uses the principles of geometry to determine the measurement of angles. It works on the principles of a protractor, but with more advanced features like digital displays, magnets, and locking mechanisms. So whether you’re a carpenter looking to install crown molding or a math student learning about angles, the angle finder is a clever tool that helps you measure, calculate, and cut with precision.

With an angle finder in hand, never again will you have to ponder the mystery of angled cuts or struggle with complicated calculations. It’s a handy little device that will undoubtedly become your new best friend!

FAQs

What is an angle finder and how does it work?

An angle finder is a tool that measures angles, typically used in construction and woodworking. It works by placing the tool against the angle to be measured and using a protractor to read the angle.

Can an angle finder measure both internal and external angles?

Yes, an angle finder can be used to measure both internal and external angles.

Are electronic angle finders more accurate than manual ones?

Electronic angle finders tend to be more accurate than manual ones, due to their ability to display measurements with more precision.

Is it necessary to calibrate an angle finder before use?

Yes, it is important to calibrate an angle finder before use to ensure accurate measurements. Calibration instructions can typically be found in the tool’s manual.

Can an angle finder be used to measure slope angles?

Yes, some angle finders come with a built-in slope measurement feature, allowing them to measure the angle of slopes and inclines.

What are some common uses for an angle finder in construction?

Angle finders are commonly used for tasks such as framing, installing trim and molding, and aligning roof rafters.

Are there different types of angle finders available?

Yes, there are several types of angle finders available, including digital angle finders, protractor-style angle finders, and level-style angle finders.