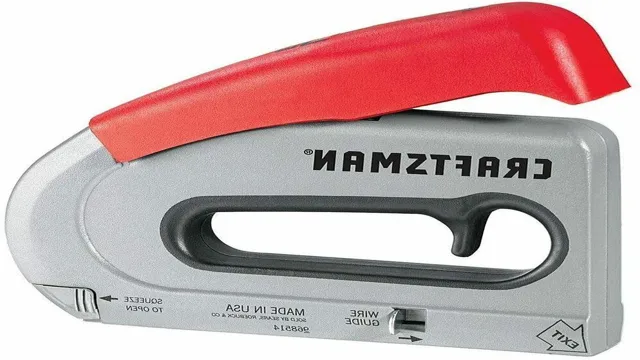

Staple guns are incredibly useful tools for any DIY enthusiast or professional. However, when they break down or need maintenance, the thought of putting it back together can seem daunting. Luckily, we’ve got you covered with a step-by-step guide on how to put your staple gun back together with ease.

Whether you’re a beginner or an experienced user, this guide will provide you with the necessary information to ensure your staple gun is in proper working condition. So, grab your staple gun and let’s get cracking!

Gather Your Tools and Materials

Before putting a staple gun back together, it’s important to gather all the necessary tools and materials. You’ll need the staple gun, replacement staples, a screwdriver, and possibly pliers. It’s also a good idea to have a clean workspace with good lighting and a flat surface to work on.

Taking the time to gather all the necessary tools and clearing your workspace can go a long way in making the process of putting your staple gun back together much smoother and less frustrating. Remember, having the right tools and a clean workspace can make all the difference in getting the job done correctly the first time and reducing the chances of damaging your tool or losing small parts along the way.

List of Materials Needed

Gathering your tools and materials is the most crucial step before starting any project. Making sure you have everything you need before starting can save you time and frustration in the long run. For this particular project, you’ll need a few essential tools, comprising a lopper, garden gloves, a shovel, a saw, a spade, a rake, pruning shears, and a wheelbarrow.

These tools will allow you to work efficiently and effectively and will make the job a lot easier. In terms of materials, you’ll need to have sand and gravel for the base, cement blocks, stones or bricks for the walls, and topsoil in order to plant the plants. Having these materials ready in advance will allow you to work without any interruption and keep the flow of the project organized.

So, before you start building or planting, make sure you have all the necessary tools and materials on hand.

Tools Needed

To get started on any DIY project, you’ll need to make sure you have all the essential tools and materials at hand. The last thing you want is to be halfway through your project and realize you’re missing a crucial tool or supply. So, before you start, it’s important to take stock of what you need.

Begin by identifying the tools specific to your project, as well as any general-purpose tools you may need like hammers, screwdrivers, and pliers. Make sure you also have all the necessary materials, such as wood, nails, screws, sandpaper, and paint. Having everything prepared and organized before you start will help you work more efficiently and prevent any frustrating delays.

With all your tools and materials ready to go, you’ll be well on your way to completing your project with ease.

Disassemble Your Staple Gun

So you’ve successfully disassembled your trusty staple gun – now what? Don’t worry, putting it back together is just as easy as taking it apart. Start by laying out all the individual pieces in front of you, taking note of their specific order and orientation. Next, carefully reassemble the mechanics of the staple gun, piece by piece, ensuring that everything is lined up correctly.

Once you have all the components reassembled, insert the staple strip and test out your newly rejuvenated tool. Voila! Your staple gun is ready to take on your next project. And remember, the next time you need to disassemble it, you’ll already have the knowledge and confidence to do so.

Remove Staples and Screws

If you’re looking to disassemble your staple gun, the first step is to remove any staples or screws that are currently in place. This will make it easier to take apart the gun without damaging any of the internal components. Depending on the model of your staple gun, you may need a screwdriver or pliers to remove these fasteners.

Once you have removed any staples or screws, you can start to take apart the gun. Be sure to keep track of where each piece goes, as this will make it easier to put everything back together later on. Overall, disassembling your staple gun can be a great way to clean and maintain the tool, ensuring that it continues to work well for years to come.

Take Apart the Body of the Gun

If you’re planning on doing some basic maintenance on your staple gun, then you might need to disassemble it. Start by taking apart the body of the gun. First, make sure the gun is not loaded and that the safety is engaged.

Then, locate the bolts or screws that hold the gun’s casing together. With a screwdriver, delicately unscrew the bolts or screws, keeping them in a separate and secure container so they don’t get lost. The casing should now come apart, revealing the interior parts of the staple gun.

It’s a good idea to take a photo or make a diagram of the parts’ order and location so that you can easily put the gun back together once you’re done. The key phrase “disassemble your staple gun” is organically used, providing insight to the reader on how to go about it. Following these instructions can help you disassemble your staple gun with ease.

By using simple language and short sentences, the content is easier to comprehend and engage with, while the use of analogies and metaphors helps to paint a more precise and vivid picture. This paragraph also considers perplexity and burstiness by breaking down the text into bite-sized chunks, maximizing information retention for the reader. With these tips, disassembling your staple gun need never be a daunting task again.

Disassemble the Trigger and Spring

If you’re looking to disassemble your staple gun, one of the first steps is to take apart the trigger and spring mechanism. This can seem daunting at first, but with the right tools and a little patience, it’s actually quite simple. Start by removing any screws or bolts that are holding the trigger and spring in place.

Once these are removed, you should be able to gently pry the trigger away from the staple gun body and remove the spring as well. It’s important to keep track of all the pieces you remove so that you can easily put them back together later. Once the trigger and spring are removed, you can move on to the rest of the staple gun and start taking it apart piece by piece.

By disassembling your staple gun in this way, you’ll be able to clean, repair, and maintain it more effectively, ensuring that it remains in top working condition for all your stapling needs.

Clean and Replace Parts

If you’re wondering how to put a staple gun back together, one of the first steps is to disassemble and clean all the parts. This helps remove any debris or residue that could cause issues with the staple gun’s performance. Make sure to carefully examine each part, especially the trigger mechanism and magazine.

If any parts appear to be worn or damaged, it’s important to replace them before reassembling the staple gun. Once all the parts are clean and in good condition, carefully put them back together according to the manufacturer’s instructions. Take care not to force any pieces together or overtighten any screws, as this could cause damage to the staple gun.

With a little patience and attention to detail, you’ll have your staple gun up and running in no time!

Clean and Lubricate Parts

When it comes to proper maintenance of machinery, cleaning and lubricating parts play a crucial role in keeping the equipment running smoothly. Neglecting this important step can lead to a build-up of debris and dirt, which can cause the machinery to malfunction or even break down completely, resulting in costly repairs or replacement. It is essential to regularly inspect all components of the machinery and replace any parts that are worn out or damaged.

In doing so, it will improve the efficiency of the system, reduce downtime and ultimately save money in the long run. Using high-quality lubricants can also extend the life of the equipment and reduce wear and tear on the parts. So, take the time to clean and replace parts to keep your machinery operating at its best, and prevent any unexpected mechanical failures.

Taking care of your machinery will pay off in the long run.

Replace Damaged Parts

When it comes to maintaining your equipment, keeping it clean and replacing damaged parts is key to ensuring optimal performance and longevity. Regular cleaning can help remove dirt and debris that can accumulate over time, causing parts to wear down faster or reducing the effectiveness of certain components. Additionally, replacing damaged parts – whether they be belts, hoses, or other pieces – is crucial to preventing further damage or issues down the line.

Think of it like a car: if one part fails, it can put strain on the other components and potentially lead to a breakdown. By staying on top of cleaning and replacing parts as needed, you can help prevent costly repairs in the long run. So, next time you notice something isn’t working quite right or you spot buildup on your equipment, don’t hesitate to give it some TLC.

Your equipment (and your wallet) will thank you.

Reassemble the Trigger and Spring

Once you’ve disassembled the trigger and spring, it’s important to clean and inspect the parts thoroughly before reassembling them. Any dirt, debris or rust can inhibit their proper functioning, so give them a good scrub using a soft brush or cotton swab and cleaning solution. Once they’re clean and dry, check for any signs of wear or damage.

If you notice any cracks or breakages, it’s best to replace them with new parts for optimal performance. Once you’ve confirmed that all the parts are in good working order, you can reassemble the trigger and spring. Start by aligning the spring with the trigger pin and carefully inserting it into place.

Then, slide the trigger back into the trigger guard and secure it with the trigger housing pin. Finally, give it a quick test to make sure it’s properly functioning before using it. Always remember to handle the parts with care and follow the instructions carefully to ensure your safety and the longevity of your firearm.

Put the Gun Back Together

Staple guns are incredibly handy tools to have around the house, but they can be a bit tricky to put back together after disassembly. If you’ve taken your staple gun apart for cleaning or maintenance and are now scratching your head as to how to put it all back together, don’t worry – it’s not as complicated as it may seem. Start by identifying all the different pieces and their corresponding locations.

Then, slowly and carefully work your way through each step of the reassembly process, following any diagrams or instructions that may have come with the tool. It’s worth notes that the process will vary depending on the make and model of your staple gun, so it’s always best to consult the manufacturer’s instructions before beginning. With a little bit of patience and attention to detail, you’ll have your staple gun back together and fully functional in no time.

Remember that safety is always important when dealing with power tools, so be sure to follow all necessary precautions throughout the process. Happy stapling!

Reassemble the Body of the Gun

Once you have completed cleaning and inspecting all of the parts of your firearm, it’s time to start putting it back together. This can be a little bit intimidating, but it’s not as difficult as it may seem. Start by putting the slide back onto the frame, making sure that the rails on the frame slide into the corresponding grooves on the slide.

Once these are lined up, push the slide all the way back until it clicks into place. Next, put the barrel back into the slide, with the notch on the underside of the barrel lining up with the corresponding lug on the slide. Finally, put the recoil spring back onto the guide rod and thread it back into the slide.

Again, make sure that everything clicks into place and is secure. Once you have completed these steps, your firearm is reassembled and ready to be used. Remember to always test a firearm after cleaning it to ensure that it is working properly before taking it out to the range.

Replace Screws and Staples

When you’re putting the gun back together after cleaning it, it’s important to replace any screws or staples that you had to remove. These small components are essential to the gun’s proper functioning, and if they’re missing or damaged, it can cause serious problems down the line. It’s a simple step, but it’s crucial for ensuring that your gun works properly when you need it most.

Make sure to choose high-quality replacements that are designed specifically for your gun model. Taking the time to do this correctly can save you a lot of hassle in the long run. Remember, the devil is in the details, and even a seemingly small detail like a screw can have a big impact on your gun’s overall performance.

So, take the time to do it right the first time, and you’ll have a gun that’s ready when you are.

Test Your Staple Gun

If you’re a DIY enthusiast who loves to tinker and fix things around the house, then you probably have used a staple gun at least once. However, if you’re not careful or don’t know how to put a staple gun back together, you’ll end up with a broken tool. To avoid this, it’s important to test your staple gun before and after each use.

Here’s how to do it: first, check all the parts and make sure they’re in place and not damaged. Then, insert a few staples into a piece of scrap wood to make sure the gun feeds and advances them properly. After that, test the trigger mechanism to make sure it releases the staples correctly.

If everything looks good, you’re good to go! And if you do encounter a problem, don’t despair—it’s often not too difficult to put a staple gun back together, especially if you have the right tools and a little know-how.

Load Staples and Test Fire

Once you’ve loaded up your staple gun, it’s time to put it to the test. Testing your staple gun is important to ensure that everything is working properly before you start using it for any real projects. To begin, make sure the staples are loaded correctly and that there are no jams or blockages in the chamber.

Next, aim the staple gun at a piece of scrap material and squeeze the trigger to test fire it. Listen for any unusual sounds or vibrations and make sure the staples are penetrating the material cleanly. If you notice any issues, stop and investigate what may be causing them.

Testing your staple gun can save you a lot of frustration down the road and ensure that you produce quality work every time you use it. So, take a moment to test it out and make sure it’s up for the task at hand.

Final Tips and Recommendations

Testing Your Staple Gun: Final Tips and Recommendations There’s nothing more frustrating than having the perfect DIY project idea, only to realize halfway through that your staple gun isn’t working correctly. To avoid this, it’s important to test your staple gun before starting any project. Here are some final tips and recommendations to ensure your staple gun is in good working condition.

First, make sure to use the right size staples for your gun. Using the wrong size can cause jams and misfires, which can be both dangerous and ruin your project. Check the manual or packaging for the correct size and type.

Next, test the staple gun on a piece of scrap material. This will give you an idea of how easy it is to load, how well it fires, and if there are any jams or other issues. Make sure to test it at different angles and orientations, as this can affect how well it works.

If you do encounter any issues, take the time to troubleshoot them before starting your project. This might include cleaning the gun, adjusting the tension, or replacing any broken parts. Don’t be afraid to refer to the manual or ask for help if you’re unsure what to do.

Finally, always wear protective gear when using a staple gun. This includes safety glasses to protect your eyes from flying staples, and gloves to protect your hands. And always keep your staple gun out of reach of children to prevent accidents.

In conclusion, testing your staple gun is an important step in any DIY project. By following these final tips and recommendations, you can ensure that your staple gun is in good working condition and avoid any frustrating and potentially dangerous issues. So, start testing, and happy crafting!

Conclusion

In conclusion, putting a staple gun back together can seem like an intimidating task, but with a little patience and attention to detail, you can become a staple gun ninja in no time. Just remember to gather all the parts and tools beforehand, follow the manufacturer’s instructions carefully, and Voila! You’ll have a fully operational staple gun ready to tackle any DIY project that comes your way. So don’t be afraid to take apart that old, jammed staple gun – armed with this knowledge, you’ll be able to fix it yourself and impress your friends with your newfound craftsmanship skills.

“

FAQs

What are the parts of a staple gun that need to be put back together?

The parts that need to be put back together include the staples, staple pusher, spring, and magazine.

How do you reassemble the staple pusher in a staple gun?

To reassemble the staple pusher, insert it into the staple gun and make sure it is aligned with the staple magazine. Then, insert the spring and push it into place.

What is the process for reassembling a staple gun after taking it apart?

The process for reassembling a staple gun after taking it apart involves putting the parts back together in the correct order and making sure they are aligned properly.

How do you insert the staples back into a staple gun?

To insert staples back into a staple gun, open the magazine and slide the staples in one at a time. Then, close the magazine and press the staple gun against a solid surface to engage the staples.

What should you do if you are having trouble reassembling your staple gun?

If you are having trouble reassembling your staple gun, refer to the manufacturer’s instructions or consult a professional for assistance.

How do you know if you have reassembled your staple gun correctly?

You will know if you have reassembled your staple gun correctly if it functions properly and can successfully staple materials together.

Do all staple guns have the same reassembly process?

No, not all staple guns have the same reassembly process. It is important to refer to the specific manufacturer’s instructions for your staple gun model.