Looking for an efficient and portable spot welding machine that runs on a 12V battery? You’ve come to the right place! Whether you’re a DIY enthusiast or a professional welder, having a reliable spot welding machine will definitely come in handy. With the rise of electric vehicles and the increasing popularity of renewable energy sources, the demand for lightweight and compact welding solutions has grown tremendously. Fortunately, modern technology has made it possible to create spot welding machines that are not only small and powerful but also easy to use.

In this blog, we’ll discuss how a spot welding machine with a 12V battery can be a game-changer for your welding projects. From its benefits to its applications, we’ve got you covered. So, sit back, relax, and let’s dive in!

Introduction

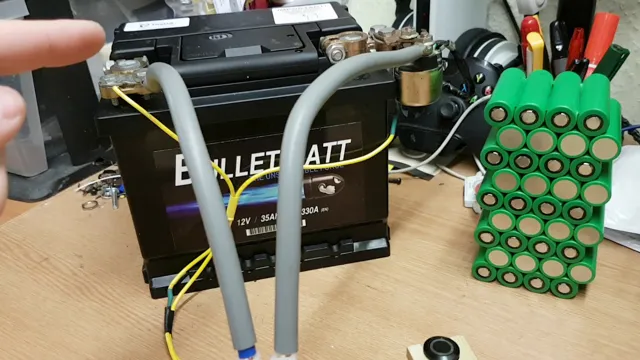

Making a spot welding machine at home can save you a lot of money and can be a fun DIY project. In this article, we will guide you on how to make a spot welding machine using a 12v battery. Spot welding is a process where two pieces of metal are welded together at a specific point.

To make a spot welding machine, you will need some basic materials such as copper wire, a switch, a 12v car battery, and a set of welding electrodes. By following some simple steps, you can build your own spot welding machine that can be used for small welding jobs around the house. So, let’s get started and build your very own spot welding machine using a 12v battery!

Explaining Spot Welding and Its Uses

Spot welding is a welding method used to join two metal pieces together. It is electrically powered and uses intense heat and pressure to produce a welded joint that is strong and durable. One of the metals being welded is clamped or held down while the other piece is brought into contact with a copper electrode.

A strong electrical current is then passed through both pieces, which heats them up rapidly. This causes the metal to melt and fuse together, creating a solid joint. Spot welding is fast and efficient, making it a popular choice in many industries.

It is commonly used in the automotive, construction, and electronics industries, among others. Additionally, spot welding is very environmentally friendly as it doesn’t require any additional materials or chemicals, making it an eco-friendly option.

Materials Needed

If you’re looking to make a spot welding machine using a 12v battery, there are a few materials that you’ll need in order to get started. First and foremost, you’ll need a 12v battery, as this will be the primary power source for your welding machine. Additionally, you’ll need a few other pieces of equipment, including copper wire, a soldering iron, and a pair of pliers.

You’ll also need a sturdy enclosure to house your welding machine, as well as some basic electrical components like resistors and capacitors. Once you’ve gathered all of your materials, you can begin the process of building your spot welding machine. With a little bit of patience and some careful attention to detail, you’ll have a functioning welding machine in no time!

12V Battery, Cable, Electrodes, and Insulators

When it comes to building your very own battery-powered device, there are a few key materials you’ll need to get started. First and foremost, you’ll want a 12V battery to power your device. Make sure to select a battery with enough power and capacity to suit your needs.

You’ll also need appropriate cables to make the necessary connections between the battery and your device. Once you have those basics in place, you’ll need electrodes and insulators. These are crucial components that help ensure your battery operates properly and stays safe to use.

Electrodes are the part of the battery that allows for the flow of electrical current, while insulators help prevent accidental electrical shocks. Together, these materials provide the foundation for a well-built battery-powered device. So, if you’re ready to take on a new DIY project, gather your materials and get started today!

Building Process

Spot welding machines can be very expensive to buy, which is why many people choose to create their own using a 12V battery. The process can be challenging, but with the right tools and knowledge, it’s doable. First, you’ll need to gather all the necessary materials, including copper wires, a transformer, a switch, and steel plates.

Once you have everything, start by creating the copper wires by stripping them to size and shaping them into electrodes. Then, attach the transformer to the electrodes and connect it to the switch. Finally, connect the steel plates to the electrodes, and you’re ready to test out your new spot welding machine.

Keep in mind that this is only a basic overview of the process, so it’s important to do thorough research and follow detailed instructions to ensure a safe and successful build. With a little practice and experimentation, you’ll be able to create professional-grade spot welds from the comfort of your home.

Connecting the Battery to the Electrodes

Connecting the battery to the electrodes is a critical step in building an electronic device. It is important to ensure that the electrodes are connected correctly to avoid any short circuits or damage to the battery. Firstly, it is necessary to identify the positive and negative terminals of the battery and the electrodes.

Once done, the positive terminal of the battery should be connected to the positive electrode, and similarly, the negative terminal should be connected to the negative electrode using conductive wires or clips. It is crucial to make sure the wires are correctly attached, and there is no looseness or breakage. A sturdy connection ensures that power flows steadily, and the device functions efficiently.

Remember, that incorrect connections can lead to searing heat, sparks, fire, or even an explosion. So, take necessary precautions and do not over tighten the electrodes or the wires to avoid damage to the device and ensure safety.

Applying Insulators to Electrodes

Electrode Insulators When it comes to building electrodes, applying insulators is an essential part of the process. Insulators are materials that prevent the flow of electricity and are necessary to protect the electrode’s surroundings. The first step in applying insulators to electrodes is choosing the right material.

There are various types of insulators available, each with its unique properties, such as silicone, epoxy, polyurethane, and ceramics. Once the material is selected, the next step is to apply it to the electrode’s surface. The process involves coating the entire electrode surface with the insulator, ensuring that it is evenly applied.

It is essential to use enough insulating material to ensure the complete absence of electrical contact between the electrode and its surroundings. The final step is to cure the insulating material to form a hardened and durable coating. This process can be achieved either through heating or exposure to UV light, depending on the type of material used.

Overall, applying insulators to electrodes plays a crucial role in ensuring the electrode’s longevity, safety, and efficient performance.

Testing the Setup

After setting up the build environment, it’s important to test the setup to ensure everything is working correctly. The build process involves compiling and linking source code to create a working application. One way to test the setup is to create a simple “Hello, World” program and ensure that it compiles and runs successfully.

This can help identify any issues with the build environment, such as missing libraries or dependencies. Another important step is to test the build process for the actual application being developed, as it may have different requirements than a simple program. This can help catch any errors early in the development process, saving time and effort later on.

Overall, testing the setup is an important step in ensuring a smooth development process.

Safety Precautions

When it comes to making your own spot welding machine using a 12v battery, there are some important safety precautions you need to keep in mind. First and foremost, it’s crucial to wear protective gear such as goggles, gloves, and clothing that covers your skin to avoid the risk of burns and other injuries. Additionally, you should be working in a well-ventilated area to prevent the build-up of harmful fumes and gases.

It’s also important to ensure that your workspace is free from any flammable materials that could ignite during the welding process. When welding, be sure to use proper technique and avoid touching the welding electrode or workpiece with your bare skin. And finally, always make sure to disconnect your battery and any other power sources before starting any work on your welding machine to avoid the risk of electric shock or other hazards.

By taking these safety precautions, you can reduce the risk of injury when making your own spot welding machine at home.

Avoiding Electric Shocks and Burns

Electric shocks and burns can cause serious harm, so taking safety precautions is essential to avoid such accidents. The first step is to ensure that all electrical appliances and cords are in good condition before use. If any of them are damaged or frayed, they should be replaced immediately.

Another important precaution is to avoid using electrical appliances near water since water is a conductor of electricity. Moreover, it’s important to use grounded outlets since they reduce the risk of electrical shocks. Additionally, children should be kept away from electrical equipment and cords to avoid any incidents.

Finally, it’s crucial to turn off and unplug all electrical appliances before attempting to clean or fix them. By following these precautions, we can substantially reduce any risk of electric shocks and burns, ensuring a safe and healthy environment at home and work.

Using Protective Gear

Safety gear is an essential part of protecting yourself while engaging in certain activities or professions. Whether you’re a construction worker on a job site or a cyclist on a busy road, wearing protective gear can save your life in case of an accident. A helmet is the most common and basic type of protective gear you should wear, but other gear like goggles, gloves, and knee pads can also be incredibly important depending on your activity.

Investing in high-quality gear is crucial, as low-quality gear may not provide adequate protection during an emergency. Remember, your safety is your responsibility, so always take the necessary precautions to keep yourself safe and secure.

Conclusion

In conclusion, making a spot welding machine using a 12v battery isn’t rocket science. However, it does require some technical knowledge and skills. With the right components and proper assembly, you’ll be on your way to welding like a pro in no time.

Just remember to take all necessary precautions to avoid injuries and damages, and always wear protective gear. Weld on, my friends!”

FAQs

What materials are needed to make a spot welding machine using a 12v battery?

To make a spot welding machine using a 12v battery, you will need copper wires, a switch, a 12v battery, welding tips, and metal sheets.

How can I connect the copper wires to the switch correctly?

To connect the copper wires to the switch correctly, strip the insulation from the ends of the wires, twist the wires together, and secure them to the switch terminals using a screwdriver.

Is it necessary to use welding tips for this DIY project?

Yes, welding tips are necessary for this DIY project as they produce a high amount of heat that is needed for spot welding.

Can I use a car battery instead of a 12v battery?

Yes, you can use a car battery instead of a 12v battery, but you may need additional materials such as a voltage regulator to ensure that the current is stable.

How thick of a metal sheet can this spot welding machine weld?

This spot welding machine can weld metal sheets that are up to 3mm thick.

What safety precautions should I take when making and using this machine?

Some safety precautions to take when making and using this machine include wearing welding gloves, eye protection, and protective clothing, keeping the machine in a dry location, and ensuring that there is adequate ventilation.

Can this spot welding machine be used for commercial purposes?

This spot welding machine is not designed for commercial purposes, and it is recommended to only use it for small DIY projects.