How to Install a Drill Bit into a Drill Press: Step-by-Step Guide for Beginners

Are you stuck wondering how to install a drill bit in your drill press? Don’t worry, it’s an easy process that anyone can do! Whether you’re a DIY enthusiast, a weekend warrior, or a professional craftsman, knowing how to install a drill bit in your drill press is essential for any drilling project. Think about it like changing a light bulb – it’s a simple task, but without knowing how to do it, you won’t be able to accomplish your goal. Similarly, without knowing how to install a drill bit, you won’t be able to bore holes into wood, metal, or any other material.

In this blog post, we’ll take you step-by-step through the process of installing a drill bit in your drill press. We’ll discuss the tools and materials you’ll need, safety precautions, and some helpful tips and tricks. By the end of this post, you’ll be confident in your ability to install a drill bit and ready to tackle any drilling project that comes your way!

Gather Your Tools and Supplies

Installing a drill bit into a drill press is a task that requires some basic tools and supplies. First and foremost, you will need a drill press, a set of drill bits, and a chuck key. The chuck key is the tool that you will use to tighten and loosen the chuck, which is the mechanism that holds the drill bit in place.

You will also need a clean work surface, a pair of safety glasses, and some lubricant. Before beginning the installation process, it’s important to make sure that your drill press is plugged in and turned on. Once you have gathered your tools and supplies, you can now proceed to install the drill bit into the drill press.

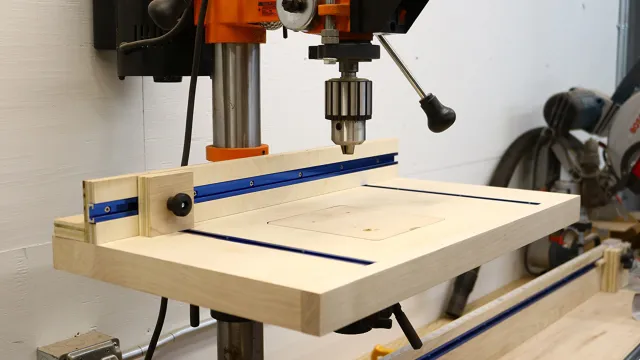

Drill press

When it comes to using a drill press, the first step is to gather all the necessary tools and supplies. This includes the drill press itself, the appropriate drill bits, clamps or vises to secure the material being drilled, and safety gear like gloves and goggles. It’s crucial to select the correct drill bit size and type for the material being drilled, whether it’s wood, metal, or plastic.

Once you have all your equipment in order, it’s time to prepare for drilling. Clear the surrounding area of any debris and position the material securely before turning on the drill press. Remember to keep your hands and loose clothing away from the drill bit as it spins.

With the right tools and precautions in place, using a drill press can be a safe and efficient way to create precise holes in any material.

Drill bit

When it comes to using a drill bit, having the right tools and supplies is crucial. First off, make sure you have the correct size and type of drill bit for the job at hand. Depending on what you’re drilling into, you may need a carbide-tipped masonry bit, a spade bit for wood, or a titanium-coated bit for metal.

Once you have the right bit, you’ll need a corded or cordless drill and a sturdy work surface. It’s also important to have safety gear on hand, like safety glasses and dust masks if you’re drilling into concrete or other materials that may produce dust. And don’t forget lubrication – a few drops of oil or cutting fluid can go a long way in prolonging the life of your drill bit.

By gathering all of your tools and supplies before you start drilling, you can ensure a successful and safe project.

Chuck key

When it comes to using a drill press, having a chuck key is essential. It is crucial to ensure that the chuck key fits the drill press and fastens securely to prevent accidents while using the tool. Before starting your project, gather all the necessary tools and supplies needed, including the chuck key.

Ensure that the chuck key is the correct size for your drill press and is readily accessible during use. A loose chuck key can pose a safety hazard, so it’s vital to keep it securely in place. By acquiring the right tools and ensuring they are appropriately stored, you can increase efficiency and minimize accidents while using a drill press.

Overall, having a chuck key that fits securely and is easily accessible is essential for safe and effective use of your drill press.

Safety glasses

Safety glasses are a must-have when undertaking any task that involves the possibility of debris flying around. And the first step you need to take before embarking on such a project is to gather the appropriate tools and supplies. The good news is that you don’t need many things to get started, but make sure you have some safety glasses that fit you well.

These should be ANSI-approved, which indicates that they meet the rigorous safety requirements set by the American National Standards Institute. Depending on what you plan to do, you can choose between various types and styles of safety glasses, including wraparound, goggles, and prescription glasses. Remember, preventing eye injury is key when working with potentially dangerous materials, so do not compromise on the quality of your safety glasses.

Prepare Your Drill Press

If you’re new to using a drill press, one of the first things you’ll need to know is how to install a drill bit into it. Start by making sure your drill press is properly set up and secured to a stable surface. Next, locate the chuck on the spindle of the drill press and loosen the jaws by hand or with a chuck key.

Insert the drill bit into the chuck and tighten the jaws by hand or with the chuck key to hold the bit securely in place. It’s important to make sure the bit is centered and straight in the chuck to avoid any wobbling or vibration during use. Once the drill bit is securely in place, you’re ready to start drilling.

Remember to always wear personal protective equipment like eye and ear protection, and to follow all safety guidelines when using your drill press. With a little bit of practice, you’ll be able to install drill bits quickly and easily every time you use your drill press.

Unplug the drill press

Unplugging your drill press is an essential safety precaution that should not be overlooked. Before you start using your drill press, make sure you unplug it from its power source. This is to ensure that the machine remains off while you prepare it for usage.

Additionally, it’s crucial to check for any damages before using the machine. This step involves checking the pulleys, belts, and the chuck to ensure that everything is in good condition. If there are any damages, you should not use the machine until it’s fixed.

Keeping your drill press well-maintained and in good working condition is key to ensuring its longevity and safe operation. So, take a few minutes to prepare and inspect your drill press before use to prevent accidents from happening.

Loosen the chuck

When getting ready to use a drill press, it’s crucial to prepare it properly. The first step is to loosen the chuck. The chuck is the metal piece at the end of the spindle that holds the drill bit in place.

Loosening it will allow you to easily insert and change out different drill bits. To do this, use the chuck key that came with your drill press. Insert it into one of the three holes on the side of the chuck and turn it counterclockwise.

This will release the jaws of the chuck, allowing you to insert the bit of your choice. Once you’ve inserted your bit, use the chuck key again to tighten the chuck by turning it clockwise. It’s important to make sure the chuck is tightened securely to prevent slippage while drilling.

By taking the time to properly prepare your drill press, you’ll ensure that your work goes smoothly and safely.

Raise the drill press platform

One important step to take before using your drill press is to prepare it properly. One of the first things you’ll need to do is to raise the platform of the drill press. This is important because it allows you to adjust the distance between the drill bit and the workpiece.

To do this, you’ll need to locate the mechanism that raises and lowers the platform, which is usually found on the side of the drill press. Once you’ve found it, you can use the handle or lever to raise the platform to the desired height. Make sure to adjust it so that the drill bit is at the correct height for your project.

By taking this simple step, you’ll be able to use your drill press safely and effectively for your next woodworking project.

Inserting the Drill Bit

Installing a drill bit into a drill press may seem daunting, but it’s actually quite simple with the right steps. First, make sure the drill press is turned off and unplugged for safety. Next, insert the appropriate size of drill bit into the chuck, which is typically located at the end of the spindle, and tighten with a chuck key.

It’s important to ensure the drill bit is centered in the chuck for accuracy. Double-check that the drill bit is securely fastened before turning on the drill press to avoid any accidents. Remember to always wear protective gear, such as safety glasses, when operating power tools.

With these steps, installing a drill bit into a drill press can be done quickly and easily, allowing you to begin your project with confidence.

Insert the bit into the chuck

Inserting a drill bit into a chuck may seem simple, but it’s important to do it correctly to avoid accidents or damaging your tools. First, make sure that the drill is turned off and unplugged. Then, loosen the chuck by turning it counterclockwise.

Insert the bit into the chuck, making sure that it is straight and centered. Continue tightening the chuck by turning it clockwise until the bit is secure. You can give it a gentle tug to ensure that it’s properly tightened.

It’s crucial that the bit is not loose as it may come out while drilling and cause an injury or damage to the workpiece. With these simple steps, you can safely and effectively insert a drill bit into a chuck, making sure that your work is precise and accident-free.

Use the chuck key to tighten the bit in the chuck

As you start using your drill, you need to be aware of how to correctly insert a drill bit to avoid any accidents. It’s important to use the right size bit for the job at hand and ensure that it’s secure and stable before starting to drill. To insert the bit, first, loosen the chuck with your hand by twisting the chuck counterclockwise.

Insert the bit into the chuck, making sure it’s straight and centered. Then, use the chuck key to tighten the bit in place by turning it clockwise. Don’t overtighten it, but ensure that it’s firm and stable.

Using an unstable bit can cause it to break or fly out while drilling, injuring you or anyone nearby. So always ensure that your drill bit is fully and securely tightened before starting the drill. With this simple procedure, you can be confident in your ability to use your drill safely and efficiently.

Make sure the bit is straight and secure

When it comes to inserting a drill bit, it’s important to make sure that the bit is straight and secure. This is critical for getting accurate and precise holes every time. To begin, make sure your drill is unplugged or the battery is removed.

Then, insert the bit into the chuck of the drill, ensuring that it is straight and lined up with the center of the chuck. Once it is lined up, tighten the chuck by hand or with a chuck key if one is provided. It is important to make sure that the bit is secure and does not wobble in the chuck.

If it does, it could cause inaccurate holes or damage to the bit and tool. Once the bit is straight and secure, you can plug in your drill or reattach the battery and start drilling. By taking the time to properly insert the drill bit, you can ensure that your project goes smoothly and efficiently.

Lower the Platform and Test the Bit

If you want to install a drill bit into a drill press, there are several steps you need to follow. First, you need to lower the platform of the drill press to the point where you can access the chuck. Once you can see the chuck, use the chuck key to loosen the jaws of the chuck.

Once the jaws are loose, insert the drill bit into the jaws and tighten them until the drill bit is secure. It’s important to make sure the drill bit is centered and straight in the chuck to avoid any wobbling during use. Once the bit is in place, you can raise the platform of the drill press to the desired height and start drilling.

With these simple steps, you can install a drill bit into a drill press and start tackling your next project with ease!

Lower the drill press platform

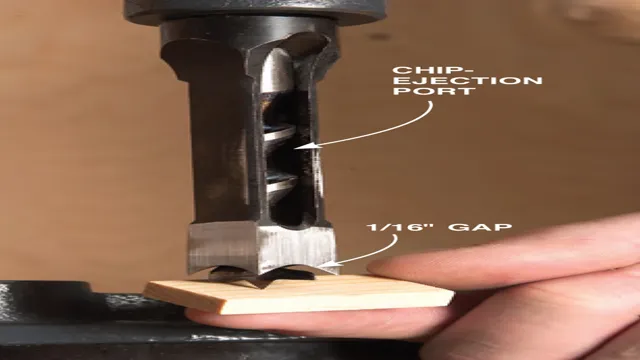

Lowering the drill press platform is an essential step when drilling holes in your workpiece. The platform’s height must be adjusted to the proper positioning before drilling it. After setting the drilling depth, you can lower the platform to test the bit.

To do this, first, turn off the drill press and hold the drill bit and the depth stopper. Then, lower the platform until the drill bit touches the material’s surface. Before drilling any holes, test the hole’s size and depth by drilling a small hole in a scrap piece of material to make sure everything is aligned.

Additionally, ensure that the material is secured before drilling, as it can move around during the process and ruin your workpiece. By lowering the drill press platform and testing the bit beforehand, you can ensure successful and accurate drilling every time.

Turn the drill press on

Now that you’ve positioned your workpiece and selected the proper drill bit, it’s time to turn on the drill press. Before drilling, you need to lower the platform to the level of the drill bit to ensure accurate results. Most drill presses have a depth stop that you can adjust to control the depth of the drill – this is crucial if you need to make multiple holes of the same depth.

Once the platform is lowered, it’s time to test the drill bit and make sure it’s secure. Turn the drill press on and listen for any strange noises or vibrations that might indicate a loose bit. Don’t forget to wear safety goggles and keep fingers and loose clothing away from the moving parts.

Now, you’re ready to start drilling your hole with confidence. Remember, safety should always be your top priority when using the drill press. Before beginning any drilling project, make sure you have the appropriate safety gear and that your workpiece is solidly clamped in place.

Rushing can lead to mistakes, so take your time and carefully lower the platform to the desired level. By following these steps and taking your time, you’ll ensure accurate and safe results each time you use your drill press. Happy drilling!

Test the drilling depth and alignment

When it comes to drilling for oil or gas, it’s essential to test the drilling depth and alignment of the platform and bit. One way to do this is by lowering the platform and testing the bit’s performance. This process allows engineers to make sure that they are drilling at the appropriate depth and aligning the bit correctly.

By testing the bit, engineers can make adjustments to the platform and the drill string to ensure that the drilling operation runs smoothly. It’s crucial to keep in mind that drilling is a complex process, and even small errors in drilling depth or alignment can result in costly errors or even accidents. Therefore, careful testing and monitoring of the drilling operation is essential to ensure safety and efficiency.

So, before starting the drilling process, it’s essential to test and check everything to avoid further complications.

Conclusion

After all is said and done, installing a drill bit into a drill press is like putting a wedding cake topper on the cake – you need precision and patience to ensure everything aligns perfectly. Take your time, make sure the drill bit is the right size and securely fastened into the chuck, and you’ll be able to drill with confidence and precision. Happy drilling!”

FAQs

What is the proper way to insert a drill bit into a drill press?

To insert a drill bit into a drill press, first make sure the drill press is turned off. Then, loosen the drill chuck by turning it counterclockwise. Insert the drill bit into the chuck, making sure it is straight and aligns with the jaws of the chuck. Tighten the chuck by turning it clockwise, making sure it is securely holding the drill bit.

Can any type of drill bit be used with a drill press?

Most standard drill bits can be used with a drill press, as long as they fit securely in the chuck. However, some specialized bits, such as forstner bits, may require a different type of chuck or adapter.

How do you remove a drill bit from a drill press?

To remove a drill bit from a drill press, first make sure the drill press is turned off. Then, loosen the chuck by turning it counterclockwise. The drill bit should then be easy to remove from the chuck.

What is the recommended drill bit speed for a drill press?

The recommended drill bit speed for a drill press depends on the material being drilled and the size of the drill bit. As a general guideline, larger bits require slower speeds and harder materials require slower speeds. Consult the drill bit manufacturer’s recommendations for specific speed settings.

Can a drill press be used for other types of tools besides drill bits?

Some drill presses can be used with other types of tools, such as sanding drums or mortising attachments. However, it is important to consult the manufacturer’s guidelines and instructions before using any tool with a drill press.

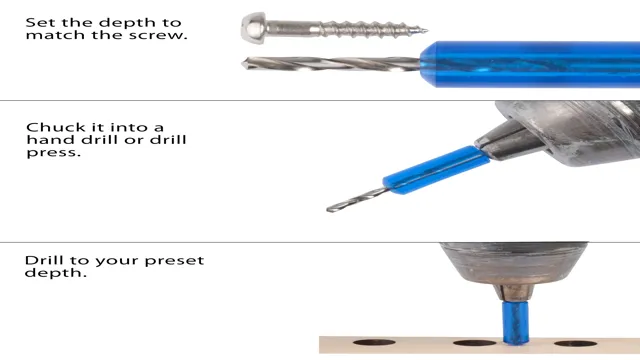

How do you adjust the depth of a hole drilled with a drill press?

To adjust the depth of a hole drilled with a drill press, lower the drill bit to the desired depth and adjust the depth stop accordingly. The depth stop can usually be adjusted using a set screw or lever on the side of the drill press column.

What safety precautions should be taken when using a drill press?

When using a drill press, always wear eye protection and avoid loose clothing or jewelry that could get caught in the machine. Keep fingers and hands away from moving parts and never touch the drill bit while it is spinning. Always follow the manufacturer’s instructions and guidelines for safe operation.