Have you ever wondered how to check the volts and amps on your welding machine? This is a crucial step to ensure that your machine is functioning properly before starting any welding task. It provides you with the necessary information to select the right settings for your welding application and avoid any malfunctions. In this blog post, we will cover the steps you need to follow to check the volts and amps on your welding machine.

Keep reading to learn more about it!

Why it’s Important to Check Volts and Amps

When it comes to welding, checking volts and amps on your welding machine is essential for a successful weld. Volts and amps are two of the most important factors in determining the strength and quality of your weld. Welding requires a specific amount of voltage and amperage, and if either of these is not set correctly, the weld can be weak, brittle, or fail altogether.

Checking volts and amps on your welding machine is easy and can be done in just a few simple steps, making it an essential part of the welding process. By ensuring that your volts and amps are set correctly, you can have peace of mind knowing that your welds will be strong and reliable every time. So, next time you fire up your welding machine, take a few minutes to check your volts and amps, and you’ll be well on your way to a successful weld.

Preventing Overheating

Preventing Overheating One important factor in preventing your electronic devices from overheating is to regularly check their volts and amps. Overheating can cause damage to your device, decrease your battery life, and even cause it to stop working altogether. By monitoring the volts and amps, you can ensure that your device is receiving the appropriate amount of power and that it’s not overheating from an excess of energy.

Checking the volts and amps is easy, and you can do it using a multimeter to measure the voltage and current of your device. This will help you to identify any potential issues before they become problems, and ensure that your device is performing at optimal levels. So, it’s important to keep an eye on your volts and amps and take action to prevent any potential damage caused by overheating.

Avoiding Electrical Hazards

Electrical hazards can pose a serious threat to not only our safety but also the life of our appliances and electronics. We all know that certain devices require a specific amount of voltage to function properly, and exceeding that limit could lead to a spark or even a fire. That’s why it’s important to regularly check the volts and amps before plugging any appliance or tool into an outlet.

Not only will this ensure that your equipment is safe to use, but it will also save you from potentially costly damages. Think of it like driving a car – you wouldn’t want to exceed the recommended speed limit or drive without properly checking the oil levels. By taking the necessary precautions and regularly checking volts and amps, you can avoid electrical hazards and keep your home and appliances safe.

How to Check Volts and Amps

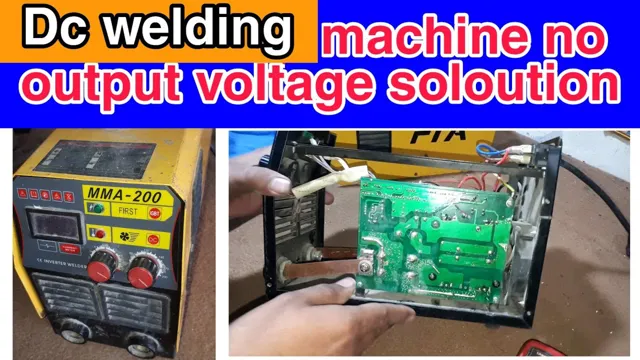

If you’re a welder, you know how important it is to Check Volts and Amps on a welding machine. These two measurements determine the amount of electrical power your welding machine is drawing in and putting out, which determines the quality of your welds. Checking volts and amps on your welding machine is not as complex as you might think.

To check the volts, you need to connect a voltmeter to the welder’s output terminals, then turn on the machine and select the voltage you want to use, and the voltmeter will show you the voltage the machine is producing. To check the amps, you also need a multimeter, which you can connect to the machine’s output terminals. Then, turn on the machine and adjust the amperage settings to the desired level.

The multimeter will show the amount of amps your welding machine is producing. Remember, checking the volts and amps is critical to ensuring the quality of welds you’ll produce, so make sure to check both measurements regularly.

Step 1: Turn Off the Welding Machine

If you want to check the volts and amps of your welding machine, the first step is to turn it off. Safety should always come first, and shutting off the machine is the best way to prevent accidents. Once you have turned off the welding machine, you should locate the specifications label which can typically be found on the side or back of the machine.

This label contains information about the volts and amps that your welding machine is capable of producing. Make note of these values, as they will be important in determining whether your machine is operating correctly. When you are ready to test the volts and amps, you will need a voltmeter and an ammeter.

These tools can be purchased at your local hardware store, and they are essential for accurately measuring the electricity flowing through your welding machine. By taking the time to check your volts and amps, you can ensure that your welds are strong and reliable every time.

Step 2: Locate the Voltmeter and Ammeter on the Welding Machine

When it comes to welding machines, checking the volts and amps is essential to ensure that you get the desired results. One of the first steps in doing this is to locate the voltmeter and ammeter on the machine. Usually, both of these are present on the front of the machine, near the display panel.

The voltmeter measures the voltage, and the ammeter measures the current. Both of these readings are important for a quality weld. To check the volts, turn on the welding machine and set it to the desired voltage level.

Once the machine is ready, use the voltmeter to measure the voltage output. The amperage, on the other hand, is checked by setting the welding machine to the desired amperage level and measuring it using the ammeter. By checking these two measurements, you can ensure that your welding machine is functioning correctly and that you’re getting the quality weld you want.

Remember to keep an eye on these readings throughout the welding process for consistent results.

Step 3: Set the Multimeter to the Appropriate Range

When it comes to checking volts and amps with a multimeter, it’s important to set the device to the appropriate range. This will ensure that you get an accurate reading and avoid damaging the multimeter or the circuit you’re testing. To find the appropriate range, look at the settings on your multimeter and choose the one that is closest to the expected voltage or current.

For example, if you’re checking a 12-volt circuit, you would likely choose the 20-volt range on your multimeter. Similarly, if you’re checking a 2-amp circuit, you might choose the 10-amp range on your multimeter. It’s always better to choose a range that is slightly higher than what you expect, rather than lower, as this will avoid overloading the device.

By setting the multimeter to the appropriate range, and carefully reading the results, you can ensure that you get accurate and useful information about the circuit you’re testing.

Step 4: Connect the Multimeter to the Welding Machine

To check the volts and amps of your welding machine, the next step is to connect a multimeter to the machine. A multimeter is a versatile tool that measures different electrical values such as voltage, currents, and resistance. To use it, ensure that the welding machine is turned off, and attach the red and black leads of the multimeter to the positive and negative terminals of the machine respectively.

Turn on the machine, and set the multimeter to measure voltage if you want to check the welding machine’s output voltage, or set it to measure current if you want to measure the amperage of the welder. When you switch on the machine, the multimeter should give you a reading of the volts or amps being drawn by the machine. If you want a more accurate reading, attach a clamp meter to the welding cable and measure the amps on the cable as close to the machine as possible.

This will give you a better sense of the output of the welder and its performance. Remember to always check the volts and amps the welding machine is drawing before you start welding. This will ensure that you are using the right settings and that the machine is working correctly.

If you notice any discrepancies or deviations from the normal readings, take the time to troubleshoot the issue to avoid injury or damage to your workpiece. A properly functioning welding machine will give you the best results and ensure that your welds are strong and long-lasting.

Step 5: Turn On the Welding Machine

When turning on a welding machine, it’s important to first check the volts and amps to ensure safe usage before starting any welding work. The volts represent the electrical pressure while the amps indicate the amount of electrical current passing through the machine. To check the volts and amps, start by turning off the welder and unplugging it from the wall.

Next, locate the digital display or analog gauges on the front of the machine and read the values shown. If the volts or amps are set too high, it can cause damage to the machine or pose a safety risk. Always adjust the settings to match the type of metal you will be welding.

Keeping the volts and amps at a proper range will help ensure that the welding process goes smoothly and safely.

Step 6: Read the Voltmeter and Ammeter

After connecting the voltmeter and ammeter, you can now proceed to measure the voltage and current of the circuit. The voltmeter measures the voltage difference between two points in the circuit, while the ammeter measures the flow of electric current through the circuit. It’s essential to read these measurements accurately to avoid causing damage to the circuit or injuring yourself.

To read the voltmeter, you need to take note of the scale reading and the unit to which it is calibrated. For instance, if the scale is calibrated in volts, and the voltage reading is 10, the voltage of the circuit is ten volts. On the other hand, reading the ammeter requires you to note the direction of the flow of current and the unit calibration of the scale.

This helps to ensure that you read the current flow correctly. Always ensure that you follow the user manual guidelines and safety precautions when checking voltage and current to avoid accidents.

Conclusion

In summary, checking volts and amps on a welding machine is a vital part of ensuring safe and efficient welding operations. With the right tools and knowledge, it can be a breeze to get accurate readings and make any necessary adjustments. So, remember: volts and amps may be all numeric, but in the welding world, they’re the key to keeping your welds in shape and your workspace electrically sound.

Happy welding!”

FAQs

What is the purpose of measuring volts and amps on a welding machine?

Measuring volts and amps on a welding machine is important to ensure that the machine is operating correctly, and that the correct amount of power is being supplied to the welding process.

How can I check the voltage on a welding machine?

You can check the voltage on a welding machine by using a voltmeter, which is a simple electrical measuring instrument used to measure voltage.

What is the ideal range of voltage for welding machine?

The ideal range of voltage for a welding machine depends on the specific type of welding machine being used, the materials being welded, and the welding process being employed.

How can I check the amperage on a welding machine?

you can check the amperage on a welding machine by using an ammeter, which is a type of electrical measuring instrument that measures the flow of electric current in a circuit.

What is the ideal range of amperage for a welding machine?

The ideal range of amperage for a welding machine also depends on the specific type of welding machine being used, the materials being welded, and the welding process being employed.

What are the common problems that can occur if the voltage or amperage is incorrect on a welding machine?

Common problems that can occur if the voltage or amperage is incorrect on a welding machine include poor weld quality, unstable arcs, and equipment failure.

How often should I check the voltage and amperage on my welding machine?

It is recommended to check the voltage and amperage on your welding machine before each welding session to ensure that the machine is operating correctly and safely.