How to Put a Vice on a Drill Press: A Step-by-Step Guide for Precision Drilling

Are you looking to attach a vice to your drill press but not sure where to start? Well, we’ve got you covered! Adding a vice to your drill press can make your drilling projects more efficient, accurate, and safe. It allows you to securely hold your material in place, preventing slips and slides that can lead to uneven cuts or even injuries. Putting a vice on a drill press might seem like a daunting task, especially for beginners.

But with the right tools and instructions, it’s actually quite simple. In this blog post, we’ll walk you through the step-by-step process of attaching a vice to your drill press. Whether you’re a DIY enthusiast or a seasoned woodworker, you’ll find our tips and tricks helpful for getting the job done right.

So, don’t let the fear of the unknown stop you from enjoying the benefits of a drill press vice. Follow our guide and get ready to take your drilling game to the next level!

Gather Necessary Tools

If you want to put a vice on your drill press, the first step is gathering all the necessary tools. You’ll need a drill press, a vice that fits securely onto the drill press table, and some bolts and nuts to fasten the vice to the table. Make sure your vice is made of sturdy materials and has a smooth operation before using it with your drill press.

It’s also important to select the right size and type of vice to match your drill press. A good quality vice is essential to securely clamp your workpiece in place and avoid accidents or injury. Take your time to carefully choose the right vice and check that it’s suitable for your drill press before attempting to attach it.

With the right tools and preparation, you’ll soon be able to confidently put your vice on your drill press and take on a range of precision drilling projects.

Vice or Clamps

When it comes to woodworking or any DIY project that requires holding two pieces of wood together, having the right tools is crucial. And when it comes to deciding between using vice or clamps, it ultimately depends on the job at hand. Both tools have their advantages and disadvantages.

Gathering the necessary tools for any woodworking project requires careful planning. You can start by making a list of the necessary materials and tools you will need. For instance, if you are planning to use clamps, you will need to consider the size of the clamps, the type of wood you will be working with, and the position in which you will need to clamp the wood.

Vices, on the other hand, are ideal for holding wood in place and are available in a variety of shapes and sizes. They are also capable of exerting a significant amount of pressure on the wood, ensuring that it is held securely in place. Before starting any project, it’s essential to know which tools you will be using and have them readily available.

Drill Press

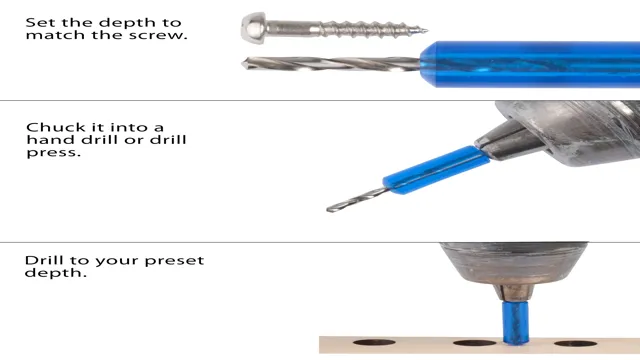

When it comes to using a drill press, there are a few essential tools you’ll need to have on hand to get the job done right. First and foremost, you’ll need a set of drill bits that are the appropriate size and shape for the project at hand. It’s also a good idea to invest in a vice or clamp to keep your workpiece securely in place while you drill.

Depending on the type of drill press you’re using, you may also need a chuck key to change out the bits, as well as a depth stop to help you achieve consistent hole depths. And don’t forget about safety gear – always wear eye protection and keep loose clothing, jewelry, and long hair safely out of the way. By gathering all the necessary tools before you start, you’ll be sure to have a smooth and successful drilling experience.

Allen Wrenches

When it comes to assembling furniture, one necessary tool you’ll need is an allen wrench. Also known as a hex key, these versatile tools come in various sizes and shapes, depending on the job at hand. Before beginning any assembly project, gather all the necessary tools, including an appropriate allen wrench.

It’s essential to have the correct size, as using the wrong one could strip the screws or damage the furniture. Using a proper allen wrench will make the assembly process smoother and more efficient. Think of an allen wrench as a key to unlock the potential of your furniture pieces.

Without it, you’re left with a pile of unassembled parts and missed opportunities for an organized home. So make sure to gather all your necessary tools, including the right size allen wrench, to avoid frustration and ensure a successful project.

Attach Vice to Drill Press Table

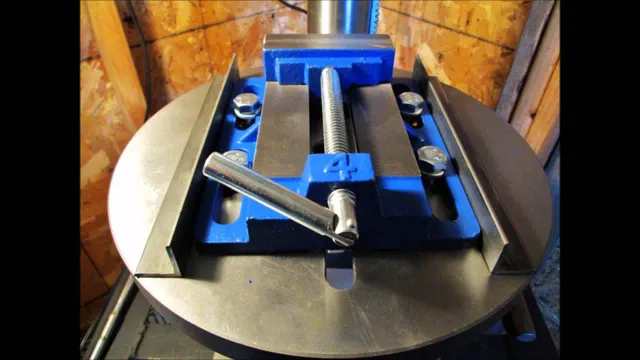

So, you just got your brand new drill press and you want to attach a vice to it. Well, lucky for you, it’s a pretty easy process! First, you’ll want to make sure the drill press table is clean and free of any debris. Next, grab your vice and place it onto the table where you want it to go.

Make sure it’s centered and lined up with the drill bit. Once you have it in the right position, clamp it down tight. Now, you’re ready to start drilling! Remember to always use protective gear, like safety glasses and gloves, and take your time to ensure accuracy and precision.

And that’s it! You’ve successfully attached a vice to your drill press, and now you’re ready for any DIY project that comes your way.

Select Table Slot and Align Vice

When it comes to using a drill press, attaching the vice securely is essential to ensure precision and accuracy. The first step is to select the appropriate slot on the drill press table where the vice will be placed. This will depend on the size of the workpiece and the type of drilling operation that will be performed.

Once the slot is selected, the vice can be attached to the table using the bolts or clamps provided. It is important to ensure that the vice is aligned with the drill bit to avoid any wobbling or imbalance during the drilling process. Tighten the bolts or clamps securely to hold the vice in place.

With the vice properly attached and aligned, you can now start drilling with confidence and accuracy. Remember, taking the time to properly attach the vice is crucial to producing high-quality and precise holes.

Insert Clamps or Screws

If you’re planning on doing some serious drilling on your drill press, then it’s essential that you attach a vice to your drill press table. There are two main ways to do this: by using insert clamps or screws. Insert clamps are a quick and easy way to attach a vice to your drill press table, as they simply slide into the slots on the table and lock in place.

Once you’ve inserted the clamps, you can then attach your vice to them using the screws provided. This method is ideal if you only need to use your vice occasionally, as it’s quick and easy to set up and remove. Screws, on the other hand, offer a more permanent way to attach your vice to your drill press table.

You’ll need to drill holes into the table and then use screws to secure the vice in place. This method is ideal if you need to use your vice on a regular basis, as it provides a much more secure and stable attachment. It also allows you to position your vice exactly where you need it and ensures that it won’t move around during use.

Whether you choose to use insert clamps or screws, it’s important to make sure that your vice is securely attached to your drill press table before you begin drilling. If your vice isn’t properly attached, you could end up damaging your workpiece, your drill press or even yourself. So take your time, follow the manufacturer’s instructions and make sure that everything is in place before you start drilling.

With a securely attached vice, you’re sure to achieve accurate and precise drilling results every time.

Tighten Clamps or Screws

One of the most important steps to ensure accurate drilling with your drill press is to properly attach the vice to the table. To do this, you’ll want to start by tightening the clamps or screws so that the vice is firmly in place. This will prevent any movement or wobbling during the drilling process, which could lead to inaccurate holes or even dangerous situations.

Once the vice is securely attached, you can begin setting up your workpiece and adjusting the drilling depth. It’s important to always double-check your measurements and make sure everything is aligned properly before beginning to drill. By taking the time to attach your vice correctly and carefully measuring your workpiece, you’ll be able to achieve professional-grade results every time.

Secure Workpiece in Vice

If you want to use a vice on a drill press, you first need to make sure it’s installed correctly. The first thing you should do is to secure your workpiece in the vice. You can do this by placing your workpiece in between the jaws of the vice and tightening them with a wrench.

Make sure that your workpiece is securely held in place so that it doesn’t move around while you’re working on it. Once your workpiece is properly secured, you can then attach the vice to your drill press. This is typically done by clamping the vice to the table of the drill press.

Make sure that the vice is tightly attached to the table so that it doesn’t move during use. With your vice securely installed, you can now begin to drill holes in your workpiece with precise accuracy using your drill press.

Open Vice Jaws

If you’re working with a vice to hold your workpiece, it’s essential to ensure that it is securely fastened. One common issue that many people face is the vice jaws slipping or not gripping the workpiece firmly enough. Luckily, there’s an easy solution to this problem – simply open the vice jaws a bit wider than your workpiece before tightening them down.

By doing this, you’ll create a more solid grip on the workpiece, reducing the risk of slippage or movement while you work. It’s important to note that you don’t want to open the jaws too wide, as this can cause them to damage or deform the workpiece. Instead, aim for a slight gap that provides enough room for the piece to fit snugly without creating too much pressure.

With this simple trick, you’ll be able to secure your workpiece and focus on the task at hand without worrying about it slipping or moving out of place.

Insert Workpiece and Close Jaws

When working with a vice, the first step is to insert your workpiece and close the jaws securely. This is a crucial step in any task as it ensures that your piece stays in place and that you have adequate control of it. One of the significant benefits of using a vice is that it provides a reliable way of securing your workpiece.

Whether you’re sawing, filing, grinding, or drilling, it’s essential to ensure that your piece remains stable and doesn’t move around. To insert your workpiece, place it into the vice jaws, as close to the centre as possible, and then tighten the jaws by turning the handle. You’ll want to tighten them enough so that there is no movement, but not so tight that you damage your piece.

With your workpiece securely in place, you can now move on to the next step of your task with renewed confidence and peace of mind.

Tighten Vice Jaws to Secure Workpiece

One of the most important steps in using a vice is securing the workpiece properly. This can be achieved by tightening the vice jaws around the workpiece until it is firmly held in place. The jaws of the vice should be tightened gradually, checking the positioning of the workpiece at each stage to ensure it is properly secured.

A loose workpiece can shift while you work on it, which can cause inaccuracies, damage to the workpiece, and possible injury to the operator. By tightening the vice jaws, you can be sure that the workpiece is held safely and securely in place, allowing you to work with confidence and precision. Properly tightened vice jaws can also extend the lifespan of the vice and prevent damage to its components.

Remember, a well-secured workpiece is the first step to producing high-quality work.

Conclusion

In conclusion, putting a vice on a drill press may seem like a daunting task, but with the right tools and technique, it can be done in no time. It’s all about finding the perfect spot to place the vice, making sure it’s secure, and taking advantage of the drill press’s precision and power. Just remember, a vice is like a trusty sidekick to a superhero – it provides stability and support, allowing you to conquer even the toughest drilling challenges.

So next time you need to drill a precise hole or make a clean cut, don’t underestimate the power of a good vice on your trusty drill press.”

FAQs

What is a drill press vice and why is it important to have one?

A drill press vice is a clamping device that holds a workpiece securely in place while drilling. It is important to have one to ensure accuracy and safety while using a drill press.

Can any vice be used on a drill press or do I need a specific type?

While some vices may work with a drill press, it is recommended to use a drill press vice specifically designed for use with a drill press. These vices typically have features such as a V-shaped jaw to hold round objects, a guide bar for accurate positioning, and a quick-release mechanism for easy adjustments.

How do I attach a vice to my drill press?

To attach a vice to your drill press, first make sure the surface of the drill press table is clean and clear of debris. Then, slide the mounting bracket on the bottom of the vice into the T-slots on the drill press table and tighten the locking bolts.

What is the maximum width of a workpiece a drill press vice can hold?

The maximum width of a workpiece that a drill press vice can hold varies depending on the size of the vice. It is important to choose a vice with a jaw width that can accommodate the size of your workpiece.

How tight should I clamp the workpiece in the vice before drilling?

You should clamp the workpiece securely in the vice, making sure it is held firmly in place but not so tight that it causes damage to the workpiece or the drill bit.

Can I move the vice while the drill press is running?

No, you should never move the vice while the drill press is running. This can cause the workpiece to become loose and lead to inaccurate drilling or even injury.

How do I release the workpiece from the vice?

To release the workpiece from the vice, loosen the locking bolts and slide the vice jaws apart until the workpiece can be removed. Be sure to use caution as the workpiece may still be hot or sharp.