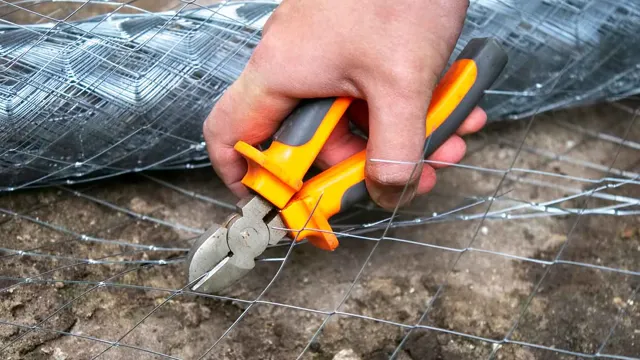

Are your wire cutters not performing as well as they used to? Are they struggling to make clean cuts or requiring more force than usual to snip through wires? If so, it might be time to sharpen them! Sharpening your wire cutters not only prolongs their lifespan but also ensures a smooth and effortless cutting experience. But how do you sharpen wire cutters, you may ask? Don’t worry, we have got you covered! In this blog, we will guide you through the step-by-step process of sharpening your wire cutters, saving you time and money in the long run.

Why Sharpening is Important

Wire cutters are essential tools that must be in every toolbox. Just like any cutting tool, they can dull over time, making it difficult to get a precise cut. This is where sharpening comes in.

Sharpening your wire cutters helps to maintain their cutting effectiveness and ensures a clean cut every time. So, how can you sharpen your wire cutters effectively? First, pick the right sharpening tool depending on the blade’s material. For instance, you can sharpen cutters made of soft materials using a metal file, while cutters made of harder materials may require more abrasive sharpening tools.

Secondly, hold the cutter’s blade with one hand while using the sharpening tool to file it with the other hand. Be gentle and place the file at the cutter’s blade’s angle and move it back and forth evenly. Repeat the same process for the other blade.

Regularly sharpening your wire cutters can prolong their lifespan and save you money in the long run, as you don’t have to buy a new pair of cutters every time they become dull.

Ensures Efficient Cutting

Sharpening is a crucial aspect of ensuring efficient cutting. Just like how a pencil needs to be sharpened periodically to write smoothly, a sharp blade is essential to cut through various materials with ease. A dull blade tends to squish or tear the item being cut, leading to an uneven result.

On the other hand, a sharp blade ensures a clean, precise, and effortless cut. Therefore, sharpening your cutting tools like knives and scissors must be done regularly, especially if you frequently use them. By maintaining the sharpness of your cutting tools, you not only enhance precision but also extend their lifespan.

Remember, a sharp blade is not only more beneficial, but it’s also safer to use as it reduces the chances of slips and accidents. So, the next time you struggle to cut through anything, don’t throw away your tool. Sharpen it, and see the magic it can do!

Extends Life of Wire Cutters

Sharpening your wire cutters is crucial if you want them to last longer and remain effective. Over time, your wire cutters can become dull and blunt, making it harder to cut through tougher materials and wires. This not only affects the quality of your work but can also cause damage to your cutters and reduce their lifespan.

By regularly sharpening your wire cutters, you can maintain their sharpness and precision, making them more efficient and effective. Think of it like sharpening a kitchen knife to ensure it can easily cut through food without squishing or tearing it. The same principle applies to your wire cutters.

So, the next time your wire cutters feel dull, take a few minutes to sharpen them – your smooth, precise cuts will thank you.

Tools Needed for Sharpening

When it comes to keeping your wire cutters sharp, it’s important to have the right tools on hand. You’ll need a sharpening stone or file, as well as a lubricant such as oil or water to keep the metal from overheating during the sharpening process. Before getting started, make sure to clean your wire cutters thoroughly to remove any debris or rust that may have accumulated.

Once clean, hold the sharpening tool at a 20-degree angle and run it along the cutting edge of the wire cutter, making sure to maintain a consistent angle throughout. Take care not to apply too much pressure, as this can damage the metal. After sharpening, wipe the metal clean and reapply any lubricant.

With a little practice, you can keep your wire cutters sharp and ready to tackle any task.

Sharpening Stone

A sharpening stone can be a great tool to make your knives and blades sharp, but you’ll need a few other tools to get started. First, you’ll need to have a honing guide to hold the blade at the correct angle. This is crucial for getting a consistent sharpening angle every time you use the stone.

You’ll also need a flattening stone to keep the sharpening stone flat and level. A water stone needs to be flat for the sharpening to work properly; otherwise, you’ll end up with an uneven edge. Finally, you should get a honing oil to lubricate the stone and help prevent your sharpening stone from clogging up with metal particles.

With these tools, you’ll be able to get a razor-sharp edge on your knives. Keep them handy in a small kit, and touch up your blades as often as necessary to maintain that perfect edge.

Rubbing Alcohol

When it comes to sharpening tools, having the right equipment is crucial. One item that should never be overlooked is rubbing alcohol. Not only can it help clean and disinfect your tools, but it can also assist in sharpening.

Rubbing alcohol works by removing any debris or build-up on the tool’s surface, making it easier for the blade to cut through materials. Additionally, it can be used in conjunction with sharpening stones to create a smoother surface. To use rubbing alcohol for sharpening, simply soak a cloth in the solution and wipe down your blade before beginning the sharpening process.

By incorporating rubbing alcohol into your tool sharpening routine, you can ensure that your tools are clean, sharp and ready for use.

Safety Gloves

When it comes to sharpening tools, having the right equipment is crucial for achieving the desired results and avoiding any accidents. One of the most important tools you need is a pair of safety gloves. These gloves protect your hands from the sharp edges of the tools you’re sharpening, as well as any flying debris that might come off during the process.

Not only do gloves protect your hands, but they also provide a better grip and improve accuracy. When choosing safety gloves, make sure they fit properly and are made of a durable material that can resist cuts and punctures. It’s also important to note that safety gloves are not a substitute for safe practices.

Always pay attention to what you’re doing and keep your fingers away from the sharp edges of your tools. With the right tools and proper safety measures, you can achieve sharp and precise results every time.

Steps to Sharpen Wire Cutters

Wire cutters are an essential tool when it comes to electrical work or DIY projects. However, with time, their cutting edges can become dull and ineffective. That’s why it’s essential to know how to sharpen wire cutters to keep them working correctly.

Firstly, you’ll need to gather the necessary tools, which include a sharpening stone, oil, and a cleaning cloth. Secondly, clean the wire cutters to remove any debris or rust that could interfere during the sharpening process. Then, use the sharpening stone to sharpen the cutting edge of the wire cutters, ensuring that you maintain the original shape.

Finally, wipe the wire cutters with oil and a cleaning cloth to prevent rust. Knowing how to sharpen wire cutters will not only save you money but also maximize the lifespan of your tool and increase its efficiency when working on your projects.

Step 1: Clean the Cutters

If you want to extend the life of your wire cutters and ensure that they perform their best when you need them, it’s essential to keep them sharp. Fortunately, sharpening wire cutters isn’t as daunting a task as it may seem. Here are some easy steps to help you sharpen your wire cutters.

Step one is to clean the cutters to remove any debris or foreign material that might have accumulated on the blades. This is essential as any debris can get in the way and make it harder to sharpen the blades effectively. To clean your cutters, use a soft cloth to wipe them down, making sure to remove any visible dirt and grime.

Once the cutters are clean, you can then move on to the next steps to sharpen them and keep them in top shape for all your wire cutting needs. Remember, taking good care of your tools can save you time and money in the long run, so put in the effort to keep them sharp and in good working condition.

Step 2: Lubricate the Blades

When sharpening wire cutters, lubricating the blades is an important step to follow. With use, these blades can become sticky or rusty, leading to a less effective cutting experience. Using a lubricant such as WD-40 or oil can help to remove any dirt or debris that may be stuck in the blades, while also providing a smooth surface for a sharper edge.

To do this, simply apply a small amount of lubricant to the blades and work it in with a cloth or brush. Make sure to wipe away any excess lubricant before moving on to the next step. Taking the time to lubricate your wire cutters before sharpening can make a big difference in their performance and lifespan.

So don’t skip this important step in the process!

Step 3: Begin Sharpening

When it comes to sharpening wire cutters, the third step is to actually begin sharpening. This may seem like a no-brainer, but it’s important to approach the task methodically and with care. First, make sure your work area is clean and well-lit.

Then, grab your sharpening tool of choice (such as a sharpening stone or file) and hold the wire cutters in one hand, using the other hand to guide the sharpening tool. It’s essential to maintain a consistent angle throughout the sharpening process, typically around 30 degrees. Work slowly and methodically, checking frequently to ensure that the blades are becoming sharper without any nicks or other damage.

Once you’re satisfied with the sharpness, be sure to wipe down the blades and oil any moving parts to prevent rust and ensure smooth operation. With a little patience and attention to detail, sharpening your wire cutters should be a breeze.

Step 4: Check for Sharpness

When it comes to wire cutters, sharpness is crucial. Dull cutters can damage the wire, make cutting more difficult, and even cause injury to the user. In step 4, you’ll want to check for sharpness.

There are a few ways to do this. First, you can visually inspect the blades for any nicks or blunt spots. Next, you can gently run the blades over your fingernail to see if they catch.

If they don’t catch, they may be too dull. You can also test the cutters on a piece of scrap wire. If they can’t cleanly cut through it, it’s time to sharpen them.

Sharpening wire cutters may seem intimidating at first, but it’s a skill that can be learned with practice. By keeping your cutters sharp, you’ll ensure that they perform at their best and last longer.

Tips and Tricks for Maintaining Sharp Cutters

If you’re a DIY enthusiast or a professional, you probably use wire cutters a lot, and after plenty of hard work, you may notice that your wire cutters are not performing as well as they used to. No worries, though, as it’s easy to sharpen them yourself. The first thing you need to do when sharpening wire cutters is to clean them thoroughly.

Once you’ve done that, you can use a sharpening stone or a sharpening file to hone the cutters’ edges. Remember to follow the angle of the blade when sharpening and apply minimal pressure. It’s also important to keep the cutting edges correctly aligned while sharpening.

You can check this by holding the cutters up to the light and looking at the edges, or by cutting a piece of paper to test their sharpness. With a little practice and patience, you can sharpen your wire cutters in no time and keep them working as sharp as new.

Avoid Cutting Hard Materials

When it comes to maintaining sharp cutters, there are a few things you’ll want to keep in mind to ensure they stay in top condition. One key tip is to avoid cutting hard materials with your cutters. While it may seem like they can handle anything, cutting hard substances like metal or thick cardboard can quickly dull your blades.

Instead, opt for softer materials like paper or fabric to prolong the life of your cutters. Another trick is to regularly clean and sharpen your cutters. Use a soft cloth to wipe away any debris and invest in a high-quality sharpener to keep your blades in tip-top shape.

By following these simple tips, you can ensure that your cutters will stay sharp and effective for all of your crafting needs.

Store in a Dry Place

“sharp cutters” If you want to maintain your sharp cutters, one of the things you need to do is store them in a dry place. Moisture can cause rust on your cutters, which will ultimately dull their edges. Additionally, damp air can potentially cause your cutter’s handle to rot or even become loose.

To avoid these issues, make sure you store your cutters in a dry place. If you don’t have a dedicated space for your cutters, consider investing in a drawer or container with a dehumidifier installed. This will help keep your cutters dry and rust-free.

Remember, taking proper care of your tools ensures that they will last a long time and perform at the highest level possible whenever you need them.

Regularly Clean and Lubricate Blades

Maintaining sharp cutters is essential for getting the most out of your tools and ensuring a clean and precise cut every time. One of the most important tips for keeping your blades sharp is to regularly clean and lubricate them. Over time, debris and dirt can build up on the blade, making it dull and less effective.

A quick wipe with a clean cloth and some lubricating oil can go a long way in extending the life of your blade and keeping it in top condition. A well-lubricated blade also helps prevent rust and other corrosion from setting in. With just a little bit of maintenance, you can keep your blades sharp and your tools working smoothly for years to come.

So the next time you’re ready to start your next DIY project, take a moment to give your blades a little TLC and enjoy the benefits of a clean and precise cut every time.

Use with Care

Maintaining sharp cutters can be a real challenge, but with the right tips and tricks, you can keep your cutters in pristine condition! It’s important to use your cutters with care to avoid unnecessary damage. one of the best ways to ensure longevity is to regularly clean and oil your blades. This will help keep them from becoming dull or rusted over time.

Another helpful tip is to avoid using your cutters on materials that are too tough or thick. While it may be tempting to power through a tough piece of material, doing so can quickly dull your blades. Instead, invest in cutters that are specifically designed to handle that type of material.

Remember, proper maintenance now can save you time and money in the long run. By taking care of your cutters, you’ll be able to enjoy clean and precise cuts for years to come!

Conclusion

In conclusion, sharpening wire cutters is a simple yet crucial task that enhances the productivity and efficiency of your daily work. With a few basic tools and techniques, anyone can sharpen their wire cutters and ensure they are always in top-notch shape. So, go ahead and give your wire cutters the TLC they deserve, and watch them slice through wires like butter.

Remember, a sharp cutter is a happy cutter!”

FAQs

What is the best way to sharpen wire cutters?

The best way to sharpen wire cutters is by using a fine-grit sharpening stone. Hold the cutter at a 20-degree angle and run it along the stone until the blade is sharp.

Can wire cutters be sharpened with a file?

Yes, wire cutters can be sharpened with a file. Use a fine metal file and hold the cutter at a 20-degree angle, then run the file along the blade until it is sharp.

How often should wire cutters be sharpened?

Wire cutters should be sharpened whenever they start to feel dull and are not cutting as cleanly as they should. This could be after several uses or after a few months or years of use.

Can wire cutters be sharpened at home or should they be taken to a professional?

Wire cutters can be sharpened at home by following the proper techniques, however, if you are not comfortable doing so, you can take them to a professional to ensure they are sharpened correctly.

What are some other tools that can be used to sharpen wire cutters?

Other tools that can be used to sharpen wire cutters include a honing rod, sharpening stone, or electric sharpener.

What is the difference between a dull and a sharp wire cutter?

A dull wire cutter will struggle to cut through wires, leaving frayed ends and requiring more force to complete the cut. A sharp wire cutter will make clean cuts with ease.

How can I tell if my wire cutters need to be sharpened?

If you notice that your wire cutters are not cutting cleanly through wires, or if you hear a grinding or scraping sound while using them, it may be time to sharpen them.