Is your orbital sander giving you trouble? Perhaps it’s not working as it used to, or it’s making strange noises that seem out of the ordinary. While this can be frustrating, it’s not uncommon for power tools to require occasional maintenance to keep them running at their best. With a little bit of know-how and some elbow grease, fixing your orbital sander might be easier than you think.

In this blog post, we’ll go over some common issues that can arise with orbital sanders and give you some tips on how to fix them. So, put on your work gloves and let’s get started!

Identify the Problem

If you’re having trouble with your orbital sander, it’s important to identify the problem before attempting any fixes. The most common issues with an orbital sander include the sander not turning on, the sandpaper not sticking properly, or the sander leaving swirl marks on the surface. To fix these problems, you may need to check the power cord, replace the sandpaper, or adjust the speed and pressure of the sander.

It’s also important to use the correct type of sandpaper for the job and to ensure that the sander is properly stored and maintained. Overall, taking the time to identify the problem and making the necessary adjustments can help ensure that your orbital sander continues to work properly and efficiently.

Check for Loose Parts and Connections

When it comes to your car, regular maintenance is essential to keep it running smoothly. One common issue that can arise is loose parts or connections. This can cause all kinds of problems, from strange noises to poor performance or even a breakdown.

The first step in addressing this is to identify the problem. Start by listening for any unusual sounds or vibrations while driving. Then, visually inspect the engine and undercarriage for any loose or disconnected components.

You may need to use a flashlight to get a good look. Once you’ve identified the problem, you can take steps to fix it. This might involve tightening bolts or replacing damaged parts.

By taking care of loose parts and connections, you can help prolong the life of your car and avoid costly repairs down the line.

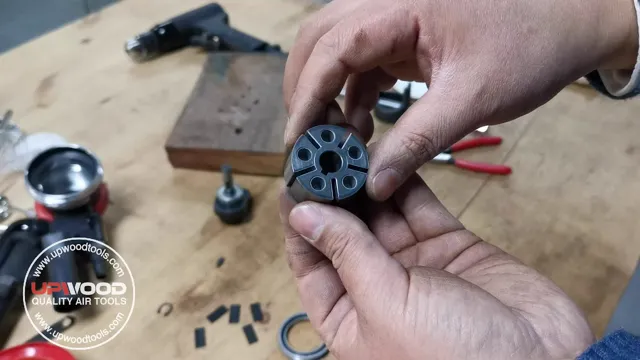

Inspect the Sanding Pad and Disc

If you’re experiencing issues with your sanding disc, it’s a good idea to inspect the sanding pad and disc themselves. One potential problem is that your sanding pad may be worn down or damaged, which can cause the disc to slip or wobble during use. Additionally, particles or debris may accumulate on the pad, which can reduce its grip and cause similar issues.

On the other hand, if the problem seems to be with the sanding disc, you’ll want to check for any tears, gouges, or other defects that may be impairing its performance. If you identify any potential issues with either the pad or disc, it may be necessary to replace these components to ensure that your tool is functioning properly and protect the quality of your work.

Replace or Repair the Parts

If your orbital sander is showing signs of wear and tear, the first thing you should do is determine whether repairing or replacing parts is the best course of action. The benefit of repairing is that it can be more cost-effective than buying a new sander. However, if the damage is significant or the repair costs are too high, it may be best to invest in a new sander.

When repairing, it’s important to identify the specific part that needs to be replaced, which may include the sandpaper pad, bearings, or switch. Replacement parts can typically be found online or through the manufacturer, and a simple internet search can provide you with a step-by-step guide on how to install these parts. Ultimately, whether you decide to repair or replace your sander, taking the time to properly care for your equipment will help extend its overall lifespan and ensure that it continues to perform at a high level.

Order Replacement Parts

Order Replacement Parts If a part of your device or machine is no longer functioning properly, it can be a real inconvenience. It’s important to find the cause of the problem and get it fixed as soon as possible. Sometimes the solution is a simple repair, but other times it’s necessary to replace parts.

When you need to order replacement parts, the process can be intimidating if you’re unfamiliar with how things work. However, it’s actually a fairly straightforward process. Firstly, you need to identify the manufacturer and model number of your device or machine so you can search for the required parts.

Many manufacturers have online stores where you can enter this information to get a list of the appropriate parts. Once you’ve found the part you need, you can either order it online or through a local supplier. The key things to keep in mind are accuracy and quality.

Ensure you choose the right part and check that it’s of good quality to avoid any future problems. Remember, taking care of your device or machine means regular maintenance and timely repairs or replacements when necessary.

Replace the Sanding Pad and Disc

As with any power tool, the sanding pad and disc of your sander can wear down and become damaged over time. This can result in uneven sanding and poor results. Fortunately, replacing or repairing these parts is relatively easy and can extend the life of your sander.

To replace the sanding pad, simply remove the old pad and attach the new one with the screws provided. When replacing the disc, first remove the old disc and clean the spindle. Then, attach the new disc and tighten the spindle nut.

If you notice any severe damage to these parts, it may be necessary to replace them completely. By keeping your sander in good condition and replacing or repairing worn-down parts, you can ensure that your sanding projects are always smooth and successful.

Fix or Replace the Motor

When it comes to fixing or replacing parts in your motor, there are a few factors to consider. While replacing the motor entirely might seem like the easiest solution, it can also be the most expensive. Before making a decision, consider the specific parts that need to be repaired or replaced.

Are they easily accessible? Is the damage severe enough to warrant a replacement? If the answers to these questions point towards a simple repair, it’s probably best to opt for that option. However, if the damage is extensive or the parts are difficult or expensive to replace, it might be better in the long run to replace the motor entirely. Another factor you should consider is the age and overall condition of the motor.

If it’s an older model or has had multiple mechanical issues in the past, it might be more cost-effective to replace it entirely. On the other hand, if the motor is relatively new and in good condition besides the broken parts, repairing it might be the better option. Ultimately, the decision to fix or replace your motor depends on a variety of factors.

Consider all the information before making your final choice.

Maintenance and Preventative Measures

If you’re experiencing issues with your orbital sander, fear not! There are a few things you can do to fix it and prevent further damage. First, make sure to clean your sander regularly. After every use, wipe down the sanding pad with a soft cloth and remove any debris from the dust collection bag.

If your sander is losing power or is vibrating excessively, check the motor brushes for wear and tear and replace if necessary. Additionally, make sure to use the correct sandpaper grit for the job and don’t apply too much pressure when sanding. Overworking the sander can cause damage to both the tool and your material.

By taking these preventative measures, you can ensure that your orbital sander stays in good working condition and lasts for years to come.

Clean the Sander After Each Use

Maintaining your sander is essential to ensure its longevity and optimal performance. One of the critical maintenance measures to take is cleaning the sander after each use. Sanding causes a buildup of sawdust, which can accumulate on the sandpaper and clog the sander’s motor, reducing its performance.

Cleaning the sander involves wiping it down with a clean cloth and ensuring that there is no sawdust left on the sandpaper or in the sander’s vents. By taking this simple preventative measure, you can reduce the risk of damage to your sander and extend its lifespan. Keeping your sander clean will also ensure that it continues to operate at its best and deliver smooth finishes on your projects.

It only takes a few minutes to clean your sander, but the results are worth the effort. Make it a habit to clean your sander after each use to keep it in top working condition.

Use the Right Sandpaper Grits

When it comes to maintaining your surfaces, one important factor to consider is using the right sandpaper grits. Different grits will have different uses, and it’s crucial to select the correct one for the job to prevent unnecessary damage. Generally, lower grit sandpapers around 60-80 are ideal for removing rough materials, while higher grits between 120-220 are useful for smoothing surfaces.

However, it’s important to remember that finer grits don’t remove as much material, so it may take longer to achieve a smooth finish. Proper sanding techniques can help you achieve the desired results while preventing damage to the surface. Sandpaper grits can be a simple yet essential part of maintaining and preserving your surfaces.

Conclusion

In conclusion, fixing an orbital sander is like solving a puzzle – it requires patience, attention to detail, and a willingness to experiment. Just like a puzzle, every problem has a solution, and once you find the right piece, everything will fall into place. So don’t be afraid to tinker with your sander, explore different options, and try out new techniques.

With a little bit of know-how and a dash of ingenuity, you can bring your trusty tool back to life and achieve the smooth, polished finish you desire. After all, in the world of DIY, the only limit is your own imagination (and the occasional missing screw or worn-out pad). Happy sanding!”

FAQs

What are some common problems with orbital sanders and how can I fix them?

Some common problems with orbital sanders include issues with the sanding pad, dust collection, and motor. To fix a sanding pad issue, make sure it is securely attached and not worn out. For dust collection problems, clean the filter or replace it if necessary. If the motor is not functioning properly, check the power source and make sure the switch is on.

How often should I replace the sandpaper on my orbital sander?

It is recommended to replace the sandpaper on your orbital sander once it becomes dull or starts to tear, which can vary depending on the type of sandpaper and the frequency of use.

How can I improve the efficiency of my orbital sander?

To improve the efficiency of your orbital sander, make sure you are using the appropriate grit sandpaper for the task at hand and applying consistent pressure. You can also try adjusting the speed settings and using a dust collection system to minimize cleanup time.

What safety precautions should I take when using an orbital sander?

To ensure safety when using an orbital sander, wear eye and ear protection, avoid loose clothing and jewelry, and keep your hands and fingers away from the sanding pad. Always turn off and unplug the sander before changing the sandpaper or making any adjustments.

Can I use my orbital sander on different types of materials?

Yes, an orbital sander can be used on a variety of materials including wood, metal, plastic, and even drywall. Just be sure to use the appropriate grit sandpaper for each material and follow proper safety precautions.

What is the difference between a random orbital sander and a conventional orbital sander?

The main difference between a random orbital sander and a conventional orbital sander is the motion of the sanding pad. A random orbital sander moves in a circular and random pattern, while a conventional orbital sander moves in a circular and predictable pattern. This means that a random orbital sander is less likely to leave swirl marks on the surface being sanded.

How can I prevent my orbital sander from leaving swirl marks?

To prevent swirl marks when using an orbital sander, use a higher grit sandpaper and apply light pressure while sanding. It can also be helpful to use a random orbital sander instead of a conventional orbital sander.