Removing a stuck brake bleeder screw can undoubtedly be frustrating, leaving you feeling like you want to throw in the towel and take your car to a mechanic. However, fear not, as there are some easy ways to remove a stuck brake bleeder screw without spending a ton of money. Brake bleeder screws help to release air trapped inside your car’s braking system, ensuring that your brakes work correctly.

Thus, it’s essential to maintain them and know how to remove them when stuck. While there are multiple reasons why a brake bleeder screw becomes stuck, rust and corrosion are the primary culprits. When the screw is exposed to the elements, it can rust, making it difficult to turn it with the appropriate tool.

Attempting to remove a stuck brake bleeder screw can result in the tool slipping, twisting, or even breaking, and it can also damage the brake caliper. Therefore, it’s essential to know some tricks to remove the stuck brake bleeder screw efficiently. The methods used to remove a stuck brake bleeder screw include using penetrating oil, applying heat, and using a bolt extractor kit.

The type of method you choose depends on the severity of the issue and the tools available. However, with perseverance and the correct tools, you can remove a stuck brake bleeder screw and save yourself the cost of a mechanic. So let’s dive into the different strategies and choose the best one for you.

Why Brake Bleeder Screws Get Stuck

If you’ve ever worked on your car’s brakes, then you know how frustrating it can be when the brake bleeder screw gets stuck. These screws are small and delicate, yet incredibly important for maintaining the safety and functionality of your brakes. So why do brake bleeder screws get stuck in the first place? Well, it’s usually due to corrosion or rust buildup over time.

This can happen when moisture gets trapped in the brake lines or if the screws haven’t been properly maintained. When this happens, the screws can become almost impossible to remove without breaking them off. If you find yourself in this situation, don’t panic.

There are a few things you can try to remove a stuck brake bleeder screw without damaging the rest of your brake system.

Rusty or Corroded Screw Threads

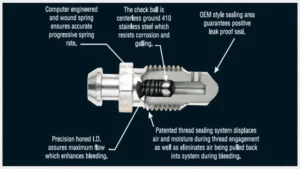

Brake Bleeder Screws Brake bleeder screws can be a pain to deal with when they get stuck, but why do they get stuck in the first place? Well, one reason is the corrosion of screw threads. When brake fluid gets in contact with the metal, it can cause rust build-up over time. This rust will make it difficult to turn the screw, and in the worst-case scenario, it can totally prevent it from coming out.

Another reason brake bleeder screws get stuck is over-tightening during repair or inspection. When a screw is tightened too much, it can cause the threads to become damaged or deformed. Because the bleeder screw is typically made from softer metal than the caliper or cylinder it screws into, it’s much easier to damage the bleeder thread than the caliper or cylinder thread.

So it’s vital to use the correct torque to avoid damaging the brake bleeder screw threads. Though sometimes brake bleeder screws may seem like a small component of the braking system, they play a crucial role in maintaining brake performance and safety.

Overtightening of the Screw

Brake Bleeder Screws Overtightening of the screw is one of the primary reasons why brake bleeder screws get stuck. The significance of the brake bleeder screw is to take out air bubbles in the braking system to ensure proper functioning. The screw is generally constructed of soft metals like aluminum or brass to avoid corrosion, which facilitates tightening.

However, overtightening can lead to the structural deformation of its soft metal, causing it to stick to its seat. Another reason for the brake bleeder screw to get stuck is corrosion that happens when using non-compatible brake fluids. If you notice that the brake bleeder screw is hard to turn, then it’s time to replace or repair it.

Don’t take chances with your car’s brakes; it’s always best to fix problems as soon as they arise. In conclusion, always be extra cautious and gentle when handling the brake bleeder screw to prevent overtightening and potential breakdown of your car’s braking system.

Tools You Will Need

If you’re trying to replace or bleed your brakes, a stuck brake bleeder screw can be a major headache. It may seem impossible to remove without damaging the screw or the brake caliper, but with the right tools and technique, it can be done. First, you’ll need a few tools: a penetrating oil to loosen the screw, a wrench or socket to turn the screw, pliers to hold the screw steady, and possibly a metal file to smooth out any damage.

The key to getting a stuck brake bleeder screw out is to start with gentle pressure, allowing the penetrating oil time to work its magic. If it still won’t budge, you can try tapping the end of the wrench with a hammer to break up any corrosion. With persistence and care, you can eventually loosen and remove the screw, making the brake job much easier.

Don’t forget to clean the area thoroughly and replace the screw with a new one before reassembly.

PB Blaster or Liquid Wrench Penetrating Oil

When it comes to automotive repairs, having the right tools is crucial. Two popular penetrating oils that mechanics love to use are PB Blaster and Liquid Wrench. These products work by loosening rusted or corroded parts, making them easier to remove.

To use them, you will need a few basic tools like a wrench, pliers, and gloves to protect your hands. PB Blaster and Liquid Wrench are both excellent at penetrating deep into rusted parts, but they work slightly differently. PB Blaster has a more powerful formula and dries slower than Liquid Wrench, which gives it more time to penetrate the rust.

On the other hand, Liquid Wrench has a more viscous consistency and clings to the rusted part longer. When using either of these penetrating oils, you want to start by applying a generous amount to the rusty part and letting it sit for a few minutes – or even a few hours – depending on how badly rusted the part is. This allows the oil to penetrate deeply and loosen the rust.

Once you’ve given the oil sufficient time to penetrate, try using your wrench or pliers to gently twist the part back and forth, breaking the rust’s grip. In conclusion, both PB Blaster and Liquid Wrench are useful tools in any mechanic’s arsenal. If you deal with a lot of corroded or rusted parts, you’ll benefit from having both on hand.

Just remember to use proper safety precautions, such as wearing gloves, and to give the oil enough time to penetrate fully. With a little patience and the right tools, you’ll have those rusted parts loosened up in no time.

Vise-grips or Locking Pliers

Vise-grips or locking pliers are essential tools to have in your toolbox. These versatile pliers have a locking mechanism that allows them to grip onto an object and hold it in place without you having to apply any pressure. They come in handy when you need to hold something tightly in place while you work on it.

They are great for removing nails, bolts, and screws, as well as bending wires and holding pipes in place. Vise-grips and locking pliers come in a variety of shapes and sizes, and each one is designed for a specific purpose. Whether you need to hold something big or small, there is a pair of vise-grips or locking pliers out there that will do the job.

So the next time you need to do some DIY or automotive work, don’t forget to include vise-grips or locking pliers in your toolkit. They are a must-have for every handyman or DIY enthusiast out there.

Bleeder Screw Wrench

If you ever find yourself needing to work on the braking system of your vehicle, a tool you will definitely need is a bleeder screw wrench. This specialized wrench is designed to fit onto the bleeder screw, which is the valve located on each brake caliper that releases air or old brake fluid when the brake system is being bled. Having the right tool for the job makes it easier to perform brake maintenance and repairs, which is essential for keeping your vehicle running smoothly and safely.

Without a bleeder screw wrench, attempting to bleed your brakes can be a real headache, as standard wrenches won’t fit properly on the bleeder screw. With a bleeder screw wrench, you can easily loosen or tighten the bleeder screw, which will allow you to remove any air or old fluid from the brake line, ensuring proper brake function. Investing in a bleeder screw wrench is a smart move for anyone who regularly works on their own vehicle, as it will save you time, effort, and hassle.

Plus, it’s a relatively inexpensive tool, so it won’t break the bank. With a little bit of know-how and the right tools, you can keep your vehicle’s braking system in top shape, which is crucial for staying safe on the road. So, if you don’t already have a bleeder screw wrench in your toolbox, it’s definitely worth adding to your collection.

Box-end Wrench

If you’re planning to do some minor car repairs at home, there are a few essential tools you will need to have on hand. One such tool is a box-end wrench. This wrench has a closed loop on each end and is designed to fit over the head of a bolt or nut.

Unlike an open-end wrench, which can slip off the bolt head, a box-end wrench provides a better grip and is less likely to round off the edges of the bolt head. When choosing a box-end wrench, you’ll need to decide between a standard or metric set. Standard sets are measured in inches, while metric sets are measured in millimeters.

It’s important to choose the correct size wrench for the bolt or nut you’re tightening or loosening to avoid damaging the fastener or the wrench itself. Box-end wrenches are commonly used in automotive repairs, but can also be useful for other DIY projects around the house. Just remember to always use the right size wrench and to apply even pressure when turning the bolt or nut.

With a good set of box-end wrenches, you’ll be ready to tackle a wide variety of home repairs.

Heat Gun or Propane Torch

When it comes to applying heat to a surface, there are a variety of tools to choose from, but two of the most popular are heat guns and propane torches. Depending on the job you need to tackle, one of these tools might be better suited for the task at hand. If you’re looking for precision and control, a heat gun is a great option.

Heat guns produce a steady stream of hot air, perfect for tasks such as removing paint or thawing frozen pipes. On the other hand, if you need to produce a large amount of heat quickly, a propane torch might be a better choice. Propane torches produce an intense flame, making them ideal for tasks such as soldering copper pipes or lighting a grill.

Ultimately, the tool you choose will depend on the specific job you’re working on, and both heat guns and propane torches can be valuable additions to any DIY toolkit.

Step-by-Step Process

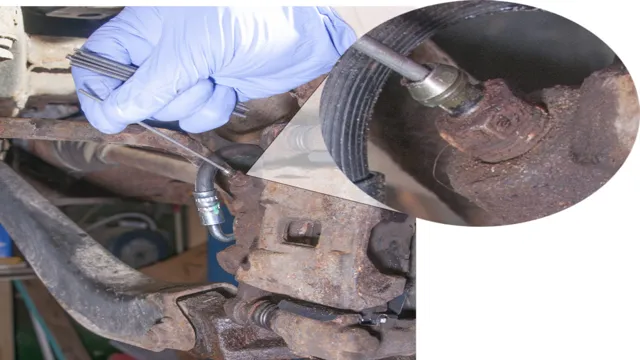

If you’re dealing with a stuck brake bleeder screw, it can be frustrating and time-consuming to get it unstuck. However, with the right tools and approach, it’s possible to remove the screw without causing any damage to your vehicle. The first step is to apply a penetrating oil to the screw and let it sit for at least 15 minutes.

This will help to loosen the screw and make it easier to remove. Next, use a wrench or pliers to grip the bleeder screw and attempt to turn it counterclockwise. If it doesn’t budge, try tapping the end of the wrench or pliers lightly with a hammer to help loosen it.

If this still doesn’t work, you may need to apply heat to the screw using a torch. Be careful not to overheat the surrounding area or cause any damage. Once the screw is loose, you can remove it completely and replace it with a new one if necessary.

With these steps and some patience, you can successfully remove a stuck brake bleeder screw without causing any harm to your vehicle.

Step 1: Spray Penetrating Oil on the Screw

If you’re struggling with a stubborn screw, don’t worry – there’s a solution! The first step in removing a stubborn screw is to spray penetrating oil on it. Penetrating oil is designed to seep into the thread of the screw and provide lubrication, making it easier to remove. You can find penetrating oil at most hardware stores, and it’s relatively inexpensive.

Once you’ve sprayed the oil on the screw, let it sit for a few minutes to work its way into the threads. This will make the process of removing the screw much smoother and less frustrating. Remember to take your time and be patient, and don’t be afraid to reapply the penetrating oil if necessary.

With a little persistence, you’ll be able to remove even the most stubborn screws!

Step 2: Apply Heat to the Screw Head

After successfully penetrating the rust or corrosion with penetrating oil, the next step is to apply heat to the screw head. This helps to expand the metal and break the bond between the screw and the object. You can use a hairdryer or heat gun to manage the heat application.

Hold it close to the screw and move it around continuously to avoid burning the nearby materials. You can also use a soldering iron for small screws. Once the screwhead has been heated up, wait for it to cool down slightly before attempting to unscrew it.

Remember to use a suitable screwdriver and turn it slowly in an anticlockwise motion. If the screw seems to be stuck, try repeating the process again to loosen it up. Applying heat can be an effective method for removing stubborn screws that are stuck due to rust or corrosion build-up.

It is a safe and reliable method that requires little effort and equipment.

Step 3: Turn the Screw with a Box-end Wrench

Once you have positioned the screw and tightened it with pliers, it’s time to use the box-end wrench. This tool is essential for achieving the proper torque on the screw. The box-end wrench will provide more leverage, making it easier to turn the screw without slipping.

To use it, simply fit the wrench over the head of the screw and turn it clockwise. Depending on the size and type of screw, you may need to apply more or less pressure to turn it. Be sure to apply steady and consistent pressure until the screw is securely fastened.

Remember, over-tightening the screw can strip the threads, so use caution and stop once the screw is firmly in place. With this step completed, your project is well on its way to completion.

Step 4: Locking Pliers May Help Loosen the Screw

If you’re struggling to loosen a stubborn screw, locking pliers may come to your rescue. This is a handy tool that can grip onto the head of the screw, providing a better grip and more torque. If you’re using locking pliers, just clamp the jaws onto the head of the screw, ensuring that they are securely attached.

Next, apply a little pressure and attempt to turn the screwdriver again. The advantage of using locking pliers is that they add an extra layer of grip, which can be especially useful if you’re dealing with a stripped or damaged screw. With this tool, you can increase the torque and hopefully loosen the screw without damaging your screwdriver or the surrounding material.

So, if you’re battling with a stubborn screw, reach for your locking pliers and give them a try.

Step 5: Use a Bleeder Screw Wrench to Turn the Screw

When it comes to bleeding your car’s brake system, using a bleeder screw wrench is essential. Once you have located the correct bleeder screw, insert the wrench and turn the screw counterclockwise. This will release the air and old brake fluid from the system.

As you turn the screw, pay close attention to the brake fluid that comes out. Once the fluid looks clean and free of air bubbles, you can stop bleeding that particular brake line. Keeping an eye on the fluid ensures that there isn’t any air still trapped in the system.

Failure to release all the air can lead to a spongy brake pedal, which can compromise your vehicle’s safety. Always use the right size of wrench to avoid damaging the screw head. Taking proper precautions keeps your brake system functioning correctly and keeps you safe when driving.

Step 6: Replace the Bleeder Screw

Replacing the bleeder screw is an easy process that you can complete in just a few steps. First, make sure that you have the right tools for the job. You’ll need a wrench, pliers, and a new bleeder screw.

Begin by taking the old bleeder screw out of the brake caliper. You can use pliers or a wrench for this step, depending on how tight the screw is. Once it’s out, inspect the old screw for any damage.

If it’s damaged, you’ll need to replace it. Otherwise, clean it off with a wire brush and some solvent. Then, screw in the new bleeder screw.

Use your wrench to tighten it, being careful not to over-tighten it. Finally, bleed the brake system as necessary to remove any air from the system. Remember that safety is paramount when working on brakes, so be extra careful.

With this simple process, you can replace your bleeder screw and ensure that your brakes work properly.

Conclusion

After many hours of frustration and multiple attempts, I have finally found the foolproof method for getting a stubborn brake bleeder screw out. First, soak the area with penetrating oil and let it sit for at least 15 minutes. Then, carefully apply heat to the surrounding area with a blowtorch or heat gun.

Finally, use a high-quality wrench or socket to slowly and steadily work the screw out. And remember, if all else fails, just blame the previous owner for over-tightening the darn thing in the first place.”

Prevent Future Stuck Screws with Proper Maintenance

Proper maintenance is key when it comes to preventing stuck screws in the future. Here’s a step-by-step process to ensure you’re taking good care of your tools. First, make sure to clean your tools after each use.

This will help prevent rust buildup which can lead to stuck screws. Next, lubricate your screws and the corresponding holes to make them easier to turn. Consider using a wax-based lubricant as oil-based ones can attract dirt and debris.

Third, store your tools properly to prevent any unnecessary wear and tear. Keep them in a dry and cool place, and make sure they’re not too tightly packed. Lastly, inspect your tools regularly, looking for any signs of wear or damage.

This proactive approach will help prevent any issues before they become bigger problems. Taking these simple steps can go a long way in prolonging the life of your tools and preventing stuck screws.

FAQs

What is a brake bleeder screw and why does it get stuck?

A brake bleeder screw is a small valve located on a brake caliper or wheel cylinder that allows air to escape from the brake lines during bleeding. It can get stuck due to rust, corrosion, or overtightening.

What are the risks of leaving a stuck brake bleeder screw in place?

Leaving a stuck brake bleeder screw can result in reduced braking performance, air in the brake lines, and potential brake failure in emergency situations.

How can I loosen a stuck brake bleeder screw?

Use a penetrating oil or rust dissolver and let the solution soak into the threads for several hours before attempting to loosen the screw with a wrench or pliers.

What are some common tools used for removing a stuck brake bleeder screw?

Vise grips, a wrench, pliers, penetrating oil, rust dissolver, and a torch are common tools used for removing a stuck brake bleeder screw.

How can I prevent a brake bleeder screw from getting stuck in the future?

Regular maintenance and lubrication of the threads can prevent the screw from getting stuck. Also, avoid overtightening the screw during installation.

Can a stuck brake bleeder screw be repaired or should it be replaced?

In some cases, a stuck brake bleeder screw can be repaired by rethreading or using a thread repair kit. However, if the screw is severely damaged or corroded, replacement may be necessary.

What should I do if I can’t remove a stuck brake bleeder screw on my own?

If you’re unable to remove a stuck brake bleeder screw on your own, take your vehicle to a professional mechanic who has the proper tools and expertise to safely remove and replace the screw.