What Size Torque Wrench Do I Need for Automotive Work? A Comprehensive Guide

Have you ever tried to use a wrench that was either too big or too small for the job and ended up with a stripped bolt or a broken tool? It’s frustrating and can lead to costly mistakes. Choosing the right size torque wrench is essential to get the job done efficiently and correctly. It’s not just about the size of the bolt or nut you’re tightening, but also the torque required for the specific job.

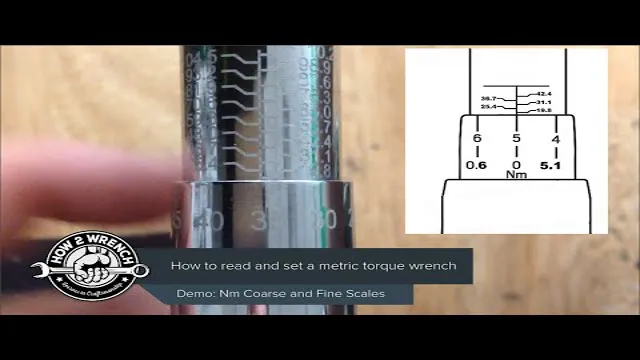

A torque wrench uses calibrated mechanisms to measure the amount of torque applied, ensuring that you don’t over or under tighten the fastener. In this blog post, we’ll guide you through the process of selecting the right size torque wrench for your needs, making your work easier and more efficient.

Understanding Torque

When it comes to working on your car or other machinery, having the correct size torque wrench is crucial. A torque wrench is a tool used to apply a specific amount of force or “twist” to a bolt or nut. This force is measured in torque, which is usually represented in foot-pounds or Newton-meters.

To determine what size torque wrench you need, you must first consider the amount of torque required for the job. Generally, torque wrenches come in a variety of sizes ranging from ¼ inch to 1 inch. The size of the torque wrench required for the job depends on the size of the bolt or nut being tightened.

For instance, smaller bolts or nuts require smaller torque wrenches while larger bolts or nuts require larger torque wrenches. It is important to use the correct size torque wrench to prevent over-tightening or under-tightening, which can result in damaged or failing machinery. So, before starting any job, ensure that you have the correct size torque wrench for the task at hand.

Definition of Torque

Torque is a term used to describe the amount of force applied to an object to make it rotate around an axis. In simpler terms, it is the measure of a twisting force that causes rotation. The magnitude of the torque depends on two main factors – the force applied and the distance from the point of rotation.

A greater force applied at a greater distance will result in a higher torque. Torque plays a crucial role in various areas of daily life, ranging from the operation of machinery and vehicles to the movement of human limbs. For instance, a mechanic uses torque wrenches to tighten bolts and nuts to a certain level of tightness, while athletes use torque to generate power and speed in their movements.

Understanding torque is important for people who work in fields that require the use of rotational force, as it helps them make more precise and effective calculations for their work.

Units of Torque Measurement

Torque measurement refers to the measurement of rotational force that is exerted by an object or a machine. This could be in the form of a motor or an engine, or even in everyday objects like door handles or twistable jars. Torque is usually measured in units such as Newton-meters (Nm), kilogram-meters (kgm), or foot-pounds (ftlb).

The choice of unit is usually based on the context of the situation and the preference of the user. For example, in the automotive industry, Newton-meters are commonly used to measure the torque produced by an engine, while in the construction industry, foot-pounds are more widely used. Understanding the units of torque measurement is important in ensuring the accuracy and efficiency of machines and equipment that rely on rotational force.

Factors to Consider When Choosing a Torque Wrench

When it comes to choosing a torque wrench, one of the most important factors to consider is what size you need. The size of the torque wrench you’ll need depends on the specific application you’ll be using it for. Generally, torque wrenches come in several sizes, ranging from small, compact models to larger, heavy-duty options.

The size of the torque wrench you need largely depends on the size of the nuts or bolts you’ll be tightening or loosening. For instance, if you’re working with small nuts and bolts, you’ll need a smaller, more precise torque wrench. On the other hand, if you’re working with larger or heavier-duty nuts and bolts found in heavy machinery, you’ll need a larger, more powerful wrench.

So, before selecting a torque wrench, you should consider the specific application you’ll be using it for and choose a size that fits those needs. That way, you can be certain that your job will be done to the highest standard and avoid any damage.

Size of Bolt or Nut Being Tightened

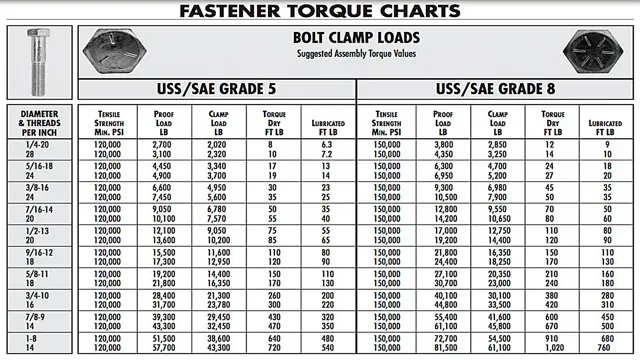

When it comes to choosing a torque wrench, one of the key factors to consider is the size of the bolt or nut being tightened. Different sized fasteners will require different levels of torque, and using the wrong torque wrench could result in damage or improper fastening. It’s important to carefully review the manufacturer’s specifications and choose a torque wrench that is appropriate for the size of the fastener you will be working with.

Additionally, make sure to adjust the torque settings on the wrench according to the size of the bolt or nut being tightened. Remember, using the correct size torque wrench can help ensure that your project is completed safely and effectively, while also avoiding the potential for costly mistakes. So take the time to consider the size of your fastener when choosing a torque wrench and make sure to use the appropriate tool for the job.

Torque Specification for the Task at Hand

When it comes to working with tools, it’s essential to have the right torque wrench for the job and to understand the factors that go into choosing one. One critical factor to consider is the torque specification required for the task at hand. This specification indicates the amount of force needed to tighten a bolt or fastener to a specific level.

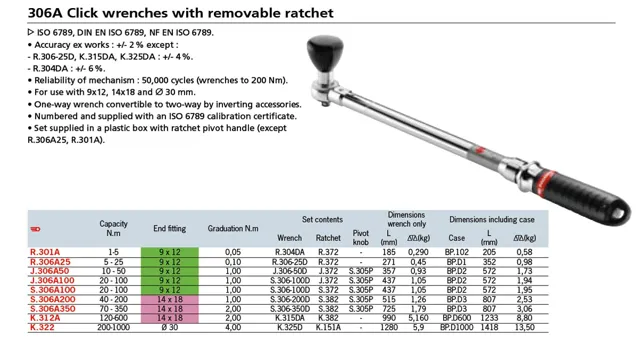

Choosing a wrench that doesn’t meet this specification could result in under or over-tightening, leading to potential safety hazards or damage to equipment. It’s also important to consider the type of torque wrench needed, such as a beam type or click type wrench. Each type has its advantages, and the decision will depend on the user’s preferences and requirements.

Additionally, the size and design of the wrench should match the fastener’s size and location, making it accessible and easy to use. By taking these factors into account, you can ensure that you select the proper torque wrench for the task at hand, providing accurate and consistent results.

Accuracy Required for the Job

Torque wrench When selecting a torque wrench, the accuracy required for the job is a significant factor to consider. The torque wrench’s purpose is to measure the amount of force applied to a fastener, so it is critical to have accurate readings to avoid over or under-tightening. Depending on the job, different levels of accuracy may be needed.

For example, if you are working on an automotive engine, a torque wrench with a higher accuracy rating would be necessary to prevent damage to the engine. However, for general household repairs, a wrench with a lower accuracy rating would suffice. It is essential to choose the appropriate torque wrench for the job at hand to ensure safety and avoid costly mistakes.

Common Torque Wrench Sizes

If you’re looking to add a torque wrench to your tool kit, you may be wondering what size to get. The size you need will depend on the type of work you plan on doing. Generally speaking, most torque wrenches come in sizes ranging from 1/4 inch to 1 inch, with some larger sizes available for heavy-duty applications.

For most DIY tasks, a 3/8 inch torque wrench will do the trick. However, if you plan on working on larger equipment or vehicles, you may want to consider a 1/2 inch torque wrench. It’s important to note that the size of the torque wrench refers to the size of the square drive, which is the part that fits into the socket.

So, when selecting a torque wrench, be sure to match the size of the square drive to the sockets you plan on using. Ultimately, the size torque wrench you need will depend on the specific task you’re performing, but with a little research, you’ll be able to find the perfect size for your needs.

1/4-inch Drive Torque Wrenches

When it comes to choosing a torque wrench, the drive size is an important consideration. One of the most common sizes is the 1/4-inch drive torque wrench, which is often used for smaller bolts and fittings. This size is frequently used for automotive and mechanical work, as well as for tasks around the home.

A 1/4-inch drive torque wrench can provide precise torque control, which is essential for avoiding damage to delicate components and ensuring proper tightening. There are many different torque wrench sizes available, but the 1/4-inch drive is a popular choice due to its versatility and ease of use. So, whether you’re working on a car, bike, or household appliance, a 1/4-inch drive torque wrench can help you achieve accurate and consistent results.

3/8-inch Drive Torque Wrenches

When it comes to torque wrenches, there are several common sizes you should be aware of. One of these is the 3/8-inch drive torque wrench, which is a popular choice among mechanics and DIY enthusiasts alike. This particular wrench size is ideal for working on smaller bolts and nuts, and it offers a range of torque settings to accommodate a variety of different applications.

Whether you’re tightening bolts on your car engine or assembling furniture at home, a 3/8-inch drive torque wrench is a versatile and reliable tool to have in your arsenal. So if you’re in the market for a new torque wrench, be sure to consider this popular size for all your tightening needs.

1/2-inch Drive Torque Wrenches

Torque wrenches come in different sizes and use, depending on the job requirements. Half-inch drive torque wrenches are one of the most commonly used sizes. This size is ideal for a wide range of applications, from automotive repairs to industrial and heavy-duty tasks.

With this size of wrench, you can achieve the desired torque on nuts and bolts accurately, ensuring safety and efficiency. Whether you’re installing new wheels on your car or performing maintenance on some equipment, using a half-inch drive torque wrench will give you the precision and control you need. So, consider investing in one to make your tasks a lot easier and safer.

Conclusion

In conclusion, when it comes to choosing the right size torque wrench, it’s important to remember that bigger isn’t always better. Just like Goldilocks and the three bears, you need to find the one that’s just right for the job at hand. So, whether you’re tightening lug nuts on your car or adjusting bolts on heavy machinery, make sure to do your research and select a torque wrench that’s the perfect fit.

Happy tightening, folks!”

FAQs

What is a torque wrench and why is it important?

A torque wrench is a tool used to tighten bolts and nuts with a specific amount of force. It is important to use a torque wrench to ensure that fasteners are tightened to the correct specifications, which helps prevent damage to equipment or injury to people.

What are the different types of torque wrenches available?

There are several types of torque wrenches available, including beam-type, click-type, digital, and hydraulic. Each type has its own advantages and disadvantages, and the best type for you will depend on your application.

What size torque wrench do I need for my car?

The size of torque wrench you need for your car will depend on the specific bolts and nuts you are working with. Typically, a 1/2 inch drive torque wrench is a good all-around option for automotive work, but it’s important to consult your vehicle’s manual or a professional mechanic to determine the exact torque specifications for your specific application.

Can I use a torque wrench for loosening bolts?

No, torque wrenches are not intended for loosening bolts. Doing so can damage the wrench and render it inaccurate. Instead, use a ratchet or breaker bar to loosen bolts, and then use the torque wrench to tighten them to the correct specification.

How often should I calibrate my torque wrench?

It’s recommended to calibrate your torque wrench at least once a year, or more frequently if you use it frequently or drop it. Calibration ensures that the wrench is accurate and reliable, which is essential for safe and effective use.

Should I buy a cheap or expensive torque wrench?

The cost of a torque wrench varies widely, but it’s important to choose a high-quality tool that meets your needs and budget. Cheaper torque wrenches may be less accurate or reliable, which can compromise safety and effectiveness. However, an expensive torque wrench may not be necessary for everyone, so it’s important to evaluate your needs and usage before making a purchase.

Can I use a torque wrench for other types of fasteners, such as screws or nails?

No, a torque wrench is designed specifically for tightening bolts and nuts to a specified torque. It’s not intended for use with other types of fasteners, which require different types of tools for proper installation.