Have you been wanting to try your hand at welding but don’t want to invest in a large, expensive machine? Or maybe you need to take your welding skills on the go? A portable welding machine could be the solution to your problem. With a few materials and some basic knowledge, you can make your own portable welding machine. Not only will it save you money, but it can also be customized to fit your specific welding needs.

In this blog post, we’ll explore the steps to make a portable welding machine, from gathering materials to assembling the final product. Get ready to learn a new skill and take your welding game to the next level!

Introduction

If you’re in need of a portable welding machine, you’ll be happy to know that it’s not too difficult to make your own. All you’ll need is a little bit of knowledge, some basic tools, and the right materials. The first thing you’ll need to do is gather your materials, which will include things like a DC welder, cables, rods, and clamps.

Once you have everything you need, you can start putting together your welding machine by connecting the cables, installing the switch, and attaching the electrodes. It’s important to follow the instructions carefully and take your time to ensure that everything is properly installed and working the way it should. Once you’ve finished putting together your welding machine, you’ll have a powerful tool that you can take with you anywhere you go.

With a little practice, you’ll be able to weld like a pro in no time. So why not give it a try and see what you can create with your own portable welding machine?

What is a Portable Welding Machine?

A portable welding machine is a compact and lightweight piece of equipment used for welding applications, making it a popular choice for on-site jobs. It is designed to be easily transported and handled by a single operator, which means that it can be taken from one place to another without much hassle. Unlike traditional welding machines that are bulky and stationary, portable welding machines typically use an inverter technology that reduces their size and weight while improving their efficiency.

A portable welding machine can be powered by either electricity or gas, depending on the type of welding that needs to be done. With a portable welding machine, welders can work in tight spaces or hard-to-reach locations, making it an excellent choice for welding repairs and maintenance work on vehicles, heavy equipment, and pipelines. Overall, a portable welding machine is a must-have for any welding professional who needs the flexibility to work on projects across multiple locations while maintaining high-quality welding results.

Advantages of Making Your Own Portable Welding Machine

If you’re into welding, having a reliable portable welding machine is essential. There are many advantages to making your own, including the flexibility to customize it to your specific needs and specifications. A homemade portable welding machine can also be cheaper than buying a pre-built one, which is especially beneficial for those on a budget.

Additionally, making your own portable welding machine allows you to understand and familiarize yourself with its inner workings better, making it easier to troubleshoot and maintain in the future. By using quality parts and following proper assembly techniques, you can ensure that your homemade welding machine is strong, durable and functional for your welding projects. Overall, taking the time to create your own portable welding machine can provide many benefits, both financially and practically.

Materials and Tools Needed

If you’re looking to make your own portable welding machine, you’ll first need to gather some essential materials and tools. One of the most important items you’ll need is a welder, which can be either an arc or MIG welder. You’ll also need a power source, such as a car battery or generator, to provide the necessary voltage for the welder to work.

Other tools you may need include clamps, a welding helmet, gloves, and safety glasses. It’s important to make sure you have all the necessary materials and tools before beginning your project to ensure your safety and the quality of your finished product. With the right tools and materials, you’ll be well on your way to creating your own portable welding machine that can be used for various DIY projects or professional endeavors.

List of Materials

When it comes to woodworking, having the right materials and tools is essential for any successful project. To start, you’ll need a variety of wood materials, including boards, plywood, and hard and softwoods, depending on the project’s design. You’ll also need materials for joining, such as screws, nails, glue, and wood filler.

Other important tools include a saw (either a handsaw or power saw), a drill, clamps, a hammer, a level, measuring tape, and sandpaper. If you’re going to be working with electrical tools, you’ll also need safety gear like goggles, gloves, and earplugs. Remember that the right materials and tools can make a big difference in the success of your project, so take some time to think about what you’ll need before you get started.

Tools Needed

When it comes to starting a new DIY project, having the right materials and tools is essential for success. Depending on the project, the materials needed can range from wood and paint to fabric and glue. It’s important to have the materials on hand before beginning to prevent any unnecessary delays.

As for tools, there are a few basic ones that every DIY enthusiast should have in their toolbox. A hammer, screwdriver set, drill with interchangeable bits, and measuring tape are just a few of the must-haves. These basic tools can be used for a wide variety of projects and can save both time and money.

Additionally, having a set of safety gear, such as gloves and safety glasses, is essential to ensure a safe and successful project. By having the right materials and tools on hand, DIY enthusiasts can make their visions become a reality.

Steps to Make a Portable Welding Machine

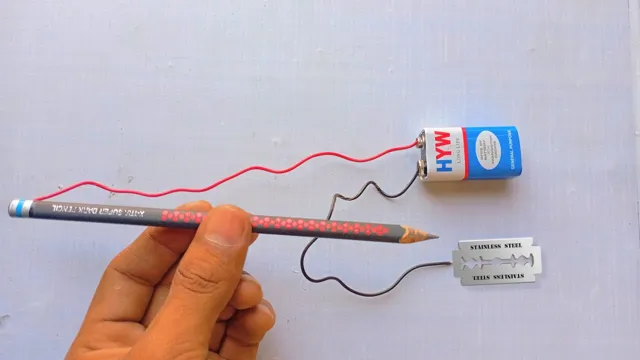

Making a portable welding machine can be a great way to save money and have the convenience of being able to take your tools with you wherever you go. To start, you will need to gather the necessary materials, including an inverter board, a battery, and a transformer. Once you have the materials, you will need to connect them together and test the welder to make sure everything is working properly.

It’s important to pay close attention to the instructions and safety precautions when creating your own portable welding machine. By following these steps and taking the time to ensure that everything is working properly, you can have a reliable and portable welding machine that you can use anytime, anywhere. So, if you’re looking for a welding machine that can easily be transported, try making one yourself and see the results.

Step 1: Design and Plan

Designing and planning are crucial steps to make a portable welding machine. Before starting any project, you should have a clear idea of what you want to achieve, and the same goes for building a welding machine. First, determine the type of welding machine you want to build – will it be a stick welding machine or a wire-feed welding machine? Once you have decided on the type, brainstorm the design and specifications.

You may want to take inspiration from existing models but ensure that your design is unique and caters to your specific needs. A few key components that you will need to focus on include the transformer, rectifier, and the control circuit. Analyzing the power requirements and estimating the cost of materials is also an essential part of the planning process.

As you progress through the designing and planning stage, keep in mind the portability factor of the machine, and strive to create a lightweight and compact model that can be easily transported from one job site to another. Through meticulous planning, you’ll be able to create a portable welding machine that suits your preferences and requirements.

Step 2: Prepare the Components

To begin making a portable welding machine, you need to prepare all the necessary components. This includes a transformer, a rectifier, capacitors, diodes, a voltage regulator, and a fan. These components will be used to convert AC current to DC current and regulate the voltage.

The transformer is used to step down the input voltage, which is typically 220V AC, to a lower voltage. The rectifier is then used to convert the low voltage AC current to DC current. Capacitors are used to stabilize the output, and diodes are used to ensure that the current only flows in one direction.

The voltage regulator is used to maintain a consistent voltage output. Lastly, a fan is necessary to cool the unit during operation. By gathering all the necessary components and having them ready, you can move on to the next step of the process.

Step 3: Assemble the Circuit Board and Power Supply

Assembling the circuit board and power supply is the crucial step in making a portable welding machine. At this stage, you will need to have the necessary components such as the transformer, diode, capacitor, and resistor. You will also need to have a circuit diagram to guide you on how to connect all the components correctly.

The power supply is responsible for converting the AC input to the DC output that is required in welding. Ensure that you pay attention to the polarity of the components as you assemble the circuit board. The components should be firmly fixed to avoid them from becoming loose during the welding process.

Once you have successfully assembled the circuit board and power supply, test it to ensure that everything is working correctly. The sound of the welding machine should be appealing, and there should be no sparks or fumes coming from the machine. With a well-assembled circuit board and power supply, your portable welding machine is ready to use.

Step 4: Connect the Transformer and Rectifier

Once you have built the transformer and rectifier units for your portable welding machine, the next step is to connect them properly. Start by connecting the transformer’s primary winding to a power source of 220V AC using a cable. Then, attach the secondary winding to the rectifier unit’s input terminals.

This will step down the voltage and increase the amperage to enable the welding process. You can use a diode bridge rectifier to convert the AC voltage coming from the transformer’s secondary winding to DC voltage that is suitable for welding. Make sure to follow the wiring diagram provided with the kits to avoid any mistakes.

In addition, it’s essential to insulate every connection and use heat shrink tubing or electrical tape to prevent any electrical shock. With everything set up correctly, you’re now a step closer to having a reliable and portable welding machine that you can use for different projects.

Step 5: Connect the Output Cables and Clamps

After connecting the welder to a power source, the next step in making a portable welding machine is to connect the output cables and clamps. These cables will transfer the welding current from the machine to the workpiece, so it’s important to make sure they are securely attached. Start by connecting the ground clamp to the workpiece.

This clamp is usually black and should be attached to the negative terminal of the welding machine. Next, attach the electrode holder or stinger to the positive terminal of the machine. This clamp should be red.

Once both clamps are securely connected, you’re ready to start welding. It’s important to make sure the cables are not twisted or tangled, as this can cause poor weld quality or even damage to the machine. By following these steps, you can create a portable welding machine that is both efficient and effective in completing your welding projects.

Step 6: Connect the Control Panel

After assembling the welding machine, the next step is to connect the control panel. This part of the process requires wiring knowledge, so it’s important to follow the instructions carefully. The control panel typically includes various switches, buttons, and displays that allow you to adjust the voltage and current levels of the welding arc.

Some panels may also include additional features like thermal overload protection, shielding gas control, and pre-flow/post-flow settings. Once you’ve connected the control panel to the other components of the machine, it’s important to test everything thoroughly to ensure that it’s working correctly. Only once you’ve completed this step can you move on to testing the welding machine as a whole.

With everything properly connected, you can now harness the power of your DIY welding machine and tackle your next project like a pro.

Step 7: Test the Welding Machine

One of the most critical steps in making a portable welding machine is to test it thoroughly. Before using the machine for any project, it is essential to ensure that it is functioning correctly and safely. To test the welding machine, you can start by powering it on and checking the voltage and amperage using a multimeter.

You can then check for any loose connections, frayed cables, or signs of damage. Next, you can conduct a spark test by striking an arc between two pieces of metal to ensure that the welding machine produces a consistent and steady arc. Finally, you should test the machine’s safety features, such as the auto shut-off system and the grounding wire, to ensure that they are functioning correctly.

By testing the welding machine thoroughly, you can avoid potential hazards and ensure that it produces high-quality welds every time.

Safety Tips

Making a portable welding machine can be a great way to have the flexibility to work on projects wherever you are. However, it’s important to take safety precautions to ensure that you and others around you aren’t put in danger. Firstly, make sure that all necessary safety gear is worn, including gloves, goggles, and protective clothing.

When building the machine, always follow the manufacturer’s instructions and ensure that all components are securely fitted. Additionally, always check for any faults or damages before using the machine. When welding, keep flammable materials away from your workspace and never touch or look at the welding arc without proper eye protection.

Lastly, be sure to turn off the machine and put away all equipment when finished to avoid any accidental injuries or fires. By taking these precautions, you can safely enjoy the convenience of a portable welding machine.

Welding Safety Gear and Equipment

Welding can be a very dangerous activity, and proper safety gear and equipment are a requirement for any welder. The most important safety gear for a welder is the welding helmet. The helmet should have a clear lens that allows the welder to see clearly while protecting their eyes from the bright light and sparks created by the welding process.

Proper clothing is also vital for a welder’s safety. Welders should wear flame-resistant clothing to prevent burns. Gloves and sleeves made from heat-resistant materials should also be worn to protect the hands and forearms.

Respirators are also necessary to prevent the inhalation of fumes and harmful particles. It is important to make sure all safety gear and equipment are properly maintained and replaced when necessary to ensure maximum protection. Remember, safety always comes first.

Precautions to Take Before and During Welding

Welding can be a dangerous activity, and as such, it’s essential to take precautions before and during the process to ensure safety. Before welding, it’s important to ensure that you are wearing the correct protective equipment, including a welding helmet, gloves, and an apron. Additionally, make sure that the area surrounding the welding site is free from flammable materials, and that you have a fire extinguisher nearby.

During welding, it’s crucial to take breaks to rest your eyes and avoid eye strain, as well as to ensure that you are not inhaling toxic fumes. It’s also important to have a welding buddy with you to help in case of an emergency or to help hold pieces together while welding. Remember, taking the necessary precautions can help ensure that you can enjoy welding safely and securely without any accidents occurring.

Conclusion

In conclusion, making your own portable welding machine doesn’t have to be a daunting task – with a bit of skill, some patience, and a lot of determination, you can create a powerful and reliable tool that will go with you wherever the job takes you. Just remember to take safety precautions seriously, and don’t be afraid to ask for help or advice along the way. And when it’s all said and done, sit back and admire your handiwork – after all, there’s nothing quite as satisfying as building something from scratch and watching it come to life.

Happy welding!”

Benefits of Making Your Own Portable Welding Machine

As much as portable welding machines can come in handy, it is essential to take safety measures when using them. Firstly, ensure that you have protective clothes and gear on before commencing any welding task. Items such as gloves, welding aprons, and protective glasses are essential for shielding your body from any welding hazards.

Secondly, ensure the welding area is well-ventilated to prevent the inhalation of toxic gases. Proper ventilation also helps in reducing the risk of fire. Thirdly, use the right welding technique and equipment for the job to prevent any accidents.

Lastly, ensure the welding equipment is well-maintained and in good working condition before use. Regular maintenance reduces the risk of equipment failure, which can lead to injuries. Ultimately, taking safety measures when using portable welding machines is vital for preventing accidents and ensuring a successful welding outcome.

Final Thoughts

Final Thoughts: Essential Safety Tips When it comes to safety, it’s always better to be prepared rather than to be caught off guard. Whether you’re at home, at work, or on the go, it’s important to keep in mind some essential safety tips to keep you and those around you safe. First of all, always be aware of your surroundings.

Whether you’re walking down the street or sitting in a crowded café, it’s important to stay alert and attentive to what’s happening around you. Avoid distractions like texting or listening to music that might prevent you from noticing potential dangers. Secondly, always have a plan.

No matter where you are, it’s important to know what to do in case of an emergency. Make sure you know where the exits are, and have a plan for how to get out of the building or area if necessary. Thirdly, be careful with your belongings.

Whether it’s your car keys, your wallet, or your phone, it’s important to keep your valuables secure. Don’t leave them lying around where they can be easily stolen or lost. Fourthly, always be cautious when using unfamiliar equipment or machinery.

Whether it’s a new power tool or a piece of fitness equipment at the gym, make sure you know how to use it properly and safely. Finally, always listen to your instincts. If something feels wrong or dangerous, trust your gut and get out of the situation as quickly as possible.

Remember, safety should always be a top priority, no matter where you are or what you’re doing. By keeping these essential safety tips in mind, you can help ensure that you and those around you stay safe and secure.

FAQs

What are the components required to make a portable welding machine?

The components required to make a portable welding machine are a welder generator, a welding electrode, a welding torch, and cables.

Is it possible to make a portable welding machine at home?

Yes, it is possible to make a portable welding machine at home with the right components and knowledge.

What is the approximate cost of making a portable welding machine?

The cost of making a portable welding machine can vary depending on the components used, but it typically ranges from $200-$500.

How do I connect the welding electrode to the generator?

The welding electrode is connected to the generator through the welding torch. The torch is connected to the cables which are then connected to the generator.

What is the maximum thickness of metal that can be welded with a portable welding machine?

The maximum thickness of metal that can be welded with a portable welding machine depends on the power output of the generator, but typically it can weld metal up to 3/8 inch thick.

Can a portable welding machine be used for stick welding?

Yes, a portable welding machine can be used for stick welding by using the correct welding electrode and torch.

How do I maintain my portable welding machine?

To maintain your portable welding machine, it is important to regularly check the connections and cables for damage and to clean the welding torch and electrodes after use. It is also important to store the machine in a dry place to prevent rusting.