Welcome to the world of DIY projects! Have you ever heard of mini spot welding machines? These devices are incredibly useful for anyone who enjoys tinkering with electronics or doing DIY repairs around the house. And the best part? You can make your very own mini spot welding machine at home! In this blog post, we’re going to show you how to create your own DIY mini spot welding machine from scratch. With just a few supplies and some basic tools, you can build a device that is perfect for welding small components like wires, connectors, and circuit boards.

We’ll guide you through the process step by step, starting with the materials you’ll need and ending with a fully functional mini spot welding machine. Along the way, we’ll provide tips and tricks to help you optimize your device and get the most out of your welding projects. So let’s get started! Whether you’re a seasoned DIYer or just starting out, this project is the perfect way to flex your creative muscles and learn a valuable new skill.

Get ready to join the mini spot welding revolution and take control of your DIY projects like never before.

Introduction

Are you looking for a way to create a mini spot welding machine from the comfort of your own home? With just a few simple tools and materials, you can make this specialized machine that will help you with your welding projects. Start by gathering the necessary materials, such as a battery charger, some copper wires, an on/off switch, and a few other small electronic components. Then, follow the step-by-step instructions found online, making sure to take your time and follow all safety precautions.

In no time, you’ll be able to produce clean, precise welds that will help you tackle your DIY projects with ease. Making a mini spot welding machine at home is a great way to save money and have fun while learning a new skill. So, why not give it a try?

Understanding What Spot Welding Is

Spot welding is a type of welding technique that involves the joining of two pieces of metal or other materials by applying pressure and heat to a small area. This process is commonly used in the manufacturing of automobiles, aircraft, and various other metal products. The spot welding process involves passing an electrical current through a small spot on the metal surface.

The heat generated by the current melts the metal and fuses the two pieces together. The resulting weld is strong, durable, and resistant to corrosion. While spot welding is a relatively simple process, it requires a high level of skill and precision to perform correctly.

Welders must have a deep understanding of the properties of metal, as well as the various techniques and tools used in the spot welding process.

What You Need for DIY Spot Welding Machine

DIY spot welding machine Introduction: If you work with metal or want to start welding as your craft, you may want to create your own spot welding machine. This DIY project can save you money and give you a sense of accomplishment that comes from building something with your own hands. However, before starting, there are a few things you need to consider.

First, you will need to have a good understanding of how spot welding works and how to safely operate a welding machine. Second, you will need to gather the necessary materials and tools, which can include anything from a transformer to copper electrodes and a welding helmet. In this blog post, we will discuss the various components needed for a DIY spot welding machine and how to put it all together for a successful welding project.

Building Your Mini Spot Welding Machine

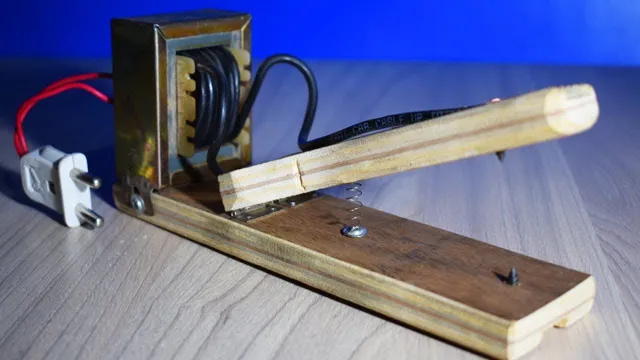

If you’re a DIY enthusiast looking to create your own mini spot welding machine, you’re in luck! Building your own mini spot welding machine at home is an excellent way to save money and gain practical experience. To begin, you’ll need a few essential tools and materials such as an electrical transformer, a few pieces of copper wire, and a timer relay switch. You’ll also need to ensure that you have a safe workspace and have taken proper safety precautions.

Once you’ve gathered all your materials, the building process involves various steps such as winding the copper wire around the transformer, soldering the leads, and connecting the timer switch. After correctly assembling all the pieces, test the spot welder using a few small pieces of metal to verify the quality of its welds. With a little bit of effort and diligence, you can have your mini spot welding machine up and running in no time!

Step 1: Designing the Circuit

If you’re someone who loves innovative DIY projects, building a mini spot welding machine is sure to be right up your alley! The first step towards building your very own welding machine is designing the circuit. When you plan the circuit, you need to think about the different components you’ll need and how they’ll all work together. The basic parts of a spot welding machine circuit include a transformer, a rectifier, and a timer.

The transformer is responsible for upping the voltage while the rectifier changes the AC to DC current. Finally, the timer controls how long the current will flow through the welding head, which determines the strength of the weld. Understanding the functions of each component and how they all interact is essential to building a functional welding machine.

So, let’s get started!

Step 2: Sourcing the Materials

Now that you have the design and plan for your mini spot welding machine, the next step is gathering the necessary materials. The good news is that most of the items can be found at your local hardware store or purchased online. The first thing to consider is the main power source.

You’ll need a transformer with an output of around 2 volts and 50 amps. For smaller projects, a car battery charger can do the trick. You’ll also need copper welding electrodes, which can be found at welding supply stores or purchased online.

Make sure to get the proper diameter and shape for your machine. To connect the transformer to the electrodes, you’ll need a set of welding cables with sturdy clamps. Lastly, you’ll need a timer or foot pedal to control the welding time.

The timer can be purchased at an electronics store, or you can use a foot pedal from an old sewing machine for a more budget-friendly option. With these materials in hand, you’ll be all set to build your mini spot welding machine and start your welding projects.

Step 3: Building the Circuit

Now that we have all the necessary components gathered, it’s time to put our mini spot welding machine together. First, let’s connect the battery to the switch, then attach the two wires from the transformer to the switch as well. It’s important to make sure the wires are connected properly and securely.

Next, we connect the welding electrodes to the transformer, ensuring they are tightened down securely. The final step is to switch on the machine and test it out. If everything is working properly, we should be able to spot-weld thin sheets of metal with ease.

Remember to be careful when using the machine and wear appropriate safety equipment, such as gloves and eye protection. With our mini spot welding machine up and running, we’re now ready to tackle a variety of DIY metalworking projects.

Testing Your DIY Mini Spot Welding Machine

If you’ve followed our tutorial on how to make a mini spot welding machine at home, then congratulations, you’re ready to test it! But before you start welding away, it’s important to ensure that your machine is functioning properly and safely. Firstly, double-check all the connections and wiring to make sure everything is securely in place. Then, test the welding machine on a small, thin piece of metal to see if you’re getting a strong enough weld.

If the weld isn’t satisfactory, try adjusting the pressure on the electrodes or increasing the welding time. It’s also crucial to wear protective gear such as gloves and goggles to avoid any potential hazards. Always keep a fire extinguisher nearby as well, just in case.

By testing and fine-tuning your mini spot welding machine, you’ll be able to create strong and precise welds on your DIY projects in no time!

Step 1: Setting up the Test

Testing your DIY mini spot welding machine is crucial for safety and efficient performance. The first step in this process is setting up the test environment. Find a workspace with good ventilation and ample space for the equipment.

Then, determine the appropriate voltage and current settings for your spot welder, based on the thickness and composition of the metal you will be welding. Next, prepare the metal pieces by cleaning the surfaces to be welded. Once everything is in place, begin the test by connecting the electrodes to the metal and initiating the weld.

Remember to wear protective gear, such as welding gloves and a face mask, and periodically check the machine for any signs of malfunction. By properly testing your DIY mini spot welding machine, you can ensure safe and effective welds every time.

Step 2: Performing the Test

Now that you’ve assembled your DIY mini spot welding machine, it’s time to put it to the test! To begin, insert the nickel strip into the electrodes and clamp it down tightly. Make sure your battery is fully charged and connected to the machine. Next, press the foot pedal to run a test weld.

You should see a spark and hear a sizzling sound. If everything looks good, repeat the process a few more times to make sure your machine is consistently producing strong welds. If you experience any issues, double-check the connections and electrode alignment.

It may take a bit of practice to get the hang of it, but with some persistence, you’ll have a functional and reliable mini spot welding machine for all your DIY projects!

Simple Tips and Tricks for DIY Mini Spot Welding Machines

Are you looking for a simple and affordable way to create your own mini spot welding machine at home? Look no further! With just a few tips and tricks, you can easily build your very own mini spot welding machine using materials that you may already have lying around your house. Start by sourcing a battery or transformer to supply power to your machine. Next, gather some welding electrodes, copper wire, and a switch to control the current flow.

Once you have all your materials, follow these easy steps to build your mini spot welding machine. Connect the copper wire to the electrodes and secure them to a base. Then, attach your switch and connect it to the power supply.

Lastly, test your machine by placing two pieces of metal between the electrodes and pressing the switch to create a weld. With a little bit of patience and practice, you’ll be creating strong, secure welds in no time!

Tip 1: Practice Safety Measures

When it comes to DIY mini spot welding machines, safety should always be your number one priority. It’s easy to get caught up in the excitement of creating your own machine, but don’t forget about the potential hazards. To avoid accidents, make sure to practice safety measures such as wearing protective gear like gloves and goggles.

You should also work in a well-ventilated area and keep children and pets away from your work area. Additionally, make sure to follow the manufacturer’s instructions carefully and double-check all connections before activating the machine. By taking these simple precautions, you can enjoy the process of creating your own mini spot welding machine while keeping yourself and those around you safe.

Tip 2: Use the Right Materials and Tools

When it comes to DIY mini spot welding machines, choosing the right materials and tools is crucial to ensure their effectiveness and longevity. The most commonly used materials for the electrodes are copper and brass because they conduct heat well and don’t melt easily. It’s also important to use good-quality welding wire and a sturdy base to prevent any mishaps during the welding process.

When selecting tools, opt for a welding plier with a decent grip and electrode holders for ease of use. It’s also recommended to invest in a good-quality welding machine with adjustable current settings, so you can customize the welding conditions according to your project needs. Remember to always prioritize safety when handling welding equipment and wear protective gear such as gloves and goggles.

By using the right materials and tools, you can enhance your mini spot welding experience and achieve impressive results.

Tip 3: Get Creative with Your Circuit Design

If you’re building your own mini spot welding machine, it’s important to get creative with your circuit design in order to make it as effective as possible. One simple tip is to consider using a transformer and rectifier combo instead of a battery to power your machine. This will allow for a more consistent flow of energy and can help to prevent overheating.

Another option is to experiment with different types of capacitors and resistors to fine-tune the performance of your machine. By being open to new ideas and taking the time to experiment with different components, you can create a truly unique and effective DIY welding machine that meets all of your needs.

Conclusion

In conclusion, making a mini spot welding machine at home is not only a great DIY project, but it’s also a useful addition to your crafting or repair arsenal. With the appropriate materials and a little bit of engineering ingenuity, you can create a highly functional mini spot welder that will stand the test of time and save you money in the long run. Just be sure to take the necessary safety precautions and keep that welding mask handy, because when it comes to welding, safety always comes first! Happy welding!”

FAQs

What are the materials required to make a mini spot welding machine at home?

To make a mini spot welding machine at home, you would need a transformer, copper wire, timer, switch, and some basic tools such as pliers and screwdrivers.

How does a mini spot welding machine work?

A mini spot welding machine works by passing a high current through copper electrodes that are placed on the surface of the metal to be welded. The current generates heat, which melts the metal. When the heat is removed, the metal solidifies and forms a weld.

What are the advantages of making a mini spot welding machine at home?

Making a mini spot welding machine at home allows you to have a welding tool that is customized to your specific needs and budget. It also gives you the satisfaction of knowing that you built something yourself.

How long does it take to make a mini spot welding machine at home?

The time it takes to make a mini spot welding machine at home depends on your skill level and the complexity of the machine. It can take anywhere from a few hours to a few days.

Can a mini spot welding machine be used to weld different types of metals?

Yes, a mini spot welding machine can be used to weld different types of metals, but the electrodes might need to be changed depending on the type of metal you are welding.

Is it safe to use a mini spot welding machine at home?

Yes, a mini spot welding machine can be safe to use at home as long as you follow proper safety procedures such as wearing protective gloves, glasses, and clothing. It is also important to use the machine on a stable surface and to avoid touching the electrodes when they are hot.

Can a mini spot welding machine be used for commercial purposes?

Yes, a mini spot welding machine can be used for commercial purposes, but it is important to make sure it meets safety and quality standards before using it on a large scale.