How to Read Drill Press RPM: A Step-by-Step Guide for Beginners

Drilling is an essential part of woodworking, metalworking, and many other fields that require precision cutting. When you have a drill press, the machine’s speed is determined by its RPM, which stands for revolutions per minute. Understanding how to read drill press RPM is crucial to ensure the best results for your project.

Have you ever wondered how to interpret the numbers on the drill press and adjust the speed accordingly? In this blog, we will guide you through the process of reading drill press RPM, so you can get the most out of this powerful tool. Think of it like reading a speedometer to know how fast you’re going in a car, but with a drill press, the speed controls the accuracy of your drilling. So, let’s dive right in and demystify drill press RPM!

Introduction

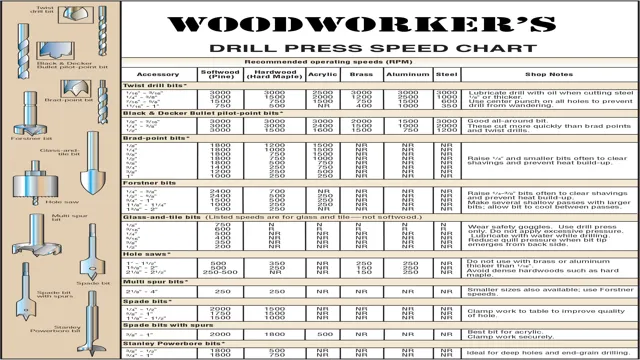

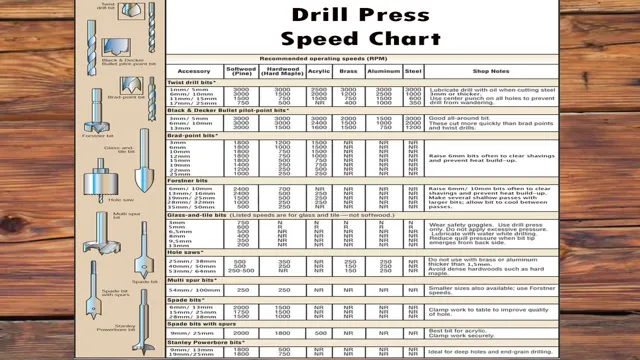

Learning how to read drill press RPM is an essential skill for anyone who works with a drill press. RPM (rotations per minute) refers to how fast the drill bit is spinning, and understanding this measurement is crucial to achieving the correct drilling speed for the material and the size of the drill bit being used. First, locate the RPM chart on the drill press or in the owner’s manual.

The chart will provide you with a range of RPM settings based on the material being drilled and the size of the drill bit being used. Next, adjust the drill press speed based on the recommended RPM range for the material and drill bit size. Be sure to keep an eye on the RPM display as you adjust the speed to ensure you are in the correct range.

With practice, reading drill press RPM will become second nature, and you’ll be able to achieve precise drilling results every time.

Why Knowing RPM is Important

RPM, or revolutions per minute, is one of the most important measurements for any mechanical device that rotates. Whether it’s a car engine, a machine in a factory, or a fan in your home, knowing the RPM can provide vital information about how it’s operating. Essentially, RPM refers to how many times the device completes a full rotation in one minute.

This measurement can give engineers and mechanics insight into the speed, power, and efficiency of the device, which can be critical for troubleshooting problems or optimizing performance. In this blog, we’ll explore why knowing RPM is so important, and how it can impact everything from safety to energy consumption. So let’s dive in and find out why RPM matters!

Factors That Affect RPM Readings

RPM readings are an essential metric in determining the performance of mechanical systems, especially engines. However, they can be affected by various factors. RPM stands for revolutions per minute, which means the number of times an object rotates around its axis in a minute.

In this blog section, we will delve deeper into the factors that affect RPM readings, such as engine load, friction, temperature, and oil viscosity. These factors can either increase or decrease RPM readings and impact the overall performance of the system. It is essential to understand these factors and their effects to ensure proper maintenance and prevent damage to the mechanical systems.

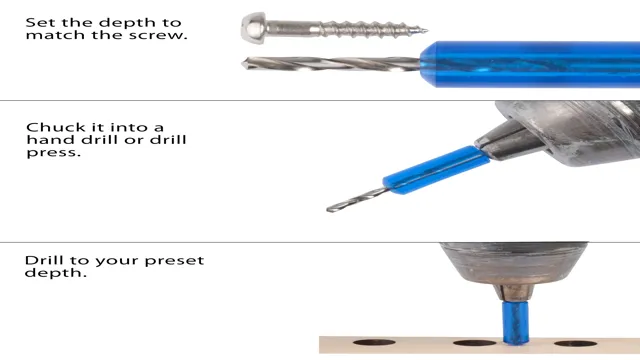

Steps to Read Drill Press RPM

How to Read Drill Press RPM When it comes to working with drill presses, knowing how to read their RPM (revolutions per minute) is crucial for getting the most efficient and accurate results. The good news is that it’s not as daunting as it may seem! With just a few simple steps, you can easily read your drill press RPM and get to work. First, make sure your drill press is turned off and unplugged.

Then, locate the RPM chart on your drill press, which can usually be found on the side of the machine or in the user manual. This chart will show you the recommended RPM settings for various types of bits and materials. Next, adjust the belt tension or pulley arrangement on your drill press to match the recommended RPM for your specific task.

Finally, turn on the drill press and check the RPM on the digital display if you have one, or use a tachometer to measure the RPM manually. By following these simple steps, you’ll be ready to tackle any drilling project with precision and ease!

Step 1: Locate RPM Reading on Drill Press

Reading the RPM on a drill press is essential to ensure that you are using the right speed for your project. To begin, you need to locate the RPM reading on your drill press. It’s usually found on the front panel or the top of the drill press, and it’s usually marked with “RPM” or “Speed.

” Once you’ve found it, you can proceed to the next step. It’s essential to note that different drill bits and materials require different speeds. For example, wood requires slower speeds compared to metal and plastic.

Therefore, it’s vital to understand the recommended RPM range for your drill bits to ensure optimal performance. Knowing how to read the RPM on your drill press is crucial to achieve accurate results and avoid damaging your drill bits or the material you’re working on.

Step 2: Determine the Number of Pulleys on the Drill Press

When it comes to using a drill press, it’s essential to know the RPM (rotations per minute) in order to work safely and efficiently. The first step is to determine the number of pulleys on the drill press. Pulleys are responsible for adjusting the speed of the drill press, and the more pulleys it has, the more speed options you’ll be working with.

This will affect how you read the drill press RPM. Once you have determined the number of pulleys, you can check the manufacturer’s manual or the information plate on the drill press to find out the recommended RPM for different materials. From there, you can adjust the drill press speed using the pulleys and a belt, until you reach the desired speed for your specific project.

The key is to always ensure the RPM is appropriate for the material you’re working with to avoid accidents and damage to your drill press or project. By following these simple steps, you’ll be able to master the art of reading drill press RPM to enhance your drilling experience.

Step 3: Find the Motor RPM on the Drill Press

Reading the RPM on a drill press is a vital part of knowing how fast your drill bit is rotating. To find the motor RPM on your drill press, you need to follow a few simple steps. First, locate the pulley system on your drill press.

This is usually located on the top side of the drill press. Once you have located the pulley system, look for the motor pulley. This will be located near the motor and connected by a belt to the spindle pulley.

Next, you will need to determine the diameter of the motor pulley. Measure the distance across the center of the pulley to get the diameter. Alternatively, check the user manual that comes with your drill press.

This will usually have a chart or table that gives pulley sizes and corresponding RPMs. Finally, use a tachometer to determine the RPM of the motor pulley. A tachometer is a device that measures the rotational speed of the spindle or motor shaft.

Attach the tachometer to the spindle or motor shaft and turn on the drill press. The tachometer will show you the RPM of the motor pulley. In summary, finding the motor RPM on your drill press involves locating the pulley system, determining the size of the motor pulley, and using a tachometer to determine the RPM.

By following these steps, you can ensure that your drill press is running at the correct speed and avoid damaging your drill bits or workpieces.

Step 4: Calculate the RPM of the Drill Bit

When working with a drill press, it’s important to know how to calculate the RPM of the drill bit. This step is crucial to drill accurately, safely, and efficiently. To calculate RPM, you need to know the speed of the drill in revolutions per minute, as well as the diameter of the drill bit.

Once you have this information, you can use a formula to determine the RPM. Remember that different materials require different RPMs, so it’s essential to adjust accordingly. This step may seem overwhelming at first, but with practice, you’ll become more familiar with the process and be able to read drill press RPM with ease.

Tips and Tricks for Accurate RPM Readings

When it comes to using a drill press, knowing how to read RPM accurately is essential to achieve the best results for your projects. RPM, or revolutions per minute, refers to the speed at which the drill bit rotates. To get an accurate reading, there are several tips and tricks to keep in mind.

Firstly, make sure the drill press is clean and free from debris as this can affect the reading. Secondly, ensure the drill press is well lubricated, as friction can cause inaccurate readings. One effective way to obtain an accurate RPM reading is to use a tachometer, which measures the speed of the rotating drill bit.

Reading the manual that came with your drill press is also helpful, as it should contain information on how to read RPM correctly. With these tips in mind, you’ll be able to get the most out of your drill press and achieve accurate and precise results for your projects.

Tip 1: Use a Tachometer to Verify RPM Reading

RPM readings are an essential aspect of vehicle maintenance, but getting an accurate reading can be a bit tricky at times. That’s where a tachometer comes in handy, as it’s a tool designed to measure and display engine RPMs accurately. If you’re not sure if your tachometer is accurate, there’s no need to worry.

You can confirm its accuracy by using a device called a reference tachometer that measures RPMs. This will allow you to compare the readings between your tachometer and the reference tachometer so that you can get a more accurate reading. Remember, an incorrect RPM reading could lead to incorrect diagnoses of engine issues, so it’s essential to use a reliable tachometer to avoid potential problems.

Keyword: “Tachometer”

Tip 2: Keep the Drill Press Clean and Properly Maintained

One of the best ways to get accurate RPM readings on your drill press is to keep it clean and properly maintained. This means removing any debris or sawdust from the machine and checking to ensure that all components are functioning correctly. A dirty or poorly maintained drill press can have a significant effect on the RPM readings you get, leading to inaccurate results and potentially dangerous operating conditions.

By taking the time to keep your drill press clean and well-maintained, you can ensure that you get consistently accurate RPM readings and that your machine operates safely and efficiently. So, whether you’re a professional woodworker or just a DIY enthusiast, always remember that cleanliness and proper maintenance are key to getting the most out of your drill press.

Conclusion

In conclusion, the key to reading drill press RPM is to be attentive and curious, like a detective. Start by identifying the spindle speed gauge and the recommended speed for your drill bit’s diameter and material. Then, adjust the belt or motor pulley settings accordingly, and don’t forget to use ear and eye protection.

Remember, the drill press may seem like a straightforward machine, but underestimating it could lead you down a dangerous path. Keep your wits about you and happy drilling!”

FAQs

What is the best way to determine the RPM on a drill press?

The easiest way to determine the RPM on a drill press is to check the manual or the label on the machine.

How do I change the RPM on my drill press?

You can change the RPM on your drill press by adjusting the pulleys on the motor and spindle.

Can I use a different RPM on my drill press for different materials?

Yes, using different RPMs on your drill press for different materials can help prevent damage to the drill bit or the material being drilled.

How can I maintain the RPM accuracy on my drill press?

Regularly checking and calibrating the RPM on your drill press can help maintain its accuracy.

What is the ideal RPM for drilling through steel?

The ideal RPM for drilling through steel can vary depending on the size of the drill bit and the thickness of the steel. Consult the drill bit manufacturer’s recommendations for the best results.

My drill press RPM seems too high or too low, what should I do?

Check the pulleys on the motor and spindle to make sure they are properly adjusted and not slipping. Additionally, make sure the drill bit is properly secured in the chuck and the material being drilled is properly clamped in place.

Can I use a variable speed drill press for more precise RPM control?

Yes, using a variable speed drill press can allow for more precise RPM control and can be helpful for drilling through various materials and sizes.