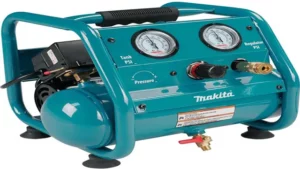

When it comes to choosing the right air compressor size, it can be overwhelming to navigate the numerous options available. With so many different sizes, it’s essential to determine what will work best for your specific needs. But fear not, because we’re here to help make this decision a little easier! Think of an air compressor as a partner in your work, helping you get the job done faster and more efficiently.

Just like any relationship, finding the right partner is key. Choosing an air compressor that isn’t powerful enough for your needs will result in wasted time, frustration, and even damage to your equipment. In this blog post, we’ll take a closer look at how to choose the right air compressor size to ensure you’re getting the most out of your investment.

We’ll discuss the various factors to consider, such as the size of the tools you’ll be using, the frequency of usage, and the air pressure requirements. So, whether you’re a professional tradesman or a DIY enthusiast, we’re here to guide you through the process and help you find the perfect air compressor size that will help you get the job done right, every time. Let’s dive in!

Understanding Your Air Tools and Their CFM Requirements

If you’re wondering how big of an air compressor you need for your air tools, it all comes down to the CFM requirement of each tool. CFM, or cubic feet per minute, measures the amount of air that an air tool requires to operate efficiently. Some air tools like nail guns or airbrushes have lower CFM requirements, while others like sanders or paint sprayers require much higher CFM.

It’s important to check the CFM rating of each tool, and add up the total CFM for all the tools you plan to use concurrently. This will give you the minimum CFM rating you need for your air compressor. Remember, having an adequate CFM rating ensures your tools will work properly and efficiently, ultimately saving you time and money in the long run.

Research your air tools and record their CFM requirements.

When it comes to using air tools, it’s essential to understand their CFM requirements. CFM stands for cubic feet per minute, which is a measurement of how much air a tool needs to operate effectively. Different air tools have different CFM requirements, so it’s vital to research each tool before using it.

Some tools, such as a small pneumatic sander, may only need 2-3 CFM, while larger tools such as a sandblaster may require up to 20 CFM. Not having enough CFM can lead to faulty tool performance, which can impact work productivity and even safety. Therefore, knowing the CFM requirements of each tool in your workshop is crucial to ensure you have sufficient air supply.

Regular maintenance of air compressors, air hoses, and air pressure regulators can also ensure that the tools get the correct CFM, contributing to optimal tool performance. So, before you start your next project, make sure you’ve researched your air tools and their CFM requirements.

Calculate the total CFM needed for concurrent tool usage.

CFM Air tools can make any task easier and faster, but they also require a continuous supply of compressed air to operate effectively. It is essential to understand the CFM (cubic feet per minute) requirements of your air tools before you start using them. Each tool has a specific CFM rating, and using multiple tools concurrently can increase the total CFM needed.

To calculate the total CFM needed, add up the individual CFM requirements of each tool. For example, if you’re using a paint gun that requires 7 CFM and an angle grinder that needs 5 CFM, you’ll need at least a 12 CFM air compressor to run both tools simultaneously. Keep in mind that some tools have a higher CFM demand during initial use or after a certain period of use.

Therefore, it’s crucial to choose an air compressor with a CFM rating that can handle the highest CFM requirement of all your air tools. By understanding your air tools’ CFM requirements, you can ensure that you have the right air compressor to handle your projects effectively and efficiently.

Factor in the duty cycle of your tools when calculating CFM.

When it comes to using air tools, it’s important to understand the CFM requirements of each tool. CFM, or cubic feet per minute, refers to the amount of air that a tool consumes during operation. Different tools have different CFM requirements, so it’s crucial to know the CFM rating of your tools and factor in the duty cycle when calculating the CFM needed for your compressor.

The duty cycle refers to the amount of time a tool is used in a given period and can significantly affect the amount of air consumption. For instance, a tool with a high duty cycle may consume more air than a lower duty cycle tool. It’s essential to consider both the tool’s duty cycle and its CFM rating to ensure that your compressor can meet the air supply demands of your tools.

By understanding these factors, you can make an informed decision when choosing the right compressor for your workshop or job site, avoiding performance issues that could lead to costly downtime.

Consider Your Air Compressor’s PSI

When trying to determine how big of an air compressor you need, it’s important to first consider the PSI (pounds per square inch) required for your specific tools and equipment. Each tool or piece of equipment will have a recommended PSI range for optimal performance, and your air compressor should be capable of meeting those requirements. If your air compressor’s PSI is too low for the tools you need to use, they may not work as efficiently or may not work at all.

On the other hand, if the PSI is too high, it can cause damage to your tools or equipment. Therefore, it’s crucial to do your research and understand the PSI needs for your specific tasks before investing in an air compressor. Using the right-sized air compressor can increase productivity and ensure a longer lifespan for your tools, ultimately saving you time and money.

Check the maximum PSI required by your tools.

When buying an air compressor, it’s essential to consider the maximum PSI required by your tools. PSI stands for pounds per square inch, and it represents the air pressure that an air compressor can deliver. Different tools require different PSI, and it’s crucial to choose an air compressor that can deliver the required pressure.

For instance, if you’re using a nail gun that needs a PSI of 100, you need to make sure that your air compressor can deliver that pressure consistently. If the air compressor doesn’t provide enough pressure, your tool won’t work correctly, and you’ll end up with a frustrating experience. So, make sure to check the PSI requirements of your tools before buying an air compressor to avoid problems and get the job done efficiently.

Ensure your air compressor can deliver the required PSI.

When considering purchasing an air compressor, it’s essential to ensure that it can deliver the required PSI for your needs. PSI stands for pounds per square inch, and it signifies the amount of pressure that the air compressor can put out. If you’re using the compressor for basic tasks like inflating tires or running small tools, you’ll only need a low PSI.

However, if you need a compressor for heavy-duty tasks like sanding or painting, you’ll need a compressor with a higher PSI output. It’s important to remember to check the PSI requirements of the tools you plan on using with the compressor to ensure that your compressor can meet those needs. So, before you make a purchase, carefully consider your needs and ensure that the air compressor you buy is capable of delivering the required PSI output.

By doing so, you’ll ensure that your compressor is powerful enough to get the job done efficiently and effectively.

Estimating the Size of Your Air Compressor

So you’re in the market for an air compressor, but you’re not sure how big of one you need. Don’t worry, it’s a common question! The size of air compressor you need depends on a few different factors. First, think about what you’ll be using it for.

Are you planning on doing small DIY projects around the house, or will you be running air tools on construction sites? The larger the project, the larger the compressor you’ll need. Second, consider the amount of air pressure and volume required for the tools you’ll be using. Tools like sanders, spray guns, and grinders require more air than things like nailers and staplers.

The general rule of thumb is to have an air compressor that can deliver 5 times the amount of air required by your most demanding tool. Finally, take a look at the compressor’s horsepower and tank size.

These factors will determine how long the compressor can run before needing to recharge. Overall, it’s better to err on the side of too much power rather than not enough when it comes to air compressors.

Calculate the minimum CFM required for your tools.

If you are a DIY enthusiast or a professional in the construction industry, you will need an air compressor to power your tools. However, choosing the right size for your air compressor can be a daunting task. One of the factors to consider is the minimum CFM (Cubic Feet per Minute) required for your tools.

CFM is the volume of air that can be delivered by the compressor per minute. Each tool has its CFM requirement, which varies depending on the tool’s power and size. To determine the minimum CFM required for your tools, check the manufacturer’s specifications or use an online calculator.

It is essential to choose an air compressor that can provide a CFM higher than your tool’s requirement to ensure that it runs correctly and efficiently. A compressor with inadequate CFM can lead to poor performance, increased downtime, and even compressor damage. Therefore, selecting the right size air compressor is vital for getting the job done effectively and efficiently.

Determine the highest CFM tool you’ll be using.

If you’re in the market for a new air compressor, one of the first things you’ll need to consider is the size of the compressor that you will need. A big factor in determining the size of the compressor is the highest CFM (cubic feet per minute) tool that you’ll be using with it. CFM is a measure of the amount of air that a tool requires to operate, so it’s important to choose an air compressor that can supply enough air to power your highest CFM tool without straining and creating inefficiencies.

So, for example, if you have a tool that requires 5 CFM to function at maximum capacity, you should select a compressor that supplies at least that amount of CFM. Be sure to also consider any other tools that you might use in combination with the highest CFM tool to determine the overall compressor size needed. By taking the time to estimate your needs, you can choose a compressor that will meet your requirements while avoiding overpaying for a unit that’s too powerful or underpowering a unit that won’t manage the job at all.

Calculate the required tank size for your needs.

If you’re in the market for an air compressor, one of the most important factors to consider is the size of the tank. The tank size will determine how long your air compressor can run before needing to be refilled and can greatly impact the efficiency of your tools. To estimate the size of your air compressor, you’ll first need to determine how much air you require for each task.

This can be done by determining the average airflow rate of your tools and the amount of time you’ll be using them. Once you have this information, you can use a simple formula to calculate the required tank size: tank size = (CFM x minutes used) / 4

For example, if your tool requires 5 CFM of air and you plan to use it for 30 minutes, your required tank size would be (5 x 30) / 48 = 20.08 gallons.

It’s important to keep in mind that this formula is just an estimate and you may want to choose a slightly larger tank size to allow for future tool upgrades or increased air demand. By taking the time to estimate the size of your air compressor tank, you can ensure that you have the right tools for the job and avoid frustration down the line.

Final Thoughts and Recommendations

When it comes to air compressors, determining how big of one you need can seem daunting. The size of the compressor you require will depend on what tasks you plan on completing. If you only plan on using it for basic DIY projects at home, a smaller compressor with a tank capacity of around 6-10 gallons should suffice.

However, if you plan on more heavy-duty tasks like sanding, painting, or using air-powered tools, a larger compressor with a tank capacity of 20-30 gallons or more may be required. It’s important to also consider the CFM output, as this will dictate the power and speed of the compressor. In general, the rule of thumb is to look for a compressor with an output of at least

5 times the CFM needs of your tools. With this in mind, you should be able to find the perfect air compressor to suit your needs and complete any project with ease.

Conclusion

In the world of air compressors, size does matter. It all depends on your specific needs and intended uses. So, whether you need a small, portable compressor for occasional home use, or a massive industrial-sized machine for a manufacturing facility, the key is to carefully consider your requirements and make an informed decision.

Remember, choosing the perfect air compressor is a bit like Goldilocks finding the perfect bowl of porridge – not too big, not too small, just right!”

FAQs

What factors should I consider when determining the size of air compressor I need?

The factors to consider include the amount of air your tools require, the frequency of use, and the size of your workspace.

What is the recommended CFM for an air compressor to run air tools?

It is recommended to have an air compressor with a minimum of 4 CFM at 90 PSI to run most air tools.

Can I use a smaller air compressor than recommended for my air tools?

It is not recommended because a smaller air compressor may not provide enough air to power your tools, resulting in reduced performance or damage to the tools.

What size air compressor do I need for painting?

You will need an air compressor with at least a 30-gallon tank and a CFM of 5.7 or higher to paint with a spray gun.

Can I use my home air compressor for industrial purposes?

It is not recommended since home air compressors are not designed for heavy-duty industrial use and may not provide enough power or air capacity.

Should I choose a single-stage or a two-stage air compressor?

A two-stage air compressor is recommended for heavy-duty use and high-demand applications, while a single-stage air compressor is suitable for light-duty use.

How often should I replace the air filter on my air compressor?

The air filter should be checked monthly and replaced every six months or more frequently if used in a dusty environment.