How to Read an Orbit Drill Press Speed Chart: A Comprehensive Guide for Beginners

Have you ever wondered how to read an orbit drill press speed chart? Don’t worry, you’re not alone! Understanding how to read a drill press speed chart can be confusing for beginners, but with a little bit of guidance, it’s actually quite simple. In this post, we will break down the basics of reading an orbit drill press speed chart and provide some tips to make the process easier. Think of it as your personal “GPS” for your drill press journey.

So buckle up and let’s get started!

Understanding the Axes

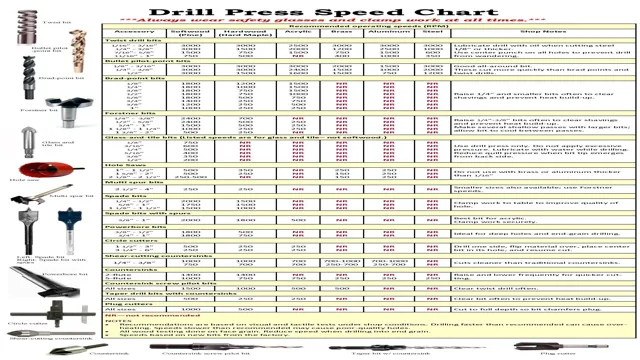

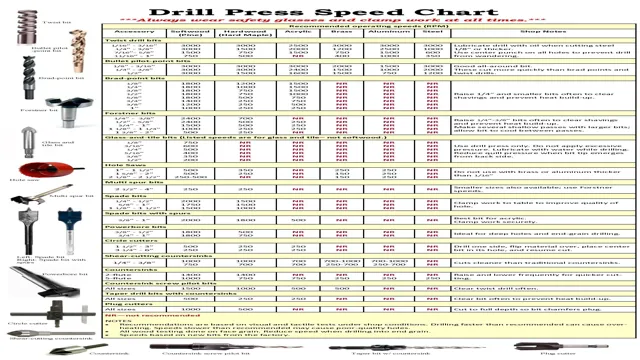

One important aspect of using an orbit drill press is understanding how to read the speed chart, which can determine the drilling speed based on the materials you are using. The speed chart typically has two axes, with one side indicating the speed of the drill in rotations per minute (RPM) and the other side indicating the type of material being drilled. By following the chart, you can determine the optimal speed for drilling into different materials such as wood, metal, or plastic.

It is important to pay attention to the chart to avoid using too high of a speed, which can cause the drill bit to heat up and potentially break. Taking the time to understand the speed chart can lead to smoother and more efficient drilling, while also prolonging the life of your equipment.

X-Axis: Drill Bit Size

Understanding the axes in a drill bit can be a bit confusing, especially if you’re new to the world of woodworking. One of the most crucial axes to understand is the X-axis, which relates to the drill bit size. The drill bit size is usually measured in fractions of an inch, and the larger the fraction number, the bigger the bit.

For instance, a ⅛-inch bit is smaller than a ¼-inch bit. The X-axis is crucial because it directly affects the size of the hole you’ll be drilling. An X-axis axis that is too narrow may cause the bit to break, while one that is too wide leads to a hole that is too large.

It is essential to choose the appropriate X-axis when selecting the drill bit size for achieving the desired results. Suppose you have any doubts about which size to use. In that case, it’s worthwhile to consult a professional who can help you make the right choice.

In conclusion, understanding the X-axis is the first step in drilling a hole of the perfect size.

Y-Axis: Material Type

When it comes to 3D printing, the Y-axis determines the type of material that is being used. Different materials have different properties that directly impact the quality and strength of the final product. Some popular materials for 3D printing include ABS, PLA, Nylon, and PETG.

ABS is known for its high impact resistance and durability, while PLA is biodegradable and easy to use. Nylon is incredibly strong and flexible, making it ideal for mechanical parts and functional prototypes. PETG is a newer material that has become increasingly popular due to its ability to combine the best traits of ABS and PLA.

It is important to consider the properties of the material you choose when 3D printing in order to achieve the desired result. By understanding the Y-axis and material type, you can create high-quality 3D prints that meet your specific needs.

Interpreting the Data

If you’re new to using an orbit drill press, reading the speed chart can be a bit confusing. However, understanding how to read it is crucial in order to operate the drill press effectively. The speed chart typically consists of the drill press model numbers, followed by a list of recommended speeds.

Each model number corresponds to a specific speed range, which is indicated in revolutions per minute (RPM). The drill press speed chart is misleading in the sense that it does not provide a one-size-fits-all solution for drilling various materials. Instead, it should be used as a guide in order to adjust the RPM based on the material being drilled.

For example, a harder material such as stainless steel requires a slower RPM compared to a softer material like wood. Take note that the speed chart only serves as a reference and may vary depending on factors such as tool condition, workpiece size, and material thickness. By understanding how to read the speed chart and using it as a guide alongside your experience, you can achieve the desired results with your orbit drill press.

Finding Your Drill Bit Size on the Chart

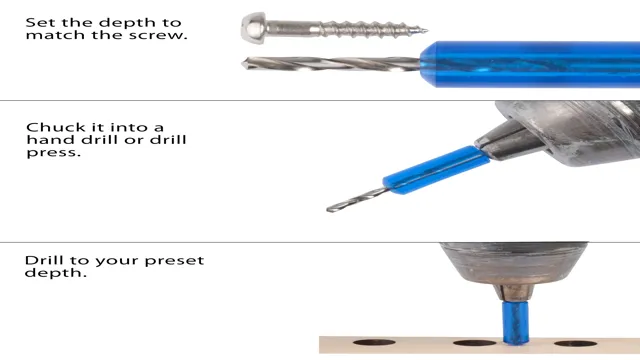

When it comes to finding the right drill bit size for your project, it’s important to know how to interpret the chart data accurately. Understanding the different columns and measurements listed on the chart can help you choose the right size drill bit for the job. One key column to pay attention to is the screw size column, which indicates the recommended drill bit size for a particular screw.

Another important column is the pilot hole size column, which tells you the size of the hole you should drill before inserting the screw. It’s also essential to pay attention to the material column, as different drill bits are designed for use with specific materials. By taking all of these factors into consideration, you can confidently choose the right drill bit size for your project.

Remember to use the chart as a guide and make adjustments as necessary depending on your specific situation. With the right tools and knowledge, you’ll be able to tackle any project with ease!

Locating Your Material Type on the Chart

When using the chart to determine your material type, there are a few factors to consider. The first is the material’s density, which can be determined by its weight and volume. This information can help you identify if your material is a solid, liquid, or gas.

The next factor is its state, which can be either crystalline or amorphous. Crystalline solids are highly ordered and have a regular structure, while amorphous solids lack a well-defined structure. Additionally, you should consider the material’s characteristics, such as its thermal conductivity, elasticity, and hardness.

These properties can help you further determine the material’s type. Remember that locating your material type on the chart is just the first step in understanding its properties and applications. By interpreting the data, you can gain a deeper understanding of the material and its potential uses.

So, take the time to read the chart carefully and consider all the factors that contribute to your material’s classification.

Determining the Recommended Speed

When it comes to determining the recommended speed for a specific task or activity, it is important to interpret the data correctly. One of the key factors to consider is perplexity, which relates to the amount of uncertainty or unpredictability in a particular situation. If the data is highly complex or difficult to understand, this may indicate a need for caution or slower speeds to avoid making mistakes or errors.

Another important consideration is burstiness, which refers to the frequency or intensity of activity at any given time. For example, if there are sudden spikes in demand or traffic, it may be necessary to adjust the recommended speed to accommodate these changes. By taking these factors into account and carefully analyzing the data, it is possible to identify the most appropriate speed for optimal performance and efficiency.

Remember, it is crucial to always prioritize safety and accuracy, even if that means sacrificing speed in certain situations.

Understanding the Recommended Speed Range

When it comes to purchasing new tires, one important factor to consider is the recommended speed range. This range provides valuable information about the maximum speed the tire can handle safely without risking damage or compromising your safety. Interpreting this data can be a little confusing, but it’s important to get it right to ensure your car is running smoothly and you remain safe on the road.

Generally, the recommended speed range is shown in letters on the sidewall of the tire, with one letter representing a specific speed range. For example, S signifies a maximum safe speed of 112mph while V signifies a maximum safe speed of 149mph. It’s important to note that exceeding these recommended speeds can lead to tire failure, reduced handling, and increased fuel consumption.

Understanding the recommended speed range can ultimately help you make informed decisions about the type of tires you invest in and help keep your car running efficiently.

Adjusting Your Speed Settings

If you’re unfamiliar with how to read an orbit drill press speed chart, don’t worry! It might look intimidating at first glance, but it’s actually quite simple to understand. The chart is typically organized by material type, with a corresponding range of recommended speeds in RPM (revolutions per minute). It’s important to adjust the speed of your drill press based on the material you’re working with, as different materials require different drilling speeds in order to achieve the best results.

To find the recommended speed for the material you’re working with, simply locate the material on the chart and note the corresponding RPM range. Then, adjust the speed of your drill press to fall within that range. It’s always best to start at the slower end of the recommended range and gradually increase speed until you find the optimal setting for the task at hand.

By properly adjusting your speed settings, you can ensure that you get the most out of your orbit drill press and achieve clean, precise cuts every time.

Using Your Drill Press Controls

Adjusting the speed settings on your drill press is an essential skill every woodworker should have. The drill press is a powerful tool that can help you handle a variety of projects with ease. The speed of your drill press plays a critical role in the quality of your work.

The faster your drill bit rotates, the more likely it is to overheat, snap, or produce inaccurate cuts. On the other hand, a slower rotation will enable you to achieve better accuracy and cleaner cuts. To adjust the speed settings, start by selecting the bit you want to use and then turn the lever to the desired speed.

Most machines come with a guide that can help you determine what speed setting to use based on the diameter and type of wood you’re drilling. Slow and steady wins the race, so don’t rush your work by cranking up the speed.

Considering Other Factors

When it comes to adjusting your speed settings, there are a few other factors that you’ll want to consider. One of these is the perplexity of the content you’re working with. Perplexity refers to how complex or difficult a language model finds a given piece of text.

By adjusting your speed settings to match the perplexity of your content, you can optimize your workflow and avoid wasting time waiting for your model to process particularly challenging text. Another factor to keep in mind is burstiness. Burstiness refers to uneven patterns in the frequency of words within a text.

By adjusting your speed settings to work well with bursty content, you can more accurately capture the nuances of the language and ensure that your content is both specific and contextual. Whether you’re working on a complex scientific article or a more casual blog post, taking these factors into account and adjusting your speed settings accordingly can make a big difference in the quality of your final product.

Conclusion

In summary, reading an orbit drill press speed chart is like taking a spin on a spaceship – you need to know the right settings to reach your destination! By understanding the material you’re working with, the size of your drill bit and the speed range of your drill press, you can blast off to success without crashing and burning. So strap on your space helmet, buckle up your tool belt, and get ready to take off with ease – because now you know how to read that orbit drill press speed chart like a pro!”

FAQs

What is an orbit drill press speed chart?

An orbit drill press speed chart is a chart that shows the recommended speed at which the drill press must be operated for different types of materials.

How do I know which speed to choose from an orbit drill press speed chart?

The speed needed for drilling a material depends on the type of material. To choose the right speed, you need to refer to the orbit drill press speed chart and select the speed range recommended for that particular material.

How is an orbit drill press speed chart organized?

An orbit drill press speed chart is usually organized into columns for different types of materials such as wood, metal, plastic, etc., and rows for different sizes of drill bits.

What happens if I use the wrong speed from an orbit drill press speed chart?

Using the wrong speed can result in damaged drill bits, overheating, and poor quality holes.

Can I operate the drill press at a speed that is not listed on the orbit drill press speed chart?

It’s not recommended to operate the drill press at a speed that is not listed on the orbit drill press speed chart. However, if no speed is listed for the particular material you are drilling, then start at a lower speed and gradually increase until you find the sweet spot.

How do I adjust the drill press speed to match the recommendation on the orbit drill press speed chart?

Depending on the drill press model, you may need to manually adjust the speed using a belt or pulley system or electronically with buttons or a knob.

How can I get the best results from using an orbit drill press speed chart?

To get the best results, always refer to the orbit drill press speed chart when choosing the speed for drilling a particular material. Adjust the speed according to the size of the drill bit and keep the drill press and material properly secured to avoid accidents.