When it comes to drilling holes in any material, one of the most important factors is keeping the drill bit perpendicular to the surface. However, this can be tricky when using a drill press, especially when working with longer drill bits or larger pieces of material. That’s why learning how to hold the rod vertical in a drill press is crucial for achieving accurate and precise drilling.

Holding the rod vertical in a drill press requires a combination of proper technique and equipment. One popular method is to use a drill press vise or clamp to secure the material in place while drilling. This allows for better control and ensures that the rod remains upright throughout the drilling process.

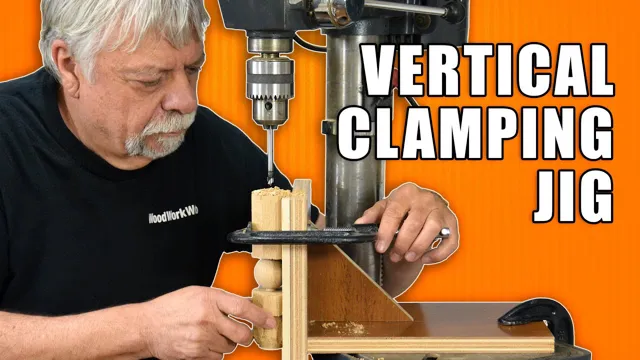

Another key technique is to use a guide block or jig to keep the drill bit aligned with the material. By positioning the guide block or jig at the desired angle, you can ensure that the drill bit remains perpendicular to the surface at all times, resulting in clean, accurate holes. Overall, learning how to hold the rod vertical in a drill press is essential for anyone looking to achieve precise and accurate drilling results.

With the right technique and equipment, you can ensure that your drill bit remains perpendicular to the surface and produce high-quality holes in any material.

Using a Drill Press

If you’re looking to drill through a rod vertically on a drill press, there are a few things to keep in mind. To start, you want to make sure you’re using the appropriate sized drill bit for your rod. Once you have that figured out, you’ll need to secure your rod in place so it doesn’t move around during drilling.

One way to do this is by using a vise grip to clamp the rod down to the press table. However, this can make it difficult to keep the rod perfectly vertical. Another option is to use a centering jig that attaches to the drill press, holding the rod in place and ensuring it stays straight as you drill.

Either way, it’s important to take the time to set up your rod securely before you start drilling, to ensure accuracy and safety. With a little patience and attention to detail, you’ll be able to drill perfectly straight holes in your rods every time.

Choose Proper Bits & Clamp Work Piece

When using a drill press, it’s essential to choose proper bits and clamp the workpiece securely in place. Choosing the right bit for your project will ensure that you get the clean and precise holes you need without damaging the material. Make sure the bit is sharp and the correct size for the hole you need to drill.

It’s also important to clamp the workpiece firmly to prevent any movement during drilling. A loose workpiece can cause the bit to slip or wander, resulting in unwanted holes or damage to the material. Remember to adjust the table height and depth stop to ensure the bit reaches the desired depth without going too far.

By taking these simple steps, you’ll be able to use your drill press with confidence and produce high-quality results.

Install V-Block and Secure Rod

If you’re looking to install V-Block and secure rods, using a drill press is a great way to go about it. Firstly, make sure your drill press is set up correctly. Attach a drill bit that’s appropriate for the size of the hole you want to create.

Next, secure the V-Block onto the drill press table, using clamps to hold it in place. Once you’ve done that, lower the drill bit onto the V-Block and drill a hole into the exact center. Next, insert the rod into the hole you’ve just created and ensure it’s properly aligned.

Finally, tighten the rod into place, securing it with the V-Block. Congratulations – you’ve successfully installed V-Block and secured a rod! Remember, this process won’t work if your drill press isn’t set up correctly, so double-check your equipment before getting started.

Adjust Height and Alignment of Drill Bit

Adjusting the height and alignment of your drill bit is a crucial step when using a drill press. To ensure the accuracy and precision of your drilling, you must first secure the drill bit at the desired height on the drill press column. This can be done by adjusting the depth stop or the table height to adjust the height of the bit.

The depth stop controls the vertical movement of the drill bit, while the table height determines the distance between the bit and the workpiece. Once you have set the height, you should align the drill bit by adjusting the angle of the table or the fence. This will ensure that the bit is perfectly perpendicular to the workpiece surface.

Proper alignment is essential to prevent the drill bit from wandering or slipping, which could result in inaccurate and uneven holes. So, take the time to adjust the height and alignment of your drill bit before starting your drilling project, and you’ll be sure to get the best results!

Additional Tips and Safety Precautions

When working with a drill press, it’s important to hold the rod vertical to ensure accurate and safe drilling. To do this, you can use a drill press v-block or clamp to hold the rod in position. Additionally, make sure the drill bit is securely fastened before beginning the drilling process.

It’s also crucial to use the appropriate drill bit for the material you’re drilling into and to wear protective gear such as goggles and gloves. When drilling, keep the drill press at a slow and steady speed and avoid forcing the material through the drill bit. With these precautions in mind, you can safely and effectively drill precise holes with your drill press while maintaining the vertical position of your rod.

Proper Clothing and Eye Protection

To ensure your safety while working with power tools, it’s important to wear the appropriate clothing and eye protection. Loose-fitting clothing and jewelry should be avoided, as they can easily become caught in machinery and cause serious injury. Instead, opt for fitted clothing and tie long hair back to avoid any accidents.

Eye protection is also crucial, as debris and dust can easily fly into the eyes during tool operation. Safety glasses with side shields or goggles are the best options for protecting your eyes from potential hazards. In addition to these basic safety precautions, there are a few other tips to keep in mind when working with power tools.

First, be sure to read and follow the manufacturer’s instructions carefully. This will help ensure that you are using the tool in the way it was intended, and can prevent accidents caused by incorrect usage. Second, always inspect your tools before using them to make sure they are in good condition and functioning properly.

Lastly, be aware of your surroundings and make sure that you are working in a well-lit, well-ventilated area. By taking these additional precautions, you can help ensure that you are staying safe while working with power tools. Remember, it’s always better to err on the side of caution when it comes to your safety.

With the proper clothing and eye protection, along with these other tips, you can enjoy working with your power tools safely and with confidence.

Avoid Overloading Drill Press

When it comes to using a drill press, avoiding overloading it is vital to ensure safe and efficient use. Overloading the drill press can cause it to overheat, wear out the motor, and even break or malfunction. One of the best ways to avoid overloading the drill press is by using the right drill bits for the job and not forcing them to go through the material.

It’s also a good idea to check the drill press’s capacity and make sure that it matches the size and type of job you’ll be doing. Additionally, always maintain the drill press and keep it clean and free from debris to prevent any potential safety hazards. By following these tips and being mindful of safety precautions, you can enjoy using your drill press without any accidents or mishaps.

Keep Work Area Clean and Organized

Keeping your work area clean and organized is not only essential for productivity and efficiency, but it’s also crucial for your safety. When your workspace is cluttered, it increases the chances of accidents happening. To prevent that, here are some additional tips and safety precautions you can follow.

Firstly, always keep your tools and equipment in their designated places when not in use. This will prevent any tripping hazards and help you find them easily when needed. Secondly, make sure to dispose of any waste materials properly, as they can also cause accidents.

Thirdly, keep your workspace well-lit and well-ventilated to avoid any eye strain or respiratory problems. Lastly, always wear appropriate personal protective equipment (PPE) when necessary, such as gloves, safety glasses, or helmets. By following these simple tips, you can ensure a safer and more organized work environment.

Conclusion

In conclusion, holding a rod vertical in a drill press may seem like a daunting task, but with the right technique and a steady hand, you can accomplish this feat with ease. Remember to use a center punch to mark your drilling spot and to secure your rod with a clamp or vise. With these tips, you’ll be able to drill straight and true, leaving your friends and colleagues in awe of your newfound prowess in the workshop.

So go forth and hold that rod vertical, my fellow DIY enthusiasts!”

FAQs

What is the proper way to align the rod before drilling?

To ensure a vertical hold, place the rod against the back fence of the drill press and adjust the table height accordingly.

What type of clamp works best for securing the rod in place?

A vise clamp or adjustable hold-down clamp will provide a secure grip on the rod for vertical drilling.

Are there any safety measures to take when drilling vertically?

Yes, always wear safety goggles and avoid loose clothing or dangling jewelry that could become caught in the drill bit.

How can I ensure the hole is perfectly vertical?

Use a drill press laser guide or attach a level to the drill bit to ensure the rod stays perpendicular to the table surface.

Is it necessary to use a lubricant when drilling vertically?

It depends on the material being drilled, but using a lubricant can help reduce friction and prevent the drill bit from overheating.

What size drill bit should I use for a vertical hole?

The drill bit size should correspond to the diameter of the hole needed in the rod, and can be determined using a drill bit size chart.

Can a drill press be used for drilling horizontal holes in a rod as well?

Yes, simply adjust the angle of the table to achieve the desired horizontal drilling angle.