Learning to weld can be a fulfilling and practical skill to have. Being able to join metal pieces together using heat and melting processes can come in handy when repairing broken items or even building new ones. However, the thought of using a portable welding machine can be intimidating and confusing if you’re a beginner.

But fret not, we’ve got you covered! In this beginner’s guide, we’ll walk you through the basics of using a portable welding machine. We’ll start with the essential safety measures you need to know before embarking on any welding project. We’ll also explain the different components of a welding machine and their functions, so you can have a better understanding of what you’re working with.

To weld successfully, you need to know how to prepare your welding machine and materials, select the right welding technique, and control the heat source. That may sound like a lot, but with our step-by-step guide and tips, you’ll be welding like a pro in no time. And don’t worry if you’re not familiar with welding-specific terminology; we’ll break it down in simple terms so that anyone can understand.

Just like any other skill, learning to weld takes time and practice. But with our guide and a bit of determination, you’ll be amazed at what you can accomplish with a portable welding machine. Plus, the satisfaction of creating your own metalwork can’t be beaten.

So, let’s dive in and get started!

Introduction

If you’re looking to take your welding skills on the go, then a portable welding machine can be a great solution. These machines are specifically designed for those who need the convenience of welding on the go. However, before using a portable welding machine, you must be familiar with the device, so you don’t put yourself in danger.

Firstly, choose the right welding machine, make sure that it’s appropriate for the type of work you’ll be doing. Secondly, make sure the machine is correctly set up with the correct power supply and that it’s grounded. Thirdly, make sure you always have proper safety equipment on hand, such as gloves and goggles for yourself and any bystanders.

Finally, practice several test welds on scrap metal before starting on your actual project. By following these steps, you can ensure that you’re using your portable welding machine safely and effectively, any time and anywhere. So, what are you waiting for? Get started on your welding project today!

What is a Portable Welding Machine

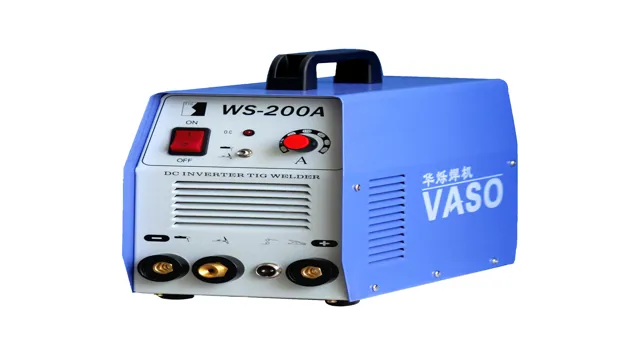

A portable welding machine is a versatile tool that allows welders to work on projects anywhere. It’s a compact, lightweight and portable device that makes welding possible. It can be used for on-site repairs and construction, as well as in remote areas where traditional welding machines cannot reach.

The main advantage of using a portable welding machine is the convenience it provides. Its compact size and lightweight design make it easy to transport and use in different locations. This tool is perfect for welders who work on a lot of different jobs or projects and requires flexibility in their work.

A portable welding machine is also cost-effective and can help save time and increase productivity. It’s an essential tool for any welder, and it’s worth considering for those who are looking for a more mobile and flexible solution.

Benefits of Using a Portable Welding Machine

Portable Welding Machine Welding is a process that has been around for centuries, with its origins dating back to the Bronze Age. It is a technique used to join two pieces of metal by heating them to melting point and allowing them to cool and fuse together. Over the years, welding has become more sophisticated, and various technologies have emerged to make the process more efficient and effective.

One such technology is the portable welding machine. This machine is essentially a small, lightweight, and highly versatile welding system that can be easily transported to different locations. The benefits of using a portable welding machine are numerous, including lower costs, increased flexibility, and greater efficiency.

Step-by-Step Guide

If you want to know how to use a portable welding machine, don’t worry! It’s simpler than you might think. First, you need to make sure you have the right equipment, including the welding machine itself, welding helmets, gloves, and goggles. Once you’ve got everything set up, you’ll need to adjust the settings on your welding machine to suit the job at hand.

This may include setting the correct voltage, amperage, and wire speed. When you’re ready to start welding, make sure you’re working in a well-ventilated area and that there are no flammable materials nearby. With the right safety precautions in place, you can begin welding.

Simply hold the welding gun steady and move it steadily along the joint you want to weld. Don’t forget to wear your protective gear throughout the process to ensure your safety. With a little bit of practice, you’ll be able to use your portable welding machine like a pro!

Step 1: Setting Up the Welding Machine

Setting Up Welding Machines First things first, let’s talk about how to set up a welding machine. Before you even begin welding, you need to ensure that your welding machine is properly configured. Start by firmly plugging in the welding machine to an appropriate power source.

Next, take a moment to familiarize yourself with the control panel and read the user manual if necessary. Adjust the voltage, amperage, and wire feed speed settings according to the welding project you’re working on. Don’t forget to ensure that the polarity is also set correctly.

If you’re using a MIG welder, choose the right shielding gas for the type of metal you’re welding. Remember, the correct setting will create better-quality welds in the end.

Step 2: Connecting the Cables

When it comes to connecting the cables in your electronics setup, it can be confusing and overwhelming, especially if you’re not tech-savvy. But don’t worry, with this step-by-step guide, you’ll have no trouble getting everything connected properly. First, make sure you have all the cables you need.

The most common types are HDMI, power, and Ethernet cables. Once you have them in front of you, start by identifying which cable goes where. HDMI ports are usually labeled, but if they’re not, you can easily look up your device’s manual online.

Connect one end of the HDMI cable to the device (TV, monitor, etc.), and the other end to the source (laptop, gaming console, etc.).

For power cables, simply plug one end into the device and the other into an outlet. Finally, Ethernet cables can be connected to routers, modems, or directly to your computer. Be sure to double-check that everything is plugged in correctly before turning on your devices.

With this easy-to-follow guide, you’ll be ready to enjoy your electronics setup in no time.

Step 3: Choosing the Right Welding Technique

When it comes to welding, selecting the appropriate technique is a critical decision. The welding technique you select should be based on the materials you are working with and your intended outcome. There are numerous welding techniques to select from, with each having its unique advantages and disadvantages.

TIG welding, MIG welding, and Stick welding are the three most popular welding techniques globally. TIG welding is ideal for welding aluminum and stainless steel due to its capacity to produce precise and controlled welds. MIG welding, on the other hand, is best suited for high-speed welding applications and creates less spatter than Stick welding.

Stick welding, also known as Shielded Metal Arc Welding (SMAW), is a cost-effective way of welding steel and can be done outside, making it perfect for mobile welding. Your selection of the proper welding technique for your project will have a significant impact on the finished product’s structural integrity and appearance. It is crucial to do your research and seek expert advice before deciding on a technique.

Step 4: Starting the Welding Process

Starting the welding process can be an exciting yet daunting task, especially for beginners. One of the first things to do is to make sure you have all the necessary safety gear, including welding gloves, a helmet, and a safety jacket. Once these are in place, it’s time to set up the welding machine and position the materials to be welded.

Before starting, it’s crucial to adjust the welding machine settings to the appropriate current, voltage, and amperage. The next step is to strike an arc by holding the electrode close to the material and then dragging it away. It’s essential to maintain a steady hand while welding, and also to keep an eye on the weld pool to ensure it maintains consistent penetration and good fusion.

As the welding progresses, it’s important to ensure that the wire or electrode is feeding properly and that the weld is progressing at a steady pace. With a little practice and attention to safety and technique, anyone can learn to start welding like a pro!

Dos and Don’ts of Using a Portable Welding Machine

If you are new to portable welding machines, there are a few dos and don’ts to bear in mind when using them. Firstly, DO ensure you have the correct personal protective equipment (PPE), such as gloves, a welding mask, and earplugs. DON’T forget to check the machine’s user manual before operation, as each brand and type may differ in setting up and operation.

DO position the welder in a well-ventilated area as to avoid inhalation of fumes. DON’T attempt welding on a damp surface or area where flammable materials are nearby. DO keep the electrode lead in good condition so it can handle and maintain the correct amount of power.

Lastly, DO regularly check your equipment for any signs of wear and tear, as this can affect the effectiveness of the welding while potentially creating a hazardous working environment. Following these tips and using a portable welding machine with care can lead to a more successful, efficient, and safe welding experience.

Dos

If you’re using a portable welding machine, there are some important dos and don’ts to keep in mind. First and foremost, always wear protective gear like gloves, a welding helmet, and appropriate clothing. It’s also essential to have a reliable power source and to regularly check your machine for any signs of damage or wear.

When it comes to welding, make sure to use the correct type of electrode for the material you’re working with, and avoid making unnecessary stops or starts to prevent defects. Additionally, always follow proper safety protocols, like having a fire extinguisher on hand and making sure your workspace is well-ventilated. By following these dos, you can ensure that your welding projects are successful, efficient, and safe.

Don’ts

When it comes to using a portable welding machine, there are a few key dos and don’ts to keep in mind. One major don’t is to never operate the machine without following the proper safety protocols. This means wearing the appropriate protective gear, such as gloves, goggles, and a welding helmet.

Additionally, it’s important to never touch the electrode or metal when the machine is on, as this can result in serious injury. Another don’t to keep in mind is to never weld near flammable materials or in an environment with poor ventilation, as this can create a fire hazard or cause harmful fumes to build up. By following these key don’ts, you can ensure that you are using your portable welding machine safely and effectively.

Conclusion

In conclusion, using a portable welding machine is like having a superhero in your toolbox. It may be small in size, but it has the power to fuse metal and save the day. By following the manufacturer’s instructions and taking the necessary safety precautions, you can confidently weld on-the-go and tackle any project that comes your way.

So, get ready to unleash the power of your portable welding machine and become a welding superhero. Ka-pow!”

FAQs

What is a portable welding machine and how does it work?

A portable welding machine is a compact, lightweight welding device that can be easily transported to different job sites. It works by using an electric current to heat metal parts and join them together.

What types of materials can be welded with a portable welding machine?

A portable welding machine can be used to weld a variety of metals, including steel, aluminum, stainless steel, and cast iron.

What safety precautions should be taken when using a portable welding machine?

Safety precautions when using a portable welding machine include wearing protective gear such as gloves, a welding mask, and flame-resistant clothing. The work area should be well-ventilated, and flammable materials should be kept away from the welding area.

Can a portable welding machine be used for industrial applications?

Yes, a portable welding machine can be used for industrial applications, provided that it has sufficient power and welding capacity to handle the job.

Is it easy to learn how to use a portable welding machine?

The learning curve for using a portable welding machine can vary depending on prior experience and the complexity of the welding job. However, with proper training and practice, most people can learn how to use a portable welding machine effectively.

What maintenance is required for a portable welding machine?

Regular maintenance of a portable welding machine includes cleaning the machine and replacing consumable parts such as electrodes and welding wire.

Can a portable welding machine be used in outdoor environments?

Yes, a portable welding machine can be used in outdoor environments provided that it is shielded from wind, rain, and other environmental factors that could affect the welding process.