Can You Use Regular Sockets with a Torque Wrench? The Ultimate Guide to Socket Compatibility.

Have you ever needed to tighten a bolt with precise torque but only had regular sockets on hand? It can be frustrating not having the right tools for the job, but fear not – it’s still possible to achieve the necessary torque with just a torque wrench and a regular socket set. Using regular sockets with a torque wrench may not be ideal, but it is a common and sometimes necessary practice. It’s important to remember that torque is the rotational force required to turn a bolt to a specific tightness, and using the wrong tools or techniques can lead to over-tightening or under-tightening, which can result in damage to the bolt or the object being secured.

In this blog post, we’ll discuss how you can safely and effectively use regular sockets with a torque wrench, including tips for selecting the right socket size and ensuring accurate torque measurements. We’ll also cover some potential pitfalls to watch out for when using this technique, so you can avoid any costly mistakes. By the end of this post, you’ll be well-equipped to use your torque wrench and socket set together, even when you don’t have access to specialized sockets.

So grab your tools and let’s get started!

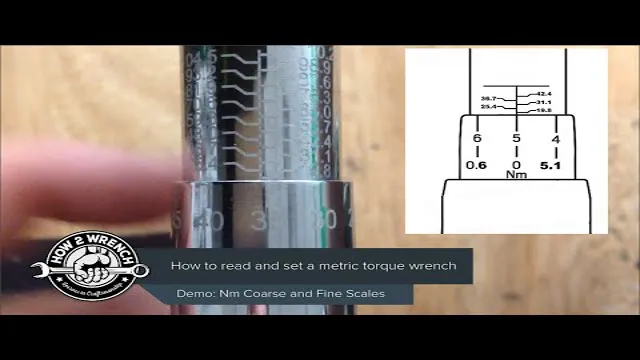

Understanding Torque Wrenches

If you’re the type of person who loves to work on your car, then you probably know how important torque wrenches are. But, can you use regular sockets with a torque wrench? The answer is, it depends on the type of torque wrench that you have. If you have a beam torque wrench or a click torque wrench, then you can use any type of socket that fits the size of the bolt that you’re working on.

However, if you have a digital torque wrench or an electronic torque wrench, then you need to use a special type of socket that has a hole in the center. This is because electronic torque wrenches have a sensor that needs to fit inside the socket. So, make sure to check the instructions that came with your torque wrench to see what type of socket you need to use.

And remember, always use the proper torque setting to avoid damaging your vehicle or equipment.

What is a Torque Wrench?

A torque wrench is a tool that is used to apply a specific amount of force or torque to a fastener, such as a bolt or nut. The tool is designed to provide accuracy and precision when tightening or loosening fasteners to ensure that they are neither under nor over-tightened. A torque wrench works by applying rotational force to the fastener, with the degree of rotational force being adjustable based on the desired level of torque.

This helps to prevent damage to the surrounding components and ensures that the fastener is secure and safe to use. Understanding how to use a torque wrench is important to ensure that you achieve the desired level of torque and avoid over-tightening or stripping of the fastener. Whether you’re a professional mechanic or just a DIY enthusiast, having a torque wrench in your arsenal can help you get the job done right every time.

So next time you’re working on a project that requires precise tightening, make sure you have a torque wrench handy.

Types of Torque Wrenches

Torque wrenches are essential tools in the world of mechanics and engineering. They are used to apply a specific amount of torque to a fastener, ensuring that it is tightened correctly and to the appropriate level. There are several types of torque wrenches available, each with their unique features and benefits.

One of the most widely used torque wrenches is the click-type torque wrench. It is designed with a ratcheting mechanism that clicks when the desired torque level is reached. Another type is the beam-style torque wrench, which works by bending a calibrated beam to indicate the torque being applied.

Electronic torque wrenches are also gaining popularity in recent years, with their digital displays allowing for greater precision and accuracy. Finally, hydraulic torque wrenches are designed for heavy-duty applications, with their hydraulic mechanism providing ample power to tighten industrial-grade bolts and nuts. Choosing the right torque wrench will depend on the specific application and requirements.

How Do Torque Wrenches Work?

Torque wrenches are specialized tools designed to apply a specific amount of force, or torque, to a fastener. As the name implies, these devices work by tightening bolts and other fasteners to a specified torque value. They are used in a variety of applications, from automotive repair to construction and manufacturing.

The main purpose of a torque wrench is to ensure that fasteners are tightened to the correct level of torque, which helps prevent over-tightening or under-tightening that can lead to damage or failure. Torque wrenches work by applying a twisting force to the head of the fastener, which is measured in units of torque. The wrench is typically calibrated to a specific torque value, and the user simply tightens the fastener until the desired torque is reached.

This ensures that the fastener is tightened to the correct level, which helps prevent problems down the road. Overall, torque wrenches are an essential tool for anyone who works with fasteners on a regular basis, and understanding how they work is key to getting the most out of them.

Using Regular Sockets with a Torque Wrench

If you’re wondering whether you can use regular sockets with a torque wrench, the answer is yes, you can. Torque wrenches are designed to measure the force applied to a bolt or nut, ensuring that it is tightened to a specific torque setting. However, the socket you use with the torque wrench needs to be of the same size as the nut or bolt you’re tightening.

If you use the wrong size socket, the torque reading will not be accurate, and you may damage both the tool and the component you’re working on. So, it’s essential to ensure that you check the socket size before using it with a torque wrench. You also want to make sure the sockets are suitable for torque wrench use to avoid any dangerous repercussions.

Using regular sockets with a torque wrench is possible, but you must be careful and pay attention to the socket’s size to avoid damage.

Benefits of Using Regular Sockets with a Torque Wrench

When it comes to using a torque wrench, many people wonder if they can use regular sockets instead of buying special sockets that are specifically designed for torque wrenches. The good news is that you can use regular sockets with a torque wrench, and there are actually some benefits to doing so. Firstly, it’s more cost-effective to use regular sockets as they are more readily available and affordable.

Additionally, using regular sockets gives you more versatility in terms of the types and sizes of sockets you have on hand. This can be particularly useful if you need to make repairs on the go and don’t have access to specialty sockets. However, it’s important to note that when using regular sockets, you’ll need to be extra careful to ensure that you’re using the correct torque rating for the particular socket you’re using – otherwise, you may end up over or undertightening your bolts.

Overall, using regular sockets with a torque wrench can be a smart and cost-effective choice, but it requires some extra attention to detail to ensure a safe and successful repair.

Risks of Using Regular Sockets with a Torque Wrench

Torque Wrench When it comes to using a torque wrench, regular sockets may not always be the best option. While they may seem like a suitable match, using the two together can lead to certain risks. For one, regular sockets might not fit properly onto a torque wrench and can therefore slip or become loose during use.

This can cause inaccurate torque readings and ultimately lead to imprecise tightening of bolts or nuts. Additionally, regular sockets may not be able to handle the torque force that a torque wrench is capable of producing, which can result in damage to both the socket and the wrench. To avoid these risks, it is recommended to use special sockets that are specifically designed for use with a torque wrench.

These sockets have a high level of precision and can handle the force produced by the wrench, ensuring accurate and safe tightening of fasteners. So if you’re planning on using a torque wrench, it’s important to invest in the appropriate sockets to avoid any potential safety hazards.

Factors to Consider Before Using Regular Sockets with a Torque Wrench

When it comes to using regular sockets with a torque wrench, there are a few factors that you should consider to ensure optimal performance. The first thing to keep in mind is the size of the socket, as it needs to be compatible with the size of your torque wrench. Additionally, you should only use high-quality sockets and never mix them with cheap or low-quality ones.

This is because poor quality sockets might not be able to handle the amount of torque applied by the wrench, leading to inaccurate torque readings or even breakage. Furthermore, it’s important to inspect the socket before each use for signs of wear or damage, as this can compromise the accuracy of the torque wrench. By taking these factors into account, you can effectively use regular sockets with your torque wrench, ensuring safety, accuracy, and maximum performance.

Tips for Using Regular Sockets with a Torque Wrench

If you’re wondering whether you can use regular sockets with a torque wrench, the answer is yes, you can. However, it’s important to keep in mind that not all sockets are created equal. Cheap or poorly-made sockets can easily break or slip, rendering your torque wrench inaccurate.

It’s important to choose high-quality sockets made from strong materials, such as chrome vanadium steel, that can withstand the force of the torque wrench. Additionally, you’ll want to ensure that the sockets are the correct size and fit securely onto the torque wrench. Always double-check your equipment before use and adjust the wrench to the correct setting for your specific application.

With the right tools and techniques, using regular sockets with a torque wrench can be safe and effective.

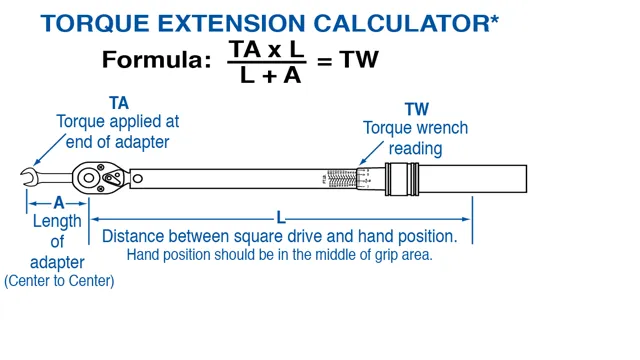

Choosing the Right Socket Size

When using a torque wrench, it’s essential to choose the right socket size. But what if you don’t have the exact size socket on hand? You can still make do with regular sockets by following a few tips. Firstly, ensure that the regular socket is of good quality and made from durable materials.

Secondly, use an adapter to increase the socket size while reducing the drive size. And lastly, consider the tolerance level of the torque wrench in relation to the regular socket to avoid over-tightening or under-tightening. One important thing to keep in mind is to never use a socket that is smaller than the recommended size as it can cause damage to the tool and lead to inaccurate results.

So, before starting any project, make sure to check and double-check the socket size to ensure that you get the job done right.

Avoid Over-Tightening

Over-tightening sockets is a common mistake when using regular sockets with a torque wrench. It is important to remember that using a torque wrench ensures that you apply the correct amount of force to a bolt or nut. When using regular sockets with a torque wrench, it is essential to be careful not to over-tighten the bolt.

Over-tightening can result in a stripped thread or a bolt that is impossible to remove. To avoid over-tightening, make sure that you follow the manufacturer’s recommended torque settings, and use a calibrated torque wrench to ensure accuracy. A good rule of thumb is to use only the force that is necessary to apply the recommended torque.

It takes practice to judge the correct amount of force, but with practice, you will develop a feel for it. Remember that a little bit of pressure goes a long way when it comes to using a torque wrench with regular sockets. Keep in mind that applying too much pressure can result in a costly mistake that could have been avoided.

Proper Technique

Proper Technique for Using Regular Sockets with a Torque Wrench If you are planning to use regular sockets with a torque wrench, it’s essential to know the proper technique to ensure accurate torque readings and prevent damage to your tools. Firstly, make sure that the socket is securely attached to the torque wrench’s square drive. You should hear a clicking sound when it connects properly.

Secondly, make sure the socket is locked onto the fastener you will be torqueing. You don’t want it to slip off as that could cause damage or even injury. Finally, set the proper torque value on the wrench, and turn it slowly and deliberately.

Don’t rush or apply excessive force as that could cause inaccurate readings or even break the fastener. Remember that a torque wrench is a precision tool, and using it accurately can prevent costly mistakes. So, whether you are a professional mechanic or a DIYer, using regular sockets with a torque wrench can be a breeze if you follow these simple steps.

Happy wrenching! Keyword: torque wrench, sockets, technique.

Conclusion

In conclusion, just like using a fork to eat soup may seem like a good idea at first, using regular sockets with a torque wrench is not the way to go. The torque wrench is a specialized tool designed to ensure precision and accuracy in tightening bolts and nuts. So unless you want to risk damaging your equipment or compromising safety, make sure to use the right socket for the job and torque it to the manufacturer’s specifications.

Remember, a good mechanic always has the right tools for the task at hand.”

FAQs

What is a torque wrench and how does it work?

A torque wrench is a tool used to tighten bolts and nuts to a specific torque value. It works by measuring the applied force and converting it into torque.

Can regular sockets be used with a torque wrench?

Yes, regular sockets can be used with a torque wrench, but they must be high-quality and made of the correct material to withstand the torque values required.

How do I know what torque setting to use on my wrench?

The torque setting will depend on the size and type of bolt or nut you are working with. Check the manufacturer’s specifications or consult a torque chart to determine the correct setting.

Can an electronic torque wrench provide more accurate readings than a manual one?

Yes, electronic torque wrenches can provide more accurate readings since they use sensors to measure torque values and display them digitally.

Can I use a torque wrench on any type of material?

No, torque wrenches should only be used on materials that are strong enough to withstand the force applied during tightening. Using a torque wrench on weak or brittle materials can cause damage or failure.

How often should I calibrate my torque wrench?

It is recommended to calibrate your torque wrench at least once a year, or more frequently if it is used heavily or dropped.

Can a torque wrench be used for loosening bolts as well as tightening them?

No, torque wrenches should only be used for tightening bolts or nuts. For loosening, use a regular wrench or socket.