Do you ever feel frustrated when your Dewalt orbital sander starts giving you less-than-perfect results? It’s natural to want seamless, smooth sanding with your power tool, but after prolonged use, it’s common for the sander pad to wear out. Don’t worry though – replacing your Dewalt orbital sander pad is an easy task that will allow you to quickly get back to your woodworking projects with precision and ease. Think of it like changing a tire on your car – it may seem intimidating at first, but with a bit of practice, it becomes a quick and simple process.

In this blog post, we’ll guide you through the steps needed to replace your sander pad like a pro. With our easy-to-follow instructions and tips, your orbital sander will be working smoothly and effectively in no time. So, grab your tools and let’s get started!

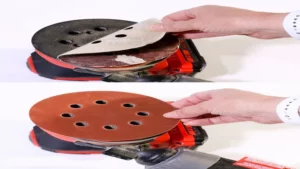

Step 1: Removing the Old Pad

Replacing the pad on your Dewalt orbital sander can help restore its performance and ensure that your sanding projects come out looking as smooth as ever. To begin, the first step is to carefully remove the old pad from the sander. Start by turning off and unplugging the sander to avoid any accidental starts.

Then, using a wrench or pliers, gently unscrew the old pad from the sander’s base. It’s important to be careful during this step as the screws may be tight and difficult to remove. Once the screws have been removed, carefully pull the old pad away from the sander.

Be sure to clean any debris or dust left behind on the sander’s base before installing the new pad. With the old pad removed and the base clean, you’re ready to move on to the next step in replacing your Dewalt orbital sander pad.

Locate the screws holding the pad in place

When it comes to replacing your old mouse pad, the first step is to remove the old pad from your desk. This might sound easy at first glance, but you need to make sure you’re doing it the right way. First, locate the screws holding the pad in place.

They are usually located on the bottom of the pad and need to be unscrewed carefully. Make sure to keep the screws in a safe place, as you’ll need them when you install your new pad. If your old mouse pad is held in place by adhesive tape, gently peel it off and avoid damaging your desk.

Once you’ve removed all the screws or adhesive tape, lift the old pad off your desk and get ready to install the new one. Remember to take your time and be careful while removing the old pad – you don’t want to leave any scratches or damage on your desk! With this simple step out of the way, you’re now ready to enjoy your brand new mouse pad.

Use a screwdriver to remove the screws

When it comes to replacing the pad on your drum brake, the first step is removing the old one. This may seem like a daunting task, but with a trusty screwdriver, it can be a breeze. Look for the screws that are holding the brake pad in place and use the screwdriver to carefully remove them.

Depending on the type of brake, there may be one or multiple screws, so be sure to check carefully. Once you have removed all the screws, gently lift the old pad out of the brake assembly. This step is crucial for maintaining the functionality and safety of your brakes.

By taking the time to carefully remove the old pad, you can ensure a smooth replacement process and a well-functioning brake system.

Gently remove the old pad from the sander

When it comes to refurbishing wooden floors, removing the old pad from the sander is the first step in the process. This may seem like a simple task, but it requires a gentle hand to avoid any damage to the equipment. Before starting, it is essential to unplug the device from the power outlet to ensure safety.

Then, use a screwdriver to unscrew the pad from the sander. Be cautious while doing this, as some models may have screws on the front and back. Once this is done, gently lift the pad off the sander and inspect it for any signs of damage or wear and tear.

If it is in good condition, it can be reused, but if not, it should be replaced with a new one. Remember, the old pad needs to be removed with care as it plays a significant role in the final finish of the floor. So, take it slow, and you will be ready for the next step in no time.

Step 2: Preparing the New Pad

Now that you’ve removed the old pad from your Dewalt orbital sander, it’s time to prepare the new pad. Start by ensuring that your new pad fits your sander’s model. Double-check this to avoid any complications during the replacement process.

After ensuring that the new pad is compatible, clean the sander’s base to remove any remaining adhesive from the old pad. This is crucial because any residual adhesive can reduce the new pad’s sticking ability. Once you’ve cleaned the base, apply new adhesive to the sander’s base.

Be sure to apply adhesive evenly and smoothly, ensuring that there are no bumps or valleys that may cause the new pad to slip or shift while in use. Wait for the adhesive to dry and cure according to the manufacturer’s directions before proceeding with the next step. By following these simple steps, you can ensure that your new pad is installed correctly, greatly improving the efficiency and performance of your Dewalt orbital sander.

Align the new pad with the sander

When it comes to replacing the pad on your sander, one crucial step is to align the new pad with the sander. This ensures that the pad is properly installed and will function correctly during use. To do this, you’ll want to take the time to carefully line up the new pad with the ridges or grooves on the sander’s base.

Once you’ve found the correct placement, press down firmly on the pad to make sure it’s fully in place. It’s also a good idea to test the new pad by turning on the sander and making sure it spins smoothly. By taking these steps and aligning the new pad correctly, you’ll ensure that your sander functions properly and that you get the results you’re looking for.

Remember, replacing the pad may seem like a simple task, but taking the time to do it right can make a big difference in the long run.

Ensure that the screw holes line up with the sander’s holes

When it’s time to replace the sander’s pad, the first step is to ensure that the screw holes line up with the sander’s holes. This is important because if they don’t line up, the pad won’t fit correctly, which can cause damage to both the sander and the material you’re trying to sand. Once you’ve confirmed the screw holes align, it’s time to prepare the new pad.

This involves removing any packaging and examining the surface of the pad. Ensure it’s smooth and free from any debris that could interfere with the sanding process. If necessary, lightly sand the surface of the pad to remove any rough spots.

By properly preparing the new pad, you’ll be able to achieve a smooth finish every time you use your sander.

Insert the screws into the holes of the new pad

When it’s time to replace the brake pads on your car, it’s crucial to follow the proper steps to ensure their functionality. Step 2 of replacing the brake pads is preparing the new pad by inserting the screws into the holes. This may seem like a small task, but it’s important not to overlook it as it ensures the new pad is securely in place.

To do this, align the holes of the new pad with the holes on the caliper bracket and insert the screws. Use a wrench to tighten the screws until they are snug. It’s crucial not to overtighten the screws, as this can damage the threads and compromise the effectiveness of the brake pad.

By properly preparing the new pad, you can ensure the safety and longevity of your car’s brake system. So, take your time and do it right. Your brakes (and your passengers) will thank you.

Tighten the screws with a screwdriver

When it comes to changing the brake pads of your car, the second step is to prepare the new pad. This involves tightening the screws with a screwdriver. It’s important to make sure that the screws are firmly secured to the rotor, as loose screws can cause dangerous accidents.

Use a high-quality screwdriver that provides a comfortable grip and allows for maximum torque. Position the screwdriver on the screw head and apply steady pressure to turn clockwise until the screw is tightened. Repeat this with all screws to ensure that the new brake pad is securely in place.

By taking the time to properly prepare the new pads, you can ensure that your braking system is working efficiently and safely on the road.

Step 3: Testing the New Pad

Now that you’ve replaced the pad on your DeWalt orbital sander, it’s time to test it out! Start by turning the sander on and letting it run for a few seconds to make sure the pad is secured in place and not wobbling. If everything looks and sounds good, try sanding a small piece of wood to see how the pad performs. Make sure the sandpaper stays firmly in place and that the sander doesn’t vibrate excessively.

If there are any issues, double-check the pad installation and make sure the screws are tight. If everything seems to be working properly, you’re all set to start tackling your next sanding project with your newly refurbished DeWalt orbital sander!

Attach the sander to a power source

When attaching the sander to a power source, there are a few things to keep in mind. First and foremost, safety is paramount. Always ensure that the power source is turned off before connecting the sander, and use only the appropriate extension cord if necessary.

Once the sander is securely connected, it’s time to test out the new pad. Turn on the power source and allow the sander to run for a few minutes without a load to make sure it’s running smoothly. Then, place the sander on a test surface and begin sanding.

Pay close attention to the feel of the sander and the quality of the sanding job. Does the sander vibrate excessively or create divots in the surface? If so, it may not be securely attached to the power source, or there may be an issue with the pad. By testing the sander thoroughly, you can ensure a successful sanding job and avoid any potential accidents.

Turn on the orbital sander to test the new pad

Now that you’ve removed the old pad and attached the new one, it’s time to test it out! Turn on your orbital sander and see how it feels. You should notice a smoother, more even surface as you move the sander over your project. If you feel any unusual vibrations or hear any strange noises, you may need to adjust the pad or make sure it’s properly attached to the sander.

Remember, the goal of replacing the pad is to improve the sanding experience by creating a more efficient and effective tool. As you test out your new pad, take note of any differences and how they impact your project. This way, you can be sure that you’re using the right equipment for the job.

With a new pad in place, you can tackle even the toughest sanding jobs with ease.

Conclusion

So there you have it, folks – the easy-peasy guide to replacing the Dewalt orbital sander pad. With just a few simple steps, you can have your trusty tool back up and running in no time. And who knows? Maybe next time, you’ll be the one showing off your DIY skills to all your friends and family.

So go forth and sand like a pro – just don’t forget to order that replacement pad first!”

By following these easy steps, replacing your Dewalt orbital sander pad is a breeze.

After you’ve successfully replaced the pad of your Dewalt orbital sander, it’s time to test it out and make sure everything is working properly. Before starting the testing process, ensure that your sander is properly plugged in and ready to use. Turn on the sander and let it run for a few seconds to make sure that the new pad is securely attached and firmly adhered to the sander.

Check the center hole of the pad to make sure it’s centered properly on the circular attachment of the sander. This will help to prevent any vibrations or wobbling while using the sander. If you notice any issues during the testing process such as slipping or wobbling, turn off the sander and double-check the pad to ensure that it is securely attached.

Once everything is in place, you’re ready to start sanding again with your new dewalt orbital sander pad.

FAQs

What is an orbital sander pad and what is its function in a Dewalt sander?

An orbital sander pad is a circular pad attached to the base of a Dewalt sander and its function is to hold the sandpaper securely in place and provide a smooth sanding surface.

How often should you replace the orbital sander pad on a Dewalt sander?

It is recommended to replace the orbital sander pad on a Dewalt sander every 6-12 months or as soon as you notice any signs of wear or tear.

Can you use non-Dewalt branded orbital sander pads on a Dewalt sander?

Yes, you can use non-Dewalt branded orbital sander pads on a Dewalt sander as long as they fit securely and are compatible with a Dewalt sander’s size and shape.

How do you correctly remove and replace the orbital sander pad on a Dewalt sander?

To remove and replace the orbital sander pad on a Dewalt sander, you first need to unplug the sander and apply pressure to the pad’s edges to release it from the base. Next, align the new pad with the base and press firmly until it clicks into place.

What are some common signs that indicate a need to replace the orbital sander pad on a Dewalt sander?

Some common signs include difficulty in attaching sandpaper, reduced sanding effectiveness, or excessive vibration and noise during sanding.

How do you maintain the orbital sander pad on a Dewalt sander?

You can maintain the orbital sander pad on a Dewalt sander by regularly cleaning it with a soft brush or damp cloth to remove dust and debris. Avoid using any harsh chemicals or abrasive materials that can damage the pad’s surface.

Where can you purchase replacement orbital sander pads for a Dewalt sander?

Replacement orbital sander pads for a Dewalt sander can be purchased at most home improvement stores, online retailers, or through the Dewalt manufacturer’s website.