Utility knives are a DIYer’s go-to for a variety of projects, but can they handle cutting fiberglass reinforced plastic (FRP)? The short answer is yes, but it requires some technique to ensure a clean and precise cut. FRP is a durable material commonly used in construction, but it can be tricky to cut without the right tools. In this blog, we’ll dive into the best practices for cutting FRP with a utility knife, including how to avoid splintering and maintaining a sharp blade.

So grab your utility knife and let’s get started!

What is FRP?

FRP or Fiber Reinforced Polymer is a composite material that consists of a polymer matrix reinforced with fibers. It is commonly used in construction, aerospace, and automotive industries due to its high strength-to-weight ratio and corrosion resistance. When it comes to cutting FRP, a utility knife can be used, but it depends on the thickness of the material.

If the FRP is thin enough, a utility knife can easily do the job. However, for thicker FRP sheets, a saw or a specialized FRP cutting tool is more suitable. It is important to note that when cutting FRP, proper safety gear such as gloves and eye protection should be worn to prevent any injury from flying debris.

So, to answer the question, yes, you can cut FRP with a utility knife, but it is not always the best option depending on the thickness of the material.

FRP Definition and Properties

FRP, or Fiber Reinforced Polymer, is a composite material made from reinforcing fibers, such as fiberglass, carbon, or aramid, embedded in a polymer matrix, typically epoxy. This combination of materials results in a strong and lightweight material that can be shaped and molded into various forms. FRP is commonly used in construction, aerospace, automotive, and marine industries due to its high strength-to-weight ratio, corrosion resistance, and durability.

FRP can also be customized with different types of fibers to suit specific applications, such as incorporating fire-retardant additives for fire resistance. Overall, FRP offers a versatile and cost-effective solution for various engineering and structural applications.

Common Applications of FRP Materials

FRP (Fiber Reinforced Polymer) is a composite material made up of fibers and a polymer matrix, often used in various industries as a substitute for traditional materials such as metal, wood, and concrete. It is often preferred due to its high strength-to-weight ratio, corrosion resistance, and overall durability. FRP can be molded into various shapes and can withstand a wide range of environmental conditions, making it a versatile material for numerous applications.

Some common applications of FRP include the construction of bridges, building facades, storage tanks, and marine structures. FRP is also used in transportation, aerospace, and sports equipment manufacturing. With its many benefits, it’s no wonder that FRP materials are becoming an increasingly popular choice across multiple industries.

Can You Cut FRP with a Utility Knife?

FRP (Fiberglass Reinforced Panels) is a popular material commonly used in constructing walls, ceilings, and other surfaces in commercial settings due to its durability and low maintenance. However, when it comes to cutting FRP panels, many people wonder if they can use a utility knife to get the job done. The answer is yes, you can use a utility knife to cut FRP, but it’s crucial to use the appropriate blade and technique.

A sharp utility knife with a new blade is recommended to ensure a clean and accurate cut. It’s also essential to take safety precautions by wearing gloves, eye protection, and respiratory protection as cutting fiberglass can release harmful particles into the air. Overall, cutting FRP with a utility knife can be an easy and efficient method as long as the correct tools and safety measures are taken.

Advantages and Limitations of Cutting FRP with a Utility Knife

Cutting FRP with a utility knife can be advantageous for certain situations. Utilizing a utility knife is often more convenient and cost-effective than using specialized tools for cutting FRP. It’s also a safer alternative to using a saw, minimizing the risk of injury.

However, there are limitations to this method. A utility knife may struggle with thick or dense FRP materials and may not produce the cleanest cuts, leading to rough edges. Additionally, using a utility knife requires a steady hand and a significant amount of patience.

If precision is crucial, it’s recommended to use specialized tools or hire a professional to ensure that the cuts are clean and accurate. Overall, cutting FRP with a utility knife can be a viable option, but it’s essential to consider the material’s thickness, density, and the level of precision required to achieve the desired outcomes.

Factors to Consider When Cutting FRP with a Utility Knife

Cutting FRP with a utility knife can be tricky, but it is possible. However, there are some factors you need to consider before attempting to cut FRP with a utility knife. First, you need to ensure that the knife is sharp enough to cut through the dense material.

Secondly, you need to take your time and cut slowly to avoid cracking or damaging the FRP. It’s also important to use a straight edge or ruler to guide your knife and ensure accuracy. Finally, you need to wear protective gear such as gloves and safety glasses to minimize the risk of injury.

Overall, cutting FRP with a utility knife is possible but requires caution, practice, and the right equipment.

Safety Precautions When Cutting FRP with a Utility Knife

When it comes to cutting FRP with a utility knife, the answer is yes, you can. However, it’s essential to take necessary safety precautions to avoid potential injury. FRP (Fiberglass-Reinforced Plastic) is a durable and lightweight material used in many applications, from construction to aerospace.

While it’s easy to cut through with a utility knife, it’s crucial to wear protective equipment to prevent microscopic fibers from entering your skin and eyes. It’s also essential to ensure the blade is sharp to avoid slippage. When cutting, be sure to use a steady and firm grip, and cut away from your body.

If the FRP is too thick, use a specialized saw instead to prevent damaging the FRP or the utility knife. With these safety measures in place, cutting FRP with a utility knife can be a straightforward and efficient process.

How to Cut FRP with a Utility Knife

If you’re wondering whether you can cut FRP with a utility knife, the answer is yes! Using a utility knife is a great way to make clean cuts on FRP panels. The key is to make sure you have a sharp blade and take your time when cutting. First, score the FRP panel along the line where you want to make the cut.

Apply firm pressure to the knife and drag it along the line, making sure to keep it straight. Once you’ve scored the panel, you can apply more pressure and cut through the panel. Be sure to wear gloves and eye protection when cutting FRP to avoid any injuries.

Using a utility knife is an easy and efficient way to cut FRP, and it’s a great tool to have in your toolbox for any DIY project.

Step-by-Step Guide for Cutting FRP with a Utility Knife

Cutting FRP with a utility knife may seem like a daunting task, but with the proper tools and technique, it can be quite simple. To start, gather a utility knife with a sharp blade and a straight edge, such as a metal ruler. Make sure the FRP panel you want to cut is secured in place to prevent any movement during cutting.

Begin by scoring the panel along the desired cut line with the utility knife, using light pressure on the blade. Repeat the scoring several times until the panel is cut through. For thicker panels, it may be necessary to score deeper, but be careful not to apply too much pressure and damage the panel.

Once the scoring is complete, use the straight edge to snap the panel along the scored line. Finally, use the utility knife to clean up any rough edges or leftover pieces. Cutting FRP with a utility knife is an easy and efficient process that can produce a professional finish.

Tips for Achieving Clean and Accurate Cuts in FRP

Cutting FRP (Fiberglass Reinforced Plastic) can be tricky, but with the right tools and techniques, it’s possible to achieve clean and accurate cuts every time. Using a utility knife is a popular method for cutting FRP, and it’s an easy tool to use. Start by marking your cut line with a marker, ensuring that it’s clear and easy to follow.

Then, score the FRP along the line using a sharp utility knife, applying pressure as you go. Once you’ve scored the entire line, snap the FRP along the score line to create a clean cut. It’s important to use a sharp knife and apply even pressure to avoid jagged edges or uneven cuts.

With a little practice, cutting FRP with a utility knife can become a quick and efficient way to achieve perfect cuts every time. So the next time you need to cut FRP, grab a utility knife and get to work!

Conclusion

In conclusion, it turns out that cutting FRP with a utility knife is a bit like trying to chop down a tree with a butter knife – it’s not impossible, but it sure is a lot of effort for very little reward. While a utility knife may be able to score the surface of FRP, it’s unlikely to make a clean cut all the way through. So, if you’re looking to dice up FRP with ease, it’s best to invest in the right tools for the job and leave the utility knife for simpler tasks that don’t require as much muscle power.

“

FAQs

What is FRP and what is it used for?

FRP stands for fiberglass reinforced plastic and it is commonly used in construction, manufacturing, and transportation industries due to its high strength and durability.

Can FRP be cut with a utility knife?

Yes, FRP can be cut with a sharp utility knife, but it may require multiple passes and may not provide a clean cut as compared to using a power saw.

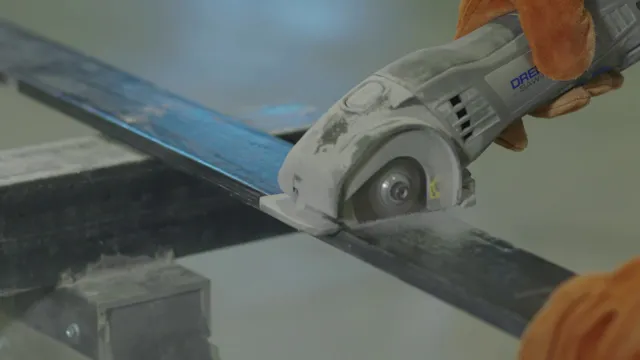

What kind of blade should I use to cut FRP?

It is recommended to use a fine-toothed saw blade with a high-speed rotary tool or jigsaw to obtain precise and clean cuts in FRP.

What safety precautions should I take while cutting FRP?

It is recommended to wear safety goggles, gloves, and a dust mask to avoid inhaling any fiberglass particles. It is also important to use a proper cutting tool and work in a well-ventilated area.

Can FRP be drilled to create holes?

Yes, FRP can be drilled to create holes, but it may require a special drill bit due to its tough and abrasive nature.

Is FRP recyclable?

Yes, FRP can be recycled and reused for other products. Recycling companies often shred and melt the FRP material to make new products such as pipes and panels.

What are the advantages of using FRP over traditional materials?

FRP has several advantages over traditional materials such as steel, wood, and concrete. It is lightweight, corrosion-resistant, non-conductive, easy to install, and requires less maintenance in the long run.