How to Raise Drill Press Table: A Beginner’s Guide to Setting up Your Workshop

Are you having trouble with your drill press table being too low for your needs? Well, have no fear because raising your drill press table is a simple process that can be done in just a few easy steps. Whether you’re a beginner or a seasoned pro, knowing how to properly adjust your drill press table can make a huge difference in your woodworking projects. Think of it like adjusting your car’s seat – it’s necessary to ensure your comfort and productivity while using the tool.

Just like how a car seat can be adjusted to fit the driver’s height and preferences, a drill press table can be raised or lowered to fit the user’s needs. But, unlike a car seat, the process of adjusting a drill press table may not be as well-known. In this blog post, we’ll walk you through exactly how to raise your drill press table, step-by-step.

From identifying the parts of your drill press to adjusting the height and securing it in place, we’ll cover it all. By the end of this post, you’ll have the knowledge and skills to easily adjust your drill press table and ensure that it’s at the perfect height for your next project. So, let’s get started!

Identify the Adjustment Mechanism

If you’re wondering how to raise a drill press table, it’s important to identify the adjustment mechanism. Most drill presses have a crank or wheel that can be turned to raise or lower the table. Look for this mechanism on the side of the drill press or near the base.

Some models may also have a locking mechanism that needs to be loosened before the table can be adjusted. Once you’ve located the adjustment mechanism, make sure to turn it carefully and slowly to avoid damaging the table or the drill press. It’s also a good idea to refer to the user manual or seek advice from an expert if you’re unsure about how to safely raise or lower the table on your drill press.

By following these steps, you can easily adjust the table to the right height for your specific drilling needs.

Locate the Crank or Handle

When it comes to adjusting your window blinds, the first step is to locate the crank or handle. Depending on the type of blinds you have, this may be located on the side of the blinds or at the top. Once you’ve located the crank or handle, it’s time to identify the adjustment mechanism.

This will typically involve turning the crank or handle either clockwise or counterclockwise to adjust the angle of the blinds, allowing more or less light to enter the room. Some blinds may also have a cord or other mechanism that can be used to adjust their position. Whatever the case may be, take the time to read through the instructions that came with your blinds to ensure that you’re using the correct mechanism and turning the crank or handle in the correct direction.

With a little patience and practice, you’ll soon be able to adjust your blinds in no time.

Check for Locking Mechanisms

When it comes to checking for locking mechanisms on a door, one needs to identify the adjustment mechanism first. The adjustment mechanism ensures that the lock functions accurately, and it is essential to have it in good working condition to prevent any unwanted access through the door. It’s critical to examine the door’s hinges and see whether they have fixed screws, and if so, whether they need tightening.

Additionally, one should check for any damage to the lock or bolt itself and ensure that the lock is lubricated correctly to maintain optimal function. Identifying the adjustment mechanism is an essential starting point in the process of maintaining effective locking mechanisms on your doors. A well-maintained lock can significantly enhance the security of your property and give you peace of mind.

So, It is necessary to perform a routine check to ensure that everything works correctly with your locks, guaranteeing that they serve their purpose and keep you and your property safe from potential threats.

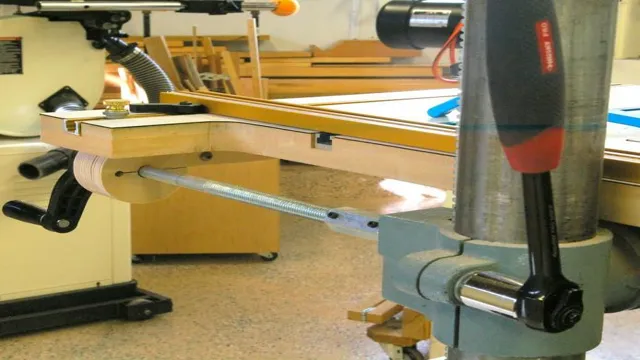

Adjusting the Drill Press Table

If you have ever struggled with a low drill press table, then you know how frustrating it can be. Fortunately, adjusting the height of the table is a simple task that can be done in just a few quick steps. First, locate the mechanism that controls the height of your drill press table.

Depending on the model, this may be a lever, crank, or knob. Once you have located it, loosen it and lift the table to the desired height. Then, re-tighten the mechanism to secure the table in place.

It is important to keep in mind that the table should be raised to a level that is comfortable for you to work with. This may require some trial and error, but once you find the right height, you’ll be able to work with ease and precision. So, the next time you need to raise your drill press table, remember these simple steps and get it done in no time!

Turn the Crank or Handle

When it comes to adjusting the table on your drill press, the process can seem daunting at first. But once you get the hang of it, you’ll find it’s a breeze. One thing to keep in mind is that the method for adjusting the table will depend on the type of drill press you have – some may require you to turn a crank, while others may have a handle you need to adjust.

Regardless of the method, you’ll want to make sure the bit is aligned with the center of the table, so your holes will be straight and accurate. It’s always a good idea to double-check your work before drilling to ensure everything is lined up correctly. By taking the time to properly adjust your drill press table, you’ll find that your drilling projects go much more smoothly and with much better results.

Raise the Table Slowly

Adjusting the drill press table can be a frustrating experience, especially if the table is heavy and difficult to control. However, one handy tip to make the process smoother is to raise the table slowly. By doing this, you can ensure that the table stays level and doesn’t tilt or shift unexpectedly, which can cause problems when trying to drill precise holes.

Additionally, raising the table slowly gives you more control over its movement, ensuring that you can position it exactly where you need it to be. Just remember to take your time and be patient when making adjustments, as rushing the process can lead to mistakes and frustration. So if you want to get the most out of your drill press, remember to adjust the table slowly and steadily for best results!

Lock the Table in Place

When using a drill press, it’s important to ensure the table is secure and won’t move while you’re trying to drill. One way to accomplish this is to lock the table in place. To do this, look for the locking mechanism on your drill press and tighten it until the table is firmly held in position.

This will give you more confidence in your drilling and ensure precise results. Adjusting the table height is also important for proper drilling, as you’ll want to have the right height for the material you’re drilling into. By taking the time to adjust and lock the table in place, you’ll be able to get the most out of your drill press and create accurate, professional results.

So don’t forget to take a minute to secure your table before you start drilling!

Safety Precautions

If you’re wondering how to raise the drill press table safely, there are several precautions you can take to ensure you don’t injure yourself. Firstly, make sure the drill press is unplugged to avoid any accidental start-ups. Use a wrench or a crank handle to adjust the table height, whichever is provided with your drill press model.

Always keep your fingers away from the moving parts to avoid any injuries. Additionally, take some time to familiarize yourself with the drill press manual before starting to prevent any mishaps. Lastly, make sure your workpiece is secure before drilling so you can maintain your balance and avoid any slips that may result in an accident.

Overall, raising the drill press table safely can be achieved by following these simple precautions, ensuring that you remain safe and injury-free throughout your drilling projects.

Turn off the Drill Press

As we all know, safety should always be the top priority in any workshop or work area, especially when operating heavy machinery like drill presses. One crucial safety precaution that everyone should be aware of is turning off the drill press properly. When you’re done using it, make sure to turn it off completely and wait until it comes to a complete stop before walking away.

This not only prevents any potential accidents from happening but also extends the lifespan of your machine. Just like a car engine needs to cool down after being used, it’s the same with a drill press. Leaving the machine on when not in use also wastes energy and puts unnecessary strain on the motor.

So, remember, always turn off the drill press when you’re done using it, and make sure it has come to a complete stop before leaving it unattended. Safety first!

Wear Protective Equipment

Protective Equipment When engaging in any activity that poses a risk of injury to oneself, it is essential to wear protective equipment. Whether you’re an athlete, construction worker, or simply riding a bicycle, wearing the appropriate protective gear can greatly reduce the risk of severe injury. Protective equipment varies depending on the activity, but often includes helmets, goggles, gloves, and knee pads.

Not only can protective gear protect you from physical harm, but it can also provide peace of mind and a sense of security. It’s crucial to properly maintain and replace protective equipment when necessary to ensure it remains effective. Remember, safety should always be a top priority, and wearing protective equipment is an essential precaution that should never be overlooked.

Conclusion

In conclusion, raising a drill press table is like taking a family photo. You want everyone to be at the right height so that they can fit together seamlessly. Just like adjusting the height of your family members, adjusting the height of your drill press table requires patience, attention to detail, and a bit of elbow grease.

But once you’ve got the perfect height, your drill press will be the star of your workshop, drilling accurate holes with ease. So, grab your wrench, adjust those bolts, and you’ll be raising your drill press table like a pro in no time!”

FAQs

What is the ideal height for a drill press table?

The ideal height for a drill press table is at a level where you can comfortably operate the machine without straining your back or arms. A good rule of thumb is to have the table height at your elbow height when you’re standing.

Can I adjust the angle of my drill press table?

Most drill press tables come with adjustable angles, allowing you to tilt the table to accommodate angled drilling. Check your drill press manual for instructions on how to adjust your table’s angle.

How can I make sure my drill press table is level?

To ensure your drill press table is level, use a bubble level to check both the front-to-back and side-to-side angles. Adjust the table’s leveling screws until it’s perfectly level.

What should I look for in a replacement drill press table?

When looking for a replacement drill press table, make sure to consider the material, size, and compatibility with your machine. Cast iron tables are durable and long-lasting, while aluminum tables are lighter and easier to adjust.

Is it necessary to lubricate the drill press table?

Yes, lubricating the drill press table is crucial to ensure smooth operation and prevent rust. Use a light machine oil to lubricate the table, and wipe it clean with a rag before use to prevent any oil from dripping onto your workpiece.

Can I add a fence to my drill press table?

Yes, adding a fence to your drill press table can help you drill holes with greater accuracy and precision. You can either purchase a pre-made fence or make one yourself using a straight edge and clamps.

How often should I clean my drill press table?

It’s recommended to clean your drill press table after every use to prevent debris and chips from accumulating and affecting the accuracy of your drilling. Use a brush or compressed air to remove any debris, and wipe the table down with a clean rag or towel.