If you’re a DIY enthusiast or professional woodworker, an orbital sander is an essential tool in your kit. But if you’ve never changed the sander pad before, it may seem like a daunting task. Fear not, for we have got you covered! In this blog, we’ll walk you through the process of changing your orbital sander pad with ease.

We understand the importance of having a well-functioning sander, and a worn-out pad can affect the quality of your work. So, let’s dive in and explore the steps you need to take to swap out your sander pad hassle-free.

Step 1: Unplug the Sander

If you want to change the orbital sander pad, the first step is to unplug the sander. This is extremely important for safety reasons, as you don’t want to accidentally turn the sander on while you’re working on it. Once the sander is unplugged, remove any sandpaper from the old pad.

Then, locate the screws that attach the pad to the sander and remove them. Carefully lift the pad off the sander and place the new pad in its place. Make sure the new pad is aligned properly before screwing it back into place.

Once the new pad is securely attached, you can reattach the sandpaper and plug the sander back in. With these simple steps, you can change the orbital sander pad and get back to your project in no time.

Heading Three

As you start using your sander regularly, it’s essential to know the proper ways to maintain it. One of the basic maintenance tips is to unplug the sander before making any modifications or cleaning the sanding pad. Thus, you can avoid any electrical mishaps or injuries while removing dust or changing the sandpaper.

This step will ensure that the device is entirely shut off, and there is no possibility of the sanding pads getting in contact with any moving parts. Whether you are using an electric sander or a cordless one, it’s crucial to take extra care while working with it. Unplugging the sander ensures your safety and prevents any potential accidents.

Remember to prioritize your safety above all else, and you’ll continue to enjoy your sander for a long time. Keyword: sander.

Heading Three

If you want to perform maintenance on your sander or replace the sanding pad, the first step is to unplug the sander from the power source. This is crucial to prevent any accidental start-ups that could cause injury. Once the sander is unplugged, you can examine it more closely and determine the best way to proceed with maintenance or replacement.

Always use caution when working with power tools and take the appropriate safety measures. Taking the time to unplug your sander at the beginning of the process will ensure that your maintenance or replacement goes smoothly and safely.

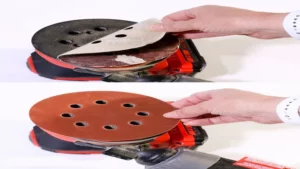

Step 2: Remove the Old Pad

Now that you’ve gathered all the necessary tools, it’s time to remove the old pad from the orbital sander. First, unplug the sander to ensure safety. Then, carefully remove the screws or clips that are securing the old pad onto the sander.

Be sure to keep these screws or clips in a secure place as you will need them later. Once the screws or clips are removed, take the old pad off and discard it properly. Use a clean cloth to wipe down any excess debris that may be lingering on the sander.

Removing the old pad is a necessary step in changing the orbital sander pad and should be done with care to avoid any damage to the sander itself.

Heading Three

After inspecting your rug or carpet and determining the old padding is beyond repair, you can now move on to the next step which is removing the old pad. This process is important because leaving the old pad on your floor can lead to unevenness and possible damage to the replacement pad. To remove the old pad, start by cutting it into smaller sections using a utility knife.

This will make it easier to handle and dispose of. Carefully pull up each section, being mindful not to damage the floor underneath. Once all sections have been removed, sweep and vacuum the area to remove any debris or small pieces of the old pad that may remain.

Now you’re ready for the next step in the process of replacing your rug or carpet padding. Remember to dispose of the old pad responsibly by following any local regulations and avoiding any harm to the environment.

Heading Three

When it comes to changing the carpet in your home or workspace, it’s essential to start with step 2 – removing the old pad. Although it may seem like an unnecessary step, leaving the old padding beneath your new carpet can cause it to appear uneven, reduce its durability, and create a breeding ground for bacteria and allergens. To start, you’ll need to gather a few tools – gloves, a utility knife, and pliers.

Then choose a corner of the room and use the pliers to grip the old pad’s edge. Gently pull the pad towards you, and it should easily come apart from the floor. Repeat the process till all the old padding is removed from the room.

You may encounter adhesive residue left on the floor, which must remove with a scraping tool before laying down the new padding. Once the old padding and adhesive residue are removed, clean your subfloor thoroughly, removing any dust or debris that may have accumulated. Remember, changing the carpet is not only about aesthetics, but it’s also about the health and safety of your living or workspace.

So don’t be tempted to skip the second step in the process of changing your carpet. By removing the old pad, you can ensure your new carpet looks better, lasts longer, and improves the quality of the air you breathe. In conclusion, while removing the old carpet pad may seem like a daunting task, with the proper tools and a little patience, it is entirely doable.

Take your time and follow the process carefully, and when finished, your new carpet will be ready to lay. So go ahead and start with step 2, and you’re one step closer to a beautifully refreshed space.

Heading Three

Once you’ve gathered all your supplies, it’s time to get started on removing the old pad. First, make sure you’re wearing gloves to protect your hands from any debris or sharp edges. Then, use pliers to grip the corners or edges of the pad and peel it away from the floor.

You may need to use a scraper or putty knife for any stubborn areas or adhesive residue. Be careful not to damage the subfloor underneath. Once the pad is removed, sweep or vacuum any loose debris and wipe down the area with a damp cloth.

This will ensure your new pad will adhere properly and create a smooth surface for your carpet. By removing the old pad, you’ll be setting yourself up for a successful carpet installation.

Step 3: Attach the New Pad

Now that you’ve removed the old pad from your orbital sander, it’s time to attach the new one. First, make sure the new pad is the correct size and type for your sander. Then, align the screw holes on the pad with those on the sander’s backing plate.

Start by placing one screw through one of the holes, and then align the other holes before screwing them in. Use a screwdriver for this step, and make sure the screws are tight. Once the new pad is securely attached, you can test it out by turning on the sander and checking for any vibrations or wobbling.

If everything looks good, then you’re ready to start sanding with your newly installed pad! By following these simple steps, you can easily change the orbital sander pad and keep your tool in top condition.

Heading Three

Once you have removed the old pad and have cleaned the surface, it’s time to attach the new pad. Before you do that, ensure that the surface is completely dry. You can use a hairdryer to dry it quicker.

Now, take the new pad and peel off the protective backing. Carefully place the pad on the surface where the old pad was removed. Make sure that the pad aligns correctly and doesn’t have any air bubbles.

If you notice any bubbles, gently lift the pad and press it down again from the middle, working your way outwards. You don’t want any parts of the pad protruding, as it will affect the stability of the chair. The adhesive needs around 24 hours to cure completely, so avoid using the chair until the pad is firmly in place.

With the new pad in place, your chair will feel as good as new, providing the comfort and support you need for long hours of work or seating.

Heading Three

Once you have removed the old brake pad, it’s time to attach the new pad. Start by positioning the new pad in place and securing it with the same bolts that held the old pad. It’s essential to ensure that the pad is positioned correctly on the caliper and the rotor to ensure efficient braking.

One way to do this is by using a C-clamp to compress the brake piston back into the caliper, creating enough space to fit the new brake pad. Once you have secured the new pad in its position, release the brake piston and check to ensure that it’s correctly aligned. Wiping both the rotor and the caliper with a clean towel can help remove any dirt or grease that may affect the braking.

Additionally, make sure all the bolts are tightened before you take your car out for a test drive. Overall, attaching a new brake pad is a pretty straightforward process that only requires a bit of care, attention to detail and, of course, the right tools for the job.

Step 4: Test the Sander

Now that you’ve successfully changed the sanding pad on your orbital sander, it’s time to test it out! Plug in your sander and turn it on to its highest speed setting. Gently touch the sanding pad to a scrap piece of wood or other material to ensure that it’s securely attached and spinning smoothly. If you notice any wobbling or unusual vibrations, turn off the sander immediately and check that the pad is correctly installed.

Otherwise, you can proceed with your sanding project, confident that your equipment is in good working order thanks to your newly acquired skills in changing the orbital sander pad. Happy sanding!

Heading Three

Now that you’ve assembled your sander, it’s time to test it out. Before starting, make sure to put on safety goggles and a dust mask to protect your eyes and lungs from flying debris. Also, be sure to secure your workpiece to a stable surface to prevent it from moving around while you sand.

Turn on the sander and begin by applying light pressure to the surface of the wood. Move the sander in a back-and-forth motion along the direction of the grain, making sure to keep the sander flat against the surface. If you press too hard, you risk damaging the wood or creating deep scratches.

As you sand, periodically check your workpiece to make sure you aren’t sanding too much in one area or missing spots. It’s also important to check that the sandpaper isn’t gumming up with sawdust, as this can affect the sander’s efficiency. Once you’re satisfied with the level of sanding, turn off the sander and inspect your work.

If there are still rough spots, repeat the sanding process with a finer grit sandpaper, moving up in grit until you’ve achieved the desired level of smoothness. Remember, testing your sander is an important step to getting the job done right. With proper technique and attention to detail, you’ll be able to achieve a smooth, professional-looking finish on your woodworking project.

Heading Three

Heading Three: Step 4: Test the Sander Now, it’s time to test out your sander and see if it’s working effectively. Start by placing some scrap wood on your workbench and clamping it in place. Then, turn on your sander and hold it firmly with both hands.

Make sure to keep the sander moving in a back and forth motion, and apply consistent pressure as you go. Keep an eye on the surface of the wood to see if the sander is smoothing it out evenly. If you notice any areas that aren’t smoothing out or are being overly sanded, you may need to adjust your technique or the grit of your sandpaper.

Once you’re satisfied with your sanding job, turn off the sander and inspect your work. If everything looks good, then you’re ready to move on to the next step of your project. However, if there are areas that need some additional sanding, simply repeat the process until you achieve your desired finish.

By testing your sander and adjusting your technique as needed, you can ensure a smooth and even finish on your woodworking project.

Conclusion

Changing the orbital sander pad may seem daunting at first, but it’s as easy as flipping a pancake! With these simple steps, you can give your sander a fresh start and achieve spectacular results. Whether you’re a DIY enthusiast or a professional, replacing the pad is essential to maintain the performance of your tool. So, don’t be afraid to give it a whirl, and in no time, you’ll be on your way to creating smooth and polished surfaces like a pro!”

FAQs

What is an orbital sander pad?

An orbital sander pad is the component of the sander that comes into contact with the surface being sanded. It is typically circular in shape and can be made from various materials such as foam, rubber, or fabric.

Why would I need to change the sander pad on my orbital sander?

There are a few reasons why you may need to change the sander pad on your orbital sander. It could be because the current one is damaged or worn out, or you need a different type of pad for a specific task, such as sanding curves.

How often should I change the sander pad on my orbital sander?

The frequency with which you should change your sander pad depends on how frequently you use your sander and how hard you use it. As a general rule, you should inspect the pad before each use and replace it if you notice any significant wear and tear.

How do I know which sander pad to use with my orbital sander?

Your sander’s user manual should provide guidance on which types of sander pads are compatible with your particular model. You can also consult with a sales associate at your local hardware store for advice on which pad to use based on your specific project needs.

How do I go about changing the sander pad on my orbital sander?

To change the pad on your orbital sander, first, unplug the tool. Then, remove the old pad by unscrewing or prying it off. Next, align the new pad with the sander’s base and secure it in place using the screws or clip on the pad. Finally, plug in your sander and test it out.

Can I use a non-branded sander pad with my orbital sander?

While it may be possible to use a non-branded or aftermarket sander pad with your orbital sander, it is not recommended. Using a non-branded pad can potentially damage your sander, lead to poor sanding results, and void your sander’s warranty.

What should I do if I am having trouble removing the old sander pad from my orbital sander?

If you are having difficulty removing the old pad from your sander, try heating it up with a hairdryer to loosen the adhesive. You can also try using a putty knife or other tool to gently pry it off. Be cautious not to damage the sander’s base or create a hazard while attempting to remove the pad.