Are you ready to take your welding game to the next level with a Liift TIG welding machine? If you’re familiar with TIG welding, you know how precise and clean the results can be. And with the added capabilities of a Liift machine, you’ll be able to take on even more challenging projects with ease. But where do you start? Setting up a Liift TIG welding machine may seem intimidating, but with a few simple steps, you’ll be on your way to producing professional-grade welds in no time.

In this blog post, we’ll walk you through the process of setting up your Liift TIG welding machine, so you can focus on the art of welding and let the machine handle the rest.

Introduction

If you’re thinking about welding, then you’ll need a good welding machine to get started. One of the most versatile welding machines on the market today is the LIIFT TIG Welding Machine. Whether you’re an experienced welder or just starting out, this machine is easy to use and can help you achieve professional results.

The first step in getting started with your LIIFT TIG Welding Machine is to take the time to learn how to set it up properly. Don’t worry, setting up this machine is easier than you might think. By following a few simple steps, you can be up and running in no time.

In this blog, we’ll look at the steps you need to take to set up your LIIFT TIG Welding Machine so that you can get started welding with confidence and ease.

What is a Liift TIG Welding Machine?

Liift TIG welding machine If you’re looking for a welding machine that can handle various materials and provide high-quality welds, you might want to consider a Liift TIG welding machine. Liift TIG welders utilize advanced inverter technology that allows for a smoother, more stable arc, and higher precision in welding. They also come with digital controls that let you fine-tune your welds for optimal results.

These machines are excellent for welding materials like stainless steel, aluminum, and other non-ferrous metals. The Liift TIG welding machine is compact and portable, making it perfect for those who work on-site or need to move around frequently. With its excellent performance, versatility, and convenience, the Liift TIG welding machine is an ideal choice for professional welders and DIY enthusiasts.

Why Use a Liift TIG Welding Machine?

TIG welding machines are known for their high precision and ability to weld intricate designs and structures. Liift TIG welding machines take this a step further with their advanced features and functionalities. Whether you are a professional welder or a DIY enthusiast, using a Liift TIG welding machine can make your work more efficient and effective.

In this blog section, we will explore the different reasons why you should consider using a Liift TIG welding machine. From its ease of operation and versatility to its low maintenance requirements and superior welding capabilities, a Liift TIG welding machine is a valuable investment for any welding project. So, let’s dive in and discover the advantages of using a Liift TIG welding machine.

Step-by-Step Guide to Setting Up Your Liift TIG Welding Machine

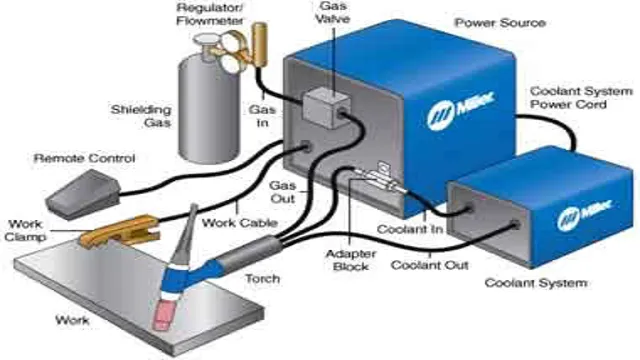

TIG welding is a popular welding technique that produces clean and precise welds. Setting up a Liift TIG welding machine is a simple process that anyone can do with a bit of patience and attention to detail. The first step is to ensure that the machine is properly connected to a power source, and that the power switch is turned off.

Next, fill the argon gas tank and attach the regulator to the tank. The regulator will control the pressure of the gas as it flows through the welding torch. Then, adjust the settings on the machine according to the thickness of the metal you are welding.

This will include setting the amperage, voltage, and gas flow rate. Finally, turn on the power switch and start welding. With a bit of practice, you’ll be able to produce high-quality welds with your Liift TIG welding machine.

Remember, practice makes perfect, so don’t be afraid to experiment with different settings and techniques until you find what works for you.

Step 1: Gather Your Equipment

If you’ve recently purchased a Liift TIG welding machine, congratulations! Before you can start welding to your heart’s content, though, you’ll need to properly set up your equipment. The first step is to gather all the necessary components. This includes your welding helmet, gloves, and safety glasses to protect yourself from the bright light, heat, and sparks created during the welding process.

Additionally, you’ll need your welding machine itself, along with any required attachments, cables, and hoses. Make sure you do not overlook anything, and double-check your inventory before you get started. It’s important to start with a complete and safe setup to ensure your welding process is smooth sailing from start to finish.

With all your equipment ready to go, you’re one step closer to a successful welding job with your Liift TIG machine.

Step 2: Prepare Your Workspace

When preparing to use your Liift TIG welding machine, setting up your workspace is crucial. Start by finding a clean and dry space with good ventilation to avoid inhaling fumes. Ensure your welding area is free from clutter and combustible materials, and do not weld near any flammable substances.

Set up your welding table or platform, make sure it is sturdy and level, and that the work area is well-lit. Consider investing in a welding curtain or screen to protect others and to contain any welding sparks. With a few preparations, you can create a safe and stable workspace that will allow you to focus on getting the job done.

Step 3: Connect the Power Source

Now that you have properly connected the gas supply and made sure that all the connections are secure, it’s time to move on to the next step: connecting the power source. This is a crucial step because without the correct power input, your Liift TIG welding machine won’t function properly. Make sure that the power source you’re using matches the voltage and phase requirements of your machine.

Most welding machines require a 220V or 240V power source, so double-check that your outlet matches the required voltage. Once you’ve confirmed that the voltage is correct, plug in the power cord to the designated outlet and turn on the machine. You should see a power light indicator switch on, letting you know that the machine is receiving power.

With the gas supply and power source properly connected, you’re almost ready to start welding!

Step 4: Connect the Ground Clamp

Now that you’ve connected the gas hose, it’s time to connect the ground clamp. This is a crucial step in setting up your Lift TIG welding machine as it ensures a safe and efficient weld. The ground clamp is responsible for completing the electrical circuit, which in turn, creates the arc necessary for welding.

The clamp should be attached to a metal surface as close to the weld as possible to reduce the resistance in the circuit and prevent arcing or sparking. Make sure to thoroughly clean the area where you plan to attach the clamp to remove any dirt, rust, or paint that may interfere with the electrical contact. Once attached, make sure the clamp is securely fastened to the metal surface.

With the gas hose and ground clamp connected, you’re ready to move onto the next step in setting up your Lift TIG welding machine.

Step 5: Connect the TIG Torch

Connecting the TIG torch is the final step in setting up your Liift TIG welding machine. This step is essential as it will ensure that the welding torch is powered up and ready to use. To connect the TIG torch, begin by locating the torch lead connection on the front panel of your machine.

Then, take the TIG torch and attach it to the lead connection by lining up the pins and twisting it into place. Once it has been secured, tighten the connector with a wrench to ensure a secure connection. It is important to note that there are different types of TIG torches, and you should choose the right one based on the type of welding you will be doing.

With this step complete, your Liift TIG welding machine is now set up and ready to be used for any welding project that comes your way.

Step 6: Turn on the Welding Machine

Now that you have properly set up your Lift TIG welding machine, it’s time to turn it on and get welding! Before you flip the switch, make sure all of your safety gear is in place – gloves, goggles, and welding helmet. Once everything is set, turn on the machine and let it warm up for a few minutes. You’ll want to adjust your amperage and shielding gas as needed for the specific project you’re working on.

It’s always best to start with a lower amperage and work your way up, as starting too high can result in a poor quality weld. With a little bit of practice, you’ll master the technique and be able to create clean, precise welds every time. So, let’s flip that switch and get to welding!

Tips for Operating Your Liift TIG Welding Machine

If you’re looking to set up and operate your Liift TIG welding machine like a pro, then you’ve come to the right place. First things first, make sure to read the user manual carefully to acquaint yourself with the specific features of your machine. Then, set up your welding area in a well-ventilated and properly lit space, check your power supply, and gather all the necessary welding accessories – including your chosen filler metal and any shielding gas required.

Don’t forget to double-check your torch’s consumables to ensure they’re in good working order. Once all the preparations are in order, it’s time to calibrate your welding machine to the appropriate settings. Factors such as the type and thickness of the metal you are welding, as well as the specific type of TIG welding technique you plan on using, will influence your machine’s voltage and amperage settings.

Don’t hesitate to experiment with different settings and parameters to get a feel for what works best for you and the job you’re working on. Remember to maintain proper safety practices, including wearing appropriate protective clothing such as eye protection and heat-resistant gloves. Take note when working with TIG welding machines, the high frequency can interfere with electronic equipment, so clear out any such equipment from the work area, unscrew them or insulate them from the ground.

With these tips in mind, you’ll be ready to start welding with your Liift TIG welding machine like a pro in no time!

Tip 1: Practice Welding on Scrap Metal First

TIG Welding Machine If you’re just starting with TIG welding, it’s best to practice on scrap metal before working on your actual projects. This way, you can get a feel for how the machine works and adjust your settings as needed. Additionally, it’s important to make sure you have all the necessary safety gear such as welding gloves and a welding helmet before starting your project.

When using your TIG welding machine, it’s also crucial to pay close attention to the tungsten electrode, which can wear out quickly if not properly maintained. As you gain more experience with your machine, you can begin experimenting with different settings and techniques to achieve the desired weld. Remember to always be patient and take your time when TIG welding, and don’t hesitate to seek guidance from more experienced welders if needed.

Tip 2: Keep Your Welding Machine Maintained

Maintaining your Liift TIG welding machine is essential to its longevity and performance. The last thing you want is for your machine to break down when you need it the most. To avoid that, it’s important to keep your machine well-maintained.

Regularly inspect and clean the machine’s components, such as the electrodes and gas nozzles, to prevent any debris buildup. Additionally, periodically check the machine’s power source and welding cables to ensure they are secure and free of any damage. It’s also crucial to follow the manufacturer’s instructions for machine maintenance and to schedule routine maintenance visits with a professional technician.

Taking these steps will help ensure that your machine remains functional and reliable for years to come. By investing in the proper upkeep of your welding machine, you’ll be able to work with confidence knowing that your machine is in top condition.

Conclusion

In conclusion, setting up a liift tig welding machine may seem like a daunting task, but with a little bit of patience and know-how, you’ll be welding like a pro in no time. Remember to always read the manual and take safety precautions seriously. And if all else fails, just remember that with the right machine and technique, you can weld just about anything.

So grab your gear and get to it – the welding world is waiting for you!”

FAQs

What is a lift TIG welding machine used for?

A lift TIG welding machine is designed for welding materials like aluminum, stainless steel, steel, and copper. It provides precise and high-quality welds on thin metals without warping.

How do I set up my lift TIG welding machine?

Firstly, connect the argon gas tank to the regulator and the regulator to the welding machine. Set the correct current rating and choose the type of tungsten electrode that suits the material you are welding. Then, select the type of filler rod that you will need for the job.

What is the difference between lift TIG and conventional TIG welding?

The main difference is that lift TIG welding does not require a high-frequency arc start like conventional TIG welding. Instead, it uses the lift arc technique that provides easy arc initiation. This method eliminates the need for a large tungsten electrode, which can cause weld contamination.

Can a lift TIG welding machine weld thicker metals?

Yes, a lift TIG welding machine can weld thicker metals, but it is best suited for thin materials. However, you can use a lift TIG welding machine with a high amperage rating to handle thicker metals.

What are the different types of tungsten electrodes used in lift TIG welding?

There are three types of tungsten electrodes used in lift TIG welding: pure tungsten, thoriated tungsten, and ceriated tungsten. Pure tungsten is used for non-corrosive materials, thoriated tungsten for DC welding, and ceriated tungsten for AC welding.

What are some common mistakes to avoid while using a lift TIG welding machine?

Common mistakes to avoid while using a lift TIG welding machine include not properly preparing the work surface, welding with the wrong type of gas, and not using a clean filler rod. It’s also important to maintain the right distance between the tungsten electrode and the workpiece to achieve accurate and stable welds.

What safety precautions should I take while using a lift TIG welding machine?

Some safety precautions to follow while using a lift TIG welding machine include wearing protective gear such as gloves, a welding helmet, and a jacket. Ensure good ventilation and avoid welding on damp surfaces. Finally, disconnect the power supply when not using the machine.